Unistat® 510w - HUBER

Unistat® 510w - HUBER

Unistat® 510w - HUBER

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

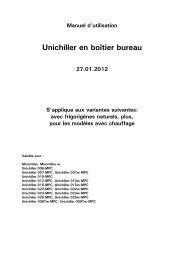

1. Simulated exothermic of 600 W @ 0 °C<br />

68 l www.huber-online.com<br />

Process temperature rises<br />

by less than 2 K<br />

Heater turned “On“<br />

50 litre glass reactor<br />

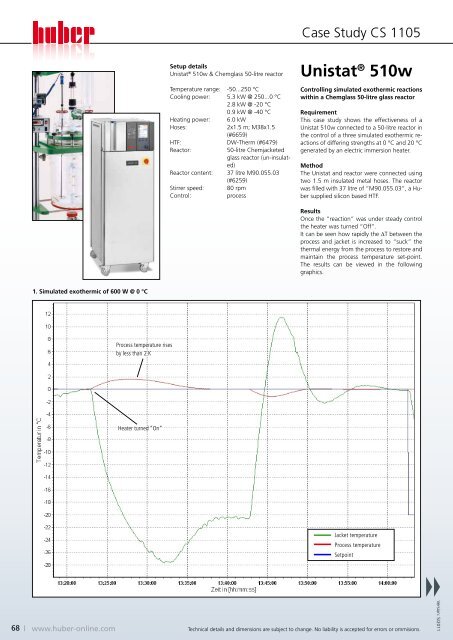

Setup details<br />

Unistat ® <strong>510w</strong> & Chemglass 50-litre reactor<br />

Temperature range: -50...250 °C<br />

Cooling power: 5.3 kW @ 250...0 °C<br />

2.8 kW @ -20 °C<br />

0.9 kW @ -40 °C<br />

Heating power: 6.0 kW<br />

Hoses: 2x1.5 m; M38x1.5<br />

(#6659)<br />

HTF: DW-Therm (#6479)<br />

Reactor: 50-litre Chemjacketed<br />

glass reactor (un-insulated)<br />

Reactor content: 37 litre M90.055.03<br />

(#6259)<br />

Stirrer speed: 80 rpm<br />

Control: process<br />

Case Study CS 1105<br />

Unistat ® <strong>510w</strong><br />

Controlling simulated exothermic reactions<br />

within a Chemglass 50-litre glass reactor<br />

Requirement<br />

This case study shows the effectiveness of a<br />

Unistat <strong>510w</strong> connected to a 50-litre reactor in<br />

the control of a three simulated exothermic reactions<br />

of differing strengths at 0 °C and 20 °C<br />

generated by an electric immersion heater.<br />

Method<br />

The Unistat and reactor were connected using<br />

two 1.5 m insulated metal hoses. The reactor<br />

was filled with 37 litre of “M90.055.03”, a Huber<br />

supplied silicon based HTF.<br />

Results<br />

Once the “reaction” was under steady control<br />

the heater was turned “Off”.<br />

It can be seen how rapidly the DT between the<br />

process and jacket is increased to “suck” the<br />

thermal energy from the process to restore and<br />

maintain the process temperature set-point.<br />

The results can be viewed in the following<br />

graphics.<br />

Jacket temperature<br />

Process temperature<br />

Setpoint<br />

Technical details and dimensions are subject to change. No liability is accepted for errors or ommisions.<br />

Version: 5/2011

Version: 5/2011<br />

Case Study CS 1105<br />

2. Simulated exothermic of 600 W @ 20 °C<br />

3. Simulated exothermic of 900 W @20 °C<br />

Technical details and dimensions are subject to change. No liability is accepted for errors or ommisions.<br />

Jacket temperature<br />

Process temperature<br />

Setpoint<br />

Jacket temperature<br />

Process temperature<br />

Setpoint<br />

www.huber-online.com l<br />

69