State prediction and optimal scheduling for fed-batch fermentation

State prediction and optimal scheduling for fed-batch fermentation State prediction and optimal scheduling for fed-batch fermentation

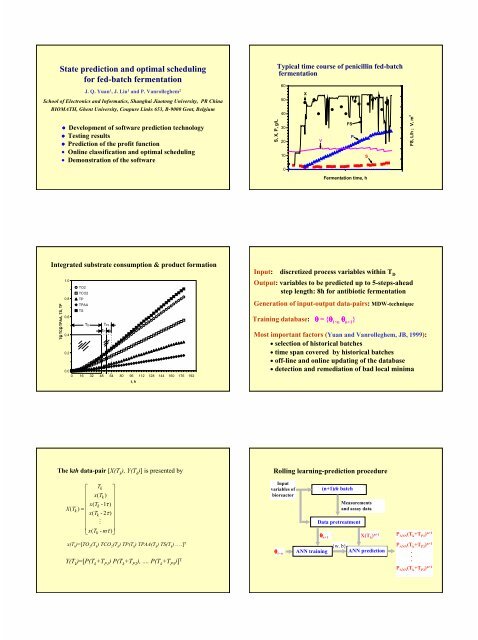

State prediction and optimal scheduling for fed-batch fermentation J. Q. Yuan 1 , J. Liu 1 and P. Vanrolleghem 2 School of Electronics and Informatics, Shanghai Jiaotong University, PR China BIOMATH, Ghent University, Coupure Links 653, B-9000 Gent, Belgium • Development of software prediction technology • Testing results • Prediction of the profit function • Online classification and optimal scheduling • Demonstration of the software S, X, P, g/L Typical time course of penicillin fed-batch fermentation 60 50 40 30 20 10 X V 0 0 0 200 Fermentation time, h FS P S 320 280 240 200 160 120 80 40 FS, L/h ; V, m 3 Integrated substrate consumption & product formation TO2, TCO2, TPAA, TS, TP 1.0 TO2 TCO2 0.8 TP TPAA TS 0.6 TD TP2 TP1 0.4 0.2 0.0 0 16 32 48 64 80 96 112 128 144 160 176 192 t, h Input: discretized process variables within T D Output: variables to be predicted up to 5-steps-ahead step length: 8h for antibiotic fermentation Generation of input-output data-pairs: MDW-technique Training database: θ = {θ 1~n θ n+1 } Most important factors (Yuan and Vanrolleghem, JB, 1999): • selection of historical batches • time span covered by historical batches • off-line and online updating of the database • detection and remediation of bad local minima The kth data-pair [X(T k ), Y(T k )] is presented by Rolling learning-prediction procedure Tk xT ( k ) xT ( k - 1τ ) XT ( k ) = xT ( k - 2τ ) xT ( k - mτ ) x(T k )=[TO 2 (T k ) TCO 2 (T k ) TP(T k ) TPAA(T k ) TS(T k ) .. ..] T Y(T k )=[P(T k +T P1 ) P(T k +T P2 ), .... P(T k +T P5 )] T Input variables of bioreactor θ 1~n (n+1)th batch Measurements and assay data Data pretreatment θ n+1 X(T k ) n+1 {w, b} ANN training ANN prediction P ANN (T k +T P1 ) n+1 P ANN (T k +T P2 ) n+1 • • • P ANN (T k +T P2 ) n+1

- Page 2 and 3: I i j l l t t t Product concentrati

<strong>State</strong> <strong>prediction</strong> <strong>and</strong> <strong>optimal</strong> <strong>scheduling</strong><br />

<strong>for</strong> <strong>fed</strong>-<strong>batch</strong> <strong>fermentation</strong><br />

J. Q. Yuan 1 , J. Liu 1 <strong>and</strong> P. Vanrolleghem 2<br />

School of Electronics <strong>and</strong> In<strong>for</strong>matics, Shanghai Jiaotong University, PR China<br />

BIOMATH, Ghent University, Coupure Links 653, B-9000 Gent, Belgium<br />

• Development of software <strong>prediction</strong> technology<br />

• Testing results<br />

• Prediction of the profit function<br />

• Online classification <strong>and</strong> <strong>optimal</strong> <strong>scheduling</strong><br />

• Demonstration of the software<br />

S, X, P, g/L<br />

Typical time course of penicillin <strong>fed</strong>-<strong>batch</strong><br />

<strong>fermentation</strong><br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

