DS-Horizontal Dual Pot Sand Filter series 2-SF 10K-0902.pdf - FCE

DS-Horizontal Dual Pot Sand Filter series 2-SF 10K-0902.pdf - FCE

DS-Horizontal Dual Pot Sand Filter series 2-SF 10K-0902.pdf - FCE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

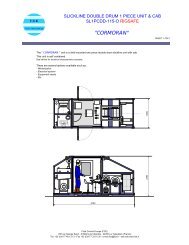

HORIZONTAL DUAL POT SAND FILTER<br />

2-<strong>SF</strong> SERIES<br />

10 000 PSI - H2S SERVICE<br />

February 2009<br />

Process and design data<br />

Description<br />

Gas capacity 35 MMSCF/D The <strong>FCE</strong> 2-Stage Filtration <strong>Dual</strong> <strong>Pot</strong> <strong>Sand</strong> <strong>Filter</strong> is designed<br />

Liquid capacity 5000 BBL/D to remove solid particles from well effluent. Located after the<br />

Sour gas service Yes (as per NACE MR01-75) flowhead, it prevents downstream equipment against erosion.<br />

Design pressure 10 000 PSI (689.5 bars)<br />

Design temperature -20°F to 250°F (-29°C to 121°C) A first stage filtration constists of a centrifugal separation and<br />

Vessel capacity 60 litres allows the bigger particles to drop down into the vessel.<br />

Std filter cutout 200 microns A second stage filtration consists of a mechanical cut-out of<br />

Std Max Diff. Pressure 1350 PSI re-entrained particles through an advanced removable screen<br />

Std filter burst pressure 2030 PSI providing a longer clogging time.<br />

Codes & Standards<br />

API 6A (based on PSL2 non monogrammed)<br />

ANSI B31-3 for pipework<br />

NACE MR 01-75<br />

As the fluid flows from outside to inside the screen, the flow<br />

area is not obstructed by the sand accumulation, providing a<br />

a longest operating time, higher allowable delta P and easier<br />

screen washing.<br />

Features<br />

The horizontal arrangement provides an easy rig-up with all<br />

- Qty 02 pots with removable wear sleeve, flush point, bottom flange connections on one side and simpler handling procedure.<br />

and ACME threaded top lid for screen removal.<br />

The easy access to process valves and gauges together<br />

- 05-Valve / 04-spool 3" 1/16 process manifold (<strong>10K</strong> gate valves). provides a safe pot switchover operation.<br />

- 02-Valve 2" 1/16 drain manifold (<strong>10K</strong> gate valves)<br />

- Dump line c/w 2" manually operated adjustable choke. External connection<br />

- 2" 1502 plug for drain or dump outlet mounting. Well effluent inlet 3" Weco fig. 1502 F<br />

- 1" Water flush manifold c/w 04 x 1/2" needle valves. Well effluent outlet 3" Weco fig. 1502 M<br />

- 1/2" Inlet and Outlet Sampling points c/w needle valves. Dump line outlet 2" Weco fig. 1502 M<br />

- 1/2" Inlet and outlet pressure gauges c/w block & bleed valves. Drain line outlet 2" Weco fig. 1502 M<br />

- 1/2" D.P. gauge c/w 5-way manifold and block valves on each pot. Water flush inlet 1" Weco fig. 1502 F<br />

- One piece skid and frame c/w operator platforms, ladder and<br />

handrails, tool box, earthing boss and retractable lifting device<br />

Dimensions & Weight<br />

above each pot with manually operated chain hoist for screen, Length 6058 mm (238.5 ")<br />

wear sleeve and threaded cap removal. The skid is fitted with Width 2438 mm (96 ")<br />

02 x 04 ISO corner blocks to match 20' ISO container foot print, Height 2700 mm (106.3 ")<br />

02 forklift pockets and 04 lift lugs with certified slings and shackles. Weight 8500 Kg (18760 lbs) Empty<br />

FIXED OPTIONS / ADDERS<br />

A-01 Standard service equipment<br />

INTERCHANGEABLE OPTIONS / ADDERS<br />

B-01 07-Valve 3" 1/16 process manifold (double valve on inlet side)<br />

A-02 Low temperature service -40°F (- 40°C)<br />

B-02 09-Valve 3" 1/16 process manifold (double valve both sides)<br />

A-03 High temperature service to 350°F (176°C)<br />

B-03 Extra screen (100 or 400 micron to be specified)<br />

A-04 PED certification<br />

B-04 High resistant wear sleeve<br />

A-05 DNV 2.7.3 certification<br />

B-05 Diff. Pressure Transmitter kit for D.A.S. c/w valves<br />

A-06 API monogram and other inspection levels (to be specified).<br />

B-06 Pneumatic hoists<br />

A-07 Specific requirement (Requires <strong>FCE</strong> engineering approval)<br />

B-07 Other interchangeable component brand / Added instruments<br />

Fluid Control Europe (<strong>FCE</strong>)<br />

786 rue George <strong>Sand</strong> - ZI Molina la Chazotte - 42350 La Talaudière (France)<br />

Tel. +33 (0)4 77 48 13 13 - Fax +33 (0)4 77 33 01 30 - e-mail fce@fce.fr - web site www.fce.fr

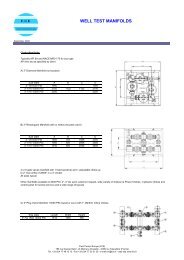

HORIZONTAL DUAL POT SAND FILTER<br />

2-<strong>SF</strong> SERIES<br />

10 000 PSI - H2S SERVICE<br />

February 2009<br />

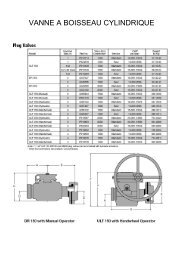

Note 1<br />

2-<strong>SF</strong> <strong>Sand</strong> <strong>Filter</strong> Unit with its 9-valve manifold option<br />

Retractable lifting device<br />

4825<br />

2438 2700<br />

Dump Outlet<br />

2'' fig.1502 male<br />

Drain Outlet<br />

2'' fig.1502 male<br />

Fluid Intlet<br />

3'' fig.1502 female<br />

6058<br />

Fluid Outlet<br />

3'' fig.1502 male<br />

Flush line Intlet<br />

1'' fig.1502 female<br />

Choke valve 2"<br />

Fluid Control Europe (<strong>FCE</strong>)<br />

786 rue George <strong>Sand</strong> - ZI Molina la Chazotte - 42350 La Talaudière (France)<br />

Tel. +33 (0)4 77 48 13 13 - Fax +33 (0)4 77 33 01 30 - e-mail fce@fce.fr - web site www.fce.fr