You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

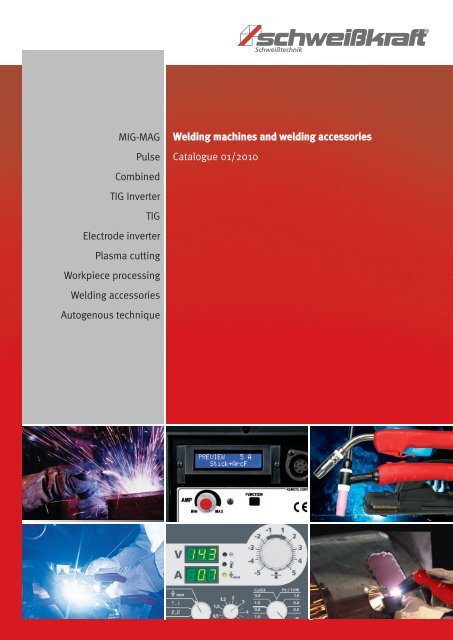

MIG-MAG<br />

Pulse<br />

Combined<br />

TIG Inverter<br />

TIG<br />

Electrode inverter<br />

Plasma cutting<br />

Workpiece processing<br />

Welding accessories<br />

Autogenous technique<br />

Welding machines and welding accessories<br />

Catalogue 01/2010

Schweißkraft ® welding devices<br />

Quality at an economical price<br />

Our goal is to satisfy your wishes!<br />

For over 25 years we have been <strong>com</strong>mitted to developing, designing and manufacturing Schweißkraft products. Anyone of our products<br />

distinguishes itself by quality, accuracy, durability and consistent value. Our knowledge and the knowledge of our customers<br />

