S3™ Proximal Humerus Plating System Surgical Technique - Biomet

S3™ Proximal Humerus Plating System Surgical Technique - Biomet

S3™ Proximal Humerus Plating System Surgical Technique - Biomet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PROXIMAL<br />

HUMERUS PLATE<br />

Spatial Subchondral Support<br />

This publication is not intended for distribution in the USA.<br />

Never Stop Moving is a trademark of DePuy International Ltd.<br />

F.A.S.T. Guide, S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate and SNP Anatomic Plate Module are trademarks of DePuy Orthopaedics, Inc.<br />

© 2009 DePuy International Limited. All rights reserved.<br />

Cat No: 0709-11-000 version 1<br />

DePuy International Ltd<br />

St Anthony’s Road<br />

Leeds LS11 8DT<br />

England<br />

Tel: +44 (0)113 387 7800<br />

Fax: +44 (0)113 387 7890<br />

0086<br />

SURGICAL TECHNIQUE<br />

Issued: 11/09

<strong>Surgical</strong> <strong>Technique</strong> Guide<br />

Designed To...<br />

S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate<br />

Based on our experience in distal radius fracture management we’ve designed the new <strong>Proximal</strong> Humeral Plate.<br />

Simplified Soft Tissue Fixation<br />

• Uniquely designed suture holes allow tuberosity repairs after humeral head fixation<br />

• Suture holes are designed to accommodate multiple passes for extensive soft tissue fixation<br />

F.A.S.T. Guide Technology<br />

• Pre-loaded single use disposable drill guides<br />

• No intraoperative assembly required resulting in significant time savings<br />

• F.A.S.T. Guide are colour coded for easy plate identification: Red = Right, Lime = Left<br />

Help Restore the Natural Anatomy<br />

• Precisely contoured plates are designed to<br />

mirror the complex shape of the<br />

proximal humerus<br />

• The S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate is designed<br />

to act as a reduction template to help restore<br />

the natural anatomy<br />

• Multiple 4.0 mm subchondral support pegs<br />

and screws maintain fracture reduction<br />

Minimise Subacromial Impingement<br />

• The S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate is designed<br />

