Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2 0 1 3<br />

www.indutherm.de<br />

Blue Power.<br />

<strong>Top</strong> <strong>Class</strong> <strong>Casting</strong> <strong>Technology</strong>

Indutherm – your partner for<br />

innovative metal casting solutions<br />

2<br />

Metal casting technology is our world. From<br />

the very beginning we have been exclusively<br />

focused on the development and<br />

construction of melting and casting systems<br />

and can offer a wide range of machines for<br />

many different purposes.<br />

Capability based on experience and<br />

research<br />

We generally develop and test our systems in<br />

close collaboration with users in a wide range<br />

of industries.<br />

foundries<br />

jewellery industry<br />

rapid prototyping<br />

automotive and<br />

component industries<br />

aircraft industry<br />

medical and dental<br />

technologies<br />

mould designers<br />

artists<br />

The conflict between the varying requirements<br />

and areas of use has been fundamental to<br />

our expertise. However, numerous machines<br />

have also resulted from research projects that<br />

we frequently carry out in conjunction with<br />

well-known research partners.<br />

All of our clients can take advantage of this<br />

expertise, in the form of advanced technology<br />

and competent consulting and support. We<br />

would be happy to meet up with you sometime<br />

at one of the international casting symposiums<br />

that we frequently participate in and where we<br />

give talks on different casting subjects.<br />

Cost-effectiveness through quality<br />

The perfect result in the least time and for the<br />

least cost<br />

Three factors are critical to cost-effective casting:<br />

• speed and, ideally, no costly testing<br />

for high quality casting results<br />

• casting processes that can be replicated at<br />

any time<br />

• the higher the casting quality, the less postproduction<br />

work there is and the lower the<br />

costs are.<br />

This is why our motto is "Cost-effectiveness<br />

through quality" – and this is reflected in every<br />

detail in the construction of our machines.

This example of extremely filigree casting demonstrates obviously the possibilities of our technology.<br />