serves to constantly advance and improve our products.<br />

Products<br />

You're looking for a functional machine<br />

offering <strong>com</strong>prehensive features at an<br />

economical price?<br />

Then Schweißkraft welding devices are<br />

the ones for you. Our machines are<br />

convincing by outstanding quality,<br />

accurate manufacturing and offer an<br />

optimum price/performance ratio.<br />

Quality<br />

Schweißkraft products are subject to our<br />

strict controls in production and final<br />

inspections. The use of best materials,<br />

outstanding welding properties as well<br />

as easiest operation for the user will<br />

give you the certainty to purchase a product,<br />

which satisfies the highest quality<br />

requirements.<br />

The manufacturing is ac<strong>com</strong>panied by<br />

thorough individual checks. Finally a<br />

100% performance and function check<br />

takes place, where the manufactured<br />

devices are being thouroughly tested.<br />

This way, we are convinced to be able to<br />

offer you the best possible quality.<br />

Production<br />

All our products are continuously further<br />

developed. The majority of the<br />

Schweißkraft welding devices is<br />

developed designed and produced by<br />

the <strong>com</strong>pany REHM GmbH at Uhingen,<br />

one of the newest and most modern<br />

<strong>com</strong>pany for welding devices in<br />

Germany.<br />

Distribution<br />

Schweißkraft welding devices are only<br />

available at specialized dealers. There is<br />

a <strong>com</strong>prehensive network of specialized<br />

dealers at your disposal offering you<br />

advice and support.<br />

After-Sales-Service<br />

If service is required trained specialized<br />

dealers on site respectively our<br />

experienced after-sales-service<br />

department is at your disposal. If<br />

necessary our <strong>com</strong>prehensive spare<br />

parts storage offers supply at short<br />

notice. Our service guarantees you consistent<br />

value of your Schweißkraft welding<br />

device for many years. If your device<br />

is failing and we are not able to<br />

repair it immediately you have the possibility<br />

to loan a device from many of<br />

our sales partners.<br />

Comprehensive warranty<br />

A warranty of 3 years for all<br />

Schweißkraft PRO-MAG and PRO-MIG<br />

welding devices as well as a warranty of<br />

5 years for the main transformer of the<br />

PRO-MAG and PRO-MIG devices<br />

according to our warranty conditions.<br />

The proper handling, treatment and use<br />

of our devices according to our<br />

operating instructions is the<br />

precondition to grant a warranty. Wear<br />

parts and consumables are not subject<br />

to the warranty.<br />

The legal warranty regulations according<br />

to our general terms and conditions<br />

remain unaffected hereby. Our warranty<br />

conditions are joint to the machine.<br />

Trainings<br />

The success of using our products is<br />

mainly determined by passing the<br />

technical knowledge on to the sales and<br />

service employees by consequent<br />

internal training measures. This<br />

qualification also includes customers<br />

performing workshops at our facility or<br />

training measures on site.<br />

Presentation<br />

service<br />

Please be convinced<br />

of the quality<br />

and good welding<br />

results during a welding<br />

presentation on site. A team<br />

of application engineers is available,<br />

who will be glad to visit you at<br />

your premises to explain and present<br />

the welding device. Of course, you will<br />

be able to weld and try out our<br />

device yourself.<br />

Test service<br />

If you need a number of<br />

welding devices we will<br />

furthermore offer you the<br />

possibility to test one or<br />

several welding devices in<br />

your application environment on site<br />

over a longer period of time.<br />

Do not hesitate to contact us!<br />

2

Table of contents<br />

MIG-MAG<br />

EASY-MAG 190 . . . . . . . . . . . . . . . . . . . . . . .7<br />

EASY-MAG 210 . . . . . . . . . . . . . . . . . . . . . . .7<br />

EASY-MAG 250-4 . . . . . . . . . . . . . . . . . . . . .7<br />

PRO-MAG 180 . . . . . . . . . . . . . . . . . . . . .8-10<br />

PRO-MAG 200 AM . . . . . . . . . . . . . . . . .8-10<br />

PRO-MAG 250 . . . . . . . . . . . . . . . . . . . . .8-10<br />

Accessories PRO-MAG . . . . . . . . . . . . .10-12<br />

PRO MIG<br />

PRO-MIG 230-2 AM . . . . . . . . . . . . . . . .14-18<br />

PRO-MIG 230-4 AM . . . . . . . . . . . . . . . .14-18<br />

PRO-MIG 280-4 . . . . . . . . . . . . . . . . . . .14-18<br />

PRO-MIG 310-4 . . . . . . . . . . . . . . . . . . .14-18<br />

PRO-MIG 300-4 . . . . . . . . . . . . . . . . . . .14-18<br />

PRO-MIG 350-4 W . . . . . . . . . . . . . . . . .14-18<br />

PRO-MIG 450-4 WS . . . . . . . . . . . . . . . .14-18<br />

Accessories PRO-MIG . . . . . . . . . . . . . .19-21<br />

PRO ARC<br />

PRO-ARC 300-4 . . . . . . . . . . . . . . . . . . .23-28<br />

PRO-ARC 450-4 WS . . . . . . . . . . . . . . .23-28<br />

Accessories PRO-ARC . . . . . . . . . . . . .28-32<br />

MIG-MAG pulse<br />

PRO-PULS 440-4 WS . . . . . . . . . . . . . .34-36<br />

Accessories PRO-PULS . . . . . . . . . . . .36-38<br />

Multi-functional inverter<br />

KOMBI 160 . . . . . . . . . . . . . . . . . . . . . .40-42<br />

KOMBI 160 HF . . . . . . . . . . . . . . . . . . .40-42<br />

Accessories KOMBI . . . . . . . . . . . . . . . . . .42<br />

Inverter TIG welding machines<br />

EASY-TIG 200 HF . . . . . . . . . . . . . . . . . . . .44<br />

Accessories EASY-TIG 200 HF . . . . . . . . . .45<br />

PRO-TIG 170 DC . . . . . . . . . . . . . . . . . .46-47<br />

PRO-TIG 170 DC TIG SET . . . . . . . . . . . .46-47<br />

Accessories PRO-TIG . . . . . . . . . . . . . .47-48<br />

PRO-TIG 170 DC Digital . . . . . . . . . . . . .50-53<br />

PRO-TIG 170 AC/DC Digital . . . . . . . . . .50-53<br />

PRO-TIG 210 AC/DC Digital . . . . . . . . .50-53<br />

PRO-TIG 170 DC Digital TIG SET . . . . . .50-53<br />

PRO-TIG 170 AC/DC Digital TIG SET . . . . .50-53<br />

PRO-TIG 210 AC/DC Digital TIG SET . . . . .50-53<br />

Water cooling device RWK 1000 . . . . . . . .54<br />

Accessories PRO-TIG Digital . . . . . . . . .53-55<br />

PRO-TIG 280 AC/DC . . . New . . . . . . . . . . .56-59<br />

PRO-TIG 350 AC/DC . . . . New . . . . . . . . . . .56-59<br />

Accessories PRO-TIG AC/DC . . . . . . . .59-60<br />

Electrode inverter<br />

EASY-STICK 145 . . . . . . . . . . . . . . . . . . . . .62<br />

EASY-STICK 185 . . . . . . . . . . . . . . . . . . . . .62<br />

Accessories EASY-STICK . . . . . . . . . . . . . .63<br />

EASY-STICK 200 CEL Digital . . . . . . . . .64-66<br />

EASY-STICK 250 Digital . . . . . . . . . . . .64-66<br />

EASY-STICK 320 Digital . . . . . . . . . . . .64-66<br />

Accessories EASY-STICK Digital . . . . . .67-68<br />

PRO-STICK 130 . . . . . . . . . . . . . . . . . . . .70-71<br />

PRO-STICK 140 . . . . . . . . . . . . . . . . . . .70-71<br />

PRO-STICK 130 SET . . . . . . . . . . . . . . . .70-71<br />

PRO-STICK 140 SET . . . . . . . . . . . . . . . .70-71<br />

PRO-STICK 170 . . . . . . . . . . . . . . . . . . .72-73<br />

PRO-STICK 170 SET . . . . . . . . . . . . . . . .72-73<br />

PRO-STICK 170 DC . . . . . . . . . . . . . . . . .72-73<br />

PRO-STICK 170 DC TIG SET . . . . . . . . . .72-73<br />

Accessories PRO-STICK . . . . . . . . . . . . .73-74<br />

PLASMA cutting device<br />

PRO-CUT Tornado . . . . . . . . . . . . . . . . .76-77<br />

PRO-CUT 35 S . . . . . . . . . . . . . . . . . . . .76-77<br />

PRO-CUT 70 . . . . . . . . . . . . . . . . . . . . . .76-77<br />

PRO-CUT 90 . . . . . . . . . . . . . . . . . . . . .76-77<br />

PRO-CUT 120 . . . . . . . . . . . . . . . . . . . . .76-77<br />

Accessories PRO-CUT . . . . . . . . . . . . . .78-79<br />

Electrochemical metal working<br />

CLEANO 1 . . . . . . . . . . . . . . . . . . . . . . . . . .81<br />

CLEANO RS . . . . . . . . . . . . . . . . . . . . . . . . .81<br />

Coal stamp . . . . . . . . . . . . . . . . . . . . . .82-84<br />

Cleaning pin . . . . . . . . . . . . . . . . . . . . .82-84<br />

Measuring cable . . . . . . . . . . . . . . . . .82-84<br />

Cleaning and marking felts . . . . . . . . .82-84<br />

Aramide band . . . . . . . . . . . . . . . . . . .82-84<br />

Electrolytes . . . . . . . . . . . . . . . . . . . . .82-84<br />

Conservates . . . . . . . . . . . . . . . . . . . . .82-84<br />

Long-term templates . . . . . . . . . . . . . .82-84<br />

Short-term templates . . . . . . . . . . . . .82-84<br />

Label printer . . . . . . . . . . . . . . . . . . . .82-84<br />

Electrode grinding device<br />

ESG 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86<br />

Welding accessories<br />

Welding safety helmets,<br />

Welding googles, etc. . . . . . . . . . . . . .88-96<br />

Welding regulator, spray for nozzles,<br />

electrode holders, etc. . . . . . . . . . . . .94-96<br />

Industrial gases . . . . . . . . . . . . . . . . . . . . .97<br />

Welding wire . . . . . . . . . . . . . . . . . . .98-100<br />

Welding rods . . . . . . . . . . . . . . . . . . .101-102<br />

Stick electrodes . . . . . . . . . . . . . . . .103-105<br />

Autogenous technique . . . . . . . . . . .106-107<br />

Welding clamps, angle magnets<br />

Metall corner clamps . . . . . New . . . . . . .108-111<br />

3

MIG-MAG Information inert gas welding devices<br />

The welding processes, materials and<br />

advantages of the individual techniques.<br />

MIG-MAG welding-Inert* gas metal-active gas metal<br />

(*Inert = poor activity)<br />

MIG/MAG welding is the most <strong>com</strong>monly used<br />

welding process in the world. This results from<br />

the various possibilities of use, no cleaning<br />

from slag, the simple penetrations welding and<br />

the deep fusion penetration.<br />

The simple use in any welding position makes<br />

this process even more interesting, especially<br />

from the economical point of view.<br />

The MIG/MAG process is a mechanical inert<br />

gas arc welding, where the arcing takes place<br />

between the live wire electrode and the<br />

workpiece in a controlled atmosphere (= active<br />

or inert gases such as mixed gases). The<br />

mechanical feed wire serves as electrode<br />

which melts off in its own arc.<br />

The MAG process<br />

Appropriate for steel, unalloyed, low-alloyed<br />

and high-alloyed source material and is<br />

therefore perfect to be used in production and<br />

for repair welding. It is applied for a sheet<br />

thickness of more than 0.6 mm.<br />

The MIG process<br />

Contrary to the MAG process, the MIG and the<br />

new MIG soldering process are used for<br />

aluminum and copper materials by adding<br />

inert (= poor activity) gases such as argon.<br />

Using this process you may weld wall<br />

thicknesses of more than 2.0 mm (MIG soldering<br />

from 0.5 mm on).<br />

It is re<strong>com</strong>mended to use a pulsed current<br />

source or the TIG method for thinner materials.<br />

The MIG-MAG welding process is a very<br />

manifold welding process but with the<br />

limitation that the workplace needs to be<br />

protected against draft and humidity, in order<br />

to maintain the inert gas effect when the welding<br />

process is performed outdoors.<br />

TIG welding-tungsten inert* gas (*inert = poor activity)<br />

For TIG welding, an arc is drawn between a<br />

non-melting tungsten electrode and the<br />

workpiece.<br />

Pure argon is used as inert gas-a rare gas<br />

which cannot be <strong>com</strong>bined with any element<br />

and therefore alsoprevents from reactions of<br />

weld metal. The additional wire is fed by hand<br />

(manual welding) or mechanically (automatic<br />

welding). But there are also weldings which<br />

may be performed without additional material.<br />

It depends on the applied material if direct<br />

current or alternating current is used.<br />

The main advantage of the TIG welding is in the<br />

large range of materials which can be welded.<br />

Materials of no more thickness than 0.3 mm<br />

(automated) such as alloyed steels, high<br />

alloyed steels, aluminum, magnesium, copper<br />

as well as their alloys, unalloyed steels, nickel,<br />