to be positioned approximately 3.0 cm distal to<br />

the greater tuberosity preventing<br />

subacromial impingement<br />

• Anatomically contoured under surface aids in<br />

restoring humeral head rotation<br />

Provide a Strong and Stable Construct<br />

• Precise fixed angle peg distribution provides<br />

spatial subchondral support to resist varus<br />

forces throughout the full range of motion<br />

• <strong>Proximal</strong> and distal locking screws and pegs<br />

ensure a strong interface for a secure and<br />

stable construct<br />

• Blunt tipped subchondral support pegs<br />

provide improved stability while preventing<br />

protrusion through the articular surface<br />

Achieve Predictable and<br />

Reproducible Results<br />

• Central guiding K-Wire provides visual<br />

confirmation for plate positioning<br />

• Manually inserted blunt-tipped drill bits provide<br />

protection against the potential perforation of<br />

the articular surface<br />

• Predetermined peg trajectories ensure a<br />

consistent spatial distribution within the<br />

humeral head<br />

2 3

<strong>Surgical</strong> <strong>Technique</strong><br />

<strong>Surgical</strong> <strong>Technique</strong><br />

Step 1: Procedure Mapping<br />

• Exposure: deltopectoral<br />

• Identify: coracoid, acromium and<br />

deltoid insertion<br />

Step 4: Exposure<br />

• The exposure is through a 12 ‐ 14 cm incision<br />

• Identify and retract the cephalic vein<br />

• Develop the interval between the pectoralis<br />

and deltoid<br />

• Extend incision line distal from coracoid<br />

• Self retaining retractors are useful for exposure<br />

Tips: during the exposure, the 2.8 mm drill<br />

bit can be loaded in preparation for plate<br />

application.<br />

Step 2: Patient Positioning<br />

• Sterile Mayo stand assists during dissection<br />

Tips: the procedure can be performed in the<br />

beach chair position or supine as per surgeon’s<br />

discretion.<br />

Step 5: Pectoralis Incision and<br />

Identification of the Biceps Tendon<br />

• Gently retract the coracobrachialis medially<br />

• Find the pectoralis insertion at the floor of the<br />

deltoid pectoralis interval<br />

• Release the proximal third of the pectoralis<br />

tendon to expose the biceps<br />

Step 3: Acquire Initial Images<br />

• Examine the fracture under fluoroscopy<br />

• Internal rotation, external rotation and<br />

sometimes axillary views are necessary<br />

Step 6: Complete Exposure<br />

• Develop the subacromial space and mobilise<br />

the proximal deltoid<br />

Tips: use of a large, blunt humeral head<br />

depressor can facilitate exposure.<br />

4 5

<strong>Surgical</strong> <strong>Technique</strong><br />

<strong>Surgical</strong> <strong>Technique</strong><br />

Step 7: Fracture Debridement<br />

• Debride the fracture<br />

Step 10: Apply Bone Graft<br />

• To facilitate healing, bone graft should<br />

be considered<br />

Step 8: Fracture Reduction<br />

• After debridement, the fracture is reduced by<br />

traction and indirect manipulation<br />

Tips: remove the Mayo table to<br />

facilitate reduction.<br />

Step 11: Determine the Proper<br />

Plate Position<br />

• Select the appropriate side plate (left or right)<br />

• Choose the appropriate length (3,4,6,8,11 or<br />

14 hole)<br />

• Fix the shaft of the plate using a 3.8 mm<br />

cortical screw through the slotted hole<br />

Tips: If using prepacked sterile implants, S3<br />

trial templates can be used to confirm the<br />

required plate size.<br />

Apply the plate 2 cm to 2.5 cm distal to the<br />

insertion of the supraspinatus, the anterior<br />

border of the plate should be immediately<br />

lateral to the bicipital groove.<br />

Step 9: Tuberosity Repair<br />

• In the case of severe comminution, suturing<br />

the rotator cuff together will help reduce<br />

the tuberosities<br />

After plate positioning a 2.0 mm guide wire will<br />

need to be loaded in the wire driver.<br />

Step 12: Drill Central Guide Wire<br />

• Drill the 2.0 mm guide wire through the central<br />

hole on the proximal portion of the plate.<br />

Advance slowly and verify its trajectory<br />

under fluoroscopy<br />

6 7

<strong>Surgical</strong> <strong>Technique</strong><br />

<strong>Surgical</strong> <strong>Technique</strong><br />

Step 13: Verify Central Guide<br />

Wire Placement<br />

• Place the guide wire in the centre of the<br />

humeral head<br />

• This plate position will reduce the risk of<br />

subacromial impingement<br />

Step 15: Manually Drill for Subchondral<br />

Support Pegs<br />

• With the 4.0 mm drill attached to the driver<br />

handle, advance the drill, through the drill<br />

guide until resistance from subchondral bone<br />

is felt<br />

• This will ensure that the peg engages<br />

subchondral bone for optimal fixation<br />

Tips: when drilling for smooth pegs use FDB40L<br />

(Drill Bit Fast 4.0 mm Long).<br />

When drilling for partially threaded pegs use<br />

FDS40 (Drill Bit Fast 4.0 mm Step).<br />

Step 14: Drill Cortex Through<br />

F.A.S.T. Guide<br />

• Using the short 4.0mm drill (FDB40S), drill<br />

through the F.A.S.T. Guide and perforate<br />

the cortex<br />

• This drill has a stop that will only<br />

allow it to penetrate the<br />

near cortex<br />

• If re-drilling is required after F.A.S.T. Guide<br />

removal, thread the drill guide (DRGSH) into<br />

the desired peg hole and drill on power using<br />

DB40S (Drill Bit Short 4.0 mm)<br />

Tips: bending the central guide wire and<br />

rotating it out of the way will ease the<br />

attachment of the drill guide to the plate.<br />

Other K-Wire holes can be used to provisionally<br />

fix the plate to the bone.<br />

Step 16: Verify Drill Depth<br />

• Once resistance is felt, fluoro imaging should<br />

verify that the tip of the manual drill is close to<br />

subchondral bone<br />

• Care should be taken not to penetrate<br />

subchondral bone<br />

Tips: the depth gauges have a bias built in that<br />

will reduce the measured depth by 2.5 mm. If<br />

peg to subchondral bone contact is desired,<br />

add 2.5 mm to the depth gauge.<br />

Depths can be Gauged from the<br />

manual drill or the sleeveless depth<br />

gauge. Both can be read through<br />

either the F.A.S.T. Guide or through<br />

the drill guide, using the appropriate<br />

calibrated scale.<br />

8 9

<strong>Surgical</strong> <strong>Technique</strong><br />

<strong>Surgical</strong> <strong>Technique</strong><br />

Step 17: Attach Tuberosities to Plate<br />

• Using 20 gauge, monofilament stainless wire,<br />

secure the tuberosities to the plate by passing<br />

the needles close to the insertion of the tendon<br />

and then through to side, front or top loading<br />

wire attachment points (see insert)<br />

Step 19: Final Verification<br />

• Evaluate the humerus under fluoroscopy to<br />

assess the reduction and to confirm<br />

proper positioning<br />

• Twist the wire until appropriate tension<br />

is reached<br />

Step 18: Fix Remaining Screws in Plate<br />

• The shaft of the plate can be fixed with either<br />

90˚ locking screws or multidirectional<br />

cortical screws<br />

Step 20: Function<br />

• The S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate is designed<br />

