Extraction Technologies for Medicinal and Aromatic ... - Capacity4Dev

Extraction Technologies for Medicinal and Aromatic ... - Capacity4Dev Extraction Technologies for Medicinal and Aromatic ... - Capacity4Dev

3 MACERATION, PERCOLATION AND INFUSION TECHNIQUES FOR THE EXTRACTION OF MEDICINAL AND AROMATIC PLANTS During maceration of organized drugs, the marc is pressed because a considerable proportion of liquid adheres to it and cannot otherwise be separated. Moreover, the volume is not adjusted because a variable amount of liquid containing soluble matter is left in the marc. If the volume is adjusted, a weak product will result. Omitting adjustment, the volume of liquid expressed infl uences the product yield and the percentage of soluble matter, regardless of the effi ciency with which the marc is pressed in a hand press, screw press or hydraulic press; the strength of the product is not affected. Preparations made by this processes include vinegar of squill (British Pharmaceutical Codex, BPC), oxymel of squill (BPC), tincture of orange (Indian Pharmacopoeia, IP), tincture of capsicum (BPC), compound tincture of gentian, tincture of lemon, and tincture of squill (BPC). In maceration of unorganized drugs, the marc is not pressed because the desirable material is mostly dissolved and the remaining marc is gummy and slimy. Thus, it is neither practicable nor necessary to press it. Moreover, the volume is adjusted because the clear upper layer is easily separated by fi ltration from the lower layer. The solution contains practically all the soluble matter of the drug; the small amount adherent to the gummy matter is recovered when the marc is washed by menstruum in the fi lter. Therefore, adjustment of volume leads to uniformity. Preparations made by this process include compound tincture of benzoin, tincture of myrrh (BPC), and tincture of tolu (BPC). 3.5.3 Modifications to the General Processes of Maceration Repeated maceration may be more effi cient than a single maceration process, as described earlier, because an appreciable amount of active principle may be left behind in the fi rst pressing of the marc. Double maceration is used when the active constituents are particularly valuable and also when the concentrated infusions contain volatile oil. Where the marc cannot be pressed, a process of triple maceration is sometimes employed. The total volume of solvent used is, however, large and the second and third macerates are usually mixed and evaporated before being added to the fi rst macerate. 3.5.4 Large-scale Extraction Procedures For large-scale, industrial extraction, certain modifications are warranted. When the extraction vessel contains a small amount of solvent (500-1000 ml), occasional shaking is no problem. But, for industrial work where a large amount of solvent and huge vessels are involved, shaking the vessels is difficult. Obviously, there are alternative methods of agitation that are just as effective and much simpler to put into practice. In addition, economics become increasingly important and one of the most important objectives is to improve the efficiency of extraction so that less solvent is needed 72