gold, silver, titanium and many more are<br />

weldable. Usable to weld any material<br />

thicknesses and to work the root of seams of<br />

thicker cross sections. With the TIG process you<br />

achieve the best results <strong>com</strong>pared to other<br />

welding processes due to the non-porous<br />

welding with a very high tensile strength.<br />

AC welding:<br />

For welding light metals. On the tungsten<br />

electrode a semi-spherical cap is formed and<br />

the arc alternates at high frequency from the<br />

negative to the positive pole.<br />

DC welding:<br />

For welding alloyed steels and<br />

non-ferrous metals. The tungsten electrode is<br />

grinded to a pointed shape. The arcing is stable.<br />

HF strike = contactless strike<br />

Lift arc strike = contact strike<br />

Welding with electrodes<br />

The welding with electrodes is a simple<br />

welding method by allowing to weld almost<br />

any metals. This process may also be used<br />

outdoors or even under water without any<br />

problems.<br />

For welding with electrodes the arc length is<br />

manually set–the electrode<br />

distance is determined by the length of the arc.<br />

You mainly weld with DC; e.g. rutile electrodes<br />

may easily be welded with negative DC;<br />

alkaline electrodes are welded with positive<br />

DC.<br />

The electrode is an arc carrier and additional<br />

material. It is <strong>com</strong>posed of an alloyed or<br />

unalloyed core wire and a casing. The casing<br />

protects the melting bath against harmful<br />

atmospheric oxygen and stabilizes the arcing.<br />

Additionally a slag is produced which protects<br />

and forms the weld.<br />

For the electrodes you distinguish rutile or<br />

alkaline electrodes according to the thickness<br />

of the casing. Rutile electrodes are weldable<br />

more easily and have a good flat seam.<br />

Furthermore, it is easy to remove the slag.<br />

Please note, that a lot of electrodes need<br />

to be retired after long storage, as they<br />

accumulate the humidity of the atmosphere.<br />

Otherwise electrode welding is a <strong>com</strong>mon easy<br />

to use welding method.<br />

The plasma arc cutting<br />

The plasma arc cutting was originally only used<br />

where the flame cutting and its process<br />

variants offered no or poor results.<br />

This applies above all for high-alloyed steels,<br />

cast iron, light metal and non-ferrous heavy<br />

metal. The technical further development of the<br />

plasma arc cutting in the past years as well as<br />

the increase of the cutting speed have led to<br />

the fact that for cutting of thin-walled<br />

workpieces (about 0.5 to 20 mm) even of<br />

unalloyed or low-alloyed steel, the plasma arc<br />

cutting is used more often.<br />

Due to the fact, that there is only external heat<br />

supply, the energy content of the plasma jet is<br />

reduced when it penetrates the workpiece. This<br />

leads to a cutting gap which tapers with the<br />

distance to the workpiece surface.<br />

In any case, the plasma producing medium is<br />

of important influence for the quality and<br />

economic effectiveness. This may be<br />

<strong>com</strong>pressed air or a gas mixture. When using<br />

<strong>com</strong>pressed air, please make sure to use<br />

absolutely pure <strong>com</strong>pressed air.<br />

The plasma gas is led into the space between<br />

electrode and nozzle under pressure. To <strong>com</strong>mission<br />

a plasma torch, a pilot arc needs to be<br />

struck by means of a high frequency discharge.<br />

It is arcing at low power between the nozzle<br />

the electrode transfers the cutting gas to the<br />

plasma state due to thermal dissociation and<br />

ionization.<br />

The plasma arc cutting is especially<br />

appropriated for steel, CrNi or aluminum sheet<br />

metal.<br />

4

MIG soldering-for new fields of application, new materials<br />

and new regulations, especially in the automotive sector.<br />

The trend is to use galvanized thin sheets.<br />

They are processed e. g. in the automotive<br />

industry, in the construction industry, in the<br />

ventilation and air condition technology,<br />

in the domestic technique and the furniture<br />

industry.<br />

Why galvanized?<br />

Zinc which is applied to steel (electrolytic or<br />

by galvanizing) creates a barrier layer which<br />

protects from corrosion. Furthermore, zinc<br />

provides for a cathodic protective effect. If this<br />

zinc layer is damaged, the material will<br />

nevertheless be protected from corrosion in an<br />

area of 1-2 mm around the damaged area.<br />

By this remote protective effect of the zinc,<br />

additionally non-coated edges and micro cracks<br />

will be protected.<br />

The parent metal<br />

will not be<br />

fuzzed<br />

By using filler metals on copper basis (bronze) it<br />

is possible to work at low temperatures. Due to<br />

the little heat supply, only a little amount of zinc<br />

evaporating and <strong>com</strong>ponent bracing is reduced.<br />

The strength values are relatively high and the<br />

joint is corrosion-resistant due to the alloying<br />

elements, as the filler metal is made of bronze.<br />

The micrograph shows that the parent metal is<br />

not fuzzed during a MIG process.<br />

Inert gases<br />

For arc soldering, argon, I1 or Ar mixtures with<br />

additives of CO2 or O2 are generally used. For<br />

solder materials with Si- or Sn-contents little<br />

active parts of CO2 or O2 are advantageous.<br />

They stabilize the arcing, reduce the tendency to<br />

form pores, but increase the heat input in the<br />

parent metal.<br />

For solder materials with Al-contents, Ar-He<br />

mixtures without active parts are suitable.<br />

N2 additives stabilize the arcing, they effect a<br />

wide seam, but may also lead to very<br />

considerable pore formation.<br />

H2 as inert gas <strong>com</strong>ponent is suitable to<br />

increase the soldering feed speed, but it may<br />

also lead to porosity. In order to adjust the inert<br />

gas to the soldering tasks, the experiences of<br />

the inert gas manufacturers are to be applied.<br />

MIG / MAG<br />

1. Werkstück<br />

2. Lötnaht<br />

3. Drahtvorschub<br />

4. Drahtspule<br />

5. Gasdüse<br />

6. Kontaktrohr<br />

7. Schutzgas 7<br />

8. Lichtbogen<br />

4<br />

8<br />

Surface coatings and<br />

pretreatment<br />

Sheet metals with zinc coatings and a thickness<br />

of up to 15 μm may generally be ac<strong>com</strong>panied<br />

by arc soldering processes without any<br />

+ -<br />

3<br />

problems.<br />

5<br />

6<br />

For aluminized parent metals, aluminous<br />

solders are re<strong>com</strong>mended. Additionally<br />

galvanized sheet metals may be coated organically<br />

which requires an adaptation of the<br />

The seam which is typical for the MIG soldering due to<br />

burning down of the CuSi wire<br />

Our re<strong>com</strong>mendation:<br />

2<br />

processing parameters.<br />

PRO-MAG 200-2 AM &<br />

1<br />

In order that there would not be a metallurgical<br />

interaction between the parent metal and the<br />

PRO-MIG 230-2 AM /<br />

moistening liquid solder, the contact surface to<br />

230-4 AM synergie<br />

the solder should be to a large extent<br />

metallically blank and free of impurities, which<br />

otherwise would lead to pore formation,<br />

in<strong>com</strong>plete fusion, etc.<br />

The advantages of the MIG soldering process<br />

at a glance:<br />

What is MIG soldering?<br />

The term MIG soldering means a hard soldering<br />

process for galvanized and coated thin steel<br />

sheets as well as higher-strength steel plates.<br />

Contrary to traditional inert gas arc welding<br />

(about 1600°C) for MIG soldering parent metal is<br />

not melted, but a hard soldered joint of the<br />

workpiece is produced by using thin solder wire<br />

(generally filler metal on copper basis) having a<br />

low melting point of about 1000°C.<br />

Zinc already starts to vaporize at about 480°C.<br />

This means that in traditional welding processes<br />

a large part of the surface of the zinc layer would<br />

burn. The evaporating zinc as well as oxides<br />

then lead to pore formation, cracks and lacks of<br />

fusion.<br />

Filler metals and accessory agents<br />

For arc soldering mainly the wire electrodes and<br />

welding rods ML CuSi3 and ML CuAl8 are used.<br />

In Germany the ML CuSi3 is traditionally<br />

preferred whereas in other countries the alloy<br />

ML CuAl8 is used for similar purposes. ML CuAl8<br />

is used for MIG soldering of stainless steels as<br />

well as for joints where the optical appearance<br />

of the joint surface is important. This is of high<br />

importance for instance in the furniture industry.<br />

· No corrosion of the soldered seam<br />

· Minimum weld splashes<br />

· Simple reworking of the soldered seam<br />

· Low working temperature<br />

· Little <strong>com</strong>ponent bracing<br />

· Reduced texture modification for<br />

high-strength steel sheets<br />

· Capillary effect of the solder, therefore 1/3<br />

higher strength for round-hole and long-hole<br />

soldering<br />

· Less melting loss of the coating<br />

· Cathodic protective effect of the parent metal<br />

in the direct seam area (zinc)<br />

· Protection against corrosion without<br />

subsequent processing<br />

· Optimum control to maintain the sheet<br />

thickness<br />

5

MIG-MAG welding devices<br />

New<br />

EASY-MAG ®<br />

EASY-MAG 190<br />

EASY-MAG 210<br />

EASY-MAG 250-4<br />

PRO-MAG ®<br />

PRO-MAG 180-2<br />

PRO-MAG 200-2 AM<br />

PRO-MAG 250-2<br />

6

SCHWEISSKRAFT ® EASY-MAG-the basic model<br />

of the MIG-MAG inert gas welding devices<br />

New<br />

· Cost-efficient inert gas welding devices<br />

for do-it-yourselfers<br />

· For welding of steel and stainless steel<br />

· Easy-to-use and adjust<br />

· The smooth and stable arc guarantees welding<br />

results with low production of spatters<br />

· Infinitely variable wire feed<br />

· Robust undercarriage with castors for<br />

easy transportation<br />

· Handy fixture for gaz bottles<br />

· S-sign: approved for welding at narrow welding<br />

spaces with increased electrical danger<br />

EASY-MAG 190 and EASY-MAG 210<br />

· With 2-roll wire feed<br />

EASY-MAG 250-4<br />

· With 4-roll wire feed<br />

EASY-MAG 210<br />

· Suitable for 230 V and 400 V operation<br />

Quality<br />

Made in<br />

Europe<br />

Process<br />

MIG / MAG<br />

Sheet metal thickness<br />

· 1.0-10 mm (MAG)<br />

· 1.0-8 mm (MAG)<br />

Parent metals<br />

· Constructional steels<br />

· CrNi steels ferritic / austenitic<br />

· Duplex steels<br />

MIG / MAG<br />

Typical applications<br />

· Repairs/maintenance of bodyworks<br />

· Agriculture<br />

· Tack weldings<br />

EASY-MAG 190<br />

(similar Fig.)<br />

EASY-MAG 250-4<br />

(similar Fig.)<br />

EASY-MAG 210<br />

(similar Fig.)<br />

Model EASY-MAG 190 210 250-4<br />

Item No 108 0191 108 0211 108 0251<br />

€ plus VAT 499.00 69.00 859.00<br />

Technical data<br />

Wire-Ø mm 0.6-1.0 0.6-1.0 0.6-1.2<br />

Wire feed 2 roll 2 roll 4 roll<br />

Power supply V 400 230 / 400 400<br />

Setting range A 30-190 30-140 / 140-200 30-250<br />

Operating time (ED) 100% A 80 70 140<br />

Switching stages 7 9 10<br />

Open-circuit voltage V 23-39 24-51 16-35<br />

Fuse protection (slow-blow) A 16 16 16<br />

Type of cooling AF AF AF<br />

Torch cooling Gas Gas Gas<br />

Protective system IP 21 IP 21 IP 21<br />

Insulation class H H H<br />

Weight kg 37 39 66<br />

Dimensions L/W/H mm 760 x 390 x 630 760 x 390 x 630 840 x 410 x 680<br />

Welding torch SMB 15 / 3m SMB 15 / 3m SMB 25 / 3m<br />

Scope of delivery EASY-MAG 190/210:<br />

Welding torch SMB 15 / 3m<br />

Ground cable 2m<br />

Pressure regulator<br />

Scope of delivery EASY-MAG 250-4:<br />

Welding torch SMB 25 / 3m<br />

Ground cable 2m<br />

Pressure regulator<br />

The right to make technical modifications is reserved. Additional equipment for the illustrated devices are available at additional cost.<br />

Schweißkraft devices are supplied with the S-sign according to the standard EN 60 974-1.<br />

