Animal identification Stock Breeding equipment Veterinary instruments

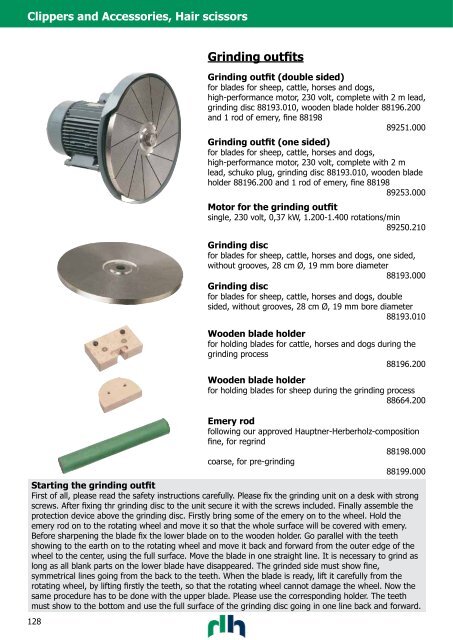

Clippers and Accessories, Hair scissors 128 Grinding outfits Grinding outfit (double sided) for blades for sheep, cattle, horses and dogs, high-performance motor, 230 volt, complete with 2 m lead, grinding disc 88193.010, wooden blade holder 88196.200 and 1 rod of emery, fine 88198 89251.000 Grinding outfit (one sided) for blades for sheep, cattle, horses and dogs, high-performance motor, 230 volt, complete with 2 m lead, schuko plug, grinding disc 88193.010, wooden blade holder 88196.200 and 1 rod of emery, fine 88198 89253.000 Motor for the grinding outfit single, 230 volt, 0,37 kW, 1.200-1.400 rotations/min 89250.210 Grinding disc for blades for sheep, cattle, horses and dogs, one sided, without grooves, 28 cm Ø, 19 mm bore diameter 88193.000 Grinding disc for blades for sheep, cattle, horses and dogs, double sided, without grooves, 28 cm Ø, 19 mm bore diameter 88193.010 Wooden blade holder for holding blades for cattle, horses and dogs during the grinding process 88196.200 Wooden blade holder for holding blades for sheep during the grinding process 88664.200 Emery rod following our approved Hauptner-Herberholz-composition fine, for regrind 88198.000 coarse, for pre-grinding 88199.000 Starting the grinding outfit First of all, please read the safety instructions carefully. Please fix the grinding unit on a desk with strong screws. After fixing thr grinding disc to the unit secure it with the screws included. Finally assemble the protection device above the grinding disc. Firstly bring some of the emery on to the wheel. Hold the emery rod on to the rotating wheel and move it so that the whole surface will be covered with emery. Before sharpening the blade fix the lower blade on to the wooden holder. Go parallel with the teeth showing to the earth on to the rotating wheel and move it back and forward from the outer edge of the wheel to the center, using the full surface. Move the blade in one straight line. It is necessary to grind as long as all blank parts on the lower blade have disappeared. The grinded side must show fine, symmetrical lines going from the back to the teeth. When the blade is ready, lift it carefully from the rotating wheel, by lifting firstly the teeth, so that the rotating wheel cannot damage the wheel. Now the same procedure has to be done with the upper blade. Please use the corresponding holder. The teeth must show to the bottom and use the full surface of the grinding disc going in one line back and forward.

Clippers and Accessories, Hair scissors Animal clipper Animal clipper PRO Series can be used with or without cord for maximum convenience Pro Series clipper with blade, 4 attachment combs (10, 13, 19 and 25 mm), oil, cleaning brush, scissors and instruction • cutting width approx. 46 mm • weight approx. 230 g • a fully charged clipper will deliver a minimum of 20 minutes of continuous trimming • input power (power supply) 230 volt, 50 Hz, 13 watt 88177.000 Optional accessory: Not included in delivery! Attachment combs 10 mm, cutting height 0,9 mm 88177.010 Attachment combs 13 mm, cutting height 2,0 mm 88177.020 Attachment combs 19 mm, cutting height 3,0 mm 88177.030 Attachment combs 25 mm, cutting height 5,0 mm 88177.040 129