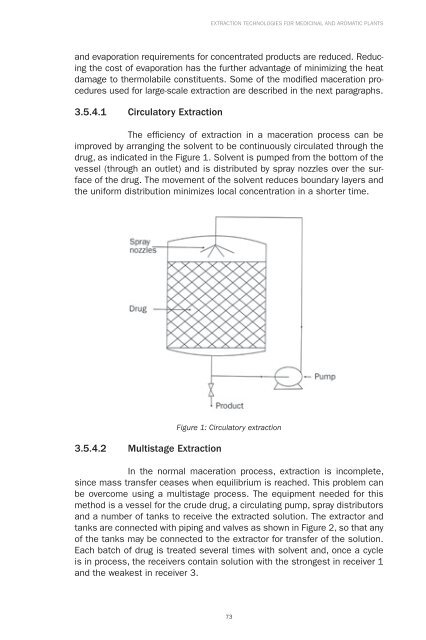

EXTRACTION TECHNOLOGIES FOR MEDICINAL AND AROMATIC PLANTS and evaporation requirements for concentrated products are reduced. Reducing the cost of evaporation has the further advantage of minimizing the heat damage to thermolabile constituents. Some of the modified maceration procedures used for large-scale extraction are described in the next paragraphs. 3.5.4.1 Circulatory Extraction The effi ciency of extraction in a maceration process can be improved by arranging the solvent to be continuously circulated through the drug, as indicated in the Figure 1. Solvent is pumped from the bottom of the vessel (through an outlet) and is distributed by spray nozzles over the surface of the drug. The movement of the solvent reduces boundary layers and the uniform distribution minimizes local concentration in a shorter time. 3.5.4.2 Multistage Extraction Figure 1: Circulatory extraction In the normal maceration process, extraction is incomplete, since mass transfer ceases when equilibrium is reached. This problem can be overcome using a multistage process. The equipment needed for this method is a vessel for the crude drug, a circulating pump, spray distributors and a number of tanks to receive the extracted solution. The extractor and tanks are connected with piping and valves as shown in Figure 2, so that any of the tanks may be connected to the extractor for transfer of the solution. Each batch of drug is treated several times with solvent and, once a cycle is in process, the receivers contain solution with the strongest in receiver 1 and the weakest in receiver 3. 73

- Page 25 and 26: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 27 and 28: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 29 and 30: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 31 and 32: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 33 and 34: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 35 and 36: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 37 and 38: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 39 and 40: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 41 and 42: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 43 and 44: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 45 and 46: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 47 and 48: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 49 and 50: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 51 and 52: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 53 and 54: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 55 and 56: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 57 and 58: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 59 and 60: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 61 and 62: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 63 and 64: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 65 and 66: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 67 and 68: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 69 and 70: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 71 and 72: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 73 and 74: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 75: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 79 and 80: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 81 and 82: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 83 and 84: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 85 and 86: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 87 and 88: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 89 and 90: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 91 and 92: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 93 and 94: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 95 and 96: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 97 and 98: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 99 and 100: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 101 and 102: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 103 and 104: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 105 and 106: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 107 and 108: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 109 and 110: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 111 and 112: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 113 and 114: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 115 and 116: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 117: EXTRACTION TECHNOLOGIES FOR MEDICIN

- Page 120 and 121: 7 DISTILLATION TECHNOLOGY FOR ESSEN

- Page 122 and 123: 7 DISTILLATION TECHNOLOGY FOR ESSEN

- Page 124 and 125: 7 DISTILLATION TECHNOLOGY FOR ESSEN

EXTRACTION TECHNOLOGIES FOR MEDICINAL AND AROMATIC PLANTS<br />

<strong>and</strong> evaporation requirements <strong>for</strong> concentrated products are reduced. Reducing<br />

the cost of evaporation has the further advantage of minimizing the heat<br />

damage to thermolabile constituents. Some of the modified maceration procedures<br />

used <strong>for</strong> large-scale extraction are described in the next paragraphs.<br />

3.5.4.1 Circulatory <strong>Extraction</strong><br />

The effi ciency of extraction in a maceration process can be<br />

improved by arranging the solvent to be continuously circulated through the<br />

drug, as indicated in the Figure 1. Solvent is pumped from the bottom of the<br />

vessel (through an outlet) <strong>and</strong> is distributed by spray nozzles over the surface<br />

of the drug. The movement of the solvent reduces boundary layers <strong>and</strong><br />

the uni<strong>for</strong>m distribution minimizes local concentration in a shorter time.<br />

3.5.4.2 Multistage <strong>Extraction</strong><br />

Figure 1: Circulatory extraction<br />

In the normal maceration process, extraction is incomplete,<br />

since mass transfer ceases when equilibrium is reached. This problem can<br />

be overcome using a multistage process. The equipment needed <strong>for</strong> this<br />

method is a vessel <strong>for</strong> the crude drug, a circulating pump, spray distributors<br />

<strong>and</strong> a number of tanks to receive the extracted solution. The extractor <strong>and</strong><br />

tanks are connected with piping <strong>and</strong> valves as shown in Figure 2, so that any<br />

of the tanks may be connected to the extractor <strong>for</strong> transfer of the solution.<br />

Each batch of drug is treated several times with solvent <strong>and</strong>, once a cycle<br />

is in process, the receivers contain solution with the strongest in receiver 1<br />

<strong>and</strong> the weakest in receiver 3.<br />

73