Energy efficiency that goes that bit<br />

further<br />

Anyone who relies on high performance values<br />

alone when manufacturing casting machines<br />

is usually thinking too narrowly. What matters<br />

most is what is ultimately accomplished with<br />

each kilowatt hour consumed. The induction<br />

generators and inductors in our casting and<br />

melting machines are designed with the<br />

highest possible level of effectiveness in mind.<br />

Efficient insulation ensures that the induction<br />

generated loses as little energy as possible for<br />

fast melting of the metal. The thermal insulation<br />

around the inductor and crucible effectively<br />

reduces heat radiation; the melting<br />

chamber acts like a Faraday cage to prevent<br />

the radiation of electromagnetic waves.<br />

The infused stainless steel coolant water lines<br />

further improve the shielding effect. With open<br />

melting machines that cannot use the 'cage<br />

effect', the radiation loss is reduced almost as<br />

effectively through the use of ring-shaped<br />

ferrites – and at the same time the electrosmog<br />

load is drastically reduced.<br />

Less energy for cooling<br />

Efficient energy use also reduces energy<br />

consumption for water re-cooling in the<br />

machine and the potential need for air-conditioning<br />

in the foundry. Moreover, a smaller<br />

installed load is sufficient.<br />

Indutherm machines save energy with<br />

peripheral devices too<br />

Thanks to the flask lift you can use flasks with<br />

no flange, offering you two ways to save<br />

money: flangeless flasks are much cheaper<br />

and require less space in your oven. In other<br />

words: with the same energy consumption<br />

you can burn ~50% more flasks – or you can<br />

work with a smaller oven.<br />

The Indutherm<br />

concept for energy<br />

efficient melting<br />

High level of efficiency<br />

for generators and inductors<br />

+<br />

Optimised use<br />

of induction power<br />

+<br />

Effective insulation<br />

against heat radiation<br />

= High melting performance<br />

with reduced power<br />

consumption<br />

flasks with flange<br />

flasks without flange<br />

3

Always in focus: the most economical<br />

solution for your demands.<br />

Easy to service:<br />

replacing the generator by opening only<br />

two screws<br />

Durable and reliable<br />

It’s important that your production<br />

equipment runs perfectly for many years from<br />

day one. Our internal quality management<br />

ensures high standards from the first screw<br />

to the last. In the event of revisions, updates<br />

or any kind of problem, we create detailed<br />

documentation for each machine, with<br />

pictures, software backups and more.<br />

Easy to service<br />

Simple replacement of all major components<br />

guarantees fast and easy servicing, minimises<br />

the risk of lengthy production interruptions<br />

and ensures long term reliability. All<br />

INDUTHERM machines with an induction<br />

generator may be equipped with a GSM<br />

modem for remote service. This enables us<br />

to connect us directly to the machine<br />

• for a regular check-up of the machine<br />

• for fast service in the event of malfunctions<br />

• for detailed help and advice with<br />

complicated casting procedures<br />

• for software updates.<br />

Simple replacement of all important components<br />

guarantees fast and easy servicing,<br />

minimises the risk of lengthy production<br />

interruptions and ensures long term<br />

reliability.<br />

Every product is only as good as the<br />

customer service supporting it.<br />

Our sales and service partners provide<br />

professional support around the world. You<br />

can find the dealer for your country on our<br />

website www.indutherm.de, in the<br />

"Company" section.<br />

■ Indutherm distribution<br />

4

More than just casting machines<br />

Original Indutherm consumables: Quality<br />

pays off!<br />

Our own high quality consumables, such as<br />

crucibles, dies or sealing rods, are specially<br />

developed for Indutherm machines. Only<br />

using original Indutherm consumables makes<br />

sense for a number of reasons:<br />

1. Compact graphite ensures greater<br />

durability for crucibles and sealing rods<br />

2. Higher quality casting results<br />

• Less contamination from extraneous<br />

material like lead etc<br />

• Less use of graphite in alloys and casts<br />

• Less gas porosity => reduced postproduction<br />

costs, less material loss<br />

3. Less stress for the casting machines<br />

• Our crucibles have lower electrical<br />

resistance, meaning that there is less<br />

stress on the inductor, condenser<br />

assembly, transformer and generator –<br />

resulting in greater durability for these<br />

components<br />

• Less power consumption<br />

4. An extra two years of warranty for free if you<br />

only use original Indutherm consumables.<br />

<strong>Casting</strong> simulation: know what you’re doing<br />

before you do it!<br />

Professional computer simulation of the<br />

casting process offers you peace of mind<br />

before embarking on complicated casting jobs:<br />

instead of tedious and costly failures, we can<br />

determine all the relevant parameters<br />

beforehand – mould construction, positioning<br />

of sprues, temperature, pressure relationships<br />

– based on your CAD data<br />

The casting process from start to finish from a<br />

single supplier – and perfectly tuned to your<br />

needs<br />

We offer not only perfectly tuned casting<br />

machines, but also competent consultation in<br />

the various moulding, casting and finishing<br />

processes.<br />

Moreover we can support you in planning and<br />

equipping your complete foundry.<br />

5

Your project...<br />

aluminium,<br />

copper,<br />

brass, zinc,<br />

gold, silver<br />

casting<br />

• rapid Prototyping<br />

• automotive parts<br />

• aerospace components<br />

• other technical parts<br />

• jewellery<br />

• arts, handicraft, models<br />

steel,<br />

titanium,<br />

platinum,<br />

palladium<br />

casting<br />

• medical and dental technology<br />

• technical parts<br />

• metallurgic R & D<br />

• moulds<br />

• jewellery<br />

melting and<br />

pouring<br />

of different<br />

metals<br />

• for metals developing a lot of<br />

smoke and oxides during<br />

melting<br />

• for large quantities of metal<br />

(recycling or own alloys)<br />

• for casting large,<br />

heavy components<br />

production of<br />

semi-finished<br />

material<br />

• wires and tubes<br />

• strips, sheet and bars<br />

• granules<br />

• micro granules

Our solution...<br />

MC series<br />

for small parts, small<br />

batches and quick casts<br />

8<br />

Vacuum Pressure <strong>Casting</strong> Machines<br />

MC 60 and VC series<br />

• two chamber differential pressure system (VC series)<br />

• casting into flasks/investment molds, also<br />

suited for shell casting<br />

• up to 12,000 ccm crucible volume<br />

VTC series<br />

for all kind of metals<br />

VC series<br />

for jewellery and other<br />

fine parts<br />

14<br />

18<br />

MC series and VTC series<br />

• vacuum pressure casting systems<br />

• one or two chamber differential pressure systems<br />

• tilting casting principle<br />

• casting into flasks/investment molds or into ingot molds<br />

High Temperature Melting Machines<br />

MU 100 C / MU 200 C, MUV 100 C / MUV200 C and TF 2000 C / TF 4000 C<br />

• for hand pouring into flasks or shell molds (MU / MUV)<br />

• or for tilting pouring into flasks, shell molds or ingot molds (TF)<br />

VC series<br />

for large parts<br />

MU / MUV series<br />

for melting and<br />

handpouring<br />

TF series<br />

for melting and casting<br />

large quantities<br />

24<br />

26<br />

28<br />

Open Melting Machines and Tilting Furnaces,<br />

MU and TF series<br />

• MU/MUV series for hand pouring into flasks or<br />

ingot molds<br />

• TF series for tilting pouring into flasks, shell molds<br />

or ingot molds, up to 12,000 ccm crucible volume<br />

MU / MUV C series<br />

TF C series<br />

for high temperature<br />

melting<br />

recycling and<br />

ingot casting<br />

30<br />

32<br />

Continuous <strong>Casting</strong> Machines CC series<br />

Granulating Units GU series<br />

Sintering Units SU series<br />

• continuous casting machines also available as VCC versions with<br />

vacuum function for de-gassing of the metal and reduced oxidation<br />

• GU units for the productions of granules or micro granules<br />

• SU units for the productions of multicolour rings<br />

(diffusion bonding)<br />

CC series<br />

for semi-finished<br />

products<br />

granulating<br />

sintering<br />

34<br />

36<br />

38

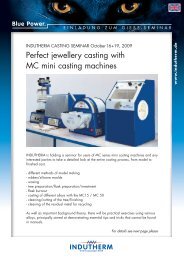

MC 15+ and MC 60 tabletop casting machines<br />

The MC 15+<br />

is designed…<br />

• for the very fast and<br />

uncomplicated<br />

casting of single<br />

models or small trees<br />

in high quality<br />

• for casting of every<br />

metal, even steel<br />

or platinum<br />

1|<br />

The MC 60<br />

is ideal…<br />

• for jewellery casting in<br />

gold or silver<br />

• for technical small series<br />

casting in aluminium,<br />

copper and other metals<br />

2|<br />

3|<br />

The compact MC series was developed to<br />

provide jewellery designers, goldsmiths, development<br />

departments and dental laboratories<br />

with a cheap yet highly professional casting<br />

machine. Our most important aims were:<br />

extremely short processing time from mould<br />

manufacturing to completed casting; simple,<br />

safe operation; high quality and, above all,<br />

reproducible casting results; and low<br />

operating costs. The overwhelming global<br />

success of the MC series in numerous<br />

industries – including some not originally<br />

