Heißkanaldüsen Typ SLT/-DLT Customer information

Heißkanaldüsen Typ SLT/-DLT Customer information

Heißkanaldüsen Typ SLT/-DLT Customer information

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

For any questions, please contact our Application Engineering department at +49 (0) 6451 5008-31 or -63.<br />

The <strong>information</strong> is given in accordance with our present-day knowledge and is meant to provide technical background.<br />

1.5. 6<br />

iA<br />

<strong>Heißkanaldüsen</strong> <strong>Typ</strong> <strong>SLT</strong>/-<strong>DLT</strong><br />

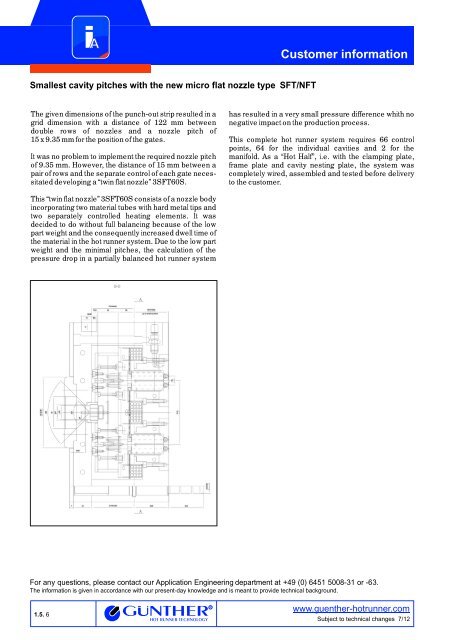

Smallest cavity pitches with the new micro flat nozzle type SFT/NFT<br />

The given dimensions of the punch-out strip resulted in a<br />

grid dimension with a distance of 122 mm between<br />

double rows of nozzles and a nozzle pitch of<br />

15 x 9.35 mm for the position of the gates.<br />

It was no problem to implement the required nozzle pitch<br />

of 9.35 mm. However, the distance of 15 mm between a<br />

pair of rows and the separate control of each gate necessitated<br />

developing a “twin flat nozzle” 3SFT60S.<br />

This “twin flat nozzle” 3SFT60S consists of a nozzle body<br />

incorporating two material tubes with hard metal tips and<br />

two separately controlled heating elements. It was<br />

decided to do without full balancing because of the low<br />

part weight and the consequently increased dwell time of<br />

the material in the hot runner system. Due to the low part<br />

weight and the minimal pitches, the calculation of the<br />

pressure drop in a partially balanced hot runner system<br />

<strong>Customer</strong> <strong>information</strong><br />

has resulted in a very small pressure difference whith no<br />

negative impact on the production process.<br />

This complete hot runner system requires 66 control<br />

points, 64 for the individual cavities and 2 for the<br />

manifold. As a “Hot Half”, i.e. with the clamping plate,<br />

frame plate and cavity nesting plate, the system was<br />

completely wired, assembled and tested before delivery<br />

to the customer.<br />

www.guenther-hotrunner.com<br />

Subject to technical changes 7/12