X<br />

V<br />

0<br />

0<br />

0 200<br />

Fermentation time, h<br />

FS<br />

P<br />

S<br />

320<br />

280<br />

240<br />

200<br />

160<br />

120<br />

80<br />

40<br />

FS, L/h ; V, m 3<br />

Integrated substrate consumption & product <strong>for</strong>mation<br />

TO2, TCO2, TPAA, TS, TP<br />

1.0<br />

TO2<br />

TCO2<br />

0.8 TP<br />

TPAA<br />

TS<br />

0.6<br />

TD TP2<br />

TP1<br />

0.4<br />

0.2<br />

0.0<br />

0 16 32 48 64 80 96 112 128 144 160 176 192<br />

t, h<br />

Input: discretized process variables within T D<br />

Output: variables to be predicted up to 5-steps-ahead<br />

step length: 8h <strong>for</strong> antibiotic <strong>fermentation</strong><br />

Generation of input-output data-pairs: MDW-technique<br />

Training database: θ = {θ 1~n<br />

θ n+1<br />

}<br />

Most important factors (Yuan <strong>and</strong> Vanrolleghem, JB, 1999):<br />

• selection of historical <strong>batch</strong>es<br />

• time span covered by historical <strong>batch</strong>es<br />

• off-line <strong>and</strong> online updating of the database<br />

• detection <strong>and</strong> remediation of bad local minima<br />

The kth data-pair [X(T k<br />

), Y(T k<br />

)] is presented by<br />

Rolling learning-<strong>prediction</strong> procedure<br />

Tk<br />

<br />

xT ( k ) <br />

<br />

xT ( k - 1τ<br />

) <br />

XT ( k ) = xT ( k - 2τ<br />

) <br />

<br />

<br />

<br />

xT<br />

( k - mτ<br />

)<br />

<br />

<br />

x(T k<br />

)=[TO 2<br />

(T k<br />

) TCO 2<br />

(T k<br />

) TP(T k<br />

) TPAA(T k<br />

) TS(T k<br />

) .. ..] T<br />

Y(T k<br />

)=[P(T k<br />

+T P1<br />

) P(T k<br />

+T P2<br />

), .... P(T k<br />

+T P5<br />

)] T<br />

Input<br />

variables of<br />

bioreactor<br />

θ 1~n<br />

(n+1)th <strong>batch</strong><br />

Measurements<br />

<strong>and</strong> assay data<br />

Data pretreatment<br />

θ n+1 X(T k ) n+1<br />

{w, b}<br />

ANN training ANN <strong>prediction</strong><br />

P ANN (T k +T P1 ) n+1<br />

P ANN (T k +T P2 ) n+1<br />

•<br />

•<br />

•<br />

P ANN (T k +T P2 ) n+1

I<br />

i<br />

j<br />

l<br />

l<br />

t<br />

t<br />

t<br />

Product concentration, g/L<br />

Industrial <strong>fed</strong>-<strong>batch</strong> <strong>fermentation</strong>s <strong>for</strong> testing<br />