envisaged – emphatically confirms the MC<br />

concept.<br />

Ingeniously simple = simply ingenious<br />

Handling the mini<br />

casting system is also extremely simple:<br />

1| Fill in the material and heat up.<br />

2| Take the flask from oven and insert into the<br />

machine. The device itself looks after all<br />

additional functions – until we get to the stroke<br />

of genius:<br />

3| Pouring off takes place using a 90° rotation<br />

of the casting unit. After pouring, the MC 15+<br />

automatically switches to overpressure in order<br />

to optimise the mould filling even for delicate<br />

parts.<br />

After pouring, the MC series automatically<br />

switch to overpressure in<br />

order to optimise the mould filling<br />

even for delicate parts.<br />

Alternatively it is also possible to<br />

keep the vacuum (example shows<br />

MC 15+).<br />

With the MC machines, you can easily cast by<br />

hand from the crucible to your mould and<br />

feel what you are doing – just as it has been<br />

done for thousands of years. So that this<br />

works consistently and safely, the entire<br />

melting/casting unit is tilted together<br />

through a 90 degree angle. For perfect<br />

balance and to make do with as few moving<br />

parts as possible, almost the whole machine<br />

moves during tilting: being cylindrical in<br />

design, the whole moving section rotates as<br />

if in a halfpipe – ingeniously simple and<br />

stylishly designed on high-quality rollers.<br />

However, unlike manual casting, the process<br />

takes place in an enclosed chamber under a<br />

vacuum or inert gas atmosphere, to prevent<br />

air pockets and oxidation. You can check the<br />

melting and pouring-off process through the<br />

sight glass.<br />

8

NEW<br />

Why did we not just make one of the tried<br />

and tested machines in the VC range smaller?<br />

There are actually machines on the market in<br />

which the construction principle of larger<br />

machines has been miniaturised, and which<br />

therefore work with a sealing rod system. We<br />

prefer the tilting casting system for the<br />

following reasons:<br />

• Small crucibles with sealing rods are hard to<br />

fill. Generally only granulate or some other<br />

ground material can be poured in; the<br />

sealing rod gets in the way with larger<br />

pieces such as manufacturing residues,<br />

sprue etc.<br />

• Naturally the pouring-off opening is also very<br />

small with small crucibles. This makes viscous<br />

alloys hard to pour out, leading to the formation<br />

of incrustations and consequently leakage.<br />

This makes the service lives of expensive<br />

consumables extremely short. The crucibles in<br />

our MC machines are not only cheaper – they<br />

can also be used for a substantially longer<br />

time. Pouring off into the mould is extremely<br />

simple.<br />

• The number of mechanically moving parts<br />

and seals – so all wearing parts – is substantially<br />

smaller with our tilting principle,<br />

reducing your running costs.<br />

• The viewing glass and open design enable<br />

you to keep an eye on the melting and<br />

casting process and control it perfectly.<br />

MC 15+, the fast all-rounder for any<br />

metal<br />

• For individual pieces or multiple small<br />

jewellery parts<br />

• Minimum material use for the sprue<br />

• Shortest combustion times for the flask<br />

in the oven – approx. 1 hr with a speed<br />

investment material<br />

• With graphite crucible for gold and silver;<br />

ceramic crucible for platinum, palladium,<br />

steel<br />

• Maximum temperature 2,000°C.<br />

MC 60, the larger capacity version for<br />

gold and silver casting<br />

• Largely the same technology as with the<br />

MC 15+, but designed for a temperature<br />

range up to 1,300°C<br />

• Hence larger capacity for gold and silver<br />

casting<br />

• For flasks up to 80 mm x 120 mm,<br />

optionally up to 100 mm x 120 mm.<br />

A significant factor for the<br />

economic efficiency is the low<br />

quantity of metal that must be<br />

calculated for button.<br />

9

MC 20 V and MC 100 V: program controlled<br />

machines featuring vibration technology<br />

These machines are<br />

designed for…<br />

• for difficult casts in the<br />

jewellery and technical<br />

sectors<br />

• for all metals, even steel,<br />

palladium and platinum<br />

MC 20 V and MC 100 V are designed based<br />

on the same tilting principle as the MC<br />

machines described above. However they are<br />

systematically designed for intricate casting<br />

projects in continuous operation in large<br />

foundries.<br />

Vibration technology for excellent<br />

casting quality<br />

The two MC machines with the “V” suffix are<br />

equipped with the Indutherm vibration<br />

system. Vibration switched on directly after<br />

casting is a decisive factor in enhancing<br />

mould filling with very filigree parts. It<br />

prevents porosity, ensures a finer grain structure<br />

and allows greater more constant<br />

density. The post-processing requirement is<br />

much lower. Parts also have measurably<br />

higher elasticity and this increases the scope<br />

for further processing significantly.<br />

Vibration technology is a compelling alternative<br />

to the frequently used and relatively delicate<br />

centrifugal systems, especially when<br />

casting platinum or palladium.<br />

You can find more information on page 18/19.<br />

Full text LCD display for fine adjustment<br />

and serial programming<br />

Temperatures up to 2000°C are precisely<br />

measured by an optical pyrometer.<br />

Place the flask in position<br />

The new operating system features individual<br />

setting of parameters to achieve maximum<br />

performance from every pattern mould and<br />

every alloy. Thanks to the transparent layout<br />

of the menu structure and full text display, all<br />

settings are quick and easy to program. Of<br />

course all process parameters can be saved<br />

for repeated castings.<br />

10

tabletop casting<br />

MC 20 V or MC 100 V? It’s only a<br />

question of the required capacity ...<br />

<strong>Casting</strong> quality, maximum temperature, operation<br />

and equipment levels are in fact identical.<br />

Even the space requirements differ only in<br />

minor points – both machines are designed<br />

as bench-top models. Due to the greater<br />

height we recommend a height-adjustable<br />

bench or a standalone version with a floor<br />

cupboard. The decisive differences are the<br />

capacity of the crucible volume and flask size.<br />

The MC 20 V is suited for up to 100 g Au 18ct<br />

or 200 g Pt, the MC 100 V for up to 200 g Au<br />

18 ct or 500 g Pt. The MC 100 V also offers<br />

very short process times. The larger flasks on<br />

the MC 100 V require a slightly longer firing<br />

time in the furnace.<br />

As always, we offer you competent consulting<br />

to achieve the best solution for you.<br />

Main benefits<br />

• Very simple and safe to operate, short<br />

training periods<br />

• Excellent price-performance ratio<br />

• Induction generator reaches melting<br />

temperature rapidly<br />

• Thorough melt mixing due to low-frequency<br />

induction tuning<br />

• Melting under a vacuum or inert gas<br />

(degassing the melt prevents oxidation)<br />

• Excellent mould filling at pressures up to<br />

3 bar (vacuum casting also available)<br />

• Low material consumption<br />

Pd<br />

Pt<br />

The MC 100 V as standalone<br />

version. The floor base offers<br />

enough space to accommodate<br />

accessories, for example<br />

the vacuum pump.<br />

11

The MC series at a glance<br />

A complete casting system covering just a few square feet<br />

1) Vacuum investment machine for bubble-free mixing of the investment compound and<br />

filling of the flask. The integrated vibrator eliminates any possible air bubbles.<br />

2) The 1,100°C furnace for melting out the wax and burning out the form,<br />

temperature pre-selection, high-quality insulation,<br />

furnace interior size: 228 x 165 x 228 (h) mm<br />

3) Sand blasting cabinet for easy removal of plaster:<br />

air pressure requirement: 270 l/min at 10 bar, 150 l/min at 5 bar,<br />

connection for suction system, foot switch for adjusting pressure<br />

performance<br />

power max. / electrical connection<br />

temperature max.<br />

capacity<br />

casting volume<br />

for use of flasks<br />

handling+control<br />

control panel<br />

automatic vacuum function<br />

automatic overpressure function<br />

casting also under vacuum only<br />

vacuum or overpressure after casting<br />

function washing by inert gas<br />

vibration system<br />

supply: cooling water,<br />

inert gas argon or nitrogen<br />

temperature measurement/control<br />

quality management<br />

RS 232 interface, diagnostic system<br />

GSM-modem for remote service<br />

accessories<br />

vacuum investment mixer Indumix 2<br />

furnace, 1,100°C<br />

sand blasting cabinet<br />

vacuum pump<br />

floor unit<br />

12

MC 15+<br />

MC 60<br />

MC 20 V<br />

MC 100 V<br />

3.5 kW 230 V single phase<br />

2000° C<br />

3.5 kW 230 V single phase<br />

1300° C<br />

3.5 kW 230 V single phase<br />

2000° C<br />

8 kW 3x400 V<br />

2000° C<br />

100 g Au 18 ct 450 g Au 18 ct 100 g Au 18 ct 450 g Au 18 ct<br />

110 g steel/200 g Pt 300 g Ag 935 110 g steel/200 g Pt 250 g steel 500 g Pt<br />

up to ø 30/50/65/80 mm x 80 mm h ø 100 mm x 120 mm h up to ø 30/50/65/80 mm x 80 mm h up to ø 80/100 mm x 120 mm h<br />

digital display digital display by LCD-Display, full text readout by LCD-Display, full text readout<br />

■ ■ ■ ■<br />

■ ■ ■ ■<br />

– – ■ ■<br />

■ –1 up to +2 bar ■ –1 up to +2 bar ■ –1 up to +3 bar ■ –1 up to +3 bar<br />

■ ■ ■ ■<br />

– – ■ ■<br />

■ ■ ■ ■<br />

■ up to 1,300°C o up to 1,600°C ■ up to 1,300°C ■ up to 2,000°C ■ up to 2,000°C<br />

