WIBOjekt® economy safety workboxes for protection of personnel ...

WIBOjekt® economy safety workboxes for protection of personnel ...

WIBOjekt® economy safety workboxes for protection of personnel ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

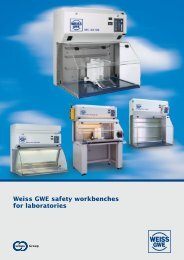

WIBOjekt ® <strong>economy</strong> <strong>safety</strong> <strong>workboxes</strong> <strong>for</strong><br />

<strong>protection</strong> <strong>of</strong> <strong>personnel</strong> and the environment

<strong>WIBOjekt®</strong> <strong>economy</strong><br />

Our expertise – your safe decision<br />

The progress being made in the fields <strong>of</strong> industry and science poses increasingly<br />

tough demands in terms <strong>of</strong> protecting <strong>personnel</strong> and the surrounding<br />

room against pollutants.<br />

Workstations and installations at which hazards can arise must meet certain<br />

requirements which are both functionally and economically critical.<br />

During the last few decades, Weiss GWE has established itself as a competent<br />

and flexible partner in this segment <strong>for</strong> industry, technology and<br />

laboratory users.<br />

As a company in the international Schunk Group, we work closely with<br />

customers to develop efficient, individual and cost-effective solutions.<br />

Continuous support from our pr<strong>of</strong>essional service department helps to<br />

ensure that the equipment can be used in a cost-effective manner and<br />

that the value <strong>of</strong> the investment is retained.<br />

The <strong>WIBOjekt®</strong> air guidance principle<br />

The <strong>WIBOjekt®</strong> principle<br />

Units employing the WIBO-jekt® air<br />

guiding principle create a stable<br />

clean-air curtain. This is generated<br />

by a combination <strong>of</strong> specially<br />

shaped and configured air outlets<br />

(so-called ejectors) and stabilisers.<br />

The ejectors target contaminants<br />

(such as gases or airborne product<br />

dust), collecting and conveying<br />

them to the exhaust system. The<br />

clean-air curtain ensures optimum<br />

<strong>protection</strong> <strong>of</strong> <strong>personnel</strong><br />

and the vicinity, safeguarding<br />

both <strong>personnel</strong> and the surroundings<br />

against emissions generated<br />

by the product.<br />

The WIBO ejectors are accurately<br />

matched in terms <strong>of</strong> design, shape,<br />

direction, speed and the air volume<br />

they can handle. This perfect interaction<br />

allows an optimum flow<br />

pattern to be established to suit<br />

prevailing requirements. The cleanair<br />

curtain even remains almost<br />

completely intact when <strong>personnel</strong><br />

working on the unit reach through<br />

the curtain to the inside <strong>of</strong> the<br />

box. This ensures that the system<br />

continues to capture any harmful<br />

pollutants and emissions which<br />

are released.<br />

2<br />

Despite the superior quality capturing<br />

and extraction per<strong>for</strong>mance,<br />

plants fitted with the <strong>WIBOjekt®</strong><br />

system require significantly less<br />

exhaust air than comparable conventional<br />

extraction systems.<br />

Costs <strong>for</strong> operation are thus<br />

reduced substantially.<br />

The <strong>WIBOjekt®</strong> <strong>economy</strong> <strong>safety</strong><br />

<strong>workboxes</strong> from Weiss GWE are<br />

available in three different designs.<br />

The EL, EB and EV designs differ in<br />

terms <strong>of</strong> equipment – i.e. with or<br />

without a sliding front shutter – as<br />

well as in terms <strong>of</strong> how individual<br />

systems can be combined with<br />

other individual systems to <strong>for</strong>m a<br />

larger system.

<strong>WIBOjekt®</strong> <strong>economy</strong> <strong>safety</strong> <strong>workboxes</strong> / industrial version<br />

EB series<br />

<strong>WIBOjekt®</strong> <strong>economy</strong> <strong>safety</strong> workbox <strong>for</strong> hazardous materials<br />

Advantages<br />

■ Reliable compliance with permissible blowout<br />

limits in accordance with BG Chemie (German<br />

Employer's Liability Insurance Association <strong>of</strong> the<br />

Chemical Industry) requirements even with a<br />

front opening height <strong>of</strong> 800 mm <strong>for</strong> access.<br />

