recoSTAR compact

recoSTAR compact

recoSTAR compact

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ecycling technology<br />

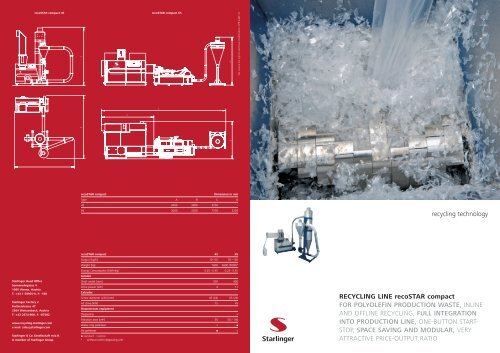

<strong>recoSTAR</strong> <strong>compact</strong> 45 <strong>recoSTAR</strong> <strong>compact</strong> 65<br />

<strong>recoSTAR</strong><br />

recycling technology<br />

r ecoSTAR <strong>compact</strong> 6 5<br />

A<br />

We reserve the right to technical modifications. DPR-24821-G<br />

C<br />

D<br />

B<br />

B<br />

A<br />

C<br />

<strong>recoSTAR</strong> <strong>compact</strong><br />

Dimension in mm<br />

Type A B C D<br />

45 3600 3900 3700 -<br />

65 3000 2350 7700 3250<br />

recycling technology<br />

Starlinger Head Office<br />

Sonnenuhrgasse 4<br />

1060 Vienna, Austria<br />

T: +43 1 59955-0, F: -180<br />

Starlinger Factory 2<br />

Furtherstrasse 47<br />

2564 Weissenbach, Austria<br />

T: +43 2674-800, F: -87582<br />

www.recycling.starlinger.com<br />

e-mail: sales@starlinger.com<br />

Starlinger & Co.Gesellschaft m.b.H.<br />

A member of Starlinger Group<br />

<strong>recoSTAR</strong> <strong>compact</strong> 45 65<br />

Output [kg/h] 10 – 50 30 – 150<br />

Weight [kg] 1600 3600 (5000)*<br />

Energy Consumption [kWh/kg] 0.25 – 0.35 0.25 – 0.35<br />

Grinder<br />

Shaft width [mm] 300 400<br />

Drive power [kW] 4 11<br />

Extruder<br />

Screw diameter (L/D) [mm] 45 (24) 65 (24)<br />

AC drive [kW] 15 45<br />

Downstream equipment<br />

Degassing<br />

Filtration area [cm 2 ] 50 50 / 140<br />

Water ring pelletiser ❍ ●<br />

Air pelletiser ● ❍<br />

● standard ❍ option<br />

* without (with) degassing unit<br />

❍<br />

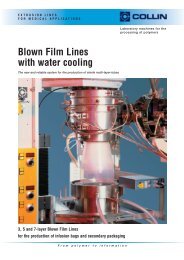

RECYCLING LINE <strong>recoSTAR</strong> <strong>compact</strong><br />

FOR POLYOLEFIN PRODUCTION WASTE, INLINE<br />

AND OFFLINE RECYCLING, FULL INTEGRATION<br />

INTO PRODUCTION LINE, ONE-BUTTON START-<br />

STOP, SPACE SAVING AND MODULAR, VERY<br />

ATTRACTIVE PRICE-OUTPUT RATIO

Machine pictured may include equipment sold as options.<br />

<strong>recoSTAR</strong> <strong>compact</strong><br />

State-of-the-art recycling technology for the low-cost processing of<br />

edge trims, dry and clean film and waste of PP, PE, LD-PE, LLD-PE and<br />

HD-PE and multi-layer films with PA content. The ideal solution for entrance<br />

into the recycling of low quantities with throughput from 10 to 150 kg/h.<br />

1<br />

Advantages<br />

•Modular design<br />

•Best cost-output ratio<br />

•For inline production (automatic<br />

start-up and stand-by)<br />

•Low space requirements<br />

•Easy to use<br />

•One-button start/stop<br />

procedure<br />

•High lifespan of knives<br />

•Self-regulating processing<br />

speed<br />

•Constant output<br />

Constant feeding into<br />

the directly attached extruder<br />

is guaranteed by load<br />

of the extruder motor. The<br />

slowturning grinder results<br />

in high lifespan of knives.<br />

The included control<br />

unit allows simple startstop<br />

procedure, automatic<br />

shut-down and stand-by<br />

mode. The line can be operated<br />

completely automatically<br />

and fully integrated<br />

into the film production line.<br />

Safety filters, discontinuous<br />

and continuous filters<br />

are available for completely<br />

molten material. Equipped<br />

with degassing, the line<br />

can process diaper lining<br />

films and multi-layer films<br />

with PA content.<br />

Air and water ring<br />

pelletising can be used,<br />

depending on type of<br />

plastic and output. Our<br />

patented solution ensures<br />

exact cutting for increased<br />

pellet quality and reduced<br />

wear of knives.<br />

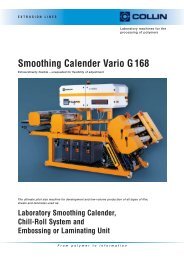

2<br />

3<br />

5<br />

4<br />

6<br />

11<br />

7 10<br />

12<br />

13<br />

1. Edge trim cyclone<br />

2. Nip roll feeder<br />

3. Conveyor belt with<br />

metal detector<br />

4. Grinder<br />

5. Extruder<br />

6. Venting extruder<br />

7. Melt filtration manual<br />

(discontinuous)<br />

8. Melt filtration continuous<br />

without backflushing<br />

9. Melt filtration continuous<br />

with backflushing<br />

10. Water ring pelletiser<br />

11. Air pelletiser with<br />

safety filter<br />

12. Storage silo<br />

13. Cooling cyclone<br />

8<br />

9