Wambo Coal AEMR 2011-2012 - Peabody Energy

Wambo Coal AEMR 2011-2012 - Peabody Energy

Wambo Coal AEMR 2011-2012 - Peabody Energy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

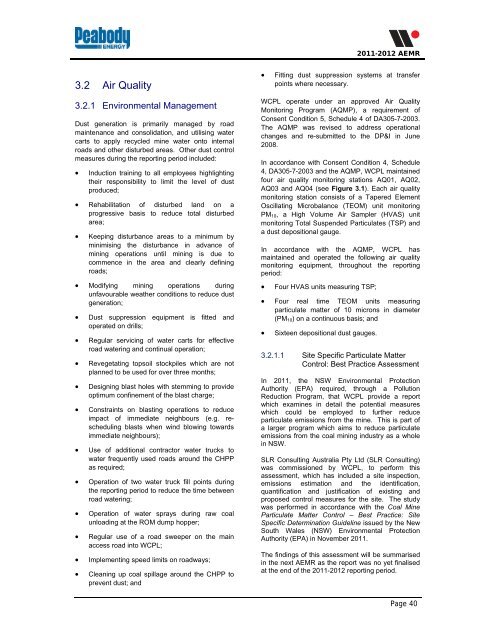

<strong>2011</strong>-<strong>2012</strong> <strong>AEMR</strong><br />

3.2 Air Quality<br />

<br />

Fitting dust suppression systems at transfer<br />

points where necessary.<br />

3.2.1 Environmental Management<br />

Dust generation is primarily managed by road<br />

maintenance and consolidation, and utilising water<br />

carts to apply recycled mine water onto internal<br />

roads and other disturbed areas. Other dust control<br />

measures during the reporting period included:<br />

<br />

Induction training to all employees highlighting<br />

their responsibility to limit the level of dust<br />

produced;<br />

Rehabilitation of disturbed land on a<br />

progressive basis to reduce total disturbed<br />

area;<br />

<br />

Keeping disturbance areas to a minimum by<br />

minimising the disturbance in advance of<br />

mining operations until mining is due to<br />

commence in the area and clearly defining<br />

roads;<br />

Modifying mining operations during<br />

unfavourable weather conditions to reduce dust<br />

generation;<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Dust suppression equipment is fitted and<br />

operated on drills;<br />

Regular servicing of water carts for effective<br />

road watering and continual operation;<br />

Revegetating topsoil stockpiles which are not<br />

planned to be used for over three months;<br />

Designing blast holes with stemming to provide<br />

optimum confinement of the blast charge;<br />

Constraints on blasting operations to reduce<br />

impact of immediate neighbours (e.g. rescheduling<br />

blasts when wind blowing towards<br />

immediate neighbours);<br />

Use of additional contractor water trucks to<br />

water frequently used roads around the CHPP<br />

as required;<br />

Operation of two water truck fill points during<br />

the reporting period to reduce the time between<br />

road watering;<br />

Operation of water sprays during raw coal<br />

unloading at the ROM dump hopper;<br />

Regular use of a road sweeper on the main<br />

access road into WCPL;<br />

Implementing speed limits on roadways;<br />

Cleaning up coal spillage around the CHPP to<br />

prevent dust; and<br />

WCPL operate under an approved Air Quality<br />

Monitoring Program (AQMP), a requirement of<br />

Consent Condition 5, Schedule 4 of DA305-7-2003.<br />

The AQMP was revised to address operational<br />

changes and re-submitted to the DP&I in June<br />

2008.<br />

In accordance with Consent Condition 4, Schedule<br />

4, DA305-7-2003 and the AQMP, WCPL maintained<br />

four air quality monitoring stations AQ01, AQ02,<br />

AQ03 and AQ04 (see Figure 3.1). Each air quality<br />

monitoring station consists of a Tapered Element<br />

Oscillating Microbalance (TEOM) unit monitoring<br />

PM 10, a High Volume Air Sampler (HVAS) unit<br />

monitoring Total Suspended Particulates (TSP) and<br />

a dust depositional gauge.<br />

In accordance with the AQMP, WCPL has<br />

maintained and operated the following air quality<br />

monitoring equipment, throughout the reporting<br />

period:<br />

<br />

Four HVAS units measuring TSP;<br />

Four real time TEOM units measuring<br />

particulate matter of 10 microns in diameter<br />

(PM 10) on a continuous basis; and<br />

<br />

Sixteen depositional dust gauges.<br />

3.2.1.1 Site Specific Particulate Matter<br />

Control: Best Practice Assessment<br />

In <strong>2011</strong>, the NSW Environmental Protection<br />

Authority (EPA) required, through a Pollution<br />

Reduction Program, that WCPL provide a report<br />

which examines in detail the potential measures<br />

which could be employed to further reduce<br />

particulate emissions from the mine. This is part of<br />

a larger program which aims to reduce particulate<br />

emissions from the coal mining industry as a whole<br />

in NSW.<br />

SLR Consulting Australia Pty Ltd (SLR Consulting)<br />

was commissioned by WCPL, to perform this<br />

assessment, which has included a site inspection,<br />

emissions estimation and the identification,<br />

quantification and justification of existing and<br />

proposed control measures for the site. The study<br />

was performed in accordance with the <strong>Coal</strong> Mine<br />

Particulate Matter Control – Best Practice: Site<br />

Specific Determination Guideline issued by the New<br />

South Wales (NSW) Environmental Protection<br />

Authority (EPA) in November <strong>2011</strong>.<br />

The findings of this assessment will be summarised<br />

in the next <strong>AEMR</strong> as the report was no yet finalised<br />

at the end of the <strong>2011</strong>-<strong>2012</strong> reporting period.<br />

Page 40