■ Particularly spacious internal usable height, width and<br />

depth thanks to the compact design using special<br />

moulded pr<strong>of</strong>iles made from a high-quality aluminium<br />

alloy.<br />

■ Reduced air requirements – energy bills are reduced<br />

thanks to the effective <strong>WIBOjekt®</strong> system.<br />

■ Particularly narrow side spoilers <strong>of</strong>fer greater access<br />

width <strong>for</strong> reaching inside the box.<br />

■ Multifunctional and freely programmable “WIBO Control<br />

System“.<br />

■ Easily accessible media installation duct (<strong>for</strong> retr<strong>of</strong>itting).<br />

■ A comprehensive range <strong>of</strong> customer-specific accessories<br />

is available either from the factory or as aftermarket<br />

add-ons.<br />

■ Customer-specific dimensions available on request.<br />

■ Also available in Ex-pro<strong>of</strong> and clean room designs.<br />

3<br />

The <strong>WIBOjekt®</strong> air guidance principle<br />

Fields <strong>of</strong> use<br />

■ Electronics industry<br />

■ Medical technology<br />

■ Nanotechnology<br />

■ Optical industry<br />

■ System technology<br />

■ Automotive industry<br />

■ Micromechanics<br />

■ Laboratories, institutes, universities<br />

■ Hospitals, pathology departments<br />

■ Cosmetics, foodstuffs and<br />

chemical industry<br />

Areas <strong>of</strong> application<br />

■ Filling and refilling<br />

■ Washing, cleaning<br />

■ Assembly, weighing<br />

■ General laboratory work

<strong>WIBOjekt®</strong> <strong>economy</strong> <strong>safety</strong> fume hood / laboratory version<br />

EL series<br />

<strong>WIBOjekt®</strong> <strong>economy</strong> <strong>safety</strong> workbox according to DIN EN 14175<br />

Advantages<br />

■ The <strong>WIBOjekt®</strong> <strong>economy</strong> <strong>safety</strong> fume hood according<br />

to DIN EN 14175 meets the retention per<strong>for</strong>mance<br />

requirements <strong>of</strong> BG Chemie (German Employer's Liability<br />

Insurance Association <strong>of</strong> the Chemical Industry)<br />

even with a front shutter opening <strong>of</strong> 800 mm.<br />

■ Particularly spacious internal usable height, width and<br />

depth thanks to the compact design using special moulded<br />

pr<strong>of</strong>iles made from a high-quality aluminium alloy.<br />

■ Lower air requirements – energy bills are reduced<br />

thanks to the effective <strong>WIBOjekt®</strong> system.<br />

■ Particularly narrow side spoilers <strong>of</strong>fer greater access<br />

width <strong>for</strong> reaching inside the box.<br />

■ Automatic exhaust air volume regulation according to the<br />

vertical front shutter opening height at 500 mm and 800 mm.<br />

■ Multifunctional and freely programmable “WIBO Control<br />

System“.<br />

■ Easily accessible media installation duct (also <strong>for</strong> retr<strong>of</strong>itting).<br />

■ A comprehensive range <strong>of</strong> customer-specific accessories is<br />

available either from the factory or as aftermarket add-ons.<br />

■ Customer-specific dimensions available on request.<br />

■ Low-height version also available.<br />

■ Also available as an Ex-pro<strong>of</strong> version.<br />

4<br />

The <strong>WIBOjekt®</strong> air guidance principle<br />

Fields <strong>of</strong> use<br />

■ Pharmaceutical industry<br />

■ Genetics and biotechnology<br />

■ Cosmetics, foodstuffs and<br />

chemical industry<br />

■ Medical technology<br />

■ Nanotechnology<br />

■ Safety technology<br />

■ Laboratories, institutes, universities<br />

■ Hospitals, pathology departments<br />

Areas <strong>of</strong> application<br />

■ Filling and refilling<br />

■ Washing, cleaning<br />

■ General laboratory work

<strong>WIBOjekt®</strong> <strong>economy</strong> <strong>safety</strong> vario fume hood <strong>for</strong> hazardous materials<br />