of ANN-predictor<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

bg B<br />

52<br />

58 59 60 6<br />

az ba<br />

51<br />

BABBBC bb bc BD bd be bf 56<br />

57<br />

50<br />

49<br />

47<br />

48 AYAZBABBBCBDBEBFBGBH bh b<br />

53 54<br />

55<br />

bf<br />

bg<br />

avaw 52<br />

46<br />

AW AXAYAZ ax ay 51<br />

be<br />

45<br />

AX AYAZBABBBCBD<br />

ay az ba bb bc bd<br />

as at au AV 50<br />

44<br />

ax ay az ba bb<br />

ar as<br />

41 42 43 AR ASATAUAVAW 49 ax<br />

ar<br />

48<br />

AQ<br />

avaw<br />

aq<br />

AS ATAUAVAW au<br />

40<br />

39 AO at au avaw<br />

AR<br />

an ao ap as<br />

41 42 43 44 45 46 47<br />

ao<br />

AO APAQARASATAU ap aq<br />

Batch 17<br />

al am<br />

35 36 37 38 AK ALAMAN 40<br />

ao ap aq ar<br />

AL AMAN am an<br />

39<br />

AM ANAOAPAQ 34<br />

AL<br />

ah ai aj ak 33AH AI AJ AK 38<br />

al aman<br />

ag ah ai aj ak al<br />

31AF<br />

32 AG 35 36<br />

ag<br />

AG AH AI AJAK AD 30 AE ag ah ai aj ak 37<br />

AG AH AI AJ aeAF<br />

af 33 34<br />

32<br />

ae<br />

AE AF af AC<br />

adAE<br />

af<br />

Batch 27 (aberrant)<br />

29 acAD<br />

AB<br />

28 AD<br />

ab ad 31 ae<br />

Z AA ab 30 ad<br />

27AB AC aa<br />

AB AC ac<br />

26<br />

AA<br />

28 29<br />

X Y y 27<br />

Zz<br />

aa Batch 39 (aberrant)<br />

AA ab<br />

25 Y Z<br />

W 24 Y<br />

y<br />

26 z<br />

25<br />

23<br />

U V 24 X<br />

v w x x<br />

22<br />

22<br />

v 23<br />

u W<br />

V<br />

w<br />

T<br />

21 U<br />

V<br />

S<br />

U u<br />

v s<br />

20<br />

Rr<br />

19<br />

Q<br />

s<br />

18 R S T q<br />

P<br />

p<br />

17 Qq r<br />

Oo<br />

16 p<br />

M N 15 O P m n o<br />

14 Nn<br />

L<br />

13 mM<br />

Kk<br />

12 L<br />

Jj<br />

11 Kk<br />

l j<br />

8 9 10 J<br />

h<br />

H I<br />

i<br />

0<br />

0 240<br />

Fermentaton time, h<br />

Prediction accuracy (<strong>prediction</strong> of product<br />

concentration as an example)<br />

Averaged <strong>prediction</strong> error<br />

0.14<br />

0.12<br />

0.10<br />

0.08<br />

0.06<br />

0.04<br />

0.02<br />

+8h<br />

+24h<br />

+40h<br />

Batch 17<br />

Batch 27<br />

Batch 36<br />

Batch 39<br />

Batch 48<br />

0.00<br />

0 10 20 30 40 50 60<br />

Batch number<br />

40h-ahead <strong>prediction</strong> of product<br />

concentration<br />

Applications of the predicted state variables<br />

Product concentration, g/L<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

Batch 53<br />

Batch 38<br />

Batch 59<br />

• Improvement of daily process supervision<br />

• Early diagnosis of abnormal <strong>batch</strong>es (indicated by<br />

unusual high <strong>prediction</strong> errors)<br />

• Sub-<strong>optimal</strong> predictive control of feeding rates based<br />

on the predicted precursor/substrate uptake rates<br />

• Estimation of economic potential <strong>for</strong> individual<br />

<strong>batch</strong>es which may lead to <strong>optimal</strong> <strong>scheduling</strong><br />

8<br />

0<br />

Fermnetation time, h<br />

240<br />

Profit function <strong>and</strong> <strong>optimal</strong> <strong>scheduling</strong><br />

Profit function: J(T ) = Revenue− Total costs<br />

f T + T f p<br />

J(T f<br />

), unit/h<br />

J(T 2<br />

)<br />

0 T 1<br />

T 2<br />

T 3<br />

T f<br />

, h<br />

Profit function, unit/h<br />

40h-ahead predicted profit function in<br />

comparison with its measurement<br />

300<br />

250<br />

200<br />

150<br />

Batch 22<br />

Batch 56<br />

Batch 38<br />

100<br />

50<br />

0<br />

-50<br />

-100<br />

-150<br />

-200<br />

-250<br />

-300<br />

-350<br />

-400<br />

0 288<br />

Fermentation time, h

Scheduling is done during last quarter of T f<br />

Using average predicted value J(t,t+40) AP<br />

to<br />

indicate the future tendency:<br />

+8 +16 +24 +32 +40<br />

Present<br />

time<br />

Using average measured value J(t,t+40) AM<br />

of the<br />

profit function as basis<br />

Profit function, unit/h<br />

300<br />

200<br />

100<br />

0<br />

-100<br />

Saturation value<br />

gs<br />

fwfxfyfzgagb gc gdgegf ggghgigj gkgl gmgngogpgqgr<br />

24<br />

137<br />

129 130 131 132 133 134<br />

135<br />

136<br />

138<br />

140<br />

139<br />

141 142 143 144 145<br />

128 146<br />

127 147<br />

126<br />

148 149<br />

117 118 119 120 121 122 123 124<br />

125<br />

150<br />

151<br />

152<br />

155 156 157<br />

159<br />

115 116<br />

160<br />

161<br />

113<br />

99 100<br />

101<br />

102 103 104<br />

105 106 107 108 109 110 111 112 114<br />

FWFXFYFZ<br />

GC<br />

GEGF GG GHGI GJ GKGL GMGN GOGP GQ GR GS GT GU GV GWGX GY GZ<br />

HAHB HCHDHE HF HG HHI HJ HKHL HM<br />

fmfnfofpfqfrfsft fu fv fwfxfyfzgagbgcgdgegf<br />

145 146 147 148 149 150 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170<br />

171 172<br />

173 174 175 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 219 220 221 2223<br />