to provide the greatest patient function and the<br />

lowest risk of subacromial impingement<br />

• Using the appropriate end of the tissue<br />

protector, drill to the correct depth (far cortex)<br />

and measure with the barrel depth gauge<br />

• Multiple divergent blunt pegs provide optimum<br />

subchondral support<br />

• Use a set screw for each 90˚ screw to lock it<br />

into place<br />

• Do not use a set screw when using<br />

multidirectional screws<br />

Tips: an alternate approach is to apply the wire<br />

tension bands to the plate prior to placing the<br />

subchondral support pegs. This may aid in the<br />

reduction.<br />

10 11

Peg and Screw Options<br />

S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate Shoulder Fixation <strong>System</strong><br />

Description<br />

1 Smooth Pegs, Locking<br />

2 Threaded Pegs, Locking<br />

3 90˚ Cortical Screws,<br />

Non-locking<br />

4 Multi-directional Cortical<br />

Screws, Non-Locking<br />

5 90˚ Locking Set Screw<br />

Provides spatial subchondral support<br />

Help to capture and lag the humeral head<br />

Provide bi-cortical fixation while locking to<br />

the plate using the NL-SS sets crews<br />

Provide multi-directional fixation when used<br />

through the oblong hole<br />

Secures the 90˚ lock distal screws to the plate<br />

1<br />

STP Series<br />

4 MD Series 5 NL-SS Series<br />

2 STPT Series 3 NL Series<br />

Important:<br />

This <strong>Surgical</strong> <strong>Technique</strong> guide does not include all of the information necessary for the selection and use of this device. Please<br />

refer to instructions for use (I.F.U.) and product labelling for all necessary information.<br />

Indications:<br />

The S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate is indicated for fractures and fracture dislocations, osteotomies, and non-unions of the<br />

proximal humerus.<br />

Plate Options<br />

Description<br />

head Width x Shaft Width x Overall Length<br />

STP, STPT Series available in 20 mm - 65 mm Lengths (2.5 mm Steps)<br />

NL, MD Series available in 20 mm - 38 mm Lengths (2 mm Steps)<br />

Contraindications:<br />

If any of the following are suspected, tests are to be performed prior to implantation. Active or latent infection. Sepsis. Insufficient<br />

quantity or quality of bone and/or soft tissue. Material sensitivity. Patients who are unwilling or incapable of following post operative<br />

care instructions.<br />

Warning and Precautions:<br />

If any of the following are suspected, tests are to be performed prior to implantation:<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate<br />

S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate<br />

S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate<br />

S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate<br />

S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate<br />

S 3 <strong>Proximal</strong> <strong>Humerus</strong> Plate<br />

16.0 mm x 11.8 mm x 70.0 mm<br />

17.0 mm x 12.3 mm x 87.1 mm<br />

17.0 mm x 17.0 mm x 110 mm<br />

17.0 mm x 17.0 mm x 150 mm<br />

17.0 mm x 17.0 mm x 195 mm<br />

17.0 mm x 17.0 mm x 246 mm<br />

6<br />

7<br />

8<br />

3 hole<br />

4 hole<br />

6 hole<br />

• Active or latent infection<br />

• Insufficient quantity or quality of bone and/or soft tissue<br />

• Material sensitivity<br />

9<br />

8 hole<br />

• Sepsis<br />

10<br />

11<br />

11 hole<br />

14 hole<br />

• Patients who are unwilling or incapable of following post operative care instructions<br />

Warnings and Precautions:<br />

An implant must never be reused. Previous stresses may have created imperfections that can potentially lead to device failure.<br />

Instrumentation must be inspected for wear or damage prior to usage. Protect implants against scratching or nicking. Such stress<br />

concentration can lead to failure.<br />

Adverse Effects:<br />

Potential for these devices failing as a result of loose fixation and/or loosening, caused by:<br />

