Asahi Kasei Plastics North America Inc. Xyron® G702H ... - Promaplast

Asahi Kasei Plastics North America Inc. Xyron® G702H ... - Promaplast

Asahi Kasei Plastics North America Inc. Xyron® G702H ... - Promaplast

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

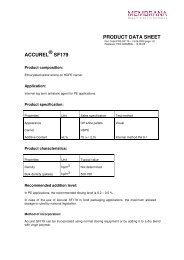

Xyron® <strong>G702H</strong><br />

<strong>Asahi</strong> <strong>Kasei</strong> <strong>Plastics</strong> <strong>North</strong> <strong>America</strong> <strong>Inc</strong>. - Polyphenylene Ether + PS<br />

Actions<br />

Thursday, May 22, 2008<br />

Unit System: English<br />

Legend (Open)<br />

General<br />

Material Status<br />

Availability<br />

Filler / Reinforcement<br />

Uses<br />

Forms<br />

Processing Method<br />

General Information<br />

Commercial: Active<br />

<strong>North</strong> <strong>America</strong><br />

Glass fiber reinforcement, 20 % Filler by Weight<br />

Electrical/Electronic Applications<br />

Pellets<br />

Injection Molding<br />

ASTM and ISO Properties 1<br />

Physical Nominal Value Unit Test Method<br />

Specific Gravity 1.20 ASTM D792<br />

Density 1.20 g/cm³ ISO 1183<br />

Molding Shrink (Flow) 0.20 to 0.40 % ASTM D955<br />

Water Absorption (24 hr, 73 °F) 0.060 % ASTM D570<br />

Water Absorption (73 °F, 24 hr) 0.060 % ISO 62<br />

Mechanical Nominal Value Unit Test Method<br />

Tensile Strength (73 °F) 13600 psi ASTM D638<br />

Tensile Stress (Yield, 73 °F) 13600 psi ISO 527-1, -2<br />

Tensile Elongation (Break, 73 °F) 5.0 % ASTM D638<br />

Tensile Strain (Break, 73 °F) 2.0 % ISO 527-1, -2<br />

Flexural Modulus (73 °F) 725000 psi ASTM D790<br />

Flexural Modulus (73 °F) 703000 psi ISO 178<br />

Flexural Strength (73 °F) 19900 psi ASTM D790<br />

Flexural Strength (73 °F) 21600 psi ISO 178<br />

Impact Nominal Value Unit Test Method<br />

Charpy Notched Impact Strength (73 °F) 3.81 ft·lb/in² ISO 179/1<br />

Notched Izod Impact ASTM D256<br />

(73 °F, 0.126 in) 1.84 ft·lb/in<br />

(73 °F, 0.252 in) 1.46 ft·lb/in<br />

Thermal Nominal Value Unit Test Method<br />

Deflection Temperature Under Load (264 psi, Unannealed) 284 °F ASTM D648<br />

Heat Deflection Temperature (264 psi, Unannealed) 282 °F ISO 75A-1, -2<br />

CLTE, Flow (-30°C to 65°C) 0.000019 in/in/°F ASTM D696<br />

Coefficient of Linear Thermal Expansion, Flow (-30°C to 65°C) 0.000019 in/in/°F ISO 11359-1, -2<br />

Electrical Nominal Value Unit Test Method<br />

Surface Resistivity 1.0E+16 ohms ASTM D257<br />

Surface Resistivity 1.0E+16 ohms IEC 60093<br />

Volume Resistivity 1.0E+16 ohm·cm ASTM D257<br />

Volume Resistivity 1.0E+16 ohm·cm IEC 60093<br />

Dielectric Strength 2 (0.0787 in) 1090 V/mil ASTM D149<br />

Dielectric Constant ASTM D150<br />

(60 Hz) 3.100<br />

(1E+6 Hz) 3.100

Dielectric Constant IEC 60250<br />

(100 Hz) 3.100<br />

(1E+6 Hz) 3.100<br />

Dissipation Factor ASTM D150<br />

(60 Hz) 0.00060<br />

(1E+6 Hz) 0.0011<br />

Dissipation Factor IEC 60250<br />

(100 Hz) 0.00600<br />

(1E+6 Hz) 0.00110<br />

Arc Resistance 70.0 sec ASTM D495<br />

Electric Strength (0.0787 in) 1100 V/mil IEC 60243-1<br />

Flammability Nominal Value Unit Test Method<br />

Flame Rating - UL UL 94<br />

(0.0630 in) HB<br />

(0.126 in) HB<br />

Additional Properties<br />

The value listed as Mold Shrinkage, was tested in accordance with <strong>Asahi</strong> <strong>Kasei</strong> method.<br />

Processing Information<br />

Injection Nominal Value Unit<br />

Drying Temperature 175 to 195 °F<br />

Drying Time 2.0 to 4.0 hr<br />

Drying Time, Maximum 8.0 hr<br />

Suggested Max Regrind 20 %<br />

Rear Temperature 430 to 500 °F<br />

Middle Temperature 435 to 510 °F<br />

Front Temperature 445 to 520 °F<br />

Nozzle Temperature 445 to 520 °F<br />

Mold Temperature 120 to 180 °F<br />

Vent Depth 0.0012 to 0.0020 in<br />

Injection Notes<br />

Screw Type: General Purpose<br />

Nozzle Tip: General Purpose<br />

Max. spiral flow distance: 2mm=17 in. 3mm=21 in.<br />

Vent width: 5.0 to 10 mm<br />

Boss Venting - Clearance at pin: 0.03 to 0.05 mm<br />

Boss Venting - Clearance at sleeve: 0.5 to 1 mm<br />

Special considerations: If splay is noticed, check melt temperature and moisture content of the material. If the splay is shaped like a U, it could<br />

be material that is not molten.<br />

1 Typical properties: these are not to be construed as specifications.<br />

2 Method A (Short-Time)<br />

Notes<br />

Copyright © 2008 IDES - The <strong>Plastics</strong> Web®<br />

The information presented on this data sheet was acquired by IDES from the producer of the material. IDES makes substantial efforts to<br />

assure the accuracy of this data. However, IDES assumes no responsibility for the data values and strongly encourages that upon final<br />

material selection, data points are validated with the material supplier.