224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239 240<br />

fefffgfh fifjfkfl fmfnfofpfqfrfsftfufv<br />

176<br />

eset euev ewexeyez fafbfc fd<br />

ek gkgl gmgngogpgqgr<br />

es<br />

dz eaebec<br />

edeef egeheiej ekel emeneo epeqer et<br />

ey ez fafbfcfdfeffgfhfifjfkfl<br />

ggghgigj gs<br />

gt gugv gwgxgygzhahbhchdhe<br />

129 130 131 132 133 134 135 136 137 138 139 140 141<br />

142 143<br />

144<br />

egeheiej 151<br />

euev ew<br />

127<br />

ex FWFXFYFZ<br />

GA GB GC<br />

GD GEGF GG GHGI GJ GKGL GMGN GOGP GQ GR GS GT GU GV GWGX GYGZ<br />

HA HB HCHDHE HF HG HHI HJ HKHL HMHNHOHP HQHRHSHT HUHV HW HX HYHZ IAIBICIDIEIFIG<br />

Average<br />

el emeneoepeqer<br />

du EV EWEX EYEZ FAFBFC FD FEFF<br />

dwdxdy<br />

9495969798<br />

90 919293<br />

DJ<br />

DK DL DMDNDODP<br />

DQDRDSDT<br />

DUDV DWDXDYDZ<br />

EAEBEC ED EE<br />

EF EGEHEI EJ EKEL EMEN EOEP<br />

EQERES<br />

dpdqdr dsdt dudv<br />

99 100<br />

101 102 103 105<br />

106 107 108<br />

109 110 111 112<br />

113 114 115 116<br />

117 118 119 120 121 122 123 124 125<br />

126 128<br />

ETEU EV EWEX EYEZ FAFBFCFD FE FF FGFHFI FJFKFL FMFNFOFPFQFRFSFTFUFV<br />

di dj dkdl<br />

dmdndo<br />

dsdt dv dwdxdydzeaeb ec edee ef<br />

dpdqdr<br />

dg dh<br />

EAEBEC EDEE EF<br />

104<br />

dgdhdidj dkdl dmdndo DUDV<br />

DWDXDYDZ EG EHEI EJ EKEL EMEN EOEP<br />

EQERES<br />

9495969798 cucv cwcxcyczdadbdcdddedf<br />

89<br />

DC DDDE DF DHDI<br />

DG<br />

cu cv cwcxcycz db dcdddedf DQDRDSDT<br />

95% confidence limits<br />

da<br />

DC DDDE DF DG DI<br />

DJ<br />

DK DL DMDNDODP<br />

ck cl cmcncocpcqcrcsct DH<br />

7374 757677 7879 808182838485868788 81 828384858687888990919293 CUCV CWCXCYCZDADB<br />

ckcl cmcncocpcqcrcsct CWCXCYCZDADB<br />

cg chci cj<br />

79<br />

CQ CRCSCT CUCV<br />

72 cd cecf cgchcicj<br />

78 80 CQ CRCSCT<br />

71<br />

cb CMCNCOCP<br />

cc 757677<br />

CL<br />

70<br />

ca CJ<br />

CI<br />

73<br />

-200<br />

74 CK CL CMCNCOCP<br />

Fermentation period<br />

bwbxbybzcacbcccdcecf bz<br />

65 66676869 72<br />

CE CF CG CH 71<br />

70bu bv bwbxby CG<br />

CHCI CJ<br />

when average profit<br />

bsbtbubv<br />

61 6263 64 bt<br />

bs<br />

60 66 676869 br<br />

BYBZCA BYBZCA<br />

CB CCCDCECF<br />

function ertering<br />

bn bobpbqbr<br />

BWBX<br />

59 64 bl<br />

stationary phase<br />

bm<br />

58<br />

BMBNBP BQ<br />

-300<br />

65 BTBUBV<br />

63 bk<br />

bm bnbobpbq BRBS<br />

62 BR BS BTBUBV<br />

bj<br />

0 240<br />

Fermentation time, h<br />

Classification of <strong>batch</strong>es according to<br />

economic potential<br />

If ||J(t,t+40) AP - J(t,t+40) AM || > J(t,t+40) AM × (1+β)<br />

Then the Good category<br />

If ||J(t,t+40) AP - J(t,t+40) AM || < J(t,t+40) AM × (1–β)<br />

Then the Bad category<br />

Otherwise, the Normal category<br />

β - significance factor, confidence limit- related<br />

β= 0.35~0.40 <strong>for</strong> the testing data set<br />

Scheduling rules <strong>for</strong> <strong>fed</strong>-<strong>batch</strong> cultivation<br />

_________________________________________<br />

Category Scheduling strategy<br />

_________________________________________<br />

Good Maintain operation as long as possible<br />

Normal Terminating as planned<br />

Bad Break off at an earlier time point<br />

_________________________________________<br />

Feasibility of online <strong>optimal</strong> <strong>scheduling</strong><br />

under “golden recipe”<br />

15<br />

Number of <strong>batch</strong>es<br />

10<br />

5<br />

Software demonstration given by Mr. Liu Jun<br />

0<br />

120 140 160 180 200 220 240 260<br />

Cultivation period, h