MODEL G0490/G0490X 8" X 76" JOINTER w ... - This Wiki

MODEL G0490/G0490X 8" X 76" JOINTER w ... - This Wiki

MODEL G0490/G0490X 8" X 76" JOINTER w ... - This Wiki

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

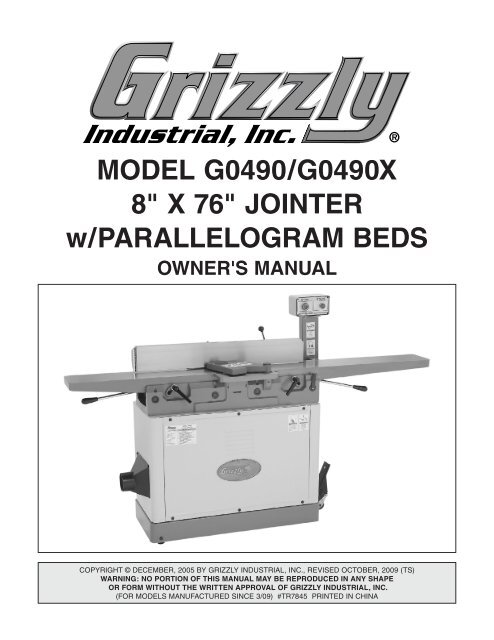

<strong>MODEL</strong> <strong>G0490</strong>/<strong>G0490</strong>X<br />

8" X 76" <strong>JOINTER</strong><br />

w/PARALLELOGRAM BEDS<br />

OWNER'S MANUAL<br />

<br />

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE<br />

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

<strong>MODEL</strong> <strong>G0490</strong>/<strong>G0490</strong>X<br />

8" X 76" <strong>JOINTER</strong><br />

w/PARALLELOGRAM BEDS<br />

OWNER'S MANUAL<br />

<br />

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE<br />

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

Model <strong>G0490</strong>/<strong>G0490</strong>X<br />

***IMPORTANT UPDATE***<br />

Installation of Pulleys<br />

& Ribbed V-Belt<br />

(T21360 Kit)<br />

Introduction<br />

The grooved aluminum pulleys and ribbed V-belt<br />

included with this jointer provide more efficient<br />

power transfer, reduced vibration, and quieter<br />

operation than standard belts.<br />

To install the pulleys and V-belt, perform the<br />

following installation procedure after completing<br />

Step 16 on Page 17 in the <strong>G0490</strong>/<strong>G0490</strong>X<br />

owner's manual.<br />

Box Contents<br />

A<br />

Installation<br />

The cutterhead blade<br />

edges are extremely sharp<br />

and can quickly slice your<br />

hands or fingers. Stay clear<br />

of the cutterhead when<br />

performing this procedure.<br />

Tools Needed<br />

Qty<br />

Hex Wrench 3mm.............................................. 1<br />

Hex Wrench 6mm.............................................. 1<br />

Rubber Mallet..................................................... 1<br />

To install the pulleys and V-belt:<br />

B<br />

1. Perform the assembly steps as instructed in<br />

the owner's manual through Step 16 on Page<br />

17.<br />

G<br />

H<br />

F<br />

C<br />

E<br />

D<br />

2. Slide the cutterhead shaft key into the keyway<br />

of the cutterhead shaft so that the flat<br />

end of the key is facing out (see Figure 2 on<br />

the next page for reference).<br />

Figure 1. Box inventory.<br />

Description<br />

Qty<br />

A. Ribbed V-Belt 8PK1172............................... 1<br />

B. Cutterhead Pulley........................................ 1<br />

C. Cutterhead Shaft Key 6 x 6 x 35mm.......... 1<br />

D. Cap Screw M8-1.25 x 25............................ 1<br />

E. Fender Washer 8mm.................................. 1<br />

F. Set Screws M6-1 x 10................................. 2<br />

G. Motor Shaft Key 5 x 5 x 25......................... 1<br />

H. Motor Pulley................................................ 1<br />

Refer to Section: 9 in the owner's manual<br />

for information of the parts listed in this<br />

update.<br />

Copyright © FEBRUARY, 2011 By Grizzly Industrial, Inc.<br />

Warning: No portion of this manual may be reproduced in any shape<br />

or form without the written approval of Grizzly Industrial, inc.<br />

#TS13766 printed in USA

3. Align the internal keyway of the cutterhead<br />

pulley with the shaft key, then slide the pulley<br />

onto the shaft, as shown in Figure 2.<br />

Note: To fully seat the pulley, it may be necessary<br />

to lightly tap on it with a rubber mallet.<br />

6. Align the internal keyway of the motor pulley<br />

with the shaft key, then slide the pulley<br />

onto the shaft until the shaft is even with the<br />

protruding face of the pulley, as shown in<br />

Figure 3.<br />

Set Screw<br />

(1 of 2)<br />

Shaft Key<br />

& Keyway<br />

Shaft Key<br />

& Keyway<br />

Cap Screw<br />

& Flat Washer<br />

Figure 2. Cutterhead pulley mounted on the<br />

cutterhead shaft.<br />

4. Secure the cutterhead pulley to the shaft with<br />

the M8-1.25 x 25 cap screw and 8mm flat<br />

washer.<br />

Figure 3. Motor pulley installed.<br />

7. Secure the motor pulley with the two M6-1 x<br />

10 set screws.<br />

8. Continue the assembly with Step 17 on Page<br />

18 of the owner's manual.<br />

5. Slide the motor shaft key into the motor shaft<br />

keyway so that the flat end of the key faces<br />

out.<br />

-2- <strong>G0490</strong>/<strong>G0490</strong>X Manual Update

<strong>MODEL</strong> <strong>G0490</strong>/<strong>G0490</strong>X<br />

8" <strong>JOINTER</strong><br />

Manual Update<br />

<strong>This</strong> update covers improvements made to this machine after the owner's manual was printed. Keep this<br />

update with your owner's manual for future reference. If you have questions, contact Tech Support at (570)<br />

546-9663 or by email at techsupport@grizzly.com.<br />

The motor and cutterhead pulleys are now made from aluminum alloy and the machine now uses a ribbed<br />

drive belt. <strong>This</strong> change improves the power transfer from the motor to the cutterhead.<br />