7

MIG-MAG inert gas welding devices<br />

Made in Germany<br />

SCHWEISSKRAFT ® PRO-MAG-standard welding devices for thin plate welding<br />

Professional quality at low prices<br />

· The serial 2-cycle function- and 4-cycle<br />

function for short tack seams or long welds.<br />

This way, fatigue-proof working for all welding<br />

tasks is guaranteed.<br />

· With the integrated position and interval<br />

control, optically faultless spot weldings and<br />

slot welds or equal, reproducible tack welds<br />

are no longer a challenge.<br />

· The infeed automatic automatically adapts the<br />

wire speed at a wide range using the switch to<br />

reduce or increase the capacity, so that<br />

continuous readjusting is being omitted.<br />

· An integrated creep-in and ignition automatic<br />

provides for rapid and safety igniting of the<br />

arc.<br />

· The permanent monitoring of the mains<br />

voltage with rectifying in case of fluctuations,<br />

ensures a smooth and equal arc providing<br />

optimum welding results.<br />

· When finishing the welding process, the free<br />

burning automatic provides for a constant<br />

wire end length at which the sticking of the<br />

wire on the workpiece or on the power nozzle<br />

is being avoided safely.<br />

(Individually adaptable)<br />

· Individually adjustable post gas time,<br />

which automatically adapts the post gas flow<br />

to the corresponding stage. Therefore, after<br />

finishing the welding process the melting bath<br />

will be protected until solidification.<br />

· The safety forced switch-off<br />

prevents from unintentional igniting and<br />

unwinding of the welding wire during the<br />

4-cycle operation as well as from the resulting<br />

fire risk thereby.<br />

· The interweaving automatic automatically<br />

increases the rate of feed when threading-up<br />

the wire.<br />

Process<br />

MIG / MAG<br />

· MIG soldering (PRO-MAG 200-2 AM)<br />

Sheet metal thickness<br />

· from 0.8 mm on (MAG)<br />

· Aluminum from 2.0 mm on (MIG)<br />

· MIG soldering from 0.6 mm on<br />

Parent metals<br />

· Constructional steels<br />

· CrNi steels ferritic / austenitic<br />

· Duplex steels<br />

· Galvanized, pretreated steels (MIG soldering)<br />

Typical applications<br />

· Repairs/maintenance of bodywork<br />

· Car workshop / steel building<br />

· Agriculture<br />

· Training<br />

· Tack weldings<br />

PRO-MAG 180-2<br />

PRO-MAG 250-2<br />

PRO-MAG 200-2 AM<br />

MIG soldering<br />

Easy operation<br />

· Indicator light OPERATION<br />

· Indicator light TEMPERATURE<br />

· Control knob for position<br />

and interval time (in seconds)<br />

· Function selector switch<br />

operational mode (2-cycle,<br />

4-cycle, position or interval)<br />

· Control knob for speed of wire feed<br />

· Stage switch<br />

8

Powerful wire feed<br />

Solid carriage<br />

Stable guide rolls<br />

for easy maneuvering<br />

MIG / MAG<br />

· High-dynamically throttle<br />

system provides an extra<br />

smooth, stable and<br />

high-dynamic arc and allows<br />

optimum low-spatter welding<br />

results for steel, stainless steel<br />

and aluminum.<br />

· High-performance transformer with<br />

high-quality double-insulated enameled<br />

copper wire with the insulation class H<br />

· Coiled and insulated in layers with<br />

additional vacuum impregnation<br />

· With thermal sensor protected against<br />

overload<br />

PRO-MAG 200-2 AM-the <strong>com</strong>bined device<br />

for MIG soldering and MIG/MAG welding<br />

MIG soldering for<br />

the automotive industry<br />

Particularly bodywork <strong>com</strong>panies need to adapt<br />

their repair methods to the continuous<br />

changes. Body works made of fully galvanized,<br />

partially high-strength steel must not be<br />

conventionally welded after an accident<br />

damage, since this way the crash properties<br />

which the manufacturer has intentionally<br />

induced will get lost. Different automotive<br />

manufacturers already instruct the MIG<br />

soldering for repairs.<br />

The PRO-MAG 200 AM is the specially designed<br />

<strong>com</strong>bined system for MIG-MAG thin plate<br />

welding and MIG soldering.<br />

In order to perform MIG soldering with the<br />

system, the “MIG soldering welding torch<br />

conversion kit” is additionally required.<br />

The parent metal<br />

will not be<br />

fuzzed<br />

The seam which is typical for the MIG<br />

soldering due to burning down the CuSi wire<br />

The Advantages of the MIG soldering<br />

· No corrosion of the soldering seam<br />

· Minimum welding splashes<br />

· Simple retreatment of the soldering seam<br />

· Low working temperature<br />

· Reduced structural transformation for<br />

high-strength steel plates<br />

· Capillary effect of the solder, therefore 1/3<br />

higher strength for round-hole and long-hole<br />

soldering<br />

· Less warping<br />

· Less melting loss of the coating·<br />

Cathodic protective effect of the parent<br />

metal in the direct seam area (zinc)<br />

· Protection against corrosion without<br />

subsequent processing<br />

· Optimum control to maintain the sheet<br />

thickness<br />

9

MIG-MAG inert gas welding devices<br />

Made in Germany<br />

Series PRO-MAG<br />

MIG soldering<br />

Modell PRO-MAG 180-2 200-2 250-2<br />

Item No 108 0118 108 0120 108 0125<br />

€ plus VAT 1'079.00 1'179.00 1'359.00<br />

Re<strong>com</strong>mended welding torch kit 15/25 15/25 25/35<br />

Item No 109 1510 109 1510 109 2510<br />

Technical data<br />

Wire Ø steel/stainless steel mm 0.6-0.8 0.6-1.0 0.8-1.2<br />

Wire Ø aluminum mm 1.0 1.0 1.0-1.2<br />

Wire feed m/min 0.3-20 0.3-20 0.3-20<br />

Drive 2 rolls 2 rolls 2 rolls<br />

Mains supply V 230/400 400 400<br />

Seting range A 30-140/50-180 25-200A 35-250A<br />

Operating time (ED) for Imax. (10 min.) % 25% / 25% 30% 30%<br />

Welding current at 100% ED A 95 / 100 100 125<br />

Switching stages 6 / 6 8 10<br />

Open-circuit voltage V 21-35 / 23-39 14-321 6-35<br />

Continuous power at 100% ED kVA 2.1/2.4 2.3 3.1<br />

Fuse protection (slow-blow) A 16 16 16<br />

cos phi 0.98<br />

Type of cooling AF AF AF<br />

Torch cooling Gas Gas Gas<br />

Protective system IP 21 IP 21 IP 21<br />

Insulation class H H H<br />

Weight kg 45 52 55<br />

Dimensions L/W/H mm 760 x 320 x 580<br />

MIG soldering<br />

The right to make technical modifications is reserved. Additional equipment for the illustrated devices are available at additional cost.<br />

Schweißkraft devices are supplied with the S-sign according to the standard EN 60 974-1.<br />

Standard equipment:<br />

2-roll drive, 2/4-cycle point/interval control, mains cable with plug 5m, central connection system Binzel,<br />

operation and temperature display, without welding torch, without ground cable, without pressure regulator<br />

(accessories)<br />

Accessories-welding torch kits<br />

consisting of: welding torch 4m, ground cable (Grca), 315 bar argon/CO2 pressure regulator (Pressreg)<br />

Item No<br />

Designation<br />

109 1510 welding torch kit 15/25 SMB 15/4m gas-cooled, Grca 25mm² 4m, Pressreg<br />

109 2510 welding torch kit 25/35 SMB 25/4m gas-cooled, Grca 35mm² 4m, Pressreg<br />

109 3610 welding torch kit 36/70 SMB 36/4m gas-cooled, Grca 70mm² 4m, Pressreg<br />

*The prices for welding torch kit are only valid when a welding deviceis purchased<br />

Kit of wearing parts welding torch<br />

Item No<br />

Designation<br />

109 1500 Kit of wearing parts SMB 15<br />

consisting of: 1 x gas nozzle support, 3 x retaining spring , each<br />

3 x power nozzle 0.6/0.8 mm 3 x gas nozzle conical, 1 x gas nozzle<br />

cylindrical size 12, sorting box large<br />

€ plus<br />

VAT<br />

109.00<br />

139.00<br />

185.00<br />

€ plus VAT<br />

22.90<br />

26.90<br />

109 2500 Kit of wearing parts SMB 25<br />

consisting of: 3 x retaining spring, 2 x blast connection, each 5 x power nozzle<br />

0.6/ 0.8 mm 2 x gas nozzle conical, 1 x gas nozzle cylindrical size 12,<br />

sorting box large<br />

109 3600 Kit of wearing parts SMB 36<br />

consisting of: 2 x blast connection M6, 3 x gas distributor brown,<br />

44.90<br />

each 5 x power nozzle 0.8/1.0/1.2 mm 4 x gas nozzle conical, 1 x gas nozzle cylin<br />