■ ■ ■ ■<br />

■ ■ ■ ■<br />

o o o o<br />

o o o o<br />

o o o o<br />

o (min. 8m 3 /h) o (min. 8m 3 /h) o (min. 8m 3 /h) o (min. 21 m 3 /h)<br />

– – – o<br />

■ = standard equipment<br />

o = optional<br />

13

The VTC series:<br />

for every metal or alloy you want to cast.<br />

The VTC machines<br />

are ideal for:<br />

• casting steel, platinum,<br />

palladium as well as<br />

all other jewellery and<br />

industrial alloys<br />

1)<br />

The VTC Ti machines<br />

are ideal for:<br />

• casting titanium, cobalt<br />

chrome, beryllium copper<br />

and other highly reactive<br />

metals<br />

2)<br />

3)<br />

VTC vacuum/pressure casting<br />

machines<br />

<strong>Casting</strong> trees in steel and in gold<br />

The VTC 100 V – VTC 800 V are extremely<br />

versatile casting machines suitable for a wide<br />

range of applications – and a number of<br />

options that were considered mutually<br />

incompatible up to now. Thus, while the VTC<br />

series was originally designed as a hightemperature<br />

casting machine for casting<br />

steel, palladium, platinum etc. (max. 2,100°C),<br />

large flasks also make it suitable for economically<br />

producing castings in gold, silver,<br />

copper, aluminium and other materials.<br />

The machine combines a dual-chamber differential<br />

pressure system with a tilting mechanism.<br />

The casting process is achieved by<br />

rotating the entire melting-casting unit by<br />

90°. One benefit of the tilting system is the<br />

use of economically priced graphite or<br />

ceramic crucibles instead of crucibles with<br />

holes and sealing rods; these tend to have a<br />

longer service life. Some alloys, such as<br />

copper beryllium, quickly cause crucibles with<br />

holes and sealing rods to become untight<br />

and therefore useless, and for this reason,<br />

many users have so far processed such alloys<br />

only in open systems – which means they<br />

can't choose to optimise the process with<br />

overpressure or vacuum. With the VTC series,<br />

these handicaps no longer apply.<br />

1) The new control system with LCD-Display<br />

2) The casting process is achieved by rotating the<br />

entire melting-casting unit by 90°.<br />

3) Flask size Ø125 mm x 220 mm<br />

A vacuum can be produced in the melting<br />

chamber and the casting chamber to avoid<br />

oxidation processes during melting and air<br />

pockets in the casting mould. The flask is<br />

automatically pressed against the melting<br />

chamber for casting, making it possible to<br />

switch to overpressure during casting for<br />

better mould filling; in addition, the vibration<br />

technology optimises the process even<br />

further. As well as casting with flasks, casting<br />

into ingot moulds is also possible.<br />

New sweep mode vibration system<br />

for perfect results even in Pt and Pd<br />

Due to the advanced vibration technology<br />

and the sophisticated vacuum/pressure<br />

system, this machine is perfectly suited to<br />

casting platinum and palladium – and all with -<br />

out the elaborate and sensitive centrifugal<br />

14

Sweep Mode<br />

Vibration<br />

<strong>Technology</strong><br />

mechanism usually required for platinum<br />

casting machines. The VTC machines are<br />

equipped with the advanced sweep mode<br />

vibration system. It considers that each<br />

casting tree and even each item of a tree has<br />

a different resonance frequency, depending<br />

on its shape and size. Generating variable<br />

frequencies the sweep mode vibration<br />

ensures that the optimum frequency is<br />

covered. Read more about the vibration<br />

advantages on page 18/19.<br />

New generator system controlled via<br />

LCD display<br />

A completely new generation of generator and<br />

control systems is present in the VTC series.<br />

Operation is simple and safe thanks to a<br />

clearly arranged and easy-to-use LCD display.<br />

All parameters, right down to the variable<br />

tilting speed, can be individually set and<br />

saved to ensure that recurring castings always<br />

produce consistent results.<br />

The high vacuum casting systems<br />

VTC 100 V Ti - VTC 800 V Ti<br />

Highly reactive metals such as titanium pose<br />

particular challenges when casting. The atmospheric<br />

conditions in a 'normal' vacuum pressure<br />

casting machine are completely inadequate for<br />

melting and casting titanium, and the crucibles<br />

and moulds need to be made of specific materials.<br />

Hence until now the only way to cast<br />

titanium was to use extremely expensive<br />

specialised machines. As part of a joint AiF<br />

ZIM research project, Indutherm has collaborated<br />

with the FEM institute in Schwaebisch<br />

Gmund under the sponsorship of the Federal<br />

Ministry for Economics and <strong>Technology</strong> to develop<br />

a cost-effective solution for casting<br />

highly reactive metals. The ideal structural<br />

basis proved to be the VTC 200 V tilting casting<br />

machine. Following numerous modifications,<br />

such as completely reconstructed valves and<br />

hose connections, special seals and an<br />

evacuation and inert gas flushing process<br />

tailored to the machine, the prerequisites for<br />

the required vacuum of 10 –3 mbar were met.<br />

Furthermore, special crucibles and inductors<br />

were developed for the Ti versions, as the ceramic<br />

crucibles that are normally used also react<br />

with titanium. They also reduce melting times<br />

– and the shorter the melting time, the less<br />

time there is for a possible reaction.<br />

The VTC V Ti machines are not only suitable<br />

for casting titanium – they can also be used<br />

for any highly reactive metal or alloy, such as<br />

copper beryllium, amorphous steel etc.<br />

Every model in the VTC range from the VTC<br />

100 V to the VTC 800 V is available in a<br />

Ti version.<br />

Graphite crucible and ceramic crucible<br />

15

The VTC series<br />

Vacuum Pressure <strong>Casting</strong> Machines<br />

performance<br />

power max. / electrical connection<br />

temperature max.<br />

VTC 100 V / Ti<br />

12 kW 3x400 V<br />

2100° C<br />

VTC 200 V / Ti<br />

15 kW 3x400 V<br />

2100° C<br />

capacity<br />

volume graphite crucible 25 ccm = 450 gr Au 18 ct 145 ccm = 2.0 kg Au 18 ct<br />

volume ceramic crucible 30 ccm = 600 gr Pt / 250 gr steel 180 ccm = 2.5 kg Pt / 1 kg steel<br />

for use of flasks up to ø 125 mm / 220 mm h ø 125 mm / 220 mm h<br />

handling+control<br />

vibration technology ■ sweep mode ■ sweep mode<br />

automatic tilting with motor drive ■ ■<br />

automatic flask fixing ■ ■<br />

casting programs 100 100<br />

temperature measurement thermocouple up to 1,300°C thermocouple up to 1,300°C<br />

optical pyrometer up to 2,000°C<br />

optical pyrometer up to 2,000°C<br />

quality management<br />

RS 232, diagnostic system ■ ■<br />

data printer ■ ■<br />

GSM-modem for remote service ■ ■<br />

accessories<br />

pyrometer with video output o o<br />

■ = standard equipment<br />

o = optional<br />

16

performance<br />

power max. / electrical connection<br />

temperature max.<br />

VTC 400 V / Ti<br />

20 kW 3x400 V<br />

2100° C<br />

VTC 800 V / Ti<br />

20 kW 3x400 V<br />

2100° C<br />

capacity<br />

volume graphite crucible 300 ccm = 4.0 kg Au 18 ct –<br />

volume ceramic crucible 300 ccm = 2.0 kg steel 600 ccm = 4.0 kg steel<br />

for use of flasks up to ø 125 mm / 220 mm h ø 125 mm / 220 mm h<br />

handling+control<br />

vibration technology ■ sweep mode ■ sweep mode<br />

automatic tilting with motor drive ■ ■<br />

automatic flask fixing ■ ■<br />

casting programs 100 100<br />

temperature measurement thermocouple up to 1,300°C thermocouple up to 1,300°C<br />