If you need to order replacement parts for these new items, refer to the information in the illustration and<br />

chart below for the correct part numbers.<br />

70V2<br />

224V2<br />

225V2<br />

Ref. No. Description Part Number<br />

70V2 Cutterhead Pulley Alum V2.03.09 P0490070V2<br />

224V2 V-Belt 8PK-1172 V2.03.09 P0490224V2<br />

225V2 Motor Pulley Alum V2.03.09 P0490225V2<br />

Copyright © JULY, 2009 By Grizzly Industrial, Inc.<br />

Warning: No portion of this manual may be reproduced in any shape<br />

or form without the written approval of Grizzly Industrial, inc.<br />

(For machines mANUFACTURED SINCE 6/09) #TS11962 printed in china

Model <strong>G0490</strong><br />

LIGHTED CONTROLS<br />

MANUAL UPDATE<br />

Improvements to this machine were made since the manual was originally printed, and this update covers<br />

those changes. Keep this update with your owner's manual in case you ever need to refer to it. If you have<br />

questions, contact Tech Support at (570) 546-9663 or by email at techsupport@grizzly.com.<br />

Lighted Controls<br />

We added lights in the control panel buttons to<br />

indicate when there is power to the machine.<br />

The addition of these lights changes the wiring<br />

diagram and two of the electrical components<br />

pictures on Page 43 of the owner's manual.<br />

Control Panel<br />

Magnetic Switch<br />

COPYRIGHT © MAY, 2006 BY GRIZZLY INDUSTRIAL, INC. REVISED NOVEMBER, 2006 (TR)<br />

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE<br />

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.<br />

#TR8282 PRINTED IN CHINA

<strong>G0490</strong> Wiring Diagram — November, 2006

Table of Contents<br />

INTRODUCTION ............................................... 2<br />

<br />

<br />

<br />

<br />

<br />

<br />

SECTION 1: SAFETY ....................................... 8<br />

<br />

<br />

SECTION 2: CIRCUIT REQUIREMENTS ...... 11<br />

<br />

SECTION 3: SETUP ....................................... 12<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

SECTION 4: OPERATIONS ........................... 23<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

SECTION 5: ACCESSORIES ......................... 31<br />

SECTION 6: MAINTENANCE ......................... 33<br />

<br />

<br />

<br />

<br />

SECTION 7: SERVICE ................................... 34<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

SECTION 8: WIRING ...................................... 46<br />

<br />

<br />

<br />

SECTION 9: PARTS ....................................... 49<br />

<br />

<br />

<br />

WARRANTY AND RETURNS ........................ 57

INTRODUCTION<br />

Manual Accuracy<br />

Contact Info<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

your machine may not exactly match the<br />

manual<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Machine Description<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

www.grizzly.com

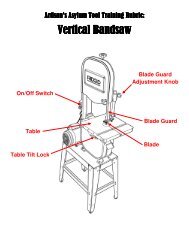

Identification<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 1.<br />

To reduce the risk of<br />

serious injury when using<br />

this machine, read and<br />

understand this entire<br />

manual before beginning<br />

any operations.

<strong>G0490</strong> Machine Data Sheet<br />

MACHINE DATA<br />

SHEET<br />

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901<br />

<strong>MODEL</strong> <strong>G0490</strong> 8" <strong>JOINTER</strong> WITH PARALLELOGRAM BEDS<br />

Product Dimensions:<br />

Weight.............................................................................................................................................................. 508 lbs.<br />

Length/Width/Height...........................................................................................................76-3/8 x 23-1/2 x 32-5/8 in.<br />

Foot Print (Length/Width)................................................................................................................. 44-1/2 x 16-1/2 in.<br />

Shipping Dimensions:<br />

Carton #1<br />

Type................................................................................................................................................. Wood Crate<br />

Content.................................................................................................................................................. Machine<br />

Weight.................................................................................................................................................... 430 lbs.<br />

Length/Width/Height................................................................................................................... 81 x 25 x 13 in.<br />

Carton #2<br />

Type................................................................................................................................................... Cardboard<br />

Content...................................................................................................................................................... Stand<br />

Weight.................................................................................................................................................... 167 lbs.<br />

Length/Width/Height................................................................................................................... 38 x 18 x 28 in.<br />

Electrical:<br />

Switch.......................................................................................................Magnetic with Thermal Overload Protection<br />

Switch Voltage...................................................................................................................................................... 220V<br />

Cord Length............................................................................................................................................................ 6 ft.<br />

Cord Gauge....................................................................................................................................................14 gauge<br />

Minimum Circuit Size........................................................................................................................................ 20 amp<br />

Plug Included............................................................................................................................................................No<br />

Motors:<br />

Main<br />

Type.................................................................................................................. TEFC Capacitor Start Induction<br />

Horsepower.................................................................................................................................................3 HP<br />

Voltage........................................................................................................................................................220V<br />

Prewired......................................................................................................................................................220V<br />

Phase........................................................................................................................................................ Single<br />

Amps.............................................................................................................................................................18A<br />

Speed.................................................................................................................................................3450 RPM<br />

Cycle..........................................................................................................................................................60 Hz<br />

Number Of Speeds........................................................................................................................................... 1<br />

Power Transfer ................................................................................................................................... Belt Drive<br />

Bearings...................................................................................................................................................Sealed<br />

Main Specifications:<br />

Fence Information<br />

Fence Length............................................................................................................................................. 36 in.<br />

Fence Width........................................................................................................................................... 1-1/4 in.<br />

Fence Height................................................................................................................................................ 5 in.<br />

Fence Stops................................................................................................................................ 45 and 90 deg.

Cutting Capacities<br />

Bevel Jointing...................................................................................................................... Left & Right 45 deg.<br />

Maximum Width of Cut................................................................................................................................. 8 in.<br />

Maximum Depth of Cut..............................................................................................................................1/8 in.<br />

Maximum Rabbeting Depth.......................................................................................................................1/2 in.<br />

Number of Cuts Per Minute.......................................................................................................................21400<br />

Knife Information<br />

Number of Knives..............................................................................................................................................4<br />

Knife Type....................................................................................................................................................HSS<br />

Knife Length................................................................................................................................................. 8 in.<br />

Knife Width................................................................................................................................................ 3/4 in.<br />

Knife Thickness......................................................................................................................................... 1/8 in.<br />

Knife Adjustment.........................................................................................................Jack Screws and Springs<br />

Cutterhead Information<br />

Cutterhead Type...................................................................................................................................... 4 Knife<br />

Cutterhead Diameter............................................................................................................................3-3/16 in.<br />

Cutterhead Speed.............................................................................................................................. 5350 RPM<br />

Table Information<br />

Table Length........................................................................................................................................ 76-3/8 in.<br />

Table Width.................................................................................................................................................. 8 in.<br />

Table Thickness..................................................................................................................................... 1-1/2 in.<br />

Floor to Table Height............................................................................................................................32-5/8 in.<br />

Table Adjustment Type................................................................................................................... Lever Action<br />

Construction<br />

Body Assembly Construction................................................................................................................Cast Iron<br />

Cabinet Construction.................................................................................................................One Piece Steel<br />

Fence Assembly Construction..............................................................................................................Cast Iron<br />

Guard Construction..................................................................................................................... Die Cast Metal<br />

