Fibertex Geotextiles - Fibertex AS

Fibertex Geotextiles - Fibertex AS

Fibertex Geotextiles - Fibertex AS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

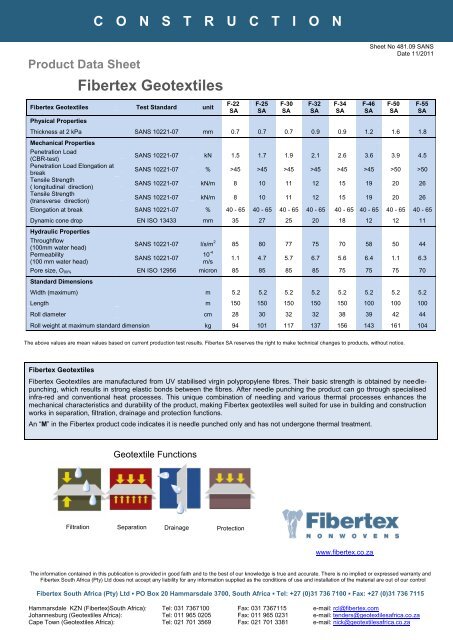

C O N S T R U C T I O N<br />

Product Data Sheet<br />

<strong>Fibertex</strong> <strong>Geotextiles</strong><br />

<strong>Fibertex</strong> <strong>Geotextiles</strong> Test Standard unit<br />

Physical Properties<br />

F-22<br />

SA<br />

F-25<br />

SA<br />

F-30<br />

SA<br />

F-32<br />

SA<br />

F-34<br />

SA<br />

F-46<br />

SA<br />

Sheet No 481.09 SANS<br />

Date 11/2011<br />

Thickness at 2 kPa SANS 10221-07 mm 0.7 0.7 0.7 0.9 0.9 1.2 1.6 1.8<br />

Mechanical Properties<br />

Penetration Load<br />

(CBR-test)<br />

SANS 10221-07 kN 1.5 1.7 1.9 2.1 2.6 3.6 3.9 4.5<br />

Penetration Load Elongation at<br />

break<br />

SANS 10221-07 % >45 >45 >45 >45 >45 >45 >50 >50<br />

Tensile Strength<br />

( longitudinal direction)<br />

SANS 10221-07 kN/m 8 10 11 12 15 19 20 26<br />

Tensile Strength<br />

(transverse direction)<br />

SANS 10221-07 kN/m 8 10 11 12 15 19 20 26<br />

Elongation at break SANS 10221-07 % 40 - 65 40 - 65 40 - 65 40 - 65 40 - 65 40 - 65 40 - 65 40 - 65<br />

Dynamic cone drop EN ISO 13433 mm 35 27 25 20 18 12 12 11<br />

Hydraulic Properties<br />

Throughflow<br />

SANS 10221-07 l/s/m 2 85 80 77 75 70 58 50 44<br />

(100mm water head)<br />

Permeability<br />

10 -4<br />

SANS 10221-07<br />

1.1 4.7 5.7 6.7 5.6 6.4 1.1 6.3<br />

(100 mm water head)<br />

m/s<br />

Pore size, O 90% EN ISO 12956 micron 85 85 85 85 75 75 75 70<br />

Standard Dimensions<br />

Width (maximum) m 5.2 5.2 5.2 5.2 5.2 5.2 5.2 5.2<br />

Length m 150 150 150 150 150 100 100 100<br />

Roll diameter cm 28 30 32 32 38 39 42 44<br />

Roll weight at maximum standard dimension kg 94 101 117 137 156 143 161 104<br />

F-50<br />

SA<br />

F-55<br />

SA<br />

The above values are mean values based on current production test results. <strong>Fibertex</strong> SA reserves the right to make technical changes to products, without notice.<br />

<strong>Fibertex</strong> <strong>Geotextiles</strong><br />

<strong>Fibertex</strong> <strong>Geotextiles</strong> are manufactured from UV stabilised virgin polypropylene fibres. Their basic strength is obtained by needlepunching,<br />

which results in strong elastic bonds between the fibres. After needle punching the product can go through specialised<br />

infra-red and conventional heat processes. This unique combination of needling and various thermal processes enhances the<br />

mechanical characteristics and durability of the product, making <strong>Fibertex</strong> geotextiles well suited for use in building and construction<br />

works in separation, filtration, drainage and protection functions.<br />

An “M” in the <strong>Fibertex</strong> product code indicates it is needle punched only and has not undergone thermal treatment.<br />

Geotextile Functions<br />

Filtration<br />

Separation<br />

Drainage<br />

Protection<br />

www.fibertex.co.za<br />

The information contained in this publication is provided in good faith and to the best of our knowledge is true and accurate. There is no implied or expressed warranty and<br />

<strong>Fibertex</strong> South Africa (Pty) Ltd does not accept any liability for any information supplied as the conditions of use and installation of the material are out of our control<br />

<strong>Fibertex</strong> South Africa (Pty) Ltd ▪ PO Box 20 Hammarsdale 3700, South Africa ▪ Tel: +27 (0)31 736 7100 ▪ Fax: +27 (0)31 736 7115<br />

