Job Report 2000 t/h Crushing Plant for Obajana Cement ... - Hazemag

Job Report 2000 t/h Crushing Plant for Obajana Cement ... - Hazemag

Job Report 2000 t/h Crushing Plant for Obajana Cement ... - Hazemag

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Job</strong> <strong>Report</strong><br />

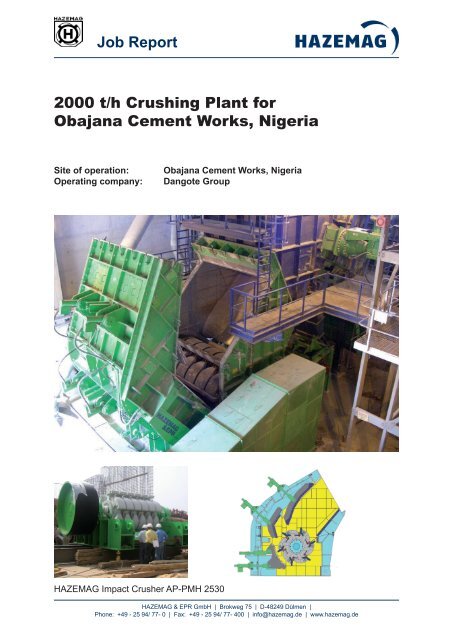

<strong>2000</strong> t/h <strong>Crushing</strong> <strong>Plant</strong> <strong>for</strong><br />

<strong>Obajana</strong> <strong>Cement</strong> Works, Nigeria<br />

Site of operation: <strong>Obajana</strong> <strong>Cement</strong> Works, Nigeria<br />

Operating company: Dangote Group<br />

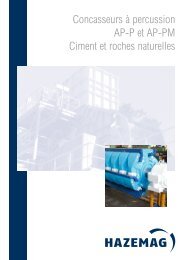

HAZEMAG Impact Crusher AP-PMH 2530<br />

HAZEMAG & EPR GmbH | Brokweg 75 | D-48249 Dülmen |<br />

Phone: +49 - 25 94/ 77- 0 | Fax: +49 - 25 94/ 77- 400 | info@hazemag.de | www.hazemag.de

<strong>Job</strong> <strong>Report</strong><br />

Description of the <strong>Plant</strong><br />

HAZEMAG has delivered an exceptionally powerful impact crusher <strong>for</strong> limestone crushing to<br />

the <strong>Obajana</strong> <strong>Cement</strong> Works in Nigeria. The cement works belongs to the renowned Dangote<br />

Group, one of the largest cement producers in Africa.<br />

Every hour this large impact crusher breaks up <strong>2000</strong> t of limestone with feed sizes that have<br />

a maximum edge length of 1.5 m to a degree of fineness of 98% < 75 mm. For this task the<br />

heavy GSK cast-iron rotor has a diameter of 2.5 m and a width of 3.0 m. Its weight is<br />

54,000 kg, while that of an individual blow bar is 1,550 kg. The impact aprons are controlled<br />

with the well-proven HAZEMAG hydraulic system. In spite of the enormous weights of these<br />

components, it is possible with this system to precisely adjust the gap width between the rotor<br />

and impact aprons at the press of a button. However, the hydraulic system is also active during<br />

the crushing process and holds the impact aprons permanently in position. If <strong>for</strong>eign materials<br />

that cannot be crushed enter the machine, the impact aprons draw aside and allow the <strong>for</strong>eign<br />

materials to pass by. They then return to the starting position. The crusher there<strong>for</strong>e has a high<br />

level of operational reliability and guarantees a consistent product quality.<br />

The raw material is fed to the crusher by means of a heavy HAZEMAG apron feeder with variable<br />

drive. This also has exceptional dimensions due to its width of 2.5 m and length of 14.2 m.<br />

HAZEMAG Apron feeder PBRK 26/142<br />

Technical Data<br />

Feed material: Limestone<br />

Feed size: max. 1,500 mm<br />

Feed rate: 2,000 t/h<br />

Product grain size: 98 % < 75 mm<br />

Impact crusher: AP-PMH 2530<br />

Rotor diameter: 2,500 mm<br />

Rotor width: 3,000 mm<br />

Weight of GSK rotor: 54,000 kg<br />

Total crusher weight: 163,000 kg<br />

Installed driving power: 2,400 kW<br />

Apron feeder: PBRK 25/142<br />

Installed driving power: 2 x 90 kW<br />

HAZEMAG & EPR GmbH | Brokweg 75 | D-48249 Dülmen |<br />

Phone: +49 - 25 94/ 77- 0 | Fax: +49 - 25 94/ 77- 400 | info@hazemag.de | www.hazemag.de