Table Construction...................................................................................................Precision Ground Cast Iron<br />

Parallelogram................................................................................................................................................Yes<br />

Paint........................................................................................................................................... Powder Coated<br />

Other Information<br />

Number of Dust Ports........................................................................................................................................1<br />

Dust Port Size.............................................................................................................................................. 4 in.<br />

Other Specifications:<br />

Country Of Origin ................................................................................................................................................China<br />

Warranty ............................................................................................................................................................ 1 Year<br />

Serial Number Location ...............................................................................................................................Data Plate<br />

Assembly Time .................................................................................................................................................2 hours

<strong>G0490</strong>X Machine Data Sheet<br />

MACHINE DATA<br />

SHEET<br />

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901<br />

<strong>MODEL</strong> <strong>G0490</strong>X 8" <strong>JOINTER</strong> W/ SPIRAL CUTTERHEAD<br />

Product Dimensions:<br />

Weight.............................................................................................................................................................. 508 lbs.<br />

Length/Width/Height...........................................................................................................76-3/8 x 23-1/2 x 32-5/8 in.<br />

Foot Print (Length/Width)................................................................................................................. 44-1/2 x 16-1/2 in.<br />

Shipping Dimensions:<br />

Carton #1<br />

Type................................................................................................................................................. Wood Crate<br />

Content.................................................................................................................................................. Machine<br />

Weight.................................................................................................................................................... 430 lbs.<br />

Length/Width/Height................................................................................................................... 81 x 25 x 13 in.<br />

Carton #2<br />

Type................................................................................................................................................... Cardboard<br />

Content...................................................................................................................................................... Stand<br />

Weight.................................................................................................................................................... 167 lbs.<br />

Length/Width/Height................................................................................................................... 38 x 18 x 28 in.<br />

Electrical:<br />

Switch................................................................. Magnetic with Thermal Overload Protection with Large OFF Button<br />

Switch Voltage...................................................................................................................................................... 220V<br />

Cord Length............................................................................................................................................................ 6 ft.<br />

Cord Gauge....................................................................................................................................................14 gauge<br />

Minimum Circuit Size........................................................................................................................................ 20 amp<br />

Plug Included............................................................................................................................................................No<br />

Motors:<br />

Main<br />

Type.................................................................................................................. TEFC Capacitor Start Induction<br />

Horsepower.................................................................................................................................................3 HP<br />

Voltage........................................................................................................................................................220V<br />

Prewired......................................................................................................................................................220V<br />

Phase........................................................................................................................................................ Single<br />

Amps.............................................................................................................................................................15A<br />

Speed.................................................................................................................................................3450 RPM<br />

Cycle..........................................................................................................................................................60 Hz<br />

Number Of Speeds........................................................................................................................................... 1<br />

Power Transfer ................................................................................................................................... Belt Drive<br />

Bearings.............................................................................................................................Sealed Ball Bearings<br />

Main Specifications:<br />

Fence Information<br />

Fence Length............................................................................................................................................. 36 in.<br />

Fence Width........................................................................................................................................... 1-1/4 in.<br />

Fence Height................................................................................................................................................ 5 in.<br />

Fence Stops................................................................................................................................ 45 and 90 deg.

Cutting Capacities<br />

Bevel Jointing...................................................................................................................... Left & Right 45 deg.<br />

Maximum Width of Cut................................................................................................................................. 8 in.<br />

Maximum Depth of Cut..............................................................................................................................1/8 in.<br />

Maximum Rabbeting Depth.......................................................................................................................1/2 in.<br />

Number of Cuts Per Minute.......................................................................................................................21400<br />

Cutterhead Information<br />

Cutterhead Type........................................................................................................................................ Sprial<br />

Cutterhead Diameter..............................................................................................................................3-3/8 in.<br />

Number of Cutter Spirals...................................................................................................................................4<br />

Number of Indexable Cutters.......................................................................................................................... 40<br />

Cutter Insert Type.................................................................................................................. Indexable Carbide<br />

Cutter Insert Length................................................................................................................................. 14 mm<br />

Cutter Insert Width................................................................................................................................... 14 mm<br />

Cutter Insert Thickness.............................................................................................................................. 2 mm<br />

Cutterhead Speed.............................................................................................................................. 5350 RPM<br />

Table Information<br />

Table Length........................................................................................................................................ 76-3/8 in.<br />

Table Width.................................................................................................................................................. 8 in.<br />

Table Thickness..................................................................................................................................... 1-1/2 in.<br />

Floor to Table Height............................................................................................................................32-5/8 in.<br />

Table Adjustment Type................................................................................................................... Lever Action<br />

Table Movement Type.................................................................................................................. Parallelogram<br />

Construction<br />

Body Assembly Construction................................................................................................................Cast Iron<br />

Cabinet Construction.................................................................................................................One Piece Steel<br />

Fence Assembly Construction..............................................................................................................Cast Iron<br />

Guard Construction..................................................................................................................... Die Cast Metal<br />

Table Construction...................................................................................................Precision Ground Cast Iron<br />

Dovetailed Ways on Bed................................................................................................................................ No<br />

Parallelogram................................................................................................................................................Yes<br />

Paint........................................................................................................................................... Powder Coated<br />

Other Information<br />

Number of Dust Ports........................................................................................................................................1<br />

Dust Port Size.............................................................................................................................................. 4 in.<br />

Mobile Base............................................................................................................................................. Built-In<br />

Other Specifications:<br />

Country Of Origin ................................................................................................................................................China<br />

Warranty ............................................................................................................................................................ 1 Year<br />

Serial Number Location ...............................................................................................................................Data Plate<br />

Assembly Time .................................................................................................................................................2 hours

SECTION 1: SAFETY<br />

For Your Own Safety, Read Instruction<br />

Manual Before Operating this Machine<br />

The purpose of safety symbols is to attract your attention to possible hazardous conditions. <strong>This</strong><br />

manual uses a series of symbols and signal words intended to convey the level of importance<br />

of the safety messages. The progression of symbols is described below. Remember that safety<br />

messages by themselves do not eliminate danger and are not a substitute for proper accident<br />

prevention measures.<br />

Indicates an imminently hazardous situation which, if not avoided,<br />

WILL result in death or serious injury.<br />

Indicates a potentially hazardous situation which, if not avoided,<br />

COULD result in death or serious injury.<br />

Indicates a potentially hazardous situation which, if not avoided,<br />

MAY result in minor or moderate injury. It may also be used to alert<br />

against unsafe practices.<br />

NOTICE<br />

Safety Instructions for Machinery<br />

<strong>This</strong> symbol is used to alert the user to useful information about<br />

proper operation of the machine.<br />

Safety Instructions for Machinery<br />

1. READ ENTIRE MANUAL BEFORE<br />

STARTING. <br />

<br />

<br />

2. ALWAYS USE ANSI APPROVED<br />

SAFETY GLASSES WHEN OPERATING<br />

MACHINERY. <br />

<br />

<br />

3. ALWAYS WEAR A NIOSH APPROVED<br />

RESPIRATOR WHEN OPERATING<br />

MACHINERY THAT PRODUCES DUST.<br />

<br />

<br />

4. ALWAYS USE HEARING PROTECTION<br />

WHEN OPERATING MACHINERY.<br />

<br />

<br />

5. WEAR PROPER APPAREL. <br />

<br />

<br />

<br />

<br />

6. NEVER OPERATE MACHINERY WHEN<br />

TIRED OR UNDER THE INFLUENCE OF<br />

DRUGS OR ALCOHOL.

