A comprehensive tool-wear/tool-life performance model in the ...

A comprehensive tool-wear/tool-life performance model in the ...

A comprehensive tool-wear/tool-life performance model in the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

884<br />

ARTICLE IN PRESS<br />

P.W. Marksberry, I.S. Jawahir / International Journal of Mach<strong>in</strong>e Tools & Manufacture 48 (2008) 878–886<br />

ASTMD 5619 Tapp<strong>in</strong>g Torque (N-cm)<br />

550<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

Straight Oil<br />

5.55-mm Reamed Hole<br />

(Lubricity)<br />

5.48-mm Reamed Hole<br />

(Cool<strong>in</strong>g)<br />

Soluble Oil Semisyn<strong>the</strong>tic<br />

Oil<br />

Syn<strong>the</strong>tic Oil<br />

MWF Type<br />

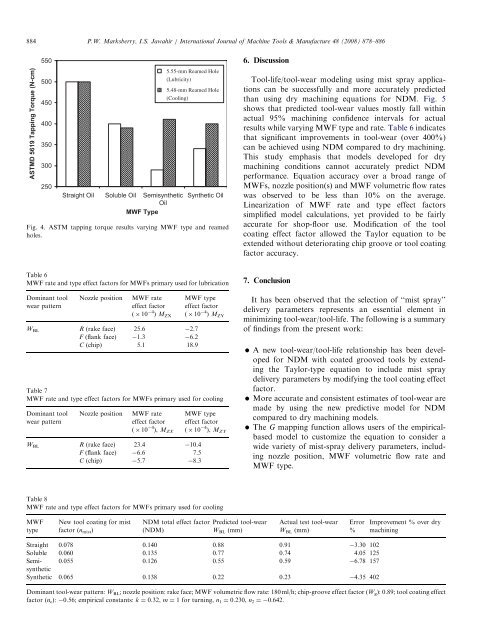

Fig. 4. ASTM tapp<strong>in</strong>g torque results vary<strong>in</strong>g MWF type and reamed<br />

holes.<br />

6. Discussion<br />

Tool-<strong>life</strong>/<strong>tool</strong>-<strong>wear</strong> <strong>model</strong><strong>in</strong>g us<strong>in</strong>g mist spray applications<br />

can be successfully and more accurately predicted<br />

than us<strong>in</strong>g dry mach<strong>in</strong><strong>in</strong>g equations for NDM. Fig. 5<br />

shows that predicted <strong>tool</strong>-<strong>wear</strong> values mostly fall with<strong>in</strong><br />

actual 95% mach<strong>in</strong><strong>in</strong>g confidence <strong>in</strong>tervals for actual<br />

results while vary<strong>in</strong>g MWF type and rate. Table 6 <strong>in</strong>dicates<br />

that significant improvements <strong>in</strong> <strong>tool</strong>-<strong>wear</strong> (over 400%)<br />

can be achieved us<strong>in</strong>g NDM compared to dry mach<strong>in</strong><strong>in</strong>g.<br />

This study emphasis that <strong>model</strong>s developed for dry<br />

mach<strong>in</strong><strong>in</strong>g conditions cannot accurately predict NDM<br />

<strong>performance</strong>. Equation accuracy over a broad range of<br />

MWFs, nozzle position(s) and MWF volumetric flow rates<br />

was observed to be less than 10% on <strong>the</strong> average.<br />

L<strong>in</strong>earization of MWF rate and type effect factors<br />

simplified <strong>model</strong> calculations, yet provided to be fairly<br />

accurate for shop-floor use. Modification of <strong>the</strong> <strong>tool</strong><br />

coat<strong>in</strong>g effect factor allowed <strong>the</strong> Taylor equation to be<br />

extended without deteriorat<strong>in</strong>g chip groove or <strong>tool</strong> coat<strong>in</strong>g<br />

factor accuracy.<br />

Table 6<br />

MWF rate and type effect factors for MWFs primary used for lubrication<br />

Dom<strong>in</strong>ant <strong>tool</strong><br />

<strong>wear</strong> pattern<br />

Nozzle position<br />

MWF type<br />

MWF rate<br />

( 10 4 ) M ZX ( 10 4 ) M ZY<br />

effect factor effect factor<br />

W BL R (rake face) 25.6 2.7<br />

F (flank face) 1.3 6.2<br />

C (chip) 5.1 18.9<br />

Table 7<br />

MWF rate and type effect factors for MWFs primary used for cool<strong>in</strong>g<br />