optical pyrometer up to 2,000°C<br />

optical pyrometer up to 2,000°C<br />

quality management<br />

RS 232, diagnostic system ■ ■<br />

data printer ■ ■<br />

GSM-modem for remote service ■ ■<br />

accessories<br />

pyrometer with video output o o<br />

■ = standard equipment<br />

o = optional<br />

17

The VC series<br />

Vacuum Pressure <strong>Casting</strong> Machines<br />

A thoroughly thought-through concept<br />

with the finest details...<br />

...forms the basis of the technological advances<br />

made in our VC machines guaranteeing opti -<br />

mal casting results whatever class of machine<br />

you opt for.<br />

A few examples of the additional features<br />

offered by Indutherm machines:<br />

Automatic vacuum in the melting and<br />

flask chambers…<br />

…provides the de-gasing of the alloy and<br />

avoids undesired oxidation during melting (a<br />

low oxygen content is particulary important<br />

when casting silver or red gold). Vacuum in<br />

the flask chamber during casting improves<br />

the form filling when casting filigree parts<br />

and avoids air inclusions.<br />

Melting by induction technology:<br />

The crucible with the material is located<br />

in the core of the induction coil. By generating<br />

a strong alternating magnetic<br />

field, the result is a strong alternating<br />

current in the graphite crucible and in<br />

the metal. This leads to fast heating up<br />

and thorough mixing of the material.<br />

Vacuum <strong>Casting</strong><br />

The special “oxidation-reduced<br />

casting“ system...<br />

…eliminates the danger of oxidation while the<br />

flask is cooling down.<br />

The Turbo Pressure function…<br />

…optimises the casting of very small and<br />

filigree objects. For the production of<br />

jewellery it guarantees perfect results when<br />

casting with stones. Turbo Pressure allows a<br />

precisely defined pressure to be achieved<br />

rapidly. For all program-controlled VC models,<br />

depending on the selected program the Turbo<br />

Pressure will start automatically exactly at the<br />

required time.<br />

18

Highest levels of safety for certified<br />

production<br />

The digital or program control of our machines<br />

and the integrated data printer (standard<br />

equipment for VC 650 V, VC 1000 V, VC 3000 V)<br />

ensure a high level of safety and the possibi -<br />

lity of precise process documentation (important<br />

for ISO certified casting processes).<br />

Until recently flasks with incorrect or different<br />

temperatures were a safety risk. During<br />

casting of very small or delicate parts the<br />

temperature of the flask is of utmost<br />

importance. The measurement of the flask<br />

temperature (standard for machines from<br />

VC 500 D onwards) is an important feature<br />

with regards to safety. The temperature of the<br />

flask can be monitored to within one degree.<br />

Overlapping casting<br />

All Indutherm machines have separate lock<br />

systems for the melting chamber and flask<br />

chamber. This allows time to be saved by<br />

"overlapping" casting: while the flask remains<br />

in the flask chamber for several minutes after<br />

the casting, you may fill in and heat up the<br />

next charge.<br />

Vibration System<br />

• Vibration during casting generally<br />

improves material flow and mould<br />

filling.<br />

• <strong>Casting</strong>s exhibit a higher and more<br />

consistent density<br />

• Porosity is substantially reduced.<br />

• Risk of hot cracks is reduced.<br />

• 50% smaller grain size<br />

• <strong>Casting</strong>s have greater stress and elasticity<br />

properties, making them easier to process<br />

further.<br />

In practice this means: higher and more<br />

consistent quality, less waste, less postprocessing,<br />

better deformability.<br />

A customer in USA has discovered that by<br />

using Indutherm vibration technology the<br />

total production time including postprocessing<br />

has been reduced by 25%<br />

(compared with the older VC 600).<br />

▲ porosity<br />

without<br />

vibration<br />

Rm<br />

with V<br />

Rm<br />

without V<br />

Rp 0,2<br />

with V<br />

Rp 0,2<br />

without V<br />

▲ porosity with vibration<br />

grain structure<br />

grain structure<br />

without vibration with vibration<br />

*Au 18 ct: 750 Au,128 Ag, 122 Cu<br />

elongation limit ~12% better<br />

tensile strength ~25% better<br />

tensile<br />

strength<br />

N/mm 2<br />

0,2%<br />

discharge<br />

elongation<br />

= with vibration<br />

= without vibration<br />

19

The semi-automatic VC versions<br />

These machines are<br />

designed for:<br />

• casting of jewellery and<br />

other filigree parts<br />

• VC 200 - 400:<br />

for smaller charges<br />

• VC 500: a semi-automatic<br />

machine for frequent<br />

operations.<br />

Resistor heated casting machines<br />

VC 200 / VC 300<br />

The resistor-heated vacuum casting machine<br />

VC 200 and the vacuum pressure casting<br />

machine VC 300 are very low priced casting<br />

machines for smaller productions.<br />

Nevertheless these machines offer a convincing<br />

casting quality. Both machines reach a<br />

maximum temperature of 1,200°C.<br />

Stone-in-place castings possible with all<br />

VC-series machines<br />

Induction heated casting machines<br />

VC 400<br />

The ideal machine for smaller companies<br />

producing moderate quantities but needing<br />

considerably more capacity than that offered<br />

by the MC machines. Often, experienced<br />

casters are not particularly interested in automated<br />

functions or program control, and they<br />

can achieve the same quality with the VC 400<br />

machine as with more advanced ones. Its<br />

induction generator guarantees fast heat-up<br />

and thorough mixing of the molten metal by<br />

inductive bath movement.<br />

VC 500<br />

For larger production quantities with<br />

continuous casting operation, greater performance<br />

(shorter casting times) with even<br />

larger crucibles and flask capacities (flasks up<br />

to 160 mm ø/400 mm H) is important. The<br />

high maximum temperature of 1,600°C<br />

extends the possible range of alloys. Temperature<br />

measurements in both the crucible and<br />

the flask mean the best possible repeat<br />

accuracy in the process. If alloys are changed<br />

frequently, 20 different temperature programs<br />

simplify working procedures.<br />

performance<br />

power max. / electrical connection<br />

maximum temperature<br />

capacity<br />

crucible volume<br />

for use of flasks up to<br />

optional up to<br />

handling+control<br />

dual temperature control<br />

flask temperature measurement<br />

flask and chamber lift<br />

temperature programs<br />

turbo pressure function<br />

quality management<br />

RS 232, diagnostic system<br />

GSM modem for remote service<br />

accessories<br />

sintering kit (for diffusion bonding)<br />

granulation tank<br />

other versions<br />

also available as granulating unit<br />

20

with an optional<br />

granulating tank<br />

VC 200/300<br />

VC 300<br />

VC 400<br />

VC 500<br />

2 kW 230 V<br />

1200° C<br />

3.5 kW 230 V or 4.5 kW 3x400 V<br />

1400° C<br />

10 kW 3x400 V / 3x208 V<br />

1600° C<br />

■ 245 ccm = 3.6 kg Au 18 ct* ■ 170 ccm = 2.5 kg Au 18 ct* ■ 245 ccm = 3.6 kg Au 18 ct*<br />

o 386 ccm = 5.8 kg Au 18 ct*<br />

ø 130 mm / 260 mm h ø 130 mm / 260 mm h ø 130 mm / 260 mm h<br />

ø 160 mm / 400 mm h<br />

– o o<br />

– – ■<br />

o o ■<br />

– 20 temperature programs 20 temperature programs<br />

– ■ ■<br />

■ ■ ■<br />

– o o<br />

o o o<br />

– o o<br />

– – GU 500<br />

*Liquid metal up to top level of the crucible<br />

■ = standard equipment o = optional<br />

21

The fully automatic VC machines<br />

These machines are<br />

designed…<br />

• for casting of jewellery and<br />

other filigree parts<br />

• for permanent use<br />

• for certified production<br />

processes<br />

• VC 650 V: for highest<br />

demands in quality and<br />

continuity<br />

VC 450<br />

The VC 450 is equipped with a program<br />

control system with full text read out LCD<br />

display.<br />

With help of the step-by-step display information<br />

and many automatic functions, the<br />

machine is very easy to handle, even for less<br />

experienced users. The program control for<br />

20 different casting cycles allow reproducible<br />

and consistent casting results.<br />

VC 480 V<br />

The construction of the new VC 480 V is<br />

based on the VC 450 and offers the same melting<br />

capacity. However, in addition to the<br />

technical equipment of the VC 450, the VC<br />

480 V comes with 8 kW generator power, an<br />

advanced program control with 100 casting<br />

programs, variable vacuum in the flask chamber<br />

and – the most important add-on – the<br />

INDUTHERM vibration system.<br />

VC 650 V<br />

The absolute “State of the art“-machine:<br />

the VC 650 V garantees highest efficiency –<br />

through maximum speed and quality.<br />

New program control system<br />

Thanks to a new control panel with full text<br />

LCD display, all programs and parameters are<br />

very easy and convenient to set. 100 casting<br />

programs guarantee fast operation and con -<br />

sistent casting results. Parameters are preprogrammed<br />

for all major alloys, e.g. for<br />

AGS, Alpha Plus, Heraeus, Legor and<br />

Pandora alloys. In practice this mean: from<br />

the first flask, you can expect good casting<br />

results without carrying out expensive pretests.<br />

Turbulence reduction software<br />

New system for faster and more laminar<br />

metal flow.<br />

Turbo Pressure PLUS<br />

Filling of the flask using fast overpressure<br />

allows casting of very filigree parts and<br />

casting with stones. Now with reduced gas<br />

consumption and with an even faster<br />

pressure degree.<br />

Sweep Mode<br />

The new sweep mode vibration system can<br />

do even more: it considers that each casting<br />

tree and even each item of a tree has a different<br />

resonance frequency, depending on its<br />

shape and size. The sweep mode vibration<br />

generating variable frequencies covers all<br />

natural resonances.<br />

performance<br />

power max. / electrical connection<br />

maximum temperature<br />

capacity<br />

crucible volume<br />

for use of flasks up to<br />

optional up to<br />

handling+control<br />

vibration technology<br />

pneumatic bell lock<br />

maximum pressure<br />

programs<br />

program control<br />

dual temperature control<br />

flask temperature measurement<br />

automatic flask and chamber lift<br />

variable vacuum in flask chamber<br />

turbo pressure PLUS system<br />

turbulence reduction software<br />

quality management<br />

RS 232, diagnostic system<br />

data printer<br />

GSM modem for remote service<br />

accessories<br />

sintering kit (for diffusion bonding)<br />

granulation tank<br />

22

Vibration<br />

<strong>Technology</strong><br />

Sweep Mode<br />

Vibration<br />

<strong>Technology</strong><br />

VC 450<br />

VC 480 V<br />

VC 650 V<br />

4.5 kW 3x400 V<br />

1400° C<br />

8 kW 3x400 V<br />

1600° C<br />

12 kW 3x400 V<br />

1700° C<br />

■ 170 ccm = 2.5 kg Au 18 ct* ■ 170 ccm = 2.5 kg Au 18 ct* ■ 245 ccm = 3.6 kg Au 18 ct*<br />

o 386 ccm = 5.8 kg Au 18 ct*<br />

ø 130 mm / 260 mm h ø 130 mm / 260 mm h ø 130 mm / 260 mm h<br />

ø 160 mm / 400 mm h<br />

– ■ ■ in sweep mode<br />

■ ■ ■<br />

1.5 bar 1.5 bar 3 bar<br />

20 100 100<br />

by LCD-display, full text readout by LCD-display, full text readout by LCD-display, full text readout<br />

o o ■<br />

– – ■<br />

■ ■ ■<br />

– ■ ■<br />

– ■ ■<br />

■ ■ ■<br />

■ ■ ■<br />

o o ■<br />

o o ■<br />

o o o<br />

o o o<br />

*Liquid metal up to top level of the crucible ■ = standard equipment o = optional<br />

23

The Vacuum Pressure <strong>Casting</strong> Machines<br />

for large casting parts<br />

These machines are<br />

designed for:<br />

• the automotive and<br />

component industries<br />

• rapid prototyping<br />

• orthopaedic and<br />

medicine technologies<br />

• machinery construction<br />

• toolmaking<br />

• sculptures<br />

Capacity and power for large scale projects<br />

Our large vacuum pressure casting machines are mostly<br />

used for precise castings in aluminium alloys. They are<br />

always the first choice for parts with complicated geometry<br />

or when the number of pieces is not large enough for diecast<br />

production. VC 1000, 3000 and 12000 offer the best<br />

pre-conditions for high quality castings in aluminium: the<br />

hydrogen content of aluminium alloys may be adjusted by<br />

regulating the vacuum during melting. This way, foaming of<br />

molten metal can be avoided without any melt additives.<br />

Overpressure in the melting chamber during and after<br />

casting and simultaneous vacuum in the flask chamber optimise<br />

form filling especially in filigree or thin-walled areas.<br />

The V-versions with vibration<br />

All our large VC machines are now equipped with a new<br />

program control system. The casting process is controlled<br />

via LCD full text display. Complete casting cycles may be<br />

stored for repeatable castings. Each machine is available in<br />

two versions:<br />

The standard versions offer 20 casting programs, the V-<br />

versions have 100 programs and as the most important<br />

innovation, they use the vibration technology for improved<br />

form filling.<br />

performance<br />

power max. / electrical connection<br />

maximum temperature<br />

capacity<br />

crucible volume<br />

for use of flasks up to<br />

optional up to<br />

handling+control<br />

20 temperature programs<br />

program control (100 programs)<br />

automatic flask and chamber lift<br />

dual temperature control<br />

flask temperature measurement<br />

quality management<br />

RS 232, diagnostic system<br />

data printer<br />

GSM modem for remote service<br />

accessories<br />

granulating tank<br />

magnesium kit<br />

Magnesium casting versions<br />

24<br />

The magnesium casting versions are constructed according<br />

to strict safety requirements and guarantee safe and easy<br />

casting of magnesium – and of course of every other metal,<br />

too.

