Shaftless Screw Compactor.pdf - Johnson Screens

Shaftless Screw Compactor.pdf - Johnson Screens

Shaftless Screw Compactor.pdf - Johnson Screens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

shaftless screw<br />

compactor

OPERATION<br />

COST EFFECTIVE COMPACTION OF SCREENINGS AND VARIOUS<br />

PROCESS OR WASTE MATERIALS<br />

<strong>Johnson</strong> <strong>Screens</strong> ® shaftless screw<br />

compactor (MD) offers a simple, costeffective<br />

solution for the dewatering,<br />

compaction and reduction of screenings<br />

and various other process or waste<br />

materials.<br />

They can be applied to numerous<br />

industrial applications including paper<br />

mills, abattoirs, food production,<br />

refineries for either recovery or removal<br />

of solids.<br />

Single units can be supplied over 5 m<br />

(16 ft.) long, facilitating transfer and<br />

compaction in a single unit.<br />

Increased lengths can be supplemented<br />

with the <strong>Johnson</strong> <strong>Screens</strong> screw<br />

conveyors (MND), allowing extended<br />

transfer capabilities. This could be over<br />

undulated areas and include vertical<br />

elevation if necessary.<br />

The MD consists of a shaft-less spiral<br />

screw conveyor inside an inclined<br />

duct with bolted removable covers.<br />

Screenings enter into a hopper where<br />

they are conveyed to the compaction<br />

and dewatering section before being<br />

disposed of into a container. Screening<br />

volume reductions of upto 40 percent<br />

can be attained. Liquids pressed from<br />

the screenings return to the screw<br />

compactor inlet base before discharging<br />

either to a drain or returned for further<br />

treatment.<br />

A discharge connection to a continuous<br />

bagging system can be supplied<br />

to provide a totally enclosed screw<br />

compacting system. This will enhance<br />

odour abatement of the system, and the<br />

screenings can be sealed without any<br />

personal contact.<br />

The MD comprises of bolted sections to<br />

grant easy inspection and maintenance<br />

access, which in turn will increase<br />

longevity and overall asset life.<br />

CAPACITIES<br />

• Up to 8 m³/ hr (282.5 ft³/ hr)<br />

FABRICATION:<br />

• Stainless steel: 304 and 316<br />

• Spiral: Mild steel or Stainless steel,<br />

304 or 316<br />

SCREENINGS VOLUME REDUCTION:<br />

• Upto 40 percent<br />

BENEFITS:<br />

• High quality and reliability at low<br />

costs<br />

• Simple and robust<br />

• Quick and easy installation<br />

• Retrofit capability<br />

• Reliable and automatic self cleaning<br />

operation<br />

• Protection of downstream plant and<br />

drains<br />

• Very low maintenance<br />

TYPICAL APPLICATIONS:<br />

• Small sewage treatment works<br />

• Municipal wastewater treatment<br />

works<br />

• Industrial effluent discharges<br />

• Paper mills, abattoirs, food<br />

processing<br />

• Chemical industry, refineries<br />

• Recovery from processing plant<br />

ADVANTAGES:<br />

• Enhanced odor abatement with<br />

continuous bagging<br />

• Improved health & safety with<br />

continuous bagging<br />

• Easy operation and maintenance<br />

• High reliability and long asset life<br />

• Non-clogging even with fibrous<br />

materials<br />

• Fully enclosed<br />

• Low noise<br />

• Low energy<br />

• No internal bearings<br />

• Heavy-duty<br />

02

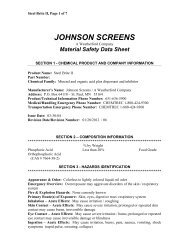

H<br />

H<br />

H<br />

M<br />

G<br />

L<br />

G<br />

D<br />

A<br />

B<br />

E<br />

C<br />

F<br />

MODEL MD 20 MD 30 MD 40<br />

mm in. mm in. mm in.<br />

A 2900 114.17 4120 162.20 5400 212.60<br />

B 2000 78.74 3000 118.10 4000 157.48<br />

C 400 15.75 400 15.75 460 18.11<br />

D 500 19.68 720 28.34 940 37.00<br />

E 530 20.86 600 23.62 720 28.35<br />

F 60 2.36 60 2.36 101 3.97<br />

G 400 15.74 560 22.05 730 28.74<br />

H 330 13.00 430 16.93 550 21.65<br />

L 255 10.04 365 14.37 480 18.89<br />

M 230 9.05 330 13.00 430 16.92<br />

kW (hP) 1.05 (1.4) 3.0 (4) 5.5 (7.4)<br />

The data contained in this document is for information only and values are typical. Please contact<br />