EV series<br />

Safety vario fume hood, EV series<br />

The unit can be converted from a single workstation up<br />

to a large-volume joint unit without a rear panel. The<br />

individual basic units can also be supplied in accordance<br />

with DIN EN 14175.<br />

The unit can also be supplied on request as an Ex-pro<strong>of</strong><br />

version or with special dimensions.<br />

5<br />

100<br />

H = 1750<br />

800 250<br />

T = 830<br />

1<br />

2<br />

2<br />

T = 830<br />

1<br />

B = 1200 / 1500 / 1800<br />

The side (1) and rear panels (2) can be<br />

removed and inserted to vary the size<br />

<strong>of</strong> the working space from an individual<br />

workstation right up to a large unit.<br />

Side view <strong>of</strong> the EV series with a front shutter

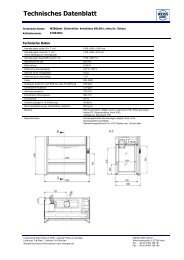

<strong>WIBOjekt®</strong> <strong>economy</strong> <strong>safety</strong> <strong>workboxes</strong> / industrial version<br />

Technical data sheet – EB series<br />

N1 / N2<br />

Technical air values<br />

free access<br />

BE=700/920/1220/1520/2200 mm<br />

B = 900/1200/1500/1800/2400 mm<br />

Type EB09N EB12N EB15N EB18N EB24N<br />

Height <strong>of</strong> the free<br />

access opening<br />

Permissible blowout<br />

800 800 800 800 800<br />

acc. to BGZ*<br />

Measured<br />

0.65 ppm 0.65 ppm 0.65 ppm 0.65 ppm 0.65 ppm<br />

blowout<br />

Exhaust air<br />

0.41 ppm 0.54 ppm 0.52 ppm<br />

m3 /h<br />

Recommended<br />

330 410 510 610 860<br />

value <strong>for</strong> planning 360 450 560 670 940<br />

Notes Spoiler Spoiler Spoiler<br />

* German Federation <strong>of</strong> Institutions <strong>for</strong> Statutory Accident Insurance<br />

and Prevention - Central Office <strong>for</strong> Safety and Health<br />

6<br />

F1 F2 F3

For <strong>protection</strong> <strong>of</strong> <strong>personnel</strong> and the environment<br />

H (1250 / 1750)<br />

900<br />

(760 <strong>for</strong> seated activities)<br />

D<br />

200<br />

Ø200<br />

830<br />

A A<br />

max. free front opening 800 mm<br />

N1=2150 / N2=2650<br />

(N1=2010 / N2=2510 <strong>for</strong> seated activities)<br />

T=750<br />

7<br />

TAI<br />

Detail Z<br />

BI<br />

free access BE<br />

Type EB09N1/N2 EB12N1/N2 EB15N1/N2 EB18N1/N2 EB24N1/N2<br />

External width<br />

B mm<br />

Internal width<br />

900 1.200 1.500 1.800 2.400<br />

BI mm<br />

Access width<br />

800 1.100 1.400 1.700 2.300<br />

BE mm<br />

External depth<br />

700 920 1.220 1.520 2.200<br />

T mm<br />

Internal depth <strong>of</strong><br />

750 750 750 750 750<br />

work surface TAI mm<br />

Height N1 / N2<br />

635 635 635 635 635<br />

H mm<br />

Internal height N1 / N2<br />

1.250 / 1.750 1.250 / 1.750 1.250 / 1.750 1.250 / 1.750 1.250 / 1.750<br />

D mm (max.) 875 / 1.375 875 / 1.375 875 / 1.375 875 / 1.375 875 / 1.375<br />

B<br />

Space <strong>for</strong><br />

media ducts<br />

Technical data<br />

Sound pressure level at a distance <strong>of</strong> 1 m: 49 dB (A). Colour: RAL 9002, other colours available on request.<br />

Illumination 2x18 W 2x18 W 2x36 W 2x36 W 2x58 W<br />

Connected<br />

electrical load 0.4 A ; 230 V 0.4 A ; 230 V 0.8 A ; 230 V 0.8 A ; 230 V 1.5 A ; 230 V<br />

Weight N1 approx. 65 kg 70 kg 75 kg 80 kg 90 kg<br />

830

<strong>WIBOjekt®</strong> <strong>economy</strong> <strong>safety</strong> fume hood / laboratory version<br />