Safety Instructions for Machinery<br />

7. ONLY ALLOW TRAINED AND PROP-<br />

ERLY SUPERVISED PERSONNEL TO<br />

OPERATE MACHINERY. <br />

<br />

<br />

8. KEEP CHILDREN/VISITORS AWAY.<br />

<br />

<br />

<br />

<br />

<br />

9. UNATTENDED OPERATION. <br />

<br />

<br />

OFF<br />

<br />

<br />

10. DO NOT USE IN DANGEROUS<br />

ENVIRONMENTS. <br />

<br />

<br />

11. KEEP WORK AREA CLEAN AND WELL<br />

LIGHTED. <br />

<br />

12. USE A GROUNDED POWER SUPPLY<br />

RATED FOR THE MACHINE AMPERAGE.<br />

<br />

<br />

<br />

13. ALWAYS DISCONNECT FROM POWER<br />

SOURCE BEFORE SERVICING<br />

MACHINERY<br />

<br />

14. MAINTAIN MACHINERY WITH CARE.<br />

<br />

<br />

<br />

15. MAKE SURE GUARDS ARE IN PLACE<br />

AND WORK CORRECTLY BEFORE<br />

USING MACHINERY.<br />

16. REMOVE CHUCK KEYS OR ADJUSTING<br />

TOOLS. <br />

<br />

<br />

17. DAMAGED MACHINERY.<br />

<br />

<br />

<br />

<br />

18. DO NOT FORCE MACHINERY. <br />

<br />

<br />

19. SECURE WORKPIECE. <br />

<br />

<br />

<br />

<br />

20. DO NOT OVERREACH.<br />

<br />

<br />

21. MANY MACHINES CAN EJECT<br />

WORKPIECES TOWARD OPERATOR.<br />

<br />

<br />

22. STABLE MACHINE. <br />

<br />

<br />

<br />

<br />

23. CERTAIN DUST MAY BE HAZARDOUS<br />

<br />

<br />

<br />

<br />

<br />

24. EXPERIENCING DIFFICULTIES.

Additional Safety Instructions for Jointers<br />

1. <strong>JOINTER</strong> KICKBACK. <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

2. OUTFEED TABLE ALIGNMENT. <br />

<br />

<br />

<br />

<br />

<br />

6. KICKBACK ZONE.<br />

<br />

<br />

<br />

7. MAXIMUM CUTTING DEPTH. <br />

<br />

<br />

<br />

<br />

<br />

8. JOINTING WITH THE GRAIN. <br />

<br />

<br />

<br />

3. PUSH BLOCKS. <br />

<br />

<br />

<br />

4. WORKPIECE SUPPORT. <br />

<br />

<br />

<br />

<br />

5. USING GOOD STOCK. <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

9. GUARDS IN PLACE. <br />

<br />

<br />

<br />

10. PROPER CUTTING. <br />

<br />

<br />

<br />

<br />

<br />

11. SAFE KNIFE PROJECTION.<br />

<br />

<br />

<br />

<br />

<br />

<br />

Like all machinery there is potential danger<br />

when operating this machine. Accidents are<br />

frequently caused by lack of familiarity or<br />

failure to pay attention. Use this machine<br />

with respect and caution to decrease the<br />

risk of operator injury. If normal safety precautions<br />

are overlooked or ignored, serious<br />

personal injury may occur.<br />

<br />

No list of safety guidelines can be complete.<br />

Every shop environment is different. Always<br />

consider safety first, as it applies to your<br />

individual working conditions. Use this and<br />

other machinery with caution and respect.<br />

Failure to do so could result in serious personal<br />

injury, damage to equipment, or poor<br />

work results.

SECTION 2: CIRCUIT REQUIREMENTS<br />

220V Single-Phase<br />

Operation<br />

Power Connection Device<br />

<br />

<br />

<br />

Figure 2<br />

Serious personal injury could occur if you<br />

connect the machine to power before completing<br />

the setup process. DO NOT connect<br />

the machine to the power until instructed<br />

later in this manual.<br />

Electrocution or fire could<br />

result if machine is not<br />

grounded and installed in<br />

compliance with electrical<br />

codes. Compliance MUST<br />

be verified by a qualified<br />

electrician!<br />

Figure 2.<br />

Extension Cords<br />

<br />

<br />

<br />

Full Load Amperage Draw<br />

<br />

<br />

<br />

Power Supply Circuit Requirements<br />

<br />

<br />

<br />

<br />

<br />

If you are unsure about<br />

the wiring codes in your area or you plan to<br />

connect your machine to a shared circuit, consult<br />

a qualified electrician.

SECTION 3: SETUP<br />

<strong>This</strong> machine presents<br />

serious injury hazards<br />

to untrained users. Read<br />

through this entire manual<br />

to become familiar with<br />

the controls and operations<br />

before starting the<br />

machine!<br />

Wear safety glasses during<br />

the entire setup process!<br />

The Model <strong>G0490</strong>/<br />

<strong>G0490</strong>X is a heavy<br />

machine (approx. 600<br />

lbs.) Serious personal<br />

injury may occur if safe<br />

moving methods are<br />

not used. To be safe,<br />

get assistance and use<br />

power lifting equipment<br />

to move the shipping<br />

containers and to place<br />

the jointer on the stand.<br />

Needed for Setup<br />

<br />

<br />

Description<br />

Qty<br />

<br />

<br />

Page 14 <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Unpacking<br />

<br />

<br />

<br />

please immediately<br />

call Customer Service at (570) 546-9663<br />

for advice.<br />

<br />

<br />

Otherwise, filing a freight claim can be difficult.