- Page 78 and 79: Heat detector, Insemination instrum

- Page 80 and 81: Heat detector, Insemination instrum

- Page 82 and 83: Sexual organ instruments, Catheters

- Page 84 and 85: Sexual organ instruments, Catheters

- Page 86 and 87: Sexual organ instruments, Catheters

- Page 88 and 89: Sexual organ instruments, Catheters

- Page 90 and 91: Sexual organ instruments, Catheters

- Page 92 and 93: Clinic equipment Examination and op

- Page 94 and 95: Clinic equipment Trays and dishes I

- Page 96 and 97: Clinic equipment Bandages Surgical

- Page 98 and 99: Restraining equipment, Castration i

- Page 100 and 101: Restraining equipment, Castration i

- Page 102 and 103: Restraining equipment, Castration i

- Page 104 and 105: Restraining equipment, Castration i

- Page 106 and 107: Restraining equipment, Castration i

- Page 108 and 109: Restraining equipment, Castration i

- Page 110 and 111: Restraining equipment, Castration i

- Page 112 and 113: Restraining equipment, Castration i

- Page 114 and 115: Restraining equipment, Castration i

- Page 116 and 117: Restraining equipment, Castration i

- Page 118 and 119: Restraining equipment, Castration i

- Page 120 and 121: Restraining equipment, Castration i

- Page 122 and 123: Clippers and Accessories, Hair scis

- Page 124 and 125: Clippers and Accessories, Hair scis

- Page 126 and 127: Clippers and Accessories, Hair scis

- Page 130 and 131: Clippers and Accessories, Hair scis

- Page 132 and 133: Clippers and Accessories, Hair scis

- Page 134 and 135: Clippers and Accessories, Hair scis

- Page 136 and 137: Livestock-Breeding equipment, Farm

- Page 138 and 139: Livestock-Breeding equipment, Farm

- Page 140 and 141: Livestock-Breeding equipment, Farm

- Page 142 and 143: Livestock-Breeding equipment, Farm

- Page 144 and 145: Livestock-Breeding equipment, Farm

- Page 146 and 147: Brass ear tags, License plates, Ear

- Page 148 and 149: Brass ear tags, License plates, Ear

- Page 150 and 151: Marking hammers and Accessories Mar

- Page 152 and 153: Tattooing pliers and Accessories, F

- Page 154 and 155: Tattooing pliers and Accessories, F

- Page 156 and 157: Tattooing pliers and Accessories, F

- Page 158 and 159: Index A Air conditioned box for liq

- Page 160 and 161: Index P Percussion hammers Pig hold

- Page 162: Terms and Conditions of Delivery an

Clippers and Accessories, Hair scissors<br />

128<br />

Grinding outfits<br />

Grinding outfit (double sided)<br />

for blades for sheep, cattle, horses and dogs,<br />

high-performance motor, 230 volt, complete with 2 m lead,<br />

grinding disc 88193.010, wooden blade holder 88196.200<br />

and 1 rod of emery, fine 88198<br />

89251.000<br />

Grinding outfit (one sided)<br />

for blades for sheep, cattle, horses and dogs,<br />

high-performance motor, 230 volt, complete with 2 m<br />

lead, schuko plug, grinding disc 88193.010, wooden blade<br />

holder 88196.200 and 1 rod of emery, fine 88198<br />

89253.000<br />

Motor for the grinding outfit<br />

single, 230 volt, 0,37 kW, 1.200-1.400 rotations/min<br />

89250.210<br />

Grinding disc<br />

for blades for sheep, cattle, horses and dogs, one sided,<br />

without grooves, 28 cm Ø, 19 mm bore diameter<br />

88193.000<br />

Grinding disc<br />

for blades for sheep, cattle, horses and dogs, double<br />

sided, without grooves, 28 cm Ø, 19 mm bore diameter<br />

88193.010<br />

Wooden blade holder<br />

for holding blades for cattle, horses and dogs during the<br />

grinding process<br />

88196.200<br />

Wooden blade holder<br />

for holding blades for sheep during the grinding process<br />

88664.200<br />

Emery rod<br />

following our approved Hauptner-Herberholz-composition<br />

fine, for regrind<br />

88198.000<br />

coarse, for pre-grinding<br />

88199.000<br />

Starting the grinding outfit<br />

First of all, please read the safety instructions carefully. Please fix the grinding unit on a desk with strong<br />

screws. After fixing thr grinding disc to the unit secure it with the screws included. Finally assemble the<br />

protection device above the grinding disc. Firstly bring some of the emery on to the wheel. Hold the<br />

emery rod on to the rotating wheel and move it so that the whole surface will be covered with emery.<br />

Before sharpening the blade fix the lower blade on to the wooden holder. Go parallel with the teeth<br />

showing to the earth on to the rotating wheel and move it back and forward from the outer edge of the<br />

wheel to the center, using the full surface. Move the blade in one straight line. It is necessary to grind as<br />

long as all blank parts on the lower blade have disappeared. The grinded side must show fine,<br />

symmetrical lines going from the back to the teeth. When the blade is ready, lift it carefully from the<br />

rotating wheel, by lifting firstly the teeth, so that the rotating wheel cannot damage the wheel. Now the<br />

same procedure has to be done with the upper blade. Please use the corresponding holder. The teeth<br />

must show to the bottom and use the full surface of the grinding disc going in one line back and forward.