Technical data sheet – EL series<br />

Measurements according to DIN EN 14175-3<br />

Shutter opened to 500 mm<br />

F 2<br />

Technical air values<br />

free access<br />

BE = 920 / 1220 / 1520 mm<br />

B = 1200 / 1500 / 1800 mm<br />

Type EL12F2 EL12F2 EL15F2 EL15F2 EL18F2 EL18F2<br />

F1 F2 F3<br />

Shutter opening<br />

(mm)<br />

Permissible blowout<br />

500 800 500 800 500 800<br />

DIN EN 14175-3<br />

Measured<br />

0.65 ppm 0.65 ppm 0.65 ppm 0.65 ppm 0.65 ppm 0.65 ppm<br />

blowout<br />

Exhaust air<br />

0.30 ppm 0.41 ppm 0.37 ppm 0.54 ppm 0.26 ppm 0.52 ppm<br />

m3 /h<br />

Recommended value <strong>for</strong><br />

planning<br />

360 410 425 510 510 610<br />

Exhaust air m3 /h 400 450 470 560 560 670<br />

8<br />

500<br />

Additional measurements<br />

Shutter opened to 800 mm<br />

800<br />

Height with open shutter 1850 mm

For <strong>protection</strong> <strong>of</strong> <strong>personnel</strong> and the environment<br />

1750<br />

D<br />

900<br />

(760 <strong>for</strong> seated activities)<br />

200<br />

Ø200<br />

830<br />

Technical data<br />

Sound pressure level at a distance <strong>of</strong> 1 m: 49 dB (A).<br />

Colour: RAL 9002, other colours available on request.<br />

100<br />

max. free front opening 800 mm<br />

A A<br />

with open shutter 1850<br />

2750<br />

(2610 <strong>for</strong> seated activities)<br />

Type EL12F2 EL15F2 EL18F2<br />

External width<br />

B mm<br />

Internal width<br />

1.200 1.500 1.800<br />

BI mm<br />

Access width<br />

1.100 1.400 1.700<br />

BE mm<br />

External depth<br />

920 1.220 1.520<br />

T mm<br />

Internal depth<br />

750 750 750<br />

<strong>of</strong> working surface TAI mm<br />

Height<br />

635 635 635<br />

H mm<br />

Internal height<br />

1.750 1.750 1.750<br />

D mm (max.) 1.375 1.375 1.375<br />

Illumination 2x18 W 2x36 W 2x36 W<br />

Connected<br />

electrical load 0.4 A ; 230 V 0.8 A ; 230 V 0.8 A ; 230 V<br />

Approx. weight 166 kg 175 kg 184 kg<br />

T=750<br />

9<br />

TAI<br />

Detail Z<br />

BI<br />

free access BE<br />

B<br />

Space <strong>for</strong><br />

media ducts<br />

830

<strong>WIBOjekt®</strong> control system<br />

Freely programmable closed-loop control and monitoring system<br />

Available in 2 different equipment levels: "Standard" Economy and "Pr<strong>of</strong>essional" Economy according to<br />

DIN EN 14175 <strong>for</strong> non Ex-pro<strong>of</strong> equipment<br />

LC-Display <strong>of</strong> the <strong>economy</strong> box control<br />

with shutter monitoring<br />

The control system<br />

■ Microprocessor-based<br />

■ Clearly laid out plastic foil keypad<br />

■ Large LC-Display<br />

■ Rechargeable battery <strong>for</strong> alarm power backup in the<br />

event <strong>of</strong> mains failure<br />

■ EEPROM <strong>for</strong> parameter storage<br />

■ Potential-free contact <strong>for</strong> connection <strong>of</strong> a higher level<br />

building control system <strong>for</strong> the transmission <strong>of</strong> fault<br />

messages and operating messages<br />

■ Potential-free contact to FC or ventilation flap <strong>for</strong> release<br />

<strong>of</strong> exhaust air<br />

■ Static differential pressure sensor<br />

■ Connection to a PC via a service interface (optional)<br />

■ Networking <strong>of</strong> multiple devices via interface RS-485<br />

(optional)<br />

Features <strong>of</strong> the “Standard” equipment level<br />

■ Simple, user-guided operation<br />

■ Alarms indicated visually via the plastic foil keypad<br />

and acoustically<br />

■ Alarms displayed in plain text on the LC-Display<br />

■ Menu-controlled configuration <strong>of</strong> the device<br />

■ Adjustment <strong>of</strong> setpoint values and alarm thresholds <strong>for</strong><br />

ejector pressure<br />

■ PWM-controlled ejector pressure control<br />

■ Free configuration <strong>of</strong>:<br />

- Alarm threshold <strong>for</strong> "Exhaust air too high" and<br />

- "Exhaust air too low"<br />

- Alarm duration <strong>for</strong> the horn<br />

- Alarm delay settings <strong>for</strong> pressure deviations<br />

Additional features <strong>of</strong> the "Pr<strong>of</strong>essional" equipment<br />