• Mechanical Stress<br />

• Excessive activity<br />

• Load bearing particularly when the implants experience increased loads due to a delayed union, nonunion, or<br />

incomplete healing<br />

12 13

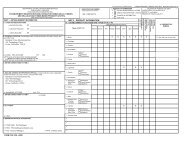

Ordering Information<br />

Ordering Information<br />

Instruments<br />

Description<br />

Order Code<br />

Implants<br />

Description<br />

Non-Sterile Code<br />

Sterile Code<br />

Guide Soft Tissue Shoulder<br />

Depth Gauge Shoulder<br />

F.A.S.T Shoulder Depth Gauge Stepped<br />

2.0 mm Square Driver Insert<br />

4.0 mm Drill Guide Shoulder<br />

Handle Mini Quick Connect<br />

Cannulated Ratcheting Handle<br />

Quick Couple Handle<br />

F.A.S.T Peg Driver 4.0 mm<br />

S3 Trial 3/4 Hole Left<br />

S3 Trial 6 Hole Left<br />

S3 Trial 8 Hole Left<br />

S3 Trial 11/14 Hole Left<br />

S3 Trial 3/4 Hole Right<br />

S3 Trial 6 Hole Right<br />

S3 Trial 8 Hole Right<br />

S3 Trial 11/14 Hole Right<br />

Instrument Cases<br />

Description<br />

Sterile Instrument Case<br />

Non-Sterile Instrument Case<br />

Disposables<br />

Description<br />

2.8 mm Drill for Distal Screw<br />

4.0 mm F.A.S.T Guide Long Drill<br />

4.0 mm F.A.S.T Guide Short Drill<br />

4.0 mm F.A.S.T Guide Drill<br />

K-wire, 2.0 mm<br />

Implants<br />

Description<br />

3.8 x 20.0 mm Multidirectional Screw<br />

3.8 x 22.0 mm Multidirectional Screw<br />

3.8 x 24.0 mm Multidirectional Screw<br />

3.8 x 26.0 mm Multidirectional Screw<br />

3.8 x 28.0 mm Multidirectional Screw<br />

3.8 x 30.0 mm Multidirectional Screw<br />

3.8 x 32.0 mm Multidirectional Screw<br />

3.8 x 34.0 mm Multidirectional Screw<br />

3.8 x 36.0 mm Multidirectional Screw<br />

3.8 x 38.0 mm Multidirectional Screw<br />

3.8 x 20.0 mm 90º Locking Screw<br />

3.8 x 22.0 mm 90º Locking Screw<br />

3.8 x 24.0 mm 90º Locking Screw<br />

3.8 x 26.0 mm 90º Locking Screw<br />

3.8 x 28.0 mm 90º Locking Screw<br />

3.8 x 30.0 mm 90º Locking Screw<br />

3.8 x 32.0 mm 90º Locking Screw<br />

3.8 x 34.0 mm 90º Locking Screw<br />

3.8 x 36.0 mm 90º Locking Screw<br />

3.8 x 38.0 mm 90º Locking Screw<br />

SSTG<br />

SBDG<br />

FSDGS<br />

SDI<br />

DRGSH<br />

MQC<br />

8261-66-000<br />

QCH<br />

FPD40<br />

2312-03-503<br />

2312-03-506<br />

2312-03-508<br />

2312-03-514<br />

2312-03-603<br />

2312-03-606<br />

2312-03-608<br />

2312-03-614<br />

Order Code<br />

2312-03-500<br />

PHT<br />

Non-Sterile Code<br />

MD20<br />

MD22<br />

MD24<br />

MD26<br />

MD28<br />

MD30<br />

MD32<br />

MD34<br />

MD36<br />

MD38<br />

NL20<br />

NL22<br />

NL24<br />

NL26<br />

NL28<br />

NL30<br />

NL32<br />

NL34<br />

NL36<br />

NL38<br />

Order Code<br />

2312-01-309<br />

2312-01-306<br />

2312-01-307<br />

2312-01-308<br />

2312-01-310<br />

Sterile Code<br />

8575-38-020<br />

8575-38-022<br />

8575-38-024<br />

8575-38-026<br />

8575-38-028<br />

8575-38-030<br />

8575-38-032<br />

8575-38-034<br />

8575-38-036<br />

8575-38-038<br />

8575-90-020<br />

8575-90-022<br />

8575-90-024<br />

8575-90-026<br />

8575-90-028<br />

8575-90-030<br />

8575-90-032<br />

8575-90-034<br />