drical, sorting box large<br />

Welding torch kit<br />

Kit of wearing parts<br />

Wire transport roller<br />

Item No Designation<br />

101 2108 Wire transport roller 0.6/0.8 mm (PRO-MAG 160-250)<br />

01 2110 Wire transport roller 0.8/1.0 mm (PRO-MAG 160-250)<br />

101 2112 Wire transport roller 1.0/1.2 mm (PRO-MAG 160-250)<br />

€ plus VAT<br />

30.00<br />

30.00<br />

30.00<br />

10

SMB 15 gas-cooled<br />

PRO-MAG 180-2200-2<br />

SMB 25 gas-cooled<br />

PRO-MAG 250-2<br />

MIG / MAG<br />

Item No<br />

Designation<br />

109 1503 SMB 15 / 3 m with Pushbutton<br />

109 1504 SMB 15 / 4 m with Pushbutton<br />

109 1505 SMB 15 / 5 m with Pushbutton<br />

109 1513 SMB 15 / 3 m for aluminum<br />

€ plus VAT<br />

69.00<br />

74.00<br />

84.00<br />

105.00<br />

Item No<br />

Designation<br />

109 2503 SMB 25 / 3 m with Pushbutton<br />

109 2504 SMB 25 / 4 m with Pushbutton<br />

109 2505 SMB 25 / 5 m with Pushbutton<br />

109 2513 SMB 25 / 3 m for aluminum<br />

€ plus VAT<br />

94.00<br />

99.00<br />

115.00<br />

129.00<br />

No. Designation PU Item No.<br />

1 Neck of torch SMB 15109 1530<br />

2 Gas nozzle support 10 109 1531<br />

3 Retaining spring 10 109 1535<br />

4 Power nozzle M6 Ø 0.6mm/25mm 10 109 1540<br />

Ø 0.8mm/25mm 10 109 1542<br />

Ø 1.mm/25mm 10 109 1544<br />

Power nozzle Al Ø 1.0mm/25mm 10 109 1547<br />

5 Gas nozzle conical Ø 12.0/53 mm 10 109 1550<br />

Gas nozzle cylindrical Ø 16.0 mm 10 109 1554<br />

Spot-gas nozzle 10 109 1552<br />

6 Spacer 10 109 1591<br />

7 Spacer black 10 109 1588<br />

8 Handle shell red 109 1517<br />

9 Pressur pushbutton 109 1518<br />

10 Screw handle shell 10 109 1590<br />

11 Ring 109 1592<br />

12 Antikink spring 109 1587<br />

13 Antiking machine-sided 109 1586<br />

14 Terminal nut 1 109 1581<br />

15 Screw terminal nut 10 109 1589<br />

16 Main plug solid pins 109 1582<br />

Kit of wearing parts SMB 15 109 1500<br />

For guide spirals/Teflon core refer to page 12<br />

€ plus VAT/piece<br />

10.90<br />

2.65<br />

0.66<br />

1.00<br />

1.00<br />

1.00<br />

1.10<br />

1.99<br />

1.99<br />

4.00<br />

2.80<br />

2.40<br />

10.00<br />

5.50<br />

0.15<br />

2.20<br />

4.80<br />

3.90<br />

2.90<br />

0.30<br />

18.40<br />

22.90<br />

No. Designation PU Item No.<br />

1 Neck of torch SMB 25 109 2530<br />

2 Retaining spring 10 109 2535<br />

3 Blast connection 10 109 2560<br />

4 Power nozzle M6 Ø 0.8mm/28mm 10 109 2542<br />

Ø 1.mm/28mm 10 109 2544<br />

Ø 1.2mm/28mm 10 109 2546<br />

Power nozzle Al Ø 1.0mm/28mm 10 109 2548<br />

Ø 1.2mm/28mm 10109 109 2549<br />

5 Gas nozzle conical Ø 14.5/57 mm 10 109 2550<br />

Gas nozzle cylindrical Ø 18.0 mm 10 109 2554<br />

Spot-gas nozzle 10 109 2552<br />

6 Spacer black 10 109 1588<br />

7 Handle shell red 109 1517<br />

8 Pushbutton 109 1518<br />

9 Screw handle shell 10 109 1590<br />

10 Ring 109 1592<br />

11 Antikink spring 109 2561<br />

12 Antikink machine-sided 109 1586<br />

13 Terminal nut 1 109 1581<br />

14 Screw terminal nut 10 109 1589<br />

15 Main plug solid pins 109 1582<br />

Kit of wearing parts SMB 25 109 2500<br />

For guide spirals/Teflon core refer to page 12<br />

€ plus VAT/piece<br />

21.70<br />

0.66<br />

1.69<br />

1.30<br />

1.30<br />

1.30<br />

1.80<br />

1.80<br />

2.49<br />

2.80<br />

5.50<br />

2.40<br />

10.00<br />

5.50<br />

0.15<br />

2.20<br />

5.00<br />

3.90<br />

2.90<br />

0.30<br />

18.40<br />

26.90<br />

Technical data:<br />

Charge: 180 A CO2 / 150 A mixed gas<br />

ED 60 %<br />

Wire Ø: 0.6-1.0 mm<br />

Technical data:<br />

Charge: 230 A CO2 / 200 A mixed gas<br />

ED 60 %<br />

Wire Ø: 0.8-1.2 mm<br />

11

Accessories MIG-MAG welding torch<br />

Guide spirals, Teflon cores and<br />

PA cores<br />

MIG soldering accessories<br />

Item No<br />

Designation € plus VAT<br />

Guide spirals with support nipple and O-ring<br />

Blue, insulated 1.5/4.5; for wire 1) Ø 0.6-0.8; SMB 15-36<br />

· 105 1573 3.0 m<br />

4.50<br />

· 105 1574 4.0 m<br />

4.95<br />

· 105 1575 5.0 m<br />

6.10<br />

Red, insulated 2.0/4.5; for wire 1) Ø 1.0-1.2; SMB 15-36<br />

· 105 2576 3.0 m<br />

4.50<br />

· 105 2577 4.0 m<br />

4.95<br />

· 105 2578 5.0 m<br />

6.10<br />

Uninsulated, 2.0/4.5; for wire 1) Ø 1.0-1.2; SMB 400<br />

· 105 4073 3.0 m<br />

3.90<br />

· 105 4074 4.0 m<br />

4.50<br />

· 105 4075 5.0 m<br />

5.20<br />

Uninsulated, 2.5/4.5; for wire 1) Ø 1.6; SMB 400<br />

· 105 4076 3.0 m<br />

3.90<br />

· 105 4077 4.0 m<br />

4.50<br />

· 105 4078 5.0 m<br />

5.20<br />

Teflon cores with support nipples and O-ring<br />

Blue, 1.5/4.0; for wire 1) Ø 0.8-1.0; SMB 25-36<br />

· 105 1593 3.0 m<br />

· 105 1594 4.0 m<br />

· 105 1595 5.0 m<br />

Red, 2.0/4.0; for wire 1) Ø 1.0-1.2; MB 25-36<br />

· 105 2590 3.0 m<br />

· 105 2591 4.0 m<br />

· 105 2592 5.0 m<br />

Yellow, 2.7/4.7; for wire 2) Ø 1.6; SMB 400<br />

· 105 3666 3.0 m<br />

· 105 3667 4.0 m<br />

· 105 3668 5.0 m<br />

PA cores with support nipples and O-ring<br />

Grey, 2.0/4.0; for wire 1) Ø 1.0-1.2; MB 25-36<br />

· 105 2583 3.0 m<br />

· 105 2584 4.0 m<br />

· 105 2585 5.0 m<br />

Grey, 2.9/4.7; for wire 1) Ø 2.4; SMB 400<br />

· 105 2586 4.0 m<br />

Combined cores with support nipples, O-ring and brass spiral<br />

Red, 2.0/4.0; for wire 1) Ø 1.0-1.2; MB 25-36<br />

· 105 2593 3.5 m<br />

· 105 2594 4.5 m<br />

· 105 2595 5.5 m<br />

Coal Teflon core with support nipple, O-ring and brass spiral<br />

2.0-4.0 for wire 2) Ø 1.0-1.2; MB 25-36<br />

· 105 2596 3.0 m<br />

20.50<br />

· 105 2597 4.0 m<br />

23.50<br />

· 105 2598 5.0 m<br />

27.00<br />

Coal Teflon core with support nipple, O-ring and brass spiral<br />

2.7/4.7 for wire 2) Ø 1.6; SMB 400<br />

· 105 2599 4.0 m<br />

17.90<br />

· 105 1583 O-ring 3.5x1.5 (PU 20 pcs.)<br />

· 105 1596 Support nipple Ø 4 mm (PU 20 pcs.)<br />

· 105 1598 HN for F.-spiral uninsulated 1.5/4.0 (PU 20)<br />

· 105 1599 HN for F.-spiral uninsulated<br />

2.0-2.5/4.0 (PU 20)<br />

· 105 1597 Conductor brass Ø 4 mm<br />

· 105 1524 Brass spiral ready-made 200 mm<br />

· 105 6081 Guide nipple, ROBO PA core<br />

1) Applicable for metal inert gas welding of unalloyed and<br />

low-alloyed steels according to DIN 8555 and DIN 8559.<br />

14.00<br />

17.00<br />

20.50<br />

14.00<br />

17.00<br />

20.50<br />

14.00<br />

17.00<br />

20.50<br />

14.90<br />

17.30<br />

19.30<br />

22.30<br />

18.70<br />

20.50<br />

24.50<br />

0.50/pc<br />

2.10/pc<br />

1.00/pc<br />

1.00/pc<br />

3.75<br />

6.90<br />

8.50<br />

2) Applicable for the metal inert gas welding of aluminum according to DIN<br />

1732, copper/copper alloys according to DIN 1733 and nickel/nickel alloys<br />

according to DIN 1736 as well as for the metal inert gas welding of stainless<br />

and heat-resisting steels according to DIN 8556.<br />

3) Applicable up to max. 150°C.<br />

MIG soldering welding torch conversion kit<br />

B 15 / 4 m for wire 0.8 mm<br />

Consisting of 10 x power nozzle Ø 0.8 mm<br />

and Teflon core blue Ø 0.8-1.0 mm, 4 m<br />

Item No 109 1521; € 23.,90<br />

MIG soldering welding torch conversion kit<br />

B 15 / 4 m for wire 1.0 mm<br />

Consisting of 10 x power nozzle Ø 1,0 mm<br />

and Teflon core red Ø 1.0-1.2 mm, 4 m<br />

Item No 109 1522; € 23.90<br />

Welding wire CuSi 3, small coil D200, 5 kg<br />

Ø 0.8 mm Item No. 113 1620; € 28.86/kg<br />

Ø 1.0 mm Item No. 113 1619; € 31.24/kg<br />

Welding wire CuSi 3, basket coil K300, 15 kg<br />

Ø 0.8 mm Item No. 113 1625; € 28.07/kg<br />

Ø 1.0 mm Item No. 113 1624; € 27.54/kg<br />

Welding wire CuSi 8, small coil D200, 5 kg<br />

Ø 0.8 mm Item No. 113 1630; € 28.86/kg<br />

Ø 1.0 mm Item No. 113 1629; € 28.86/kg<br />

Welding wire CuAl 8, basket coil K300, 15 kg<br />

Ø 0.8 mm Item No. 113 1635; € 28.46/kg<br />

Ø 1.0 mm Item No. 113 1634; € 24.10/kg<br />

(other welding wires, e.g. SG 2, aluminum,<br />

stainless steel available upon request)<br />

Inert gas argon<br />

Steel cylinder seamless, <strong>com</strong>plete incl. valve for<br />

steel cylinders, with thread<br />

according to DIN 477, top cap DIN 4667 and refill<br />

New cylinder 10 l, item No. 174 1012; € 200.00<br />

New cylinder 20 l, item No. 174 1021; € 305.00<br />

Refill 10 l, item No. 174 1013; € 37.00<br />

Refill 20 l, item No. 174 1023; € 44.00<br />

MIG/MAG special welding tongs<br />

For cutting, time-saving clearing and<br />

drawing off the inert gas nozzle<br />

(Ø 15-18 mm), loosening and<br />

tightening the power nozzle<br />

Item No 107 2000; 22.25 €<br />

Basket coil adapter,<br />

One-piece, pluggable<br />

Item No 111 0001; € 5.90<br />

All prices plus VAT<br />

12

The new intelligent<br />

welding device generation<br />

made by SCHWEISSKRAFT ®<br />

MIG / MAG<br />

PRO-MIG ® synergie<br />

PRO-MIG 230-2 AM synergie<br />

PRO-MIG 230-4 AM synergie<br />

PRO-MIG 280-4 synergie<br />

PRO-MIG 310-4 synergie<br />

PRO-MIG 300-4 synergie<br />

PRO-MIG 350-4 W synergie<br />

PRO-MIG 450-4 WS synergie<br />

13

MIG-MAG inert gas welding devices<br />

Made in Germany<br />

PRO-MIG synergie-protective gas devices with step switching<br />

Best welding results and easy operation thanks to self-adjustment and intelligent process<br />