Dom<strong>in</strong>ant <strong>tool</strong><br />

<strong>wear</strong> pattern<br />

Nozzle position<br />

MWF type<br />

MWF rate<br />

( 10 4 ), M ZX ( 10 4 ), M ZY<br />

effect factor effect factor<br />

W BL R (rake face) 23.4 10.4<br />

F (flank face) 6.6 7.5<br />

C (chip) 5.7 8.3<br />

7. Conclusion<br />

It has been observed that <strong>the</strong> selection of ‘‘mist spray’’<br />

delivery parameters represents an essential element <strong>in</strong><br />

m<strong>in</strong>imiz<strong>in</strong>g <strong>tool</strong>-<strong>wear</strong>/<strong>tool</strong>-<strong>life</strong>. The follow<strong>in</strong>g is a summary<br />

of f<strong>in</strong>d<strong>in</strong>gs from <strong>the</strong> present work:<br />

A new <strong>tool</strong>-<strong>wear</strong>/<strong>tool</strong>-<strong>life</strong> relationship has been developed<br />

for NDM with coated grooved <strong>tool</strong>s by extend<strong>in</strong>g<br />

<strong>the</strong> Taylor-type equation to <strong>in</strong>clude mist spray<br />

delivery parameters by modify<strong>in</strong>g <strong>the</strong> <strong>tool</strong> coat<strong>in</strong>g effect<br />

factor.<br />

More accurate and consistent estimates of <strong>tool</strong>-<strong>wear</strong> are<br />

made by us<strong>in</strong>g <strong>the</strong> new predictive <strong>model</strong> for NDM<br />

compared to dry mach<strong>in</strong><strong>in</strong>g <strong>model</strong>s.<br />

The G mapp<strong>in</strong>g function allows users of <strong>the</strong> empiricalbased<br />

<strong>model</strong> to customize <strong>the</strong> equation to consider a<br />

wide variety of mist-spray delivery parameters, <strong>in</strong>clud<strong>in</strong>g<br />

nozzle position, MWF volumetric flow rate and<br />

MWF type.<br />

Table 8<br />

MWF rate and type effect factors for MWFs primary used for cool<strong>in</strong>g<br />

MWF<br />

type<br />

New <strong>tool</strong> coat<strong>in</strong>g for mist<br />

factor (n mist )<br />

NDM total effect factor<br />

(NDM)<br />

Predicted <strong>tool</strong>-<strong>wear</strong><br />

W BL (mm)<br />

Actual test <strong>tool</strong>-<strong>wear</strong><br />

W BL (mm)<br />

Error<br />

%<br />

Improvement % over dry<br />

mach<strong>in</strong><strong>in</strong>g<br />

Straight 0.078 0.140 0.88 0.91 3.30 102<br />

Soluble 0.060 0.135 0.77 0.74 4.05 125<br />

Semisyn<strong>the</strong>tic<br />

0.055 0.126 0.55 0.59 6.78 157<br />

Syn<strong>the</strong>tic 0.065 0.138 0.22 0.23 4.35 402<br />

Dom<strong>in</strong>ant <strong>tool</strong>-<strong>wear</strong> pattern: W BL ; nozzle position: rake face; MWF volumetric flow rate: 180 ml/h; chip-groove effect factor (W g ): 0.89; <strong>tool</strong> coat<strong>in</strong>g effect<br />

factor (n c ): 0.56; empirical constants: k ¼ 0.32, m ¼ 1 for turn<strong>in</strong>g, n 1 ¼ 0.230, n 2 ¼ 0.642.