VC 1 000<br />

VC 1 000 V<br />

VC 3 000<br />

VC 3 000 V<br />

VC 12 000<br />

VC 12 000 V<br />

picture: VC 1000 with feeding system<br />

and window door<br />

picture: VC 3000 V<br />

with large flask chamber<br />

picture: VC 12 000<br />

25 kW 3x400 V<br />

1500° C<br />

30 kW 3x400 V<br />

1500° C<br />

40 kW 3x400 V<br />

1200° C<br />

■ 1,500 ccm = 4 kg Al ■ 3,400 ccm = 9 kg Al ■ 12,000 ccm = 30 kg Al<br />

ø 250 mm / 500 mm h ø 450 mm / 600 mm h ø 600 mm / 800 mm h<br />

– ø 300 mm / 600 mm h –<br />

■ ■ ■<br />

■ VC 1000 V ■ VC 3000 V ■ VC 12 000 V<br />

■ VC 1000 V ■ VC 3000 V –<br />

■ ■ ■<br />

■ ■ ■<br />

■ ■ ■<br />

■ ■ ■<br />

o o o<br />

o o o<br />

o o o<br />

*Liquid metal up to top level of the crucible<br />

■ = standard equipment o = optional<br />

25

Machines for melting and handpouring<br />

These machines<br />

are designed…<br />

• for all melting processes<br />

with an extensive<br />

generation of smoke and<br />

oxides, which should be<br />

absorbed<br />

• for melting down scrap and<br />

cuttings or large parts like<br />

stamping residues<br />

Some metals develop a lot of<br />

smoke and oxides during melting.<br />

It is better to melt them in open<br />

systems, with use of an air<br />

absorber.<br />

No limitation in<br />

the material size.<br />

With the MU series we offer melting machines for hand pouring<br />

for many different needs and with crucible capacities from 155 ccm<br />

up to 1,200 ccm. The material is molten in open crucibles and<br />

poured by hand into the mould.<br />

Melting Units MU Series<br />

Flexible melting furnaces designed to melt gold and silver alloys<br />

and as well as aluminium, bronze, brass.<br />

Due to the strong induction generator (15 kW) and the low<br />

induction frequency the stirring effect of the metal is excellent.<br />

performance<br />

power max. / electrical connection<br />

maximum temperature<br />

capacity<br />

crucible volume<br />

The MU as vacuum casting machine:<br />

MUV Series<br />

The V-versions include one or two additional extra large capacity<br />

vacuum chambers. Evacuating the flask immediately after<br />

pouring improves the form filling, reduces porosity and avoids<br />

oxidation of the hot metal.<br />

perforated flasks with/without flange<br />

handling+control<br />

temp. measurement by thermocouple<br />

temperature control<br />

temperature programs<br />

Ideal for melting large<br />

parts: no sealing rod construction<br />

reduces the available<br />

space.<br />

quality management<br />

interface RS 232, diagnostic system<br />

GSM modem for remote control<br />

26

MU 700<br />

MUV 700<br />

MU series<br />

MUV series<br />

MU 200 MU 400-1200 MUV 200 MUV 400-1200<br />

3.5 kW 230 V or 6.0 kW 3x400 V<br />

1300° C or 1500° C<br />

10-15 kW 3x400 V<br />

1500° C<br />

3.5 kW 230 V or 6.0 kW 3x400 V<br />

1300° C or 1500° C<br />

10-15 kW 3x400 V<br />

1500° C<br />

MU 400: 10 kW<br />

MUV 400: 10 kW<br />

MU 700: 12 kW<br />

MUV 700: 12 kW<br />

MU 900: 15 kW<br />

MUV 900: 15 kW<br />

MU 1200: 15 kW<br />

MUV 1200: 15 kW<br />

155 ccm = 2.3 kg Au 18 ct ❁ 155 ccm = 2.3 kg Au 18 ct ❁<br />

MU 400: 400 ccm = 6 kg Au 18 ct ❁<br />

MU 700: 700 ccm = 9 kg Au 18 ct ❁<br />

MU 900: 900 ccm = 13 kg Au 18 ct ❁<br />

MU 1200: 1,200 ccm = 18 kg Au 18 ct ❁<br />

MUV 400: 400 ccm = 6 kg Au 18 ct ❁<br />

MUV 700: 700 ccm = 9 kg Au 18 ct ❁<br />

MUV 900: 900 ccm = 13 kg Au 18 ct ❁<br />

MUV 1200: 1,200 ccm = 18 kg Au 18 ct ❁<br />

– ■ up to ø160 mm/400 mm h<br />

■<br />

■<br />

■<br />

20 20<br />

■<br />

■<br />

o<br />

■<br />

o<br />

❁<br />

real capacity for casting<br />

■ = standard equipment<br />

o = optional<br />

27

Tilting Furnaces for melting and casting<br />

large quantities into ingots or shell moulds<br />

These machines<br />

are designed…<br />

• for melting large quantities,<br />

for example in the recycling<br />

sector<br />

• for casting large parts into<br />

shellcasting moulds<br />

TF 1200 - TF 4000 – tried and tested<br />

in foundries and precious metal<br />

merchants across the world:<br />

Our tilting furnaces are mainly used in two<br />

areas:<br />

1. for melting down large quantities of metal<br />

such as antique gold or manufacturing<br />

residues like casting waste, scrap or swarf.<br />

15 - 60 kW output and low-frequency tuning<br />

means fast melting – even for large<br />

volumes – and excellent through-mixing.<br />

2. for casting large, heavy components<br />

e.g. according to the shell casting principle<br />

For pouring off, the inductor/crucible unit is<br />

tilted forwards, either using a pivot lever or<br />

wheel, optionally with<br />

reduction. The wheel is<br />

recommended out of<br />

preference for safety<br />

reasons, as the operator<br />

must move away from<br />

the splash zone when<br />

pouring off.<br />

The TF 6000 and TF 12000<br />

are tilted using a joystick.<br />

TF 6 000 and TF 12 000 – the giants<br />

among tilting furnaces<br />

The large crucible volumes of 6,000 respectively<br />

12,000 ccm gives these machines an<br />

enormous capacity.<br />

The generator is fitted with a 32-bit micro controller<br />

and is controlled via a console with an<br />

LCD display with full text readout.<br />

100 programs enable set process parameters<br />

to be stored. Efficient thermal insulation and<br />

electromagentic shielding ensure a high level<br />

of effectiveness. Comparison tests carried<br />

out by a customer recently proved that the<br />

TF 12000 has a higher level of productivity<br />

than a competitor model with twice the<br />

performance and correspondingly twice the<br />

energy costs.<br />

Because of the potentially<br />

large weight, the inductor/<br />

crucible unit is no longer<br />

tilted manually – it uses a<br />

motor drive with a stable<br />

shaft. Use of a joystick<br />

enables the tilting process<br />

to be controlled easily and<br />

sensitively, as with a pivot<br />

lever or wheel.<br />

28

TF 4000<br />

TF 12000<br />

TF series<br />

TF 1200 / 2000 / 4000 TF 6000 / 12 000<br />

performance<br />

power max. / electrical connection<br />

maximum temperature<br />

15-30 kW 3x400 V<br />

1500° C<br />

TF 1200: 15 kW<br />

TF 2000: 25 kW<br />

TF 4000: 30 kW<br />

40-60 kW 3x400 V<br />

1500° C<br />

TF 6000: 40 kW<br />

TF 12000: 60 kW<br />

temperature measurement thermocouple ■ ■<br />

capacity<br />

crucible volume TF 1200:1,200 ccm =18 kg Au 18 ct ❁ TF 6000: 6,000 ccm = 90 kg Au 18 ct ❁<br />