Inventory<br />

<br />

<br />

<br />

Note: If you can't find an item on this list, check<br />

the mounting location on the machine or examine<br />

the packaging materials carefully. Occasionally<br />

we pre-install certain components for shipping<br />

purposes.<br />

Inventory: (Figures 3–4)<br />

Qty<br />

A. <br />

B. <br />

C. <br />

D. <br />

E. <br />

F. <br />

<br />

<br />

<br />

G. <br />

H. <br />

I. <br />

J. <br />

K. <br />

L. <br />

M. <br />

Hardware Bag (Not Shown):<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<strong>G0490</strong> Knife Setting Gauge (Not Shown):<br />

<br />

<br />

<br />

<strong>G0490</strong>X Cutterhead Hardware (Not Shown):<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 3.<br />

<br />

<br />

Figure 4.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

SUFFOCATION HAZARD!<br />

Immediately discard all plastic<br />

bags and packing materials<br />

to eliminate choking/suffocation<br />

hazards for children<br />

and animals.

Cleanup<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Before cleaning, gather the following:<br />

<br />

<br />

<br />

H9692—Orange Power Cleaner & Degreaser<br />

<br />

<br />

Gasoline and petroleum<br />

products have low flash<br />

points and can explode<br />

or cause fire if used to<br />

clean machinery. Avoid<br />

using these products<br />

to clean machinery.<br />

Many cleaning solvents<br />

are toxic if inhaled.<br />

Minimize your risk by only<br />

using these products in a<br />

well ventilated area.<br />

NOTICE<br />

Avoid chlorine-based solvents, such as<br />

acetone or brake parts cleaner that may<br />

damage painted surfaces. Always follow<br />

the manufacturer’s instructions when using<br />

any type of cleaning product.<br />

Basic steps for removing rust preventative:<br />

1. <br />

<br />

2. <br />

<br />

<br />

3. <br />

<br />

<br />

Figure 5. <br />

<br />

Note:In a pinch, automotive degreasers, mineral<br />

ventative.<br />

Before using these products, though,<br />

test them on an inconspicuous area of your paint<br />

to make sure they will not damage it.<br />

<br />

<br />

Note:To clean off thick coats of rust preventative<br />

on flat surfaces, such as tables, use<br />

a PLASTIC paint scraper to scrape off the<br />

majority of the coating before wiping it off with<br />

your rag. (Do not use a metal scraper or you<br />

may scratch your machine.)<br />

4. Steps 2–3

Site Considerations<br />

Weight Load<br />

Machine Data Sheet<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Space Allocation<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

See below for working clearances.<br />

Children or untrained people<br />

may be seriously injured by<br />

this machine. Only install in an<br />

access restricted location.<br />

Physical Environment<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Electrical Installation<br />

<br />

<br />

<br />

<br />

<br />

<br />

Lighting<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 6.

Assembly<br />

<br />

<br />

Test Run <br />

Page 21<br />

To assemble your jointer:<br />

<br />

<br />

1. <br />

<br />

<br />

<br />

2. <br />

<br />

<br />

<br />

<br />

3. <br />

<br />

<br />

<br />

Note: Keep the cap screws and flat washers<br />

that secure the control panel pedestal to the<br />

inside of the cabinet so that it can be used to<br />

install the pedestal in a future step.<br />

4. <br />

<br />

<br />

8. <br />

<br />

<br />

<br />

Step 4Figure 7<br />

<br />

Figure 7.<br />

Note: Pulley alignment and belt installation<br />

will take place in future steps.<br />

9. <br />

<br />

<br />

<br />

Figure 8<br />

<br />

Note: Retain the two carriage bolts, hex nuts,<br />

and flat washers so that they can be used to<br />

install the motor in a future step.<br />

5. <br />

<br />

<br />

<br />

6. <br />

7. <br />

<br />

Figure 7<br />

<br />

Figure 8.

10. <br />

<br />

11. <br />

<br />

Figure 9<br />

<br />

14. <br />

<br />

<br />

<br />

<br />

<br />

Note: Make sure the cutterhead pulley is facing<br />

to the rear of the stand.<br />

15. <br />

<br />

Figure 11<br />

Figure 9.<br />

12. <br />

<br />

<br />

13. <br />

Figure 10<br />

<br />

<br />

Figure 11.<br />

<br />

16. Step 3 <br />

<br />

Figure 12<br />

<br />

Figure 10.<br />

<br />

Figure 12.

17. <br />

<br />

Figure 13<br />

<br />

<br />

<br />

Figure 15.<br />

<br />

19. <br />

Figure 16<br />

<br />

<br />

Figure 13.<br />

18. <br />

<br />

Figure 14<br />

Cutterhead<br />

Pulley<br />

Alignment<br />

Motor<br />

Pulley<br />

Figure 16.<br />

Figure 14.<br />

<br />

Figure 15

20. <br />

Figure 17 <br />

<br />

<br />

The belt guard MUST be installed before<br />

operating the jointer or else the moving<br />

V-belt will be exposed, creating an entanglement<br />

hazard at the back of the jointer.<br />

21. <br />

<br />

Figure 19<br />

<br />

Figure 17.<br />

Note: When properly tensioned, there is<br />

approximately 1 ⁄4" deflection of the V-belt as<br />

moderate pressure is applied midway between<br />

the pulleys, as illustrated in Figure 18. If<br />

necessary, apply downward pressure on the<br />

motor to attain the proper V-belt tension.<br />

<br />

Figure 19.<br />

22. <br />

Figure 20<br />

<br />

<br />

<br />

<br />

<br />

Figure 18.<br />

<br />

Figure 20.

The outfeed table MUST be level with<br />

cutterhead knives or inserts when they are<br />

at top dead center (their highest point during<br />

rotation). Otherwise, the workpiece cannot<br />

properly feed past the cutterhead, which<br />

may cause a kickback hazard to the operator.<br />

23. <br />

<br />

<br />

<br />

<br />

<br />

Figure 22<br />

<br />

<br />

<br />

<br />

<br />

Setting Outfeed Table Height <br />

Page 43<br />

24. <br />

<br />

<br />

Figures 21–22<br />

25. <br />

<br />

<br />

Figure 23<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 21.<br />

Figure 23.<br />

<br />

<br />

26. Model <strong>G0490</strong> Only: <br />

Figure 24<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 22.<br />

<br />

Figure 24.

