Brochure WIBOindustries

Brochure WIBOindustries

Brochure WIBOindustries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

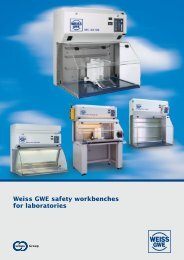

Industrial workplaces -<br />

personnel protection

Safety by reliable pollutant ejector extraction<br />

The WIBO Principle<br />

ejector<br />

Cleaning, polishing and grinding<br />

workplaces, type WBT 1210<br />

Work tables with perforated surfaces or racks<br />

covering collecting trays. Capturing of gaseous and dusty<br />

contaminants using the contaminant exhaust system.<br />

Areas of use include all working tasks involving the<br />

emission of contaminants or hazardous substances,<br />

washing and cleaning tasks involving the use of solvents.<br />

Units employing the WIBOjekt air<br />

guiding principle create a stable<br />

clean-air curtain. This is generated<br />

by a combination of specially shaped<br />

and configured ejectors and air<br />

stabilisers. The ejectors target<br />

contaminants (such as gases or<br />

airborne product dust), collecting<br />

and conveying them to the exhaust<br />

air. The clean-air curtain ensures<br />

optimum protection of personnel and<br />

the vicinity, safeguarding both<br />

personnel and the surroundings<br />

against emissions generated by the<br />

product.<br />

WIBO ejector nozzles are coordinated<br />

exactly to compliment each<br />

other in terms of design, shape,<br />

direction, speed and the air volume<br />

they can handle. This perfect<br />

interaction enables the achievement<br />

of an optimum flow pattern to suit<br />

prevailing requirements. The cleanair<br />

curtain generated is so stable that<br />

it is only slightly distorted when<br />

personnel reach into it. Capturing of<br />

contaminants originating in<br />

emissions continues uninterrupted.<br />

Plants fitted with the WIBOjekt system<br />

require considerably less exhaust air<br />

when compared with conventional<br />

extraction systems, despite the<br />

superior-quality capturing and<br />

ejection performance involved.<br />

ejector<br />

Universal, assembly, soldering and<br />

adhering workplaces, type WBT 1410<br />

Workplaces with smooth surfaces and contaminant<br />

exhaust system.<br />

Areas of use include adhering and assembly work where<br />

solvent vapours are emitted, and other processes and<br />

tasks involving gaseous and dusty emissions.