TF 2000: 2,000 ccm = 30 kg Au 18 ct ❁<br />

TF 4000: 4,000 ccm = 60 kg Au 18 ct ❁<br />

TF 12000: 12,000 ccm = 180 kg Au 18 ct ❁<br />

handling+control<br />

tilting by lever ■ –<br />

tilting by wheel o –<br />

reduction for wheel o –<br />

tilting with motordrive (remote control) – ■<br />

temperature control ■ by display ■ by LCD-Display, full text display<br />

temperature programs 16 100<br />

quality management<br />

interface RS 232, diagnostic system ■ ■<br />

GSM modem for remote service o ■<br />

❁<br />

real capacity for casting<br />

■ = standard equipment<br />

o = optional<br />

29

High temperature melting machines for steel,<br />

platinum, palladium, chrome-cobalt…<br />

These machines are ideal for…<br />

• MU 100 C: melting small<br />

quantities of steel and other<br />

metals with a high melting<br />

point<br />

• MU 200 C: for larger<br />

quantities, also for pouring<br />

into flasks<br />

• TF 2000 C/4000 C: melting<br />

large quantities and casting<br />

of voluminous steel parts<br />

We offer melting machines with three<br />

different capacities for melting metals with a<br />

high melting point, such as steel, palladium,<br />

platinum, chrome-cobalt etc.<br />

Common to all is the generator, specially<br />

designed for the most thorough throughmixing<br />

of molten metals. The ceramic<br />

crucibles are specially designed for our hightemperature<br />

casting machines and are<br />

extremely heat-resistant, ensuring the least<br />

possible amount of energy loss and a lower<br />

internal temperature in the melting chamber.<br />

The melting machines MU 100 C and<br />

MU 200 C<br />

The MU 100 C is principally used for analysis<br />

purposes, whereas the MU 200 C has sufficient<br />

crucible capacity to generate custom alloys<br />

for example, or use them on a regular<br />

basis for melting down product residues from<br />

platinum or palladium processing. For use as<br />

a casting machine we recommend the MUV<br />

versions with one or two vacuum containers<br />

High temperature tilting furnaces<br />

TF 2000 C/TF 4000 C<br />

These melting furnaces have been specially<br />

designed to melt large quantities of steel or<br />

other metals with a high melting point. The<br />

strong induction generator and low induction<br />

frequency means very good mixing of the<br />

metal can be achieved.<br />

The main areas of applications are:<br />

• casting voluminous parts such as<br />

sculptures (also sand casting)<br />

• purification melting of waste<br />

• casting of ingots<br />

• casting of solid rollers<br />

performance<br />

power max. / electrical connection<br />

maximum temperature<br />

capacity<br />

crucible volume<br />

for use of flasks up to<br />

handling+control<br />

tilting with motor drive (remote control)<br />

temperature programs<br />

temperature measurement by pyrometer<br />

LCD-Display<br />

quality management<br />

RS 232, diagnostic system<br />

GSM modem for remote service<br />

30

MU 100 C / MU 200 C<br />

MUV 100 C / MU 200 C<br />

TF 2000 C / TF 4000 C<br />

MU 100 C<br />

MUV 100 C<br />

MU 200 C<br />

MUV 200 C TF 2000 C TF 4000 C<br />

8 kW 3x400 V<br />

2000° C<br />

15 kW 3x400 V<br />

2000° C<br />

40 kW 3x400 V<br />

1700° C<br />

60 kW 3x400 V<br />

1700° C<br />

50 ccm = 1 kg Pt ❁ 155 ccm = 2.5 kg Pt ❁ 2,000 ccm = 5-14 kg steel ❁ 4,000 ccm = 8-30 kg steel ❁<br />

o up to ø160 mm/400 mm h (MUV 100 C/MUV 200 C) –<br />

– ■<br />

– 20<br />

– o<br />

– ■<br />

■<br />

o<br />

■<br />

o<br />

Tip casting under vacuum/overpressure:<br />

MC 15+ (see page 8), MC 20 V and MC 100 V (see page10)<br />

or the VTC series (see page 14)<br />

❁<br />

real capacity for casting<br />

■ = standard equipment<br />

o = optional<br />

31

Special solutions for recycling and analysis<br />

and for ingot casting<br />

These machines<br />

are designed for:<br />

• old gold, remains from<br />

production, dental gold<br />

• remains from galvanic<br />

processes, such as gold,<br />

palladium or platinum<br />

sponges, electrolytic silver<br />

• dental waste<br />

• electronic waste, thermosensors,<br />

contacts etc.<br />

• remains from anodes<br />

Indutherm systems used in the recycling process<br />

old gold<br />

dental gold<br />

remains from<br />

production and<br />

recycling<br />

ingots<br />

granules<br />

melting down melting down<br />

flakes<br />

Refining<br />

TF MU GU<br />

Subsequent processing of the pure precious metals as new alloys into…<br />

GU CC VC 400 B/P TF / MU<br />

…granulate<br />

…semi-finished material<br />

(sheets and stripes,<br />

wires and tubes)<br />

…ingots or pellets<br />

with defined<br />

quantities<br />

…ingots<br />

32

TF 4000<br />

Ingot <strong>Casting</strong> Machine<br />

VC 400<br />

Pellet <strong>Casting</strong> Machine<br />

VC 400 B<br />

Bar <strong>Casting</strong> Machine<br />

The demands on casting and smelting plants differ considerably in<br />

the field of analysis and recycling. Sometimes only a few grams have<br />

to be molten for sampling, sometimes large quantities have to be<br />

molten. Often a certain shape or size is required, such as ingots or<br />

pellets.<br />

Moreover, the metals and alloys themselves require different handling:<br />

alloys containing copper, for example, should be molten in a<br />

vacuum or inert gas atmosphere as they tend towards strong oxide<br />

formation. For other metals or alloys, in turn, open plants are recommended<br />