control IWC<br />

“IWC controls the whole system<br />

by superordinated function”<br />

The arc length is not only controlled by the<br />

measuring of the arc tension and the welding<br />

current, but additionally by the digital detection<br />

of the wire feed speed.<br />

· During the whole striking and arc process, the<br />

droplet transfer is continuously<br />

monitored and digitally controlled – as for<br />

most modern pulsed current sources<br />

· The setting of the correct welding<br />

parameters is simple and safe thanks to the<br />

integrated welding parameter database DCC<br />

and the <strong>com</strong>fortable operating concept SMI<br />

· The integrated microprocessor rapidly and<br />

very efficiently <strong>com</strong>pensates changes and is<br />

holding the arc length significantly constant.<br />

SDI technologyautomatic<br />

throttle matching<br />

SDI increases the economic efficiency: Since the<br />

heat input <strong>com</strong>pared to <strong>com</strong>mon multiple<br />

<strong>com</strong>pact switching of MIG-MAG systems can be<br />

better controlled and the spatter<br />

production of the mixed arc is considerably<br />

reduced apparently less retreatment is required.<br />

This way, the welding properties can be<br />

adapted even more perfectly to the welding conditions,<br />

e.g. in predicaments when the seam is<br />

being welded vertically upwards, when welding<br />

overhead or when welding with a long stick-out<br />

at places which are difficult to access.<br />

Due to the SDI technology, the PRO-MIG<br />

disposes of outstanding striking properties and<br />

a high-stable arc. The throttle effect will at this<br />

be optimized by the integrated process control.<br />

This way, the spatter production will be reduced<br />

to a minimum.<br />

PRO-MIG 450-4 WS synergie<br />

14

The self adjustment DCC:<br />

Three simple steps-there you go...<br />

Standard equipment for<br />

all PRO-MIG types<br />

Only select the material and the wire thickness.<br />

The machine will indicate the weldable<br />

material thickness-and there you go.<br />

The adjustment of the other welding<br />

parameters is performed by our new PRO-MIG<br />

synergie on the basis of the preset Synergie characteristic<br />

curves and the DCC itself.<br />

The wire speed and the other important<br />

parameters are automatically optimized for the<br />

programmed materials steel, stainless steel and<br />

aluminum and for the different diameters of wire<br />

electrodes and types of gas depending on the<br />

voltage level.<br />

MIG / MAG<br />

1 st Step<br />

Selecting material<br />

and wire diameter<br />

2 nd Step<br />

Selecting display<br />

“Material thickness”<br />

2<br />

1<br />

3<br />

3 rd Step<br />

Press the welding torch key and<br />

select the material thickness to be<br />

welded by pressing the stage<br />

switch. The digital display (A)<br />

indicates the material thickness in<br />

mm.<br />

DMC technologydigital<br />

motor control<br />

Thanks to the DMC arc length changes e.g. due<br />

to voltage fluctuations and resistances in the<br />

hose package are rapidly and efficiently<br />

rectified.<br />

Besides the measuring of the arc voltage, also<br />

the infeed speed is directly entered at the feed<br />

motor with the incremental<br />

transducer. With the DMC changes of the arc<br />

length are early detected and corrected.<br />

The DMC is a guarantor for constant wire feed<br />

speeds – independent from the temperature of<br />

the feed motor or of the soiling of the hose<br />

package.<br />

DCC technologyself-adjustment<br />

of the welding parameter<br />

according to the material thickness.<br />

All corresponding welding parameters are<br />

automatically selected with optimum<br />

parameter defaults. The <strong>com</strong>prehensive,<br />

integrated welding parameter database (DCC)<br />

<strong>com</strong>prises the knowledge of experienced<br />

experts. With the <strong>com</strong>bination of material, wire<br />

diameter and voltage levels, all synergie<br />

parameters are preset which are necessary for a<br />

successful welding process, using the database.<br />

During the welding process the actual values<br />

are continuously matched with these process<br />

parameters and, if required, they are<br />

corrected as quick as a flash. All parameters<br />

which are necessary for perfect welding<br />

(higher than 900) will be selected by the DCC<br />

according to the corresponding requirements of<br />

the machine.<br />

SMI technology-<br />

A mere child's play and for sure no more<br />

faulty operation:<br />

The SMI allows rapid and safe setting of the<br />

correct welding parameters and easiest<br />

operation at the same time – selecting material,<br />

setting material thickness – welding.<br />

PRO-MIG 280-4 WS synergie<br />

15

MIG-MAG inert gas welding devices<br />

Made in Germany<br />

PRO-MIG synergie-longest switch-on time, easiest operation and best welding result at<br />