27. <br />

28. <br />

<br />

29. <br />

Figure 25<br />

<br />

<br />

Figure 25.<br />

30. <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Dust Collection<br />

DO NOT operate the Model <strong>G0490</strong>/<strong>G0490</strong>X<br />

without an adequate dust collection system.<br />

<strong>This</strong> jointer creates substantial amounts of<br />

wood dust while operating. Failure to use<br />

a dust collection system can result in short<br />

and long-term respiratory illness.<br />

Recommended CFM at Dust Port: 400 CFM<br />

Do not confuse this CFM recommendation with<br />

the rating of the dust collector. To determine<br />

the CFM at the dust port, you must consider<br />

these variables: (1) CFM rating of the dust collector,<br />

(2) hose type and length between the<br />

dust collector and the machine, (3) number<br />

of branches or wyes, and (4) amount of other<br />

open lines throughout the system. Explaining<br />

how to calculate these variables is beyond the<br />

scope of this manual. Consult an expert or purchase<br />

a good dust collection "how-to" book.<br />

To connect a dust collection hose:<br />

1. <br />

<br />

2. <br />

Note: A tight fit is necessary for proper<br />

performance.<br />

Test Run<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

TroubleshootingPage 34

Before starting the jointer, make sure you<br />

have performed the preceding assembly<br />

and adjustment instructions, and you have<br />

read through the rest of the manual and<br />

are familiar with the various functions and<br />

safety features on this machine. Failure to<br />

follow this warning could result in serious<br />

personal injury or even death!<br />

To test run the machine:<br />

1. <br />

<br />

<br />

2. <br />

<br />

3. <br />

4. <br />

<br />

<br />

Figure 26<br />

Figure 26.<br />

5. <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

6. <br />

OFF<br />

7. <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

8. <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Wiring Diagram Page 47 <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Factory adjustments that should be verified:<br />

<br />

<br />

<br />

Recommended<br />

Adjustments<br />

Page<br />

36<br />

Page 44<br />

Page 45<br />

<br />

Page 40

SECTION 4: OPERATIONS<br />

Operation Overview<br />

To reduce the risk of<br />

serious injury when using<br />

this machine, read and<br />

understand this entire<br />

manual before beginning<br />

any operations.<br />

Damage to your eyes, lungs, and ears could<br />

result from using this machine without<br />

proper protective gear. Always wear safety<br />

glasses, a respirator, and hearing protection<br />

when operating this machine.<br />

<br />

<br />

<br />

Operation<br />

<br />

To complete a typical operation, the operator<br />

does the following:<br />

1. <br />

<br />

2. <br />

<br />

3. <br />

<br />

4. <br />

<br />

Loose hair, clothing, or<br />

jewelry could get caught<br />

in machinery and cause<br />

serious personal injury.<br />

Keep these items away<br />

from moving parts at all<br />

times to reduce this risk.<br />

NOTICE<br />

If you have never used this type of machine<br />

or equipment before, WE STRONGLY REC-<br />

OMMEND that you read books, review<br />

industry trade magazines, or get formal<br />

training before beginning any projects.<br />

Regardless of the content in this section,<br />

Grizzly Industrial will not be held liable for<br />

accidents caused by lack of training.<br />

5. <br />

<br />

<br />

<br />

<br />

6. <br />

<br />

7. <br />

8. <br />

<br />

<br />

<br />

<br />

<br />

9. Steps 5–8 <br />

<br />

10.

Basic Controls<br />

Figures 27–30<br />

<br />

<br />

Fence Movement: <br />

Figure 29<br />

<br />

<br />

START Button:<br />

<br />

STOP Button: <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 29.<br />

Fence Tilting: Figure 30<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 27.<br />

Table Movement: <br />

Figure 28<br />

<br />

<br />

<br />

Adjusting Infeed TableStop BoltsPage<br />

44 <br />

<br />

<br />

<br />

<br />

Figure 30.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

For the Model <strong>G0490</strong>/<strong>G0490</strong>X, the minimum<br />

depth of cut is 1 ⁄32" and the maximum<br />

depth of cut is 1 ⁄8" for the <strong>G0490</strong> and 5 ⁄16" for<br />

the <strong>G0490</strong>X. DO NOT exceed the maximum<br />

depth of cut per pass on your jointer or kickback<br />

and serious injury may occur!<br />

Figure 28.

Stock Inspection &<br />

Requirements<br />

<br />

Scrape all glue off the workpiece before<br />

jointing. <br />

<br />

<br />

Follow these rules when choosing and jointing<br />

stock:<br />

<br />

<br />

<br />

<br />

contains large or loose knots. <br />

<br />

<br />

<br />

Jointing and surface planing with the<br />

grain is safer for the operator and produces<br />

a better finish. <br />

<br />

<br />

<br />

<br />

<br />

Figure 31<br />

Note: If the grain changes direction along the<br />

edge of the workpiece, decrease the depth of<br />

cut and make additional passes.<br />

<br />

Remove foreign objects from the<br />

workpiece. <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Note: Wood stacked on a concrete or dirt<br />

surface can have small pieces of concrete or<br />

stone pressed into the surface.<br />

Make sure all stock is sufficiently dried<br />

before jointing. <br />

<br />

<br />

<br />

Make sure your workpiece exceeds the<br />

minimum dimension requirements, as<br />

shown in Figure 32, before processing it<br />

through the jointer, or the workpiece may<br />

break or kickback during the operation.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 31.<br />

<br />

Only process natural wood fiber through<br />

your jointer. <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 32.

Before turning the jointer ON, make sure<br />

the outfeed table height is properly set<br />

(refer to Setting Outfeed Table Height on<br />

Page 43 for detailed instructions) to avoid<br />

workpiece kickback and to ensure good<br />

results. Kickback of the workpiece could<br />

cause serious personal injury!<br />

Squaring Stock<br />

Squaring stock involves four steps performed<br />

in the following order:<br />

1. Surface Plane on the Jointer: <br />

<br />

Figure 33<br />

3. Edge Joint on the Jointer: <br />

<br />

Figure 35<br />

Figure 35.<br />

4. Rip Cut on a Table Saw: <br />

<br />

<br />

Figure 36<br />

<br />

<br />

<br />

<br />

Figure 36.<br />

Figure 33.<br />

2. Surface Plane on a Thickness Planer:<br />

<br />

<br />

Figure 34<br />

Making adjustments to the jointer while the<br />

machine is ON greatly increases the risk to<br />

the operator from the rotating cutterhead.<br />

ALWAYS make sure the jointer is OFF and<br />

disconnected from power before performing<br />

adjustments, maintenance, or service on the<br />

machine!<br />

<br />

<br />

<br />

Figure 34.