level according to DIN EN 14175<br />

■ Monitoring <strong>of</strong> the shutter position with triggering <strong>of</strong> an<br />

alarm if the shutter is opened more than 500 mm<br />

■ Indication <strong>of</strong> the shutter position on the LC-Display<br />

■ Exhaust air control depending on the shutter position<br />

with 4-20 mA or 0-10V <strong>for</strong> integration <strong>of</strong> a FC or ventilation<br />

flap.<br />

■ Alarm thresholds <strong>for</strong> "Exhaust air too high" and<br />

"Exhaust air too low" can be configured separately <strong>for</strong><br />

every shutter position.<br />

10

Standard details<br />

Brief overview <strong>of</strong> the ejectors, rear panel, exhaust air<br />

1. Optional choice <strong>of</strong> mounting an exhaust air pipe or exhaust air fan.<br />

Exhaust air is discharged to the top (side and rear options available<br />

on request).<br />

2. Exhaust air manifold hood, aerodynamic (less contamination), made<br />

<strong>of</strong> non-flammable, chemically and mechanically highly resistant ABS<br />

or aluminium alloy on Ex-pro<strong>of</strong> versions. Easy to clean from underneath<br />

or detach from above following removal <strong>of</strong> the air guiding unit.<br />

3. Optional demister insert. Cleans the exhaust air, protects exhaust<br />

pipes against deposits, easy to replace or clean.<br />

4. Removable air guiding unit.<br />

5. Rear panel supplied as a smooth, coated HPL panel. Simple to remove<br />

and exchange - e.g. <strong>for</strong> a 6 mm pane <strong>of</strong> laminated <strong>safety</strong> glass.<br />

5a. Large, usable net internal depth <strong>of</strong> approx. 635 mm.<br />

Simple and easy to clean.<br />

6. Sturdy shelf holder <strong>for</strong> use with glass shelves.<br />

7. Mounting panel <strong>for</strong> media supplies. Easy to dismantle,<br />

e.g. if existing media outlets are still to be used.<br />

8. Space <strong>for</strong> installation <strong>of</strong> media, power outlets etc.<br />

9a. Ejectors. Reliable extraction and collection <strong>of</strong> pollutants<br />

even if the shutter is open or no shutter is fitted.<br />

9b. The stabiliser <strong>of</strong>fers additional reliable air guidance.<br />

10. HPL panel or optional pane <strong>of</strong> laminated <strong>safety</strong> glass<br />

(this <strong>of</strong>fers the best visibility <strong>for</strong> tall installations).<br />

Housing<br />

The housing and frame are made <strong>of</strong> torsionally stiff pr<strong>of</strong>iles manufactured<br />

from a special aluminium alloy with additional high-quality anti-corrosion<br />

<strong>protection</strong> in the <strong>for</strong>m <strong>of</strong> Eloxal coating and a further two-component<br />

coating.<br />

■ Good resistance to corrosion and chemicals.<br />

■ All parts can be replaced and recycled.<br />

■ No rusting if the top surface is damaged, as would be the case e.g.<br />

with coated steel plate.<br />

■ Also available with complete PP lining, conducting or non-conducting,<br />

e.g. <strong>for</strong> acids, bases.<br />

Side windows<br />

■ Window panes: 6 mm thick laminated <strong>safety</strong> glass.<br />

■ No splintering or collapse in the event <strong>of</strong> breakage like <strong>for</strong> example<br />

with toughened glass.<br />

■ Easy to replace from the inside.<br />

■ Optionally available made from polycarbonate, HPL or similar.<br />

■ Pr<strong>of</strong>ile with 54° drain angle, no surfaces on which deposits can <strong>for</strong>m,<br />

easy to clean.<br />

11<br />

9b.<br />

330<br />

65<br />

Pr<strong>of</strong>ile<br />

7.<br />

5.<br />

8.<br />

6.<br />

4.<br />

5a.<br />

2.<br />

635<br />

1.<br />

3.<br />

9a.<br />

9a.<br />

Plane replaceable<br />

from the<br />

inside<br />

10.