ejectorventilator<br />

ejector<br />

Chemical solvent refilling / filling stations,<br />

type WBT1510<br />

Modified safe workplace for refilling<br />

and filling of new and old chemicals.<br />

Also available as a complete plastic<br />

unit (WBT 1510 PP) with exceptionally<br />

high resistance to acidic media<br />

(e.g. 100% acetic acid, 65% saltpetre,<br />

96% sulphuric acid, etc.).<br />

VARIO open workplaces, type WBF 3350<br />

Reliable contaminant capturing in the<br />

entire working area through the rear<br />

supporting wall or clean air ejectors<br />

integrated in the hood. Can be simply<br />

positioned above the emissions.<br />

Weighing and refilling workplaces, type WBT 1510<br />

Different work table designs with a<br />

barrel stowage area for large barrels.<br />

Integrated contaminant exhaust<br />

system, floor exhaust system in<br />

barrel stowage area.<br />

Areas of use include universities,<br />

research and testing facilities, the<br />

chemical industry, hospitals and<br />

anywhere where refilling of<br />

chemicals occurs.<br />

Areas of use include removal of<br />

emissions during all work involving<br />

machines, devices or coating of<br />

workpieces where contaminants are<br />

emitted and direct capturing is not<br />

possible.<br />

Areas of use include all tasks<br />

involving the removal of<br />

contaminants from large barrels<br />

and their refilling in smaller barrels.<br />

ejec tor do o r<br />

storage area<br />

Universal open workplaces,<br />

type WBF 3110<br />

ejector<br />

oetdrcojr<br />

Open-fronted, accessible workplace with integrated<br />

contaminant exhaust system. Emission capturing and<br />

extraction is reliable and unhindered by exhaust pipes.<br />

Side elements consist of PVC curtains, stainless steel or<br />

laminated glass.<br />

Areas of use include all work where direct capturing of<br />

pollutants is impossible, due to the process or working<br />

devices involved (e.g. on printing or adhering machines,<br />

refilling and weighing tasks, grinding and laminating).<br />

Optional<br />

inset<br />

ejector rail

Separate filters and filters integrated in the rear wall<br />

for table and open workplaces<br />

Suspended matter duct filter<br />

Safe extraction of solvent emissions,<br />

dusts, odors and other contaminants.<br />

The filters are equipped for<br />

specific tasks (impregnated active<br />

carbon filters, polyester fleece filters,<br />

pre-filters and downstream filters).<br />

Facilitation of handling during<br />

charging and removal operations.<br />

Rear wall filter<br />

Filters are easily replaced and operated from the front of<br />

the workplace. Exhaust air is cleaned directly and is not<br />

subject to contamination or cross-contamination. The<br />

filter is compactly integrated across the entire width of<br />

the workplace. High cleaning quality, low investment<br />

costs. Also available as a cleanable filter employing the<br />

WIBOjekt rotation system.<br />

Areas of use include all workplaces where <strong>WIBOindustries</strong><br />

open workplaces and tables are utilised.<br />

WIBOlack painting cabins, type WBL 3450<br />

Reliable overspray capturing in the<br />

entire working area. Draught-free,<br />

extensively improved overspray<br />

capturing with low air volumes and<br />

subsequent extraction. A special<br />

Ejector<br />

fan<br />

Special cyclone<br />

Areas of use include all work where<br />

reliable and efficient cleaning of<br />

exhaust air is necessary, particularly<br />

where the concentration of contaminants<br />

is continually fluctuating.<br />

Also available with non-contact filter<br />

replacement.<br />

Rear wall with changeable multi-stage filter<br />

downstream cyclone absorbs approx.<br />

99% of the overspray present in the<br />

system. Costs are reduced, particularly<br />

in relation to disposal by clean<br />

separation of individual contaminants.<br />

Approved<br />

filter<br />

Collecting vessel<br />

Ejector<br />

fan<br />

Rear wall with fine filter,<br />

non-contact filter replacement<br />

Rear wall with cleanable filter<br />

Rear wall with active carbon filter<br />

Areas of use include applications in<br />

industry (incl. large plants), trade and<br />

craft work, machine and plant<br />

construction.

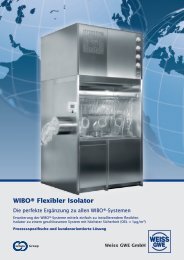

Dispensing and filling station with WIBOfill<br />

Complete dispensing and filling<br />

station with integrated contaminant<br />

ejector system, consisting of an<br />

economy EB work safety-box for<br />

industrial use, or an EA version for<br />

laboratory applications.<br />

Economy work safety-box, type EB and EA<br />

Workbox with integrated contaminant<br />

ejector system, manufactured in<br />

versions for industrial (type EB) and<br />

laboratory (type EA complying with EN<br />

14175) applications. Impressive<br />

contaminant retention capacity when<br />

the viewing window is opened.<br />

With base and one or more WIBOfill<br />

dispensing and filling units with<br />

digital volume and pulse meters,<br />

dispensing tube with solenoid valve,<br />

double membrane pump, aspiration<br />

tube, etc.<br />

Designed for fitting to existing work<br />

or laboratory tables.<br />

Areas of use include assembly and<br />

cleaning tasks in industry and<br />

research, laboratories, universities,<br />

pathology departments, authorities.<br />

Areas of use include all applications<br />

involving the exact dispensing of<br />

liquids from large vessels.<br />

The vessels can also be positioned<br />

outside the room. Automatic<br />

documentation option.

We address your needs<br />

Weiss GWE GmbH<br />

Wiechmannsallee 3<br />

27798 Hude<br />

Germany<br />

Tel.: +49 (0) 4484 189-0<br />

Fax: +49 (0) 4484 189-189<br />

contact@gwe.de<br />

www.gwe.de<br />

Pharmaceutical industry<br />

Genetic engineering<br />

Biotechnology<br />

Chemical industry<br />

Cosmetic industry<br />

Food industry<br />

Electronics industry<br />

Medical technology<br />

Micromechanics<br />

Nanotechnology<br />

Optical industry<br />

System engineering<br />

Industrial production<br />

Painting and surface engineering<br />

Safety technology<br />

Institutes<br />

Hospitals<br />

Laboratories<br />

Pathology departments<br />

Universities<br />

Assembly and installation<br />

Commissioning<br />

Validation qualification<br />

DQ, IQ, OQ<br />

Documentation<br />

SOP<br />

Service<br />

WIBOjekt, WIBOlac k, WIBOfill = Registered trademarks ®, 9/ 03,<br />

1.0 borrek. We reserve th e right to make technical changes.