Surface Planing<br />

<br />

Figures<br />

37–38<br />

<br />

NOTICE<br />

If you are not experienced with a jointer,<br />

set the depth of cut to 0" and practice<br />

feeding the workpiece across the tables as<br />

described for each of the jointing procedures.<br />

<strong>This</strong> process will better prepare you<br />

for the actual operation.<br />

To surface plane the workpiece on the jointer:<br />

1. <br />

2. Safety<br />

Instructions Page 8 <br />

Stock Inspection & Requirement <br />

Page 25<br />

3. <br />

Setting Outfeed Table Height<br />

Page 43<br />

4. <br />

<br />

<br />

Note: We suggest a 1 ⁄32" depth of cut for surface<br />

planing, and a more shallow depth for<br />

hardwood species or for wide stock.<br />

5. <br />

<br />

<br />

6. ON<br />

Figure 37.<br />

<br />

Failure to use push blocks when surface<br />

planing could result in your hands contacting<br />

the rotating cutterhead, which will cause<br />

serious personal injury. ALWAYS use push<br />

blocks when surface planing on the jointer!<br />

7. <br />

<br />

<br />

<br />

Figure 38.<br />

<br />

Note: When your leading hand comes within<br />

4" of the cutterhead, lift that push block up<br />

and place it on the workpiece portion that is<br />

on the outfeed table. Now, focus the downward<br />

pressure with the leading hand while<br />

feeding, then repeat the same action with<br />

your trailing hand when it comes within 4" of<br />

the cutterhead. Keep your hands safe! DO<br />

NOT allow them to get any closer than 4"<br />

from the cutterhead.<br />

8. Step 7

Edge Jointing<br />

<br />

<br />

Figures 39–40<br />

<br />

<br />

To edge joint on the jointer:<br />

1. <br />

2. Safety<br />

Instructions Page 8 <br />

Stock Inspection & Requirement <br />

Page 25<br />

3. <br />

Setting Outfeed Table Height<br />

Page 43<br />

4. <br />

<br />

<br />

Note: We suggest 1 ⁄16"– 1 ⁄8" depth of cut for<br />

edge jointing, and a more shallow depth for<br />

hardwood species or for wide stock.<br />

5. <br />

<br />

<br />

Figure 39.<br />

6. ON<br />

7. <br />

<br />

<br />

<br />

Figure 40.<br />

<br />

Note: When your leading hand comes within<br />

4" of the cutterhead, lift that push block up<br />

and place it on the workpiece portion that is<br />

on the outfeed table. Now, focus the downward<br />

pressure with the leading hand while<br />

feeding, then repeat the same action with<br />

your trailing hand when it comes within 4" of<br />

the cutterhead. Keep your hands safe! DO<br />

NOT allow them to get any closer than 4"<br />

from the cutterhead.<br />

8. Step 7

Bevel Cutting<br />

<br />

<br />

Figures 41–42<br />

<br />

<br />

<br />

<br />

To bevel cut on the jointer:<br />

1. <br />

2. Safety<br />

Instructions Page 8 <br />

Stock Inspection & Requirement <br />

Page 25<br />

3. <br />

Setting Outfeed Table Height<br />

Page 43<br />

4. <br />

<br />

<br />

Note: We suggest 1 ⁄16"– 1 ⁄8" depth of cut for<br />

bevel cutting, and a more shallow depth for<br />

hardwood species or for wide stock.<br />

5. <br />

<br />

<br />

6. ON<br />

Figure 41.<br />

7. <br />

<br />

<br />

<br />

<br />

Note: When your leading hand comes within<br />

4" of the cutterhead, lift that push block up<br />

and place it on the workpiece portion that is<br />

on the outfeed table. Now, focus the downward<br />

pressure with the leading hand while<br />

feeding, then repeat the same action with<br />

your trailing hand when it comes within 4" of<br />

the cutterhead. Keep your hands safe! DO<br />

NOT allow them to get any closer than 4"<br />

from the cutterhead.<br />

Figure 42.<br />

8. Step 7

Rabbet Cutting<br />

<br />

Figures 43<br />

& 44 <br />

<br />

<br />

NOTICE<br />

If you are not experienced with a jointer,<br />

set the depth of cut to 0", and practice<br />

feeding the workpiece across the tables as<br />

described below. <strong>This</strong> procedure will better<br />

prepare you for the actual operation.<br />

To rabbet cut on the jointer:<br />

1. <br />

2. SECTION 1: SAFETY,<br />

Page 8<br />

3. <br />

<br />

Stock Inspection & Requirements <br />

Page 25<br />

4. <br />

<br />

<br />

When the cutterhead guard is removed,<br />

attempting any other cut besides a rabbet<br />

directly exposes the operator to the moving<br />

cutterhead. Always replace the cutterhead<br />

guard after rabbet cutting!<br />

4. <br />

5. <br />

<br />

<br />

6. ON<br />

Figure 43.<br />

7. <br />

<br />

<br />

<br />

NoteIf your leading hand gets within 4" of the<br />

cutterhead, lift it up and over the cutterhead,<br />

and place the push block on the portion of the<br />

workpiece that is on the outfeed table. Now,<br />

focus your pressure on the outfeed end of<br />

the workpiece while feeding, and repeat the<br />

same action with your trailing hand when it<br />

gets within 4" of the cutterhead. To keep your<br />

hands safe, DO NOT let them get closer than<br />

4" from the cutterhead when it is moving!<br />

Figure 44.<br />

<br />

8. Step 7

SECTION 5: ACCESSORIES<br />

G1753—Jointer Pal ® Magnetic Knife Jig<br />

(For HSS & Cobalt Knives)<br />

G1756—Jointer Pal ® Magnetic Knife Jig<br />

(For Carbide Knives)<br />

<br />

<br />

<br />

<br />

T21151—8" SELF-TEST ® HSS System<br />

H5143—8" SELF-TEST ® Cobalt System<br />

(Includes 1 Set Knife Holders & 4 Double-<br />

Edge HSS "Dispoz-A-Blade" Knives)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 45. <br />

T21348—Carbide Indexable Insert, 10 Pk.<br />

<br />

<br />

<br />

Figure 47. <br />

G4181—Power Feeder, 1 HP Single-Phase<br />

G7873—Power Feeder, 1 HP 3-Phase<br />

<br />

<br />

<br />

Figure 46.<br />

<br />

Figure 48.

T20501—Face Shield Crown Protector 4"<br />

T20502—Face Shield Crown Protector 7"<br />

T20503—Face Shield Window<br />

T20452—"Kirova" Anti-Reflective S. Glasses<br />

T20451—"Kirova" Clear Safety Glasses<br />

H0736—Shop Fox ® Safety Glasses<br />

H7194—Bifocal Safety Glasses 1.5<br />

H7195—Bifocal Safety Glasses 2.0<br />

H7196—Bifocal Safety Glasses 2.5<br />

G5562—SLIPIT ® 1 Qt. Gel<br />

G5563—SLIPIT ® 12 oz Spray<br />

G2871—Boeshield ® T-9 12 oz Spray<br />

G2870—Boeshield ® T-9 4 oz Spray<br />

H3788—G96 ® Gun Treatment 12 oz Spray<br />

H3789—G96 ® Gun Treatment 4.5 oz Spray<br />

T20502<br />

T20452<br />

T20503<br />

T20451<br />

H7194<br />

Figure 49. <br />

H0736<br />

H2499—Small Half-Mask Respirator<br />

H3631—Medium Half-Mask Respirator<br />

H3632—Large Half-Mask Respirator<br />

H3635—Cartridge Filter Pair P100<br />

<br />

<br />

<br />

<br />

Figure 51. <br />

<br />

G1163—1 HP Dust Collector<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 50. <br />

<br />

Figure 52.