<strong>Johnson</strong> <strong>Screens</strong> for confirmation.<br />

03

Providing over 100 years of experience,<br />

innovation and customer satisfaction.<br />

Contact us today.<br />

OUR WIDE RANGE OF PRECISION<br />

ENGINEERED EQUIPMENT IS<br />

SUITABLE FOR MORE APPLICATIONS<br />

THAN EVER.<br />

Turn to <strong>Johnson</strong> <strong>Screens</strong> ® to help<br />

maximise your operational efficiency<br />

and find long-term, trouble-free<br />

solutions. Discover our ever expanding<br />

range of products, designed with your<br />

needs in mind:<br />

WATER PROCESS AND FLUID<br />

TREATMENt<br />

Solids screening<br />

Complete line of headworks products<br />

Conveyors and compactors<br />

Package plants<br />

Sludge treatment<br />

Clarification<br />

Filtration<br />

Biological and advanced treatment<br />

Sludge dewatering and handling<br />

Industrial pumps<br />

Process performance chemicals<br />

ARCHITECTURE &<br />

CONSTRUCTION<br />

Column covers<br />

Custom lighting<br />

Exterior applications<br />

Furniture<br />

Interior applications<br />

Grating<br />

Wall cladding<br />

Steel Brite<br />

GENERAL INDUSTRIAL<br />

Centrifuge baskets<br />

Flat panel screens<br />

Inline strainers<br />

Laterals<br />

Nozzles<br />

Sieve screens and boxes<br />

Support grids<br />

Water treatment equipment<br />

MINERAL AND AGGREGATE<br />

PROCESSING<br />

Vee-Wire® screening systems<br />

Polyurethane screening<br />

Rubber screening systems<br />

Woven wire screening systems<br />

Screening accessories<br />

Wear linings<br />

Mill linings<br />

Fabrication<br />

HDPE pipe<br />

Water treatment equipment<br />

PULP AND PAPER<br />

Effluent treatment equipment<br />

Fibre line equipment<br />

Pressure screens, baskets, rotors<br />

Progressive Cavity Pumps<br />

Pulpers, extraction plate, rotors<br />

Reject handling equipment, drums<br />

Sieve bends, screen panels<br />

Water treatment equipment<br />

REFINING AND PETROCHEMICAL<br />

Centerpipes<br />

Distributor trays<br />

Inlet baskets<br />

Outlet baskets<br />

Overlay grids<br />

Scale traps<br />

Scallop screens<br />

Vessel internals<br />

WATER WELL<br />

Nu-Well chemicals<br />

PVC casings and risers<br />

PVC drop pipe<br />

PVC well screens<br />

Pre-packed well screens<br />

Rod-based well screens<br />

Stainless steel casings and risers<br />

Well screen fittings and accessories<br />

ON-SITE SERVICES<br />

Installation<br />

Inspection<br />

Repair<br />

Assistance<br />

Supervision<br />

AUSTRALIA - ASIA PACIFIC<br />

<strong>Johnson</strong> <strong>Screens</strong> Australia<br />

TEL.: +61 7 3867 5555<br />

FAX: +61 7 3265 2768<br />

EMAIL: salesasiapacific@johnsonscreens.com<br />

EUROPE - MIDDLE EAST - AFRICA<br />

<strong>Johnson</strong> <strong>Screens</strong> France<br />

TEL.: +33 (0)5 4902 1600<br />

FAX : +33 (0)5 4902 1616<br />

EMAIL: saleseurope@johnsonscreens.com<br />

A Weatherford Company<br />

NORTH, SOUTH & CENTRAL AMERICA<br />

<strong>Johnson</strong> <strong>Screens</strong> USA<br />

TEL.: +1 651 636 3900<br />

FAX: +1 651 638 3171<br />

EMAIL: salesamerica@johnsonscreens.com<br />

www.johnsonscreens.com<br />

Copyright ©2011 All rights reserved to <strong>Johnson</strong> <strong>Screens</strong> (Australia) Pty Ltd 1100.01