as fumes have to be drawn off, for example.<br />

The overview shown on the left page is intended to give you an insight<br />

into the versatile possibilities of our program. The ideal solution<br />

for your application is best determined by discussion or by trial<br />

casts. Just ask us!<br />

TF 4 000 Ingot <strong>Casting</strong> Machine<br />

The ingot moulds are located in a movable slide which locks into<br />

place precisely at the casting point, thus ensuring safe filling of<br />

the individual moulds.<br />

VC 400 Pellet <strong>Casting</strong> Machine<br />

This machine has been developed for casting alloys or production<br />

leftovers into pellets with a pre-defined weight or size.<br />

A hydraulic ejector allows the pellets to be collected easily.<br />

The machine is based on the VC 400 model.<br />

VC 400 B Bar <strong>Casting</strong> Machine<br />

This machine is especially suitable for melting and casting defined<br />

quantities of metal such as one kilogram ingots. During the melting<br />

process, the crucible chamber is flooded with inert gas.<br />

At a glance: all our<br />

machines for metal<br />

recycling<br />

temperature max.<br />

capacity<br />

mostly used for<br />

vacuum/inert gas<br />

page<br />

VTC V series<br />

2,000°C<br />

25 - 600 ccm<br />

ingots<br />

■<br />

14<br />

MU/TF series<br />

1,400° - 2,000° C<br />

50 - 12,000 ccm<br />

ingots<br />

–<br />

26-31<br />

VC 400 Pellet <strong>Casting</strong><br />

1,400°C<br />

170 ccm<br />

pellets<br />

■<br />

see above<br />

VC 400 B<br />

1,300°C<br />

170 ccm<br />

ingots<br />

■<br />

see above<br />

33

The Continuous <strong>Casting</strong> Machines – the only<br />

ones with vacuum and/or quattro drive<br />

These machines<br />

are designed…<br />

• for fast and flexible<br />

production of semifinished<br />

material<br />

• for use in every<br />

metalworking<br />

industry<br />

• as multiple use<br />

instruments<br />

especially for the<br />

production of rings<br />

34<br />

More flexibility, lower costs<br />

Indutherm continuous casting machines help<br />

you to save production costs.<br />

With only one machine, you can produce your<br />

own alloys or semi-finished products in different<br />

shapes and sizes in the shortest time, for<br />

example:<br />

• wires or bars in every diameter you need, up<br />

to ø 40 mm (CC 3000)<br />

• sheets and strips, e.g. ring production, for<br />

stamping and pressing<br />

• tubes, perfect as basic material for cutting in<br />

sections for wedding ring production<br />

• granulates<br />

As the desired moulds and alloys can be<br />

produced within minutes, you can reduce your<br />

investment for material in storage. Your<br />

processes will get faster, more flexible and more<br />

efficient.<br />

The main advantages of the Indutherm<br />

CC-machines:<br />

• short change-over times for various casting<br />

sizes<br />

• a lot of additional equipment available<br />

• e.g. diffusion bonding set (“sintering”) and<br />

granulation tank<br />

• induction generators with low frequency<br />

tuning for thorough mixing of the metal<br />

• automated inert gas<br />

• high metal quality, free of porosity<br />

Optional quattro drive<br />

The optional<br />

drawing unit with<br />

four instead of two<br />

motor driven feed<br />

rolls produce very<br />

smooth tubes and<br />

sheeting without<br />

the otherwise<br />

unavoidable marks<br />

of transportation<br />

(for CC 1000 and CC 3000).<br />

All CC-machines also available as VCCversions<br />

with vacuum function (pat. pend.)<br />

With the VCC-machines, melting can take place<br />

under a vacuum or inert gas. This is ideal for<br />

alloys containing copper such as red gold or for<br />

silver as these materials tend to oxidise easily.<br />

Degasification under a vacuum results in a<br />

substantially improved – because of the absence<br />

of oxidation – semi-finished product.<br />

performance<br />

power max. / electrical connection<br />

maximum temperature<br />

capacity<br />

crucible volume<br />

wire production up to<br />

tube production up to<br />

sheet production<br />

handling+control<br />

16 programs for melting and die temp.,<br />

drawing lengths, stoptime, reverse draw<br />

inert gas overpressure<br />

vacuum<br />

neutral inert gas atmosphere<br />

quality management<br />

RS 232, diagnostic system<br />

data printer<br />

GSM modem for remote service<br />

accessories<br />

Quattro-drawing unit<br />

sintering kit<br />

granulation tank<br />

bending-unit<br />

simultaneous casting of several wires<br />

coiling equipment

picture: VCC 400<br />

CC 400<br />

VCC 400<br />

picture: VCC 1000<br />

with optional<br />

Quattro Drive<br />

CC 1000<br />

VCC 1000<br />

picture: CC 3000<br />

with optional<br />

Quattro Drive<br />

CC 3 000<br />

VCC 3 000<br />

15 kW 3x400 V / 3x208 V<br />

1500° C<br />

25 kW 3x400 V<br />

1500° C<br />

30 kW 3x400 V<br />

1500° C<br />

■ 285 ccm = 4.2kg Au 18 ct* ■ 1,500 ccm = 22 kg Au 18 ct* ■ 3,400 ccm = 51 kg Au 18 ct*<br />

o 400 ccm = 6.0 kg Au 18 ct*<br />

■ ø 15 mm ■ ø 30 mm ■ ø 40 mm**<br />

■ ø 30 mm ■ ø 40 mm ■ ø 50 mm**<br />

■ 50 x 8 mm ■ 100 x 10 mm ■ 130 x 12 mm<br />

o 60 x 8 mm<br />

■ ■ ■<br />

– CC 400/■ VCC 400 – CC 1000/■ VCC 1000 – CC 3000/■ VCC 3000<br />

– CC 400/■ VCC 400 – CC 1000/■ VCC 1000 – CC 3000/■ VCC 3000<br />

■ ■ ■<br />

■ ■ ■<br />

■ ■ ■<br />

o o o<br />

– o o<br />

o – –<br />

o o o<br />

o o o<br />

– o 3 wires*** o 5 wires***<br />

– o o<br />

*Liquid metal up to top level of the crucible<br />

■ = standard equipment o = optional<br />

** Standard sizes – special dimensions on demand such as tube Ø 85 mm,<br />

5 mm wall thickness or strips 65 x 40 mm, profiles for watch cases etc.<br />

*** not in combination<br />

with Quattro Drive 35

Solutions for Granulating<br />

For the production of granules we can offer you three different systems.<br />

• For frequent or permanent production of granules our GU series granulating machines will be<br />

the first choice.<br />

• If you only want to produce granules occasionally, the addition of a vacuum pressure or a<br />

continuous casting machine with a granulating tank is a good alternative.<br />

• For the production of micro granules we recommend our GU 500 micro.<br />

The Granulating Machines GU 500, GU 1000, GU 3000 and GU 12 000<br />

These machines are developed especially for granulating bullions, sheet metal or<br />

casting residues into proper grains. The granulation tanks are very easy to remove<br />

for clearing.<br />

The GU machines are available with crucible sizes from 245 ccm up to 12,000 ccm.<br />

The major applications are<br />

• Preparation of alloys out of gold and master alloy<br />

• Preparation of alloy components<br />

• Preparation of alloys from components<br />

• Cleaning up of already casted metal<br />

… each under inert gas atmosphere or under a vacuum<br />

GU 500<br />

GU 1000<br />

GU 3000<br />

GU 12 000<br />

crucible volume in ccm 245-386 1,500 3,400 12,000<br />

volume in kg Au 18ct 3.6-5.7 22.0 51.0 180.0<br />

generator kw (400 V) 10 25 30 40<br />

GU 12 000<br />

36

The Micro Shot Systems GU 500 micro,<br />

GU 1000 micro and GU 3000 micro<br />

The GU micro series was developed for the<br />

production of micro granules with a grain size of<br />

between 0.1 and 1 mm. The systems are based on<br />

the Indutherm granulation units as shown on the<br />

left but all key components, particularly the jet<br />

system, are special developments. The main areas<br />

of application for the micro-granules are in metal<br />

laser sintering processes, in jewellery surface<br />

design and in soldering technology.<br />

Pull-out handle for easy removal<br />

of the tank insert.<br />

GU 500 micro<br />

Pour off the residual water…<br />

The Granulating Tank for casting machines in<br />

the VC and CC series<br />

The optional equipment of a vacuum pressure or a<br />

continuous casting machine with a granulating tank<br />

is a suitable solution for occasional granulating. Granulating<br />

tanks are available for all machines in the<br />

VC series from VC 400 up to the VC 12000 and<br />

for all CC machines.<br />

…and then pour off the granules.<br />

The main advantages of the new generation of<br />

granulating tanks:<br />

• Easy installation of the granulating tank<br />

• Fast changing between casting process and granulating<br />

• Ergonomically and perfectly balanced design for<br />

safe and easy handling<br />

• Optimised streaming behaviour of the cooling water<br />

• Reliable separation of water and granules<br />

CC 3000 with<br />

optional granulation<br />

tank<br />

Granulation tanks in different sizes:<br />

left: GU 500, option for VC 400 - VC 650 V and CC 400<br />

middle: GU 1000, option for VC 1000 and CC 1000<br />

right: GU 3000, option for VC 3000 and CC 3000<br />

37

An effective solution for wedding ring production<br />

These machines are<br />

designed…<br />

• for the production of<br />

multi-colour rings<br />

in accordance with the<br />

diffusion bonding process<br />

• for solid bonding<br />

of every kind of metal<br />

38<br />

Sintering is the optimum process for producing<br />

multi-coloured rings, mostly sold as<br />

wedding rings. Metals are processed under<br />

pressure and at temperatures below the solidification<br />

point. The pressure is generated<br />

pneumatically and not mechanically via a<br />

threaded spindle. This means that there is no<br />

risk of graphite parts breaking as a result of<br />

heat expansion. The fusion between layers<br />

has the same durability as the metal itself.<br />

Pre-manufactured rings can be easily resized<br />

(7 sizes and more).<br />

Benefits of the Indutherm sintering<br />

process:<br />

• With the sintering unit processes can take<br />

place under a vacuum, which is important<br />

for alloys with a manganese component<br />

• Processes can take place under inert gas<br />

• Straightforward installation/removal of the<br />

rings<br />

• Approximate duration of process: 5 minutes<br />

• Depending on the thickness of the rings, up<br />

to 6 rings can be processed simultaneously<br />

Indutherm offers different methods of<br />

sintering:<br />

The special sintering machines (SU series) or<br />

the sintering kit for installation into existing<br />

casting or continuous casting machines.<br />

Sintering Machine SU 300<br />

With the SU 300, the temperature and<br />

pressure are controlled manually. Exceptional<br />

results can be produced using this machine<br />

after just a brief introductory period.<br />

Sintering Machine SU 450<br />

The new SU 450 is equipped with a highly<br />

sensitive sensor system, which permanently<br />

controls the reduction of the rings and<br />

provides real-time information about the<br />

reduction values on the display. The temperature<br />

may be regulated very precisely close to<br />

the solidus temperature, right until the reduction<br />

begins.<br />

As soon as the pre-defined reduction value<br />

has been reached, the process stops automatically<br />

thus preventing too much deformation<br />

(depending on the composition and alloy the<br />

pre-defined reduction value varies between<br />

0.1 mm and 0.3 mm). The “Sensor-Control-<br />

System” considerably reduces the time and<br />

material required for production for two<br />

major reasons: firstly because the process<br />