SECTION 6: MAINTENANCE<br />

Always disconnect power<br />

to the machine before<br />

performing maintenance.<br />

Failure to do this may<br />

result in serious personal<br />

injury.<br />

Schedule<br />

<br />

<br />

<br />

Daily<br />

<br />

<br />

<br />

<br />

Monthly Check<br />

<br />

<br />

<br />

Ribbed V-belt<br />

Cleaning<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Page 32<br />

Lubrication<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Steps 19–20Page 18

SECTION 7: SERVICE<br />

<br />

<br />

<br />

Troubleshooting<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Page 18<br />

Page 18<br />

<br />

<br />

<br />

<br />

Page 18<br />

<br />

Page 18<br />

<br />

<br />

Pages 43 & 44<br />

<br />

Page 39

Page 39<br />

Page 25<br />

<br />

<br />

Pages 36 & 39<br />

<br />

<br />

<br />

<br />

<br />

<br />

Pages 36<br />

& 39<br />

<br />

Pages 36 & 39<br />

<br />

<br />

Page 36

Cutterhead Knives<br />

(<strong>G0490</strong>)<br />

Inspecting Knife Height<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Tools Needed<br />

Qty<br />

<br />

Figure 53.<br />

<br />

5. <br />

<br />

Figure 54<br />

To inspect the knife height:<br />

1. <br />

<br />

<br />

<br />

The cutterhead knives<br />

are very sharp and can<br />

quickly cut your fingers<br />

or hands. Wear heavy<br />

leather gloves and take<br />

great care when handling<br />

the cutterhead knives to<br />

avoid personal injury.<br />

2. <br />

3. <br />

<br />

4. <br />

Figure 53<br />

Figure 54.<br />

<br />

6. <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Setting Outfeed<br />

Table HeightPage 43<br />

7. Steps 4–6 <br />

<br />

<br />

8.

Adjusting/Replacing Knives<br />

<br />

Check/<br />

Adjusting Table ParallelismPage 40<br />

<br />

<br />

<br />

Figure 56<br />

<br />

<br />

Figure 55<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Setting Outfeed Table Height<br />

Page 43<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 56.<br />

Tools Needed<br />

Qty<br />

<br />

<br />

<br />

To adjust/replace the knives:<br />

1. <br />

2. <br />

<br />

Figure 55.<br />

3. <br />

<br />

4. <br />

<br />

5.

6. <br />

<br />

<br />

<br />

7. <br />

<br />

<br />

Page 32<br />

<br />

8. <br />

Figure 57<br />

<br />

<br />

<br />

<br />

Steps 5–8<br />

<br />

<br />

<br />

9. <br />

<br />

<br />

<br />

Figure 58<br />

<br />

<br />

<br />

<br />

Figure 58.<br />

The outfeed table MUST be level with<br />

cutterhead knives or inserts when they are<br />

at top dead center (their highest point during<br />

rotation). Otherwise, the workpiece cannot<br />

properly feed past the cutterhead, which<br />

may cause a kickback hazard to the operator.<br />

<br />

<br />

10. <br />

Setting Outfeed Table Height <br />

Page 43<br />

Figure 57.

Cutterhead Inserts<br />

(<strong>G0490</strong>X)<br />

<br />

<br />

<br />

<br />

<br />

Figure 59<br />

5. <br />

<br />

<br />

<br />

<br />

<br />

<br />

6. <br />

<br />

<br />

<br />

7. <br />

<br />

<br />

<br />

Figure 59.<br />

Tools Needed<br />

Qty<br />

<br />

<br />

To rotate or replace a spiral cutterhead<br />

insert:<br />

1. <br />

2. <br />

<br />

3. <br />

<br />

<br />

<br />

<br />

<br />

The outfeed table MUST be level with<br />

cutterhead knives or inserts when they are<br />

at top dead center (their highest point during<br />

rotation). Otherwise, the workpiece cannot<br />

properly feed past the cutterhead, which<br />

may cause a kickback hazard to the operator.<br />

8. <br />

Setting Outfeed Table Height <br />

Page 43<br />

4. <br />

<br />

<br />

<br />

Note: Proper cleaning of the insert, Torx<br />

screw, and the cutterhead pocket is critical<br />

to achieving a smooth finish. Dirt or dust<br />

trapped between the insert and cutterhead<br />

will raise the insert slightly, and make noticeable<br />

marks on your workpiece the next time<br />

you cut.<br />

Tip: Use low-pressure compressed air or a<br />

vacuum nozzle to clean out the cutterhead<br />

pocket.

Checking/Adjusting<br />

Table Parallelism<br />

4. <br />

<br />

<br />

Figure 61<br />

<br />

<br />

<br />

Tools Needed<br />

Qty<br />

<br />

<br />

<br />

<br />

<br />

Checking Outfeed Table<br />

To check the outfeed table parallelism:<br />

1. <br />

2. <br />

<br />

3. <br />

<br />

<br />

<br />

Figure 60<br />

<br />

<br />

Figure 61.<br />

<br />

5. <br />

<br />

<br />

<br />

6. <br />

Figure 62 <br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 62.<br />

<br />

Figure 60<br />

<br />

<br />

<br />

<br />

Checking Infeed Table<br />

<br />

<br />

<br />

<br />

<br />

Adjusting Table Parallelism<br />

<br />

Checking Infeed Table

Checking Infeed Table<br />

To check the infeed table parallelism:<br />

1. <br />

<br />

<br />

<br />

<br />

<br />

2. <br />

Setting Outfeed Table Height <br />

Page 43<br />

3. <br />

<br />

<br />

<br />

<br />

Figure 63<br />

<br />

<br />

<br />

Figure 63.<br />

<br />

4. <br />

Figure 64 <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Adjusting<br />

Table Parallelism<br />

Adjusting Table Parallelism<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Figure 64.

Important: The steps below are intended to be<br />

performed directly after the steps involved in<br />

checking the outfeed table parallelism. Do not<br />

continue until you have performed those steps.<br />

To adjust the table parallelism:<br />

1. <br />

<br />

<br />

<br />

Figure 65<br />

<br />

<br />

Figure 65.<br />

<br />

2. <br />

<br />

<br />

Figure 66<br />

<br />

<br />

3. <br />

Figure 62<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

4. <br />

<br />

5. <br />

<br />

<br />

<br />

6. <br />

<br />

<br />

Figure 63<br />

7. <br />

Figure 64 <br />

<br />

<br />

<br />

<br />

<br />

<br />

8. <br />

<br />

9. <br />

<br />

<br />

<br />

10. <br />

<br />

Figure 66.

Setting Outfeed<br />

Table Height<br />

6. <br />

<br />

<br />

Figures 68–69<br />

<br />