maximum reliability<br />

Arguments<br />

· Intelligent, superordinated IWC control<br />

· Electronic throttle adjustment SDI for an even<br />

better striking process<br />

· Synergie operation DCC by the integrated<br />

database with preset characteristic curves<br />

· Special MIG soldering characteristic curves<br />

(230 AM)<br />

· Special aluminum characteristic curves in<br />

addition for PRO-MIG 230-4 AM, 300-4 up to<br />

450-4 WS<br />

· Wire interweaving automatic, without current<br />

and gas, with quick motion<br />

·Feed automatic<br />

· Creep-in automatic for safe striking<br />

· Hold function<br />

· Permanent monitoring of the supply voltage for<br />

a smooth arc<br />

· Wire re-burning automatic for constant wire<br />

length ends and free arcing time,<br />

individually adaptable<br />

· Post gas flow time individually adaptable<br />

· Safety <strong>com</strong>pulsory stop in the 4-cycle<br />

operation to prevent the wire from unintended<br />

uncoiling<br />

· Temperature-controlled ventilator and water<br />

pump with stand-by switching for little noise<br />

emission<br />

· Thermal safety switch<br />

· CE- and S-sign<br />

· 2 large guide rolls and fixed castors<br />

Equipment characteristics:<br />

· 2- or 4-roll wire feed, powerful and digitally<br />

controlled with real-time monitoring<br />

· Clearly arranged control panel<br />

· Two easily readable digital display incl. hold<br />

function for welding voltage, welding current<br />

and weldable material thickness<br />

· Overheating display<br />

· Easy exchange of the wire coil<br />

· Replacement of wire transport rolls without<br />

tools<br />

· Ergonomic design, housing according to<br />

IP 23 for welding outdoors.<br />

· Easy-to-maneuver due to robust<br />

chassis with large wheels<br />

Operational modes<br />

· 2-cycle operation<br />

· 4-cycle operation<br />

· Dotting<br />

· Synergie operation<br />

· Manual operation<br />

Adjustable parameters<br />

· Point/interval time<br />

· Welding capacity<br />

Programs / characteristic<br />

curves Fe/CrNi Alu CuSi<br />

Synergie operation DCC 0.6 0.8 1.0 1.2 0.8 1.0 1.2 0.8 1.0<br />

PRO-MIG 230-2 AM<br />

PRO-MIG 230-4 AM<br />

PRO-MIG 280-4<br />

PRO-MIG 310-4<br />

PRO-MIG 300-4<br />

PRO-MIG 350-4 W<br />

PRO-MIG 450-4 WS<br />

Process<br />

· MIG-MAG<br />

· MIG soldering (PRO-MIG 230 AM synergie)<br />

Sheet metal thickness<br />

· From 0.5 mm on (MAG)<br />

· Aluminum from 0.8 mm on (MIG)<br />

· MIG soldering from 0.5 mm on<br />

Parent metals<br />

· Constructional steels, un-, low-alloyed materials<br />

· CrNi steels ferritic / austenitic<br />

· Duplex steels<br />

· Aluminum (MIG)<br />

· Galvanized, pretreated steels (MIG soldering)<br />

Typical applications<br />

· Plant engineering, container, machine, steel<br />

construction<br />

· Overhaul / Repair<br />

· Automotive and supply industry<br />

· Vehicle manufacturing / Construction<br />

machines<br />

· Rail car construction<br />

· Shipbuilding<br />

Fig. on the left<br />

Synergie<br />

program selection<br />

PRO-MIG 230-4 AM<br />

Operational controls<br />

Rotary switch for wire<br />

speed and length<br />

correction of the arc<br />

Digital display for<br />

welding voltage<br />

incl. hold function<br />

Rough stage switch<br />

Digital display for<br />

welding current<br />

and material thickness<br />

Fine stage switch<br />

Operational modes<br />

material thickness display,<br />

2-cycle, 4-cycle,<br />

dotting, interval<br />

16<br />

Setting the point<br />

and interval time<br />

Synergie program selection:<br />

material / wire diameter<br />

program and manual operation<br />

e.g. for aluminum welding

MIG / MAG<br />

PRO-MIG synergie 230-2 AM<br />

up to 310-4<br />

Compact model with chassis<br />

spacer, guide rolls and largely dimensioned<br />

fixed castors<br />

PRO-MIG synergie 300-4<br />

up to 350-4 W<br />

Industry model for up to 50 l gas cylinders,<br />

chassis spacers, guide rolls and<br />

largely dimensioned fixed castors.<br />

Gas-cooled and<br />

water-cooled type available<br />

PRO-MIG synergie 450-4 WS<br />

WS type with water cooling and<br />

separately removable wire feed<br />

box<br />

MIG soldering with the PRO-MIG<br />

Perfect for the automotive industry-<br />

Welding from sensational 15 A on<br />

The PRO-MIG 230-4 AM and 230-2 AM are in particular<br />

appropriate to be used in the thin plate<br />

processing from sensational 15 A<br />

welding current on. The special Synergie<br />

programs for MIG/MAG welding and<br />

MIG soldering of galvanized and aluminized<br />

bodywork steel sheets are making it<br />

furthermore a perfect device for motor vehicle<br />

workshops.<br />

Unique in this class:<br />

Universal for all PRO-MIG types:<br />

· Revolutionary IWC operating concept<br />

Contrary to the other suppliers you will get the<br />

advantages of the intelligent operating concept<br />

from the smallest up to the largest<br />

system.<br />

· Digital volts and amperes display with hold<br />

function of the used parameters<br />

Perfect for certification welding works to transfer<br />

the welding data. The used<br />

parameters will remain saved until the<br />

following operation and will then be displayed.<br />

The PRO-MIG 230-4 AM with its powerful<br />

4-roll drive and the additional Synergie<br />

characteristic curves for welding<br />

aluminum materials is a real all-rounder.<br />

Anyone who needs to weld thin wires should not<br />

do without this 4-roll drive. This way, fine welding<br />

works on thin steel sheets can be performed<br />

even more process-safe.<br />

PRO-MIG 300-4 synergie<br />

· Automatic setting of the welding parameters<br />

according to the material thickness<br />

Rapid, simple and safe thanks to the<br />

database support<br />

· Particularly high duty cycle<br />

· Best cost-performance ratio<br />

Most modern technology and maximum equipment

MIG-MAG inert gas welding devices<br />

Made in Germany<br />

Compact line PRO-MIG synergie, gas-cooled<br />

MIG soldering MIG soldering<br />

Model range PRO-MIG synergie 230-2 AM 230-4 AM 280-4 310-4<br />

Item No 108 1025 108 1024 108 1028 108 1031<br />

€ plus VAT 1'350.00 1'560.00 1'810.00 1.960,00<br />

Re<strong>com</strong>mended welding torch kit 15/25 15/25 25/35 25/35<br />

Item No 109 1510 109 1510 109 2510 109 2510<br />

Technical data<br />

Wire Ø steel/stainless steel* mm 0.6-1.0 0.6-1.0 0.8-1.2 0.8-1.2<br />

Wire Ø aluminum* mm - 0.8 - 1.0<br />

Wire CuSi* mm 0.-1. 0.-1. - -<br />

Wire feed m/min 0.3-20 0.3-20 0.3-200,3-20<br />

Setting range [A] 15-230 15- 230 35-280 35-300<br />

Operating time at lmax. 20° C (40° C) [%] 40 40 40 40<br />

Welding current at 100% ED (40° C) [A] 150 150 180 210<br />

Open-circuit voltage [V] 15-37 15-37 17-37 17-40<br />

Switching stages 10 10 10 12<br />

Wire feed devices 2-roll 4-roll 4-roll 4-roll<br />

Current supply [V] 400 400 400 400<br />

Continuous power at 100% ED [kVA] 4,9 4,9 6,3 6,6<br />

Fuse protection (slow-blow) [A] 16 16 16 32<br />

Power ratio [cos phi] 0.96 0.96 0.96 0.96<br />

Insulation class H H H H<br />

Type of cooling AF AF AF AF<br />

Torch cooling Gas Gas Gas Gas<br />

Protective system IP 21 IP 21 IP 21 IP 21<br />

Weight [kg] 68 68 72 78<br />

Dimensions L/W/H [mm] 800 x 320 x 620<br />

*weldable materials, supported with program<br />

The right to make technical modifications is reserved. Additional equipment for the illustrated devices are available at additional cost.<br />

Schweißkraft devices are supplied with the S-sign according to the standard EN 60 974-1.<br />

Industry line PRO-MIG synergie, gas- and water-cooled<br />

Model range PRO-MIG synergie 300-4 350-4 W 450-4 WS<br />

Item No 108 1030 108 1036 108 1045<br />

€ plus VAT 2'470.00 3'490.00 4'230.00<br />

Re<strong>com</strong>mended welding torch kit 25/35 400/50 400/50<br />

Item No 109 2510 109 4010 109 4010<br />

Technical data<br />

Wire Ø steel/stainless steel* mm 0.8-1.2 0.8-1.6 0.8-1.6<br />

Wire Ø aluminum* mm 1.0- 1.2 1.0 1.2-1.0- 1,2<br />

Wire feed* m/min 0.3-20 0.3-20 0.3-20<br />

Setting range [A] 40-300 40-350 45-450<br />

Operating time at lmax. 20° C (40° C) [%] 50 50 50<br />

Welding current at 100% ED (40° C) [A] 210 260 320<br />

Open-circuit voltage [V] 17-42 18-43 18-51<br />

Switching stages 12 20 20<br />

Wire feed devices 4-roll 4-roll 4-roll<br />

Current supply [V] 400 400 400<br />

Endrance at 100% ED [kVA] 6,9 9,6 12,7<br />

Fuse protection (slow-blow) [A] 32 32 32<br />

Power factor [cos phi] 0.96 0.97 0.96<br />

Insulation class H H H<br />

Type of cooling AF AF AF<br />

Torch cooling Gas Gas/Water Gas/Water<br />

Protective system IP 23 IP 23 IP 23<br />

Weight [kg] 110 120 137<br />

Dimensions L/W/H mm 1040 x 560 x 850 1040 560 1400<br />

*weldable materials, supported with program<br />

The right to make technical modifications is reserved. Additional equipment for the illustrated devices are available at additional cost.<br />

Schweißkraft devices are supplied with the S-sign according to the standard EN 60 974-1.<br />

Standard equipment:<br />

multiple switch control, gas-cooled MIG-MAG welding devices; 4-roll drive,<br />

2/4-cycle point/interval control, SMC, mains cable with plug 5m, box type (S) without intermediate hose<br />

package, central connection system Binzel, digital display for welding voltage, welding current and material<br />

thickness, operating and temperature display,<br />

without welding torch, without ground cable, without pressure regulator (accessories)<br />

18<br />

PRO-MIG synergie 450-4 WS<br />

Type with separate<br />

detachable wire feed box

Equipment options PRO-MIG synergie<br />

Item No<br />

Designation<br />

103 4004 Air filter attachment PRO-MIG 300-4 AM to 450-4 <strong>com</strong>plete<br />

103 3667 Driving car for feed box<br />

€ plus VAT<br />

185.00<br />

80.00<br />

Accessories-welding torch kits<br />

consisting of: welding torch 4m, ground cable (Grca), 315 bar argon/CO2 pressure regulator (Pressreg)<br />

Item No<br />

Designation<br />

109 1510 welding torch kit 15/25 SMB 15/4m gas-cooled, Grca 25mm² 4m, Pressreg<br />

109 2510 welding torch kit 25/35 SMB 25/4m gas-cooled, Grca 35mm² 4m, Pressreg<br />

109 3610 welding torch kit 36/70 SMB 36/4m gas-cooled, Grca 70mm² 4m, Pressreg<br />

109 4010 welding torch kit 400/50 SMB 400/4m gas-cooled, Grca 50mm² 4m, Pressreg<br />

109 4011 welding torch kit 400/70 SMB 400/4m gas-cooled, Grca 70mm² 4m, Pressreg<br />

*The prices for welding torch kit are only valid when a welding device is purchased<br />

€ plus VAT<br />

109.00<br />

139.00<br />

185.00<br />

229.00<br />

239.00<br />

Air filter attachment<br />

MIG / MAG<br />

Kit of wearing parts<br />

Item No. Designation<br />

€ plus VAT<br />

109 1500 Kit of wearing parts SMB 15<br />

22.90<br />

consisting of: 1 x gas nozzle support, 3 x retaining spring , 3 x power nozzle 0.6/0.8 mm<br />

each 3 x gas nozzle conical, 1 x gas nozzle cylindrical size 12, sorting box large<br />

109 2500 Kit of wearing parts SMB 25<br />

26.90<br />

consisting of: 3 x retaining spring, 2 x blast connection, 5 x power nozzle 0.6/ 0.8 mm each<br />

2 x gas nozzle conical, 1 x gas nozzle cylindrical size 12, sorting box large<br />

109 3600 Kit of wearing parts SMB 36<br />

consisting of: 2 x blast connection M6, 3 x gas distributor brown, 5 x power nozzle<br />

44.90<br />

0.8/1.0/1.2 mm each, 4 x gas nozzle conical, 1 x gas nozzle cylindrical, sorting box large<br />

109 4000 Kit of wearing parts SMB 400<br />

43.90<br />

consisting of: 2 x ring, 2 x blast connection M8, 3 x gas distributor brown highly refractory,<br />