Hammarsdale KZN (<strong>Fibertex</strong>)South Africa):<br />

Johannesburg (<strong>Geotextiles</strong> Africa):<br />

Cape Town (<strong>Geotextiles</strong> Africa):<br />

Tel: 031 7367100<br />

Tel: 011 965 0205<br />

Tel: 021 701 3569<br />

Fax: 031 7367115<br />

Fax: 011 965 0231<br />

Fax: 021 701 3381<br />

e-mail: rcl@fibertex.com<br />

e-mail: tenders@geotextilesafrica.co.za<br />

e-mail: nick@geotextilesafrica.co.za

Product Data Sheet<br />

C O N S T R U C T I O N<br />

<strong>Fibertex</strong> <strong>Geotextiles</strong><br />

<strong>Fibertex</strong> <strong>Geotextiles</strong> Test Standard unit<br />

Physical Properties<br />

F-300M<br />

SA<br />

F-400M<br />

SA<br />

F-500M<br />

SA<br />

F-550M<br />

SA<br />

F-650M<br />

SA<br />

Sheet No 481.09 SANS<br />

Date 11/2011<br />

F-800M<br />

SA<br />

F-1000M<br />

SA<br />

Thickness at 2 kPa SANS 10221-07 mm 3.0 3.4 3.6 4.1 5.0 5.5 6.0 7.0<br />

Mechanical Properties<br />

F-1200M<br />

SA<br />

Penetration Load<br />

(CBR-test)<br />

SANS 10221-07 kN 3.9 4.5 6.5 7.0 7.5 9.5 12.0 14.0<br />

Elongation at break SANS 10221-07 % >60 >60 >60 >60 >60 >60 >60 >60<br />

Tensile Strength<br />

( longitudinal direction)<br />

SANS 10221-07 kN/m 20 25 30 40 45 50 55 65<br />

Tensile Strength<br />

(transverse direction)<br />

SANS 10221-07 kN/m 20 28 38 40 50 65 80 100<br />

Elongation at break SANS 10221-07 % >50 >50 >50 >50 >50 >50 >50 >50<br />

Dynamic cone drop EN ISO 13433 mm 16 8 4 3 3 0 0 0<br />

Hydraulic Properties<br />

Throughflow<br />

(100mm water head)<br />

SANS 10221-07 l/s/m 2 70 70 65 65 60 60 25 25<br />

Permeability<br />

(100 mm water head)<br />

SANS 10221-07 10 -3 m/s 2.1 2.6 1.04 2.4 1.5 3.6 1.4 1.6<br />

Pore size, O 90% EN ISO 12956 micron 70 80 70 70 70 70 70 60<br />

Standard Dimensions<br />

Width (maximum) m 5.2 5.2 5.2 5.2 5.2 5.2 5.2 5.2<br />

Length m 100 100 50 50 50 50 50 50<br />

Roll diameter cm 60 60 66 70 56 58 69 72<br />

Roll weight at maximum standard dimension kg 156 208 130 143 169 208 260 312<br />

The above values are mean values based on current production test results. <strong>Fibertex</strong> SA reserves the right to make technical changes to products, without notice.<br />

<strong>Fibertex</strong> <strong>Geotextiles</strong><br />

<strong>Fibertex</strong> <strong>Geotextiles</strong> are manufactured from UV stabilised virgin polypropylene fibres. Their basic strength is obtained by needlepunching,<br />

which results in strong elastic bonds between the fibres. After needle punching the product can go through specialised<br />

infra-red and conventional heat processes. This unique combination of needling and various thermal processes enhances the<br />

mechanical characteristics and durability of the product, making <strong>Fibertex</strong> geotextiles well suited for use in building and construction<br />

works in separation, filtration, drainage and protection functions.<br />

An “M” in the <strong>Fibertex</strong> product code indicates it is needle punched only and has not undergone thermal treatment.<br />

Geotextile Functions<br />

Filtration Separation Drainage Protection<br />

www.fibertex.co.za<br />

The information contained in this publication is provided in good faith and to the best of our knowledge is true and accurate. There is no implied or expressed warranty and<br />

<strong>Fibertex</strong> South Africa (Pty) Ltd does not accept any liability for any information supplied as the conditions of use and installation of the material are out of our control<br />

<strong>Fibertex</strong> South Africa (Pty) Ltd ▪ PO Box 20 Hammarsdale 3700, South Africa ▪ Tel: +27 (0)31 736 7100 ▪ Fax: +27 (0)31 736 7115<br />

Hammarsdale KZN (<strong>Fibertex</strong>)South Africa):<br />

Johannesburg (<strong>Geotextiles</strong> Africa):<br />

Cape Town (<strong>Geotextiles</strong> Africa):<br />

Tel: 031 7367100<br />

Tel: 011 965 0205<br />

Tel: 021 701 3569<br />

Fax: 031 7367115<br />

Fax: 011 965 0231<br />

Fax: 021 701 3381<br />

e-mail: rcl@fibertex.com<br />

e-mail: tenders@geotextilesafrica.co.za<br />

e-mail: nick@geotextilesafrica.co.za