1998 S/N 21329 - Walker Mowers

1998 S/N 21329 - Walker Mowers

1998 S/N 21329 - Walker Mowers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

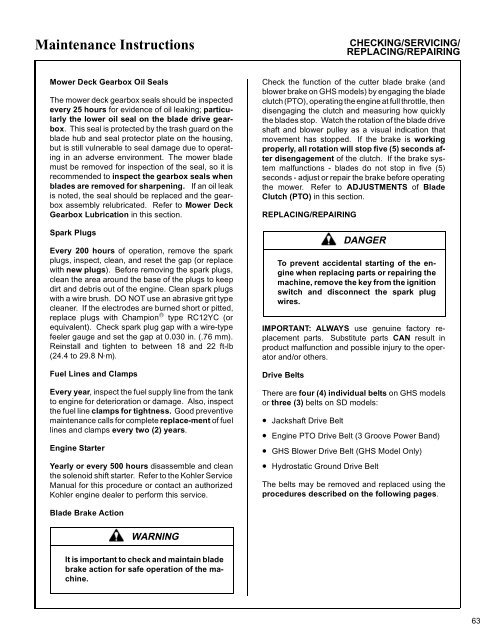

Maintenance Instructions<br />

CHECKING/SERVICING/<br />

REPLACING/REPAIRING<br />

Mower Deck Gearbox Oil Seals<br />

The mower deck gearbox seals should be inspected<br />

every 25 hours for evidence of oil leaking; particularly<br />

the lower oil seal on the blade drive gearbox.<br />

This seal is protected by the trash guard on the<br />

blade hub and seal protector plate on the housing,<br />

but is still vulnerable to seal damage due to operating<br />

in an adverse environment. The mower blade<br />

must be removed for inspection of the seal, so it is<br />

recommended to inspect the gearbox seals when<br />

blades are removed for sharpening. If an oil leak<br />

is noted, the seal should be replaced and the gearbox<br />

assembly relubricated. Refer to Mower Deck<br />

Gearbox Lubrication in this section.<br />

Spark Plugs<br />

Every 200 hours of operation, remove the spark<br />

plugs, inspect, clean, and reset the gap (or replace<br />

with new plugs). Before removing the spark plugs,<br />

clean the area around the base of the plugs to keep<br />

dirt and debris out of the engine. Clean spark plugs<br />

with a wire brush. DO NOT use an abrasive grit type<br />

cleaner. If the electrodes are burned short or pitted,<br />

replace plugs with Champion ® type RC12YC (or<br />

equivalent). Check spark plug gap with a wire-type<br />

feeler gauge and set the gap at 0.030 in. (.76 mm).<br />

Reinstall and tighten to between 18 and 22 ft-lb<br />

(24.4 to 29.8 N⋅m).<br />

Fuel Lines and Clamps<br />

Every year, inspect the fuel supply line from the tank<br />

to engine for deterioration or damage. Also, inspect<br />

the fuel line clamps for tightness. Good preventive<br />

maintenance calls for complete replace-ment of fuel<br />

lines and clamps every two (2) years.<br />

Engine Starter<br />

Yearly or every 500 hours disassemble and clean<br />

the solenoid shift starter. Refer to the Kohler Service<br />

Manual for this procedure or contact an authorized<br />

Kohler engine dealer to perform this service.<br />

Check the function of the cutter blade brake (and<br />

blower brake on GHS models) by engaging the blade<br />

clutch (PTO), operating the engine at full throttle, then<br />

disengaging the clutch and measuring how quickly<br />

the blades stop. Watch the rotation of the blade drive<br />

shaft and blower pulley as a visual indication that<br />

movement has stopped. If the brake is working<br />

properly, all rotation will stop five (5) seconds after<br />

disengagement of the clutch. If the brake system<br />

malfunctions - blades do not stop in five (5)<br />

seconds - adjust or repair the brake before operating<br />

the mower. Refer to ADJUSTMENTS of Blade<br />

Clutch (PTO) in this section.<br />

REPLACING/REPAIRING<br />

IMPORTANT: ALWAYS use genuine factory replacement<br />

parts. Substitute parts CAN result in<br />

product malfunction and possible injury to the operator<br />

and/or others.<br />

Drive Belts<br />

There are four (4) individual belts on GHS models<br />

or three (3) belts on SD models:<br />

• Jackshaft Drive Belt<br />

DANGER<br />

To prevent accidental starting of the engine<br />

when replacing parts or repairing the<br />

machine, remove the key from the ignition<br />

switch and disconnect the spark plug<br />

wires.<br />

• Engine PTO Drive Belt (3 Groove Power Band)<br />

• GHS Blower Drive Belt (GHS Model Only)<br />

• Hydrostatic Ground Drive Belt<br />

The belts may be removed and replaced using the<br />

procedures described on the following pages.<br />

Blade Brake Action<br />

WARNING<br />

It is important to check and maintain blade<br />

brake action for safe operation of the machine.<br />

63