Standard details<br />

Existing<br />

worktop<br />

Worktop as<br />

requested<br />

Version without a worktop<br />

■ The <strong>safety</strong> workbox can be easily positioned on top <strong>of</strong><br />

or above existing installations, devices, basins, equipment<br />

or machines. Simply position it on top – done!<br />

■ A worktop can be added at any time.<br />

■ The maximum dimensions <strong>of</strong> equipment to be fitted<br />

under the workbox is:<br />

Width B less 100 mm<br />

Depth T less 115 mm.<br />

Version with floor<br />

■ Simply insert the particular standard top/worktop/<br />

special worktop in the worktop mounting and seal.<br />

■ Worktops can be exchanged without dismantling the<br />

workbox.<br />

Concealed ejector strip<br />

■ The concealed ejector strip prevents faults and does<br />

not get dirty or contaminated.<br />

■ Foreign bodies cannot get in from the top.<br />

■ Special drip noses can divert even large amounts <strong>of</strong><br />

liquid.<br />

Illumination<br />

■ Low-energy fluorescent lamps, Skywhite (light colour<br />

880), with a high light yield, providing high-contrast,<br />

non-tiring lighting <strong>for</strong> increased mental and physical<br />

motivation.<br />

■ Approx. 700 Lux at a vertical distance <strong>of</strong> 0.8 m.<br />

■ Glare-free incidence <strong>of</strong> light via polycarbonate cover,<br />

which also acts as an overpressure relief device.<br />

■ Bulbs can be replaced from underneath.<br />

12

Individual components and accessories<br />

Front shutter according to EN 14175 <strong>for</strong><br />

the EB type <strong>safety</strong> workbox<br />

The <strong>safety</strong> workbox <strong>economy</strong> N2 (width = 1,200, 1,500, 1,800)<br />

can be retr<strong>of</strong>itted with a front shutter in accordance with<br />

EN 14175.<br />

■ Front shutter with a variable working opening <strong>of</strong> 500 mm max. A<br />

limiter <strong>for</strong> the front shutter needs to be deliberately released in order<br />

to enable a larger opening height <strong>of</strong> 800 mm max.<br />

■ The panes are made <strong>of</strong> 6 mm laminated <strong>safety</strong> glass and consist <strong>of</strong> 2<br />

or 3 parts which can be pushed together to <strong>for</strong>m a packet. The pakket<br />

acts as body and splash <strong>protection</strong>.<br />

■ Smallest packet width: Width = 1,200 (2-part) => 480 mm<br />

Width = 1,500 (3-part) => 430 mm<br />

Width = 1,800 (3-part) => 430 mm<br />

■ At a width <strong>of</strong> 1,800 mm, a fixed pane <strong>of</strong> laminated <strong>safety</strong> glass with<br />

a width 150 mm is used on both the left and right-hand side in order<br />

to keep the body <strong>protection</strong> packet at 430 mm.<br />

Stand holder<br />

■ The stand holder is positioned in front <strong>of</strong> the rear panel.<br />

■ The individual rods <strong>of</strong> the stand (Ø 12 mm) can be easily inserted and<br />

removed at a distance <strong>of</strong> 150 mm as required. Further setup using<br />

commercially available clamps and mountings.<br />

■ The mounting rails <strong>for</strong> the stand can also be used to mount other<br />

mounting systems.<br />

■ The lower cone on the rod provides purchase and prevents twisting<br />

<strong>of</strong> the setup. Additional clamp holders are available on request.<br />

Worktops<br />

■ A wide variety <strong>of</strong> differently designed worktops can be placed and<br />

sealed on the worktop mountings.<br />

■ Sturdy ceramic worktop, white, mounted on carrier plate<br />

■ Waterpro<strong>of</strong> chipboard with plastic coating<br />

■ Stainless steel (1.4301) worktop with internal core made <strong>of</strong> waterpro<strong>of</strong><br />

chipboard<br />

■ Sturdy ceramic top compliant with DIN 12916, T1<br />

■ Special designs are available <strong>for</strong> virtually any quality requirements,<br />

partitioning and installations.<br />

13

Individual components and accessories<br />

Rear glass panel<br />

■ A 6mm pane <strong>of</strong> laminated <strong>safety</strong> glass which bridges<br />

the gap between the top <strong>of</strong> the media connection/supply<br />

area and the bottom <strong>of</strong> the hood <strong>of</strong>fers even greater<br />

visibility (ideal <strong>for</strong> free installation <strong>of</strong> the hood).<br />

■ Conversion/retr<strong>of</strong>itting possible.<br />

Upper front panel<br />

■ A 6 mm pane <strong>of</strong> laminated <strong>safety</strong> glass between the<br />

top <strong>of</strong> the shutter unit and the bottom <strong>of</strong> the hood<br />