5 x power nozzle 1.0 mm, 10 x power nozzle 1.2 mm, 4 x gas nozzle conical,<br />

1 x gas nozzle cylindrical, sorting box large<br />

Kit of wearing parts<br />

Intermediate hose packages PRO-MIG 350-4 W / 450-4 WS<br />

Item No<br />

Designation<br />

101 0235 Interhose pluggable 1.4 m length<br />

101 0236 Interhose pluggable 5.0 m length<br />

101 0237 Interhose pluggable 10.0 m length<br />

€ plus VAT<br />

186.00<br />

320.00<br />

585.00<br />

Wire transport roller 2-roll wire feed<br />

Item No<br />

Designation<br />

101 3706 Wire transport roller 0.6/0.8 mm for 2-roll drive<br />

101 3708 Wire transport roller 0.8/1.0 mm for 2-roll drive<br />

101 3710 Wire transport roller 1.0/1.2 mm for 2-roll drive<br />

€ plus VAT<br />

30.00<br />

30.00<br />

30.00<br />

Wire transport roller 4-roll wire feed<br />

Item No<br />

Designation<br />

103 3600 Pair of transport rollers solid wire with toothed ring 0.6 mm<br />

103 3601 Pair of transport rollers solid wire with toothed ring 0.8 mm<br />

103 3602 Pair of transport rollers solid wire with toothed ring 1.0 mm<br />

103 3603 Pair of transport rollers solid wire with toothed ring 1.2 mm<br />

103 3604 Pair of transport rollers solid wire with toothed ring 1.6 mm<br />

103 3612 Pair of transport rollers tubular wire with toothed ring 1.2 mm<br />

103 3616 Pair of transport rollers tubular wire with toothed ring 1.6 mm<br />

103 3618 Pair of transport rollers tubular wire with toothed ring 1.8 mm<br />

up to 2.4 mm<br />

€ plus VAT<br />

58.00<br />

58.00<br />

58.00<br />

58.00<br />

58.00<br />

95.00<br />

95.00<br />

95.00<br />

Pair of transport rollers<br />

with toothed ring<br />

19

MIG-MAG inert gas welding devices<br />

SMB 15 gas-cooled<br />

for PRO-MIG 230-2 AM / 230-4 AM<br />

SMB 25 gas-cooled<br />

for PRO-MIG 280-4 / 310-4 / 300-4<br />

Item No. Designation<br />

109 1503 SMB 15 / 3 m with pushbutton<br />

109 1504 SMB 15 / 4 m with pushbutton<br />

109 1505 SMB 15 / 5 m with pushbutton<br />

109 1513 SMB 15 / 3 m for aluminum<br />

€ plus VAT<br />

69.00<br />

74.00<br />

84.00<br />

105.00<br />

Item No. Designation<br />

109 2503 SMB 25 / 3 m with pushbutton<br />

109 2504 SMB 25 / 4 m with pushbutton<br />

109 2505 SMB 25 / 5 m with pushbutton<br />

109 2513 SMB 25 / 3 m for aluminum<br />

€ plus VAT<br />

94.00<br />

99.00<br />

115.00<br />

129.00<br />

No. Designation PU Item No.<br />

1 Neck of torch SMB 15 109 1530<br />

2 Gas nozzle support 10 109 1531<br />

3 Retaining spring 10109 1535<br />

4 Power nozzle M6 Ø 0.6mm/25mm 10 109 1540<br />

Ø 0.8mm/25mm 10 109 1542<br />

Ø 1.mm/25mm 10 109 1544<br />

Power nozzle aluminum Ø 1.0mm/25mm10 109 1547<br />

5 Gas nozzle conical Ø 12.0/53 mm 10 109 1550<br />

Gas nozzle cylindrical Ø 16.0 mm 10 109 1554<br />

Spot-gas nozzle 10 109 1552<br />

6 Spacer 10 109 1591<br />

7 Spacer black 10 109 1588<br />

8 Handle shell red 109 1517<br />

9 Pushbutton 109 1518<br />

10 Screw handle shell 10 109 1590<br />

11 Ring 1091592<br />

12 Antikink spring 1091587<br />

13 Antikink machine-sided 109 1586<br />

14 Terminal nut 1 109 1581<br />

15 Screw terminal nut 10 109 1589<br />

16 Main plug solid pins 109 1582<br />

Kit of wearing parts SMB 15 109 1500<br />

For guide spirals/Teflon core refer to page 12<br />

€ plus VAT/piece<br />

10.90<br />

2.65<br />

0.66<br />

1.00<br />

1.00<br />

1.00<br />

1.10<br />

1.99<br />

1.99<br />

4.00<br />

2.80<br />

2.40<br />

10.00<br />

5.50<br />

0.15<br />

2.20<br />

4.80<br />

3.90<br />

2.90<br />

0.30<br />

18.40<br />

22.90<br />

No. Designation PU Item No.<br />

1 Neck of torch SMB 25 109 2530<br />

2 Retaining spring 10 109 2535<br />

3 Blast connection 10 109 2560<br />

4 Power nozzle M6 Ø 0.8mm/28mm 10 109 2542<br />

Ø 1.mm/28mm 10 109 2544<br />

Ø 1.2mm/28mm 10 109 2546<br />

Power nozzle aluminum Ø 1.0mm/28mm 10 109 2548<br />

Ø 1.2mm/28mm 10 109 2549<br />

5 Gas nozzle conical Ø 14.5/57 mm 10 109 2550<br />

Gas nozzle cylindrical Ø 18.0 mm 10 109 2554<br />

Spot-gas nozzle 10 109 2552<br />

6 Spacer black 10 109 1588<br />

7 Handle shell red 109 1517<br />

8 Pushbutton 109 1518<br />

9 Screw handle shell 10 109 1590<br />

10 Ring 109 1592<br />

11 Antikink spring 109 2561<br />

12 Antikink machine-sided 109 1586<br />

13 Terminal nut 1 109 1581<br />

14 Screw terminal nut 10 109 1589<br />

15 Main plug solid pins 109 1582<br />

Kit of wearing parts SMB 25 109 2500<br />

For guide spirals/Teflon core refer to page 12<br />

€ plus VAT/piece<br />

21.70<br />

0.66<br />

1.69<br />

1.30<br />

1.30<br />

1.30<br />

1.80<br />

1.80<br />

2.49<br />

2.80<br />

5.50<br />

2.40<br />

10.00<br />

5.50<br />

0.15<br />

2.20<br />

5.00<br />

3.90<br />

2.90<br />

0.30<br />

18.40<br />

26.90<br />

Technical data:<br />

Charge: 180 A CO2 / 150 A mixed gas<br />

ED 60 %<br />

Wire Ø: 0.6-1.0 mm<br />

Technical data:<br />

Charge: 230 A CO2 / 200 A mixed gas<br />

ED 60 %<br />

Wire Ø: 0.8-1.2 mm<br />

20

SMB 36 gas-cooled<br />

for PRO-MIG 280-4 / 310-4 / 300-4<br />

SMB 400 water-cooled<br />

for PRO-MIG 350-4 W / 450-4 WS<br />

MIG / MAG<br />

Item No. Designation<br />

109 3603 SMB 36 / 3 m with pushbutton<br />

109 3604 SMB 36 / 4 m with pushbutton<br />

109 3605 SMB 36 / 5 m with pushbutton<br />

109 3613 SMB 36 / 3 m for aluminum<br />

€ plus VAT<br />

130.00<br />

145.00<br />

160.00<br />

164.00<br />

Item No. Designation<br />

109 4003 SMB 400 / 3 m with pushbutton<br />

109 4004 SMB 400 / 4 m with pushbutton<br />

109 4005 SMB 400 / 5 m with pushbutton<br />

109 4013 SMB 400 / 3 m for aluminum<br />

€ plus VAT<br />

210.00<br />

225.00<br />

250.00<br />

259.00<br />

No. Designation PU Item No.<br />

1 Neck of torch SMB 36 109 3630<br />

2 Blast connection M6/ 28 mm 10 109 3660<br />

3 Gas distributor brown S 10 109 3661<br />

4 Power nozzle M6 Ø 0.8mm/28mm 10 109 2542<br />

Ø 1.mm/28mm 10 109 2544<br />

Ø 1.2mm/28mm 10 109 2546<br />

Power nozzle aluminum Ø 1.0mm/28mm10 109 2548<br />

Ø 1.2mm/28mm 10 109 2549<br />

5 Gas nozzle conical Ø 16,0-84 mm 10 109 3650<br />

Gas nozzle cylindrical Ø 19.0 mm 10 109 3651<br />

Gas nozzle cylindrical Ø 10 109 3654<br />

7 Handle shell red 109 1517<br />

8 Pushbutton 109 1518<br />

9 Screw pushbutton 10 109 1590<br />

10 Ring 109 1592<br />

11 Antikink spring 109 2561<br />

12 Antikink machine-sided 109 1586<br />

13 Terminal nut 1 109 1581<br />

14 Screw terminal nut 10 109 1589<br />

15 Main plug solid pins 109 1582<br />

Kit of wearing parts SMB 36 109 3600<br />

For guide spirals/Teflon core refer to page 12<br />

€ plus VAT/piece<br />

44.00<br />

1.69<br />

1.85<br />

1.30<br />

1.30<br />

1.30<br />

1.80<br />

1.80<br />

3.75<br />

3.85<br />

3.75<br />

10.00<br />

5.50<br />

0.15<br />

2.20<br />

5.00<br />

3.90<br />

2.90<br />

0.30<br />

18.40<br />

44.90<br />

No. Designation PU Item No.<br />

1 Neck of torch SMB 400 109 4030<br />

2 Ring 10 109 4031<br />

3 Blast connection M8/25 mm 10 109 4060<br />

4 Gas distributor brown highly refractory 10 109 4061<br />

5 Power nozzle M8 Ø 0.8mm/30mm 10 109 4042<br />

Ø 1.0mm/30mm 10 109 4044<br />

Ø 1.2mm/30mm 10 109 4046<br />

Power nozzle aluminum Ø 1.0mm/30mm10 109 4048<br />

Ø 1.2mm/30mm 10 109 4049<br />

6 Gas nozzle conical Ø 16.0/84 mm 10 109 2650<br />

Gas nozzle cylindrical Ø 19.0 mm 10 109 2654<br />

Spot-gas nozzle 109 2652<br />

7 Handle shell red 109 1517<br />

8 Pushbutton 109 1518<br />

9 Screw handle shell 10 109 1590<br />

10 Ring 109 1592<br />

11 Antikink spring 109 2433<br />

Socket joint 109 2562<br />

12 Antikink machine-sided <strong>com</strong>plete 109 2434<br />

13 Terminal nut 1 109 1581<br />

14 Screw terminal nut 10 109 1589<br />

15 Main plug solid pins 109 4082<br />

Kit of wearing parts SMB 400109 4000<br />

For guide spirals/Teflon core refer to page 12<br />

€ plus VAT/piece<br />

69.00<br />

0.70<br />

1.69<br />

1.85<br />

1.70<br />

1.70<br />

1.70<br />

1.70<br />

1.70<br />

3.40<br />

3.75<br />

4.70<br />

10.00<br />

5.50<br />

0.15<br />

2.20<br />

4.30<br />

3.70<br />

15.30<br />

2.90<br />

0.30<br />

24.50<br />

43.90<br />

Technical data:<br />

Charge: 300 A CO2 / 270 A mixed gas<br />

ED 60 %<br />

Wire Ø: 0.8-1.2 mm<br />

Technical data:<br />

Charge: 400 A CO2 / 350 A mixed gas<br />

ED 100 %<br />

Wire Ø: 0.8-1.6 mm<br />

21

22<br />

PRO-ARC ®<br />

PRO-ARC 300-4<br />

PRO-ARC 450-4 WS

PRO-ARC ® -infinitely variable MIG-MAG protective gas welding devices<br />

The link between MIG-MAG devices with step switching and infinitely variable<br />

impulsed current sources including innovative IWC control<br />

MIG / MAG<br />

The arc length will not be controlled by<br />

measuring the arc voltage and the welding current,<br />