CNC MACHINING/ FABRICATING & ELECTRONIC TEST FACILITY

CNC MACHINING/ FABRICATING & ELECTRONIC TEST FACILITY

CNC MACHINING/ FABRICATING & ELECTRONIC TEST FACILITY

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

AUCTION<br />

LATE<br />

MODEL<br />

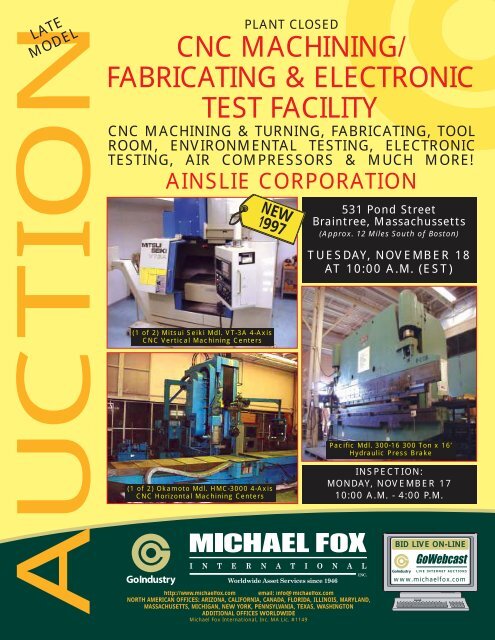

PLANT CLOSED<br />

<strong>CNC</strong> <strong>MACHINING</strong>/<br />

<strong>FABRICATING</strong> & <strong>ELECTRONIC</strong><br />

<strong>TEST</strong> <strong>FACILITY</strong><br />

<strong>CNC</strong> <strong>MACHINING</strong> & TURNING, <strong>FABRICATING</strong>, TOOL<br />

ROOM, ENVIRONMENTAL <strong>TEST</strong>ING, <strong>ELECTRONIC</strong><br />

<strong>TEST</strong>ING, AIR COMPRESSORS & MUCH MORE!<br />

AINSLIE CORPORATION<br />

NEW<br />

1997<br />

(1 of 2) Mitsui Seiki Mdl. VT-3A 4-Axis<br />

<strong>CNC</strong> Vertical Machining Centers<br />

(1 of 2) Okamoto Mdl. HMC-3000 4-Axis<br />

<strong>CNC</strong> Horizontal Machining Centers<br />

http://www.michaelfox.com email: info@michaelfox.com<br />

NORTH AMERICAN OFFICES: ARIZONA, CALIFORNIA, CANADA, FLORIDA, ILLINOIS, MARYLAND,<br />

MASSACHUSETTS, MICHIGAN, NEW YORK, PENNSYLVANIA, TEXAS, WASHINGTON<br />

ADDITIONAL OFFICES WORLDWIDE<br />

Michael Fox International, Inc. MA Lic. #1149<br />

531 Pond Street<br />

Braintree, Massachussetts<br />

(Approx. 12 Miles South of Boston)<br />

TUESDAY, NOVEMBER 18<br />

AT 10:00 A.M. (EST)<br />

Pacific Mdl. 300-16 300 Ton x 16’<br />

Hydraulic Press Brake<br />

INSPECTION:<br />

MONDAY, NOVEMBER 17<br />

10:00 A.M. - 4:00 P.M.<br />

BID LIVE ON-LINE<br />

LIVE INTERNET AUCTIONS<br />

www.michaelfox.com

NEW<br />

1997<br />

(1 of 2) Mitsui Seiki Mdl. VT-3A 4-Axis <strong>CNC</strong> Vertical Machining<br />

Centers<br />

Matsuura Mdl. MC-1000VS-2 <strong>CNC</strong> Vertical Machining Center<br />

Matsuura Mdl. MC-1500V-DC 4-Axis Twin-Spindle <strong>CNC</strong> Vertical<br />

Machining Center<br />

2<br />

<strong>CNC</strong> VERTICAL<br />

<strong>MACHINING</strong> CENTERS<br />

(2) MITSUI SEIKI MDL. VT-3A 4-AXIS X-27.6”,<br />

Y-17.7”, Z-17.7” Travels, 43.3” X 22.8” T-Slotted Table,<br />

20,000 RPM Max Spindle Speed, 40-Pos. Automatic<br />

Tool Changer, Spindle Chiller, 1320 Lbs. Max Work<br />

Weight, W/ Chip Conveyor, Fanuc 16M 4-Axis <strong>CNC</strong><br />

Control, RS-232 Interface, S/N’s 248 & 249 [1997]<br />

MATSUURA MDL. MC-1000VS-2, X-40”, Y-20”, Z-<br />

20”, 47” X 20” T-Slotted Table, Spindle Speeds to<br />

12,000 RPM, 30-Pos. Automatic Tool Changer, 15 HP<br />

Drive Motor W/ Yasnac System MX2 <strong>CNC</strong> Control, W/<br />

RS-232 Interface, S/N 85044752 [1986]<br />

TWIN-SPINDLE<br />

<strong>CNC</strong> VERTICAL<br />

<strong>MACHINING</strong> CENTER<br />

MATSUURA MDL. MC-1500V-DC 4-AXIS, X-60",<br />

Y-30.5", Z-29.5" Travels, 67” X 30” T-Slotted Table,<br />

Twin 30-Pos. Automatic Tool Changers, 25-4500 RPM<br />

Spindle Speeds, BT-45 Taper, 5500 Lbs Work Weight<br />

Capacity, (2) 15 HP Spindle Drive Motors, Fanuc 11M<br />

<strong>CNC</strong> Control, RS-232 Port, S/N 85034692 [1985]<br />

<strong>CNC</strong> & N/C HORIZONTAL<br />

<strong>MACHINING</strong> CENTERS<br />

OKAMOTO MDL. HMC-3000 4-AXIS, Traveling<br />

Column, X-120”, Y-60”, Z-30” Travels, 118” X 39.25” T-<br />

Slotted Table, 40-Pos. Auto. Tool Changer, #50 Taper,<br />

20-4000 RPM Spindle Speeds, 10,000 Lbs. Max Work<br />

Weight, 20 HP DC Drive Motor, Oilmatic Lubrication<br />

System, W/ Fanuc 11M 4-Axis <strong>CNC</strong> Control, RS-232<br />

Interface, S/N 30 [1986]<br />

OKAMOTO MDL. HMC-3000 4-AXIS, Traveling<br />

Column, X-120”, Y-60”, Z-30” Travels, 118” X 31.5” T-<br />

Slotted Table, 40-Pos. Auto. Tool Changer, 20-4000<br />

RPM Spindle Speeds, #50 Taper, 10,000 Lbs. Max<br />

Work Weight, 20 HP DC Drive Motor, Oilmatic<br />

Lubrication System, W/ Fanuc 6MB 4-Axis <strong>CNC</strong><br />

Control, RS-232 Interface, S/N 23 [1984]<br />

MAKINO MDL. MC-100, X-39.97", Y-31.49", Z-<br />

24.80" Travels, (6) 31.5” X 31.5” Pallets, Automatic<br />

Pallet Changer, 60-Pos. Automatic Tool Changer, CAT<br />

50 Taper, 20 HP Motor, W/ Broken Tool Sensor, Tool<br />

Life Monitor, Fanuc 6MB <strong>CNC</strong> Control, RS-233<br />

Interface, S/N B57-510 [1982]<br />

CINCINNATI MILACRON MDL. 10HC-2500, X-<br />

100”, Y-40”, Z-26” Travels, 104” X 31.25” T-Slotted<br />

Table, 20-4000 RPM Spindle Speeds, 10,000 Lbs. Max<br />

Work Weight, 10 HP Main Drive Motor, W/ Fanuc 11M<br />

<strong>CNC</strong> Control, RS-232 Interface, S/N 47495 [Retrofit<br />

1988]<br />

CINCINNATI MDL. CINTIMATIC DM 5H-2500,<br />

X-100", Y-40", Z-8” (Quill), Z-12” (Head) Travels, 31” X<br />

102” T-Slotted Table, 85-3800 RPM Spindle Speeds, 5<br />

HP Motor, 10,000 Lbs Max Work Weight, Acramatic 5<br />

Control, S/N 55131H5-74-11 [1974]<br />

CINCINNATI MDL. CINTIMATIC H-100, X-100",<br />

Y-40”, Z-12” Travels, 31” X 102” T-Slotted Table, 20”<br />

Diameter Rotary Table, Acramatic 5 Control W/ Rybett