8575-90-036<br />

8575-90-038<br />

S3 Shoulder Plate 3 Hole Left<br />

S3 Shoulder Plate 4 Hole Left<br />

S3 Shoulder Plate 6 Hole Left<br />

S3 Shoulder Plate 8 Hole Left<br />

S3 Shoulder Plate 11 Hole Left<br />

S3 Shoulder Plate 14 Hole Left<br />

S3 Shoulder Plate 3 Hole Right<br />

S3 Shoulder Plate 4 Hole Right<br />

S3 Shoulder Plate 6 Hole Right<br />

S3 Shoulder Plate 8 Hole Right<br />

S3 Shoulder Plate 11 Hole Right<br />

S3 Shoulder Plate 14 Hole Right<br />

4.0 x 20.0 mm Standard Peg<br />

4.0 x 25.0 mm Standard Peg<br />

4.0 x 30.0 mm Standard Peg<br />

4.0 x 32.0 mm Standard Peg<br />

4.0 x 35.0 mm Standard Peg<br />

4.0 x 37.5 mm Standard Peg<br />

4.0 x 40.0 mm Standard Peg<br />

4.0 x 42.5 mm Standard Peg<br />

4.0 x 45.0 mm Standard Peg<br />

4.0 x 47.5 mm Standard Peg<br />

4.0 x 50.0 mm Standard Peg<br />

4.0 x 52.5 mm Standard Peg<br />

4.0 x 55.0 mm Standard Peg<br />

4.0 x 57.5 mm Standard Peg<br />

4.0 x 60.0 mm Standard Peg<br />

4.0 x 62.5 mm Standard Peg<br />

4.0 x 65.0 mm Standard Peg<br />

4.0 x 20.0 mm Threaded Peg<br />

4.0 x 25.0 mm Threaded Peg<br />

4.0 x 30.0 mm Threaded Peg<br />

4.0 x 32.5 mm Threaded Peg<br />

4.0 x 35.0 mm Threaded Peg<br />

4.0 x 37.5 mm Threaded Peg<br />

4.0 x 40.0 mm Threaded Peg<br />

4.0 x 42.5 mm Threaded Peg<br />

4.0 x 45.0 mm Threaded Peg<br />

4.0 x 47.5 mm Threaded Peg<br />

4.0 x 50.0 mm Threaded Peg<br />

4.0 x 52.5 mm Threaded Peg<br />

4.0 x 55.0 mm Threaded Peg<br />

4.0 x 57.5 mm Threaded Peg<br />

4.0 x 60.0 mm Threaded Peg<br />

4.0 x 62.5 mm Threaded Peg<br />

4.0 x 65.0 mm Threaded Peg<br />

SSPL3<br />

SSPL4<br />

SSPL6<br />

SSPL8<br />

SSPL11<br />

SSPL14<br />

SSPR3<br />

SSPR4<br />

SSPR6<br />

SSPR8<br />

SSPR11<br />

SSPR14<br />

STP20<br />

STP25<br />

STP30<br />

STP325<br />

STP35<br />

STP375<br />

STP40<br />

STP425<br />

STP45<br />

STP475<br />

STP50<br />

STP525<br />

STP55<br />

STP575<br />

STP60<br />

STP625<br />

STP65<br />

STPT20<br />

STPT25<br />

STPT30<br />

STPT325<br />

STPT35<br />

STPT375<br />

STPT40<br />

STPT425<br />

STPT45<br />

STPT475<br />

STPT50<br />

STPT525<br />

STPT55<br />

STPT575<br />

STPT60<br />

STPT625<br />

STPT65<br />

8572-01-003<br />

8572-01-004<br />

8572-01-006<br />

8572-01-008<br />

8572-01-011<br />

8572-01-014<br />

8572-02-003<br />

8572-02-004<br />

8572-02-006<br />

8572-02-008<br />

8572-02-011<br />

8572-02-014<br />

8570-40-200<br />

8570-40-250<br />

8570-40-300<br />

8570-40-325<br />

8570-40-350<br />

8570-40-374<br />

8570-40-400<br />

8570-40-425<br />

8570-40-450<br />

8570-40-475<br />

8570-40-500<br />

8570-40-525<br />

8570-40-550<br />

8570-40-575<br />

8570-40-600<br />

8570-40-625<br />

8570-40-650<br />

8571-40-200<br />

8571-40-250<br />

8571-40-300<br />

8571-40-325<br />

8571-40-350<br />

8571-40-374<br />

8571-40-400<br />

8571-40-425<br />

8571-40-450<br />

8571-40-475<br />

8571-40-500<br />

8571-40-525<br />

8571-40-550<br />

8571-40-575<br />

8571-40-600<br />

8571-40-625<br />

8571-40-650<br />

90º Locking Screw<br />

NLSS<br />

8575-90-000<br />

14 15