<strong>of</strong>fers ideal visibility <strong>for</strong> tall installations. The glass can<br />

also be simply removed <strong>for</strong> more difficult installation<br />

or assembly work.<br />

■ Only available <strong>for</strong> the following versions: types N2, F2,<br />

EV2.<br />

Valves and media supplies<br />

■ All required connections <strong>for</strong> media supplies can be<br />

integrated in the available assembly space.<br />

■ EN 14175 requires that shutters are operated from outside<br />

the working area. Installation <strong>of</strong> the shut-<strong>of</strong>f<br />

valves and switches in the bottom frame is possible<br />

(refer to the photo).<br />

■ The fittings are DVGW approved and feature patented<br />

push-fit connectors.<br />

■ Power outlets in the rear panel (230 V, 50 Hz), fuse<br />

<strong>protection</strong> either via fuses in the bottom frame or via<br />

the fuse <strong>protection</strong> in the building.<br />

■ Surface-mounted power outlets (400 V, 50 Hz) or CEE<br />

power outlets, also available as Ex-pro<strong>of</strong> versions.<br />

Exhaust air fan<br />

■ Connection: 230 V, 50 Hz.<br />

■ The fan should preferably be installed as far away as<br />

possible from the extraction hood, or a sound absorber<br />

should be used.<br />

■ Other fans are available on request.<br />

14

Individual components and accessories<br />

Demister<br />

■ Precisely the particles, aerosols, smoke, vapours etc.<br />

which are deposited in the exhaust air pipes are separated<br />

out by agglomeration in the special demister.<br />

The exhaust air pipes remain clean.<br />

■ Monitored via an air volume control system.<br />

■ Easy to replace and clean.<br />

■ Available in stainless steel and plastic versions.<br />

Bottom frame (<strong>for</strong> standing and seated activities)<br />

■ Made <strong>of</strong> sturdy pr<strong>of</strong>iles manufactured from a highquality,<br />

durable aluminium alloy, <strong>for</strong> setting up the<br />

<strong>safety</strong> workbox, including worktop and rear panel<br />

made <strong>of</strong> melamine coated board.<br />

■ Height-adjustable feet (+/- 10 mm).<br />

■ Upper edge <strong>of</strong> worktop: 900 mm (standing workstation)<br />

or 760 mm (seated workstation).<br />

■ Height-adjustable versions are available on request.<br />

Bottom frame with equipment<br />

mounting panel<br />

■ For standing and seated activities.<br />

■ With panel <strong>for</strong> mounting control elements, valves,<br />

power outlets, switches, fuses etc.<br />

■ The panel is <strong>of</strong>fset to the rear by 40 mm to reduce the<br />

risk <strong>of</strong> injury and prevent <strong>personnel</strong> or equipment<br />

from being hooked/caught.<br />

■ HPL panel.<br />

Bottom cabinet<br />

■ Made <strong>of</strong> melamine coated panels<br />

■ Handles, single-cylinder lock<br />

■ Choice <strong>of</strong> different partition options and variants, e.g.<br />

with drawers.<br />

■ Correct dimensions <strong>for</strong> inserting in the bottom frame.<br />

(Illustration: shows the bottom cupboard fitted inside<br />

the bottom frame).<br />

Bottom cabinet <strong>for</strong> hazardous materials<br />

■ Type 90 bottom cabinets <strong>for</strong> regulations-compliant storage<br />

<strong>of</strong> hazardous materials in workspaces according<br />

to TRbF 20 (Annex L) and DIN 14470-1.<br />

■ Available widths: 590 mm, 1,100 mm and 1,400 mm,<br />

height 600 mm.<br />

■ Available with a drawer or door.<br />

15

<strong>WIBOjekt®</strong> and WIBObarrier® air curtain technology.<br />

Offering the perfect <strong>protection</strong> <strong>for</strong> <strong>personnel</strong>, product<br />

and the environment.<br />

Weiss GWE GmbH<br />

02/2007<br />

Date: / alterations. technical to<br />

Wiechmannsallee 3<br />

Subject / ®<br />

27798 Hude<br />

Germany<br />

trademark<br />

Tel.: +49 (0) 4484 189-0<br />

Fax: +49 (0) 4484 189-189<br />

Registered =<br />

contact@gwe.de<br />

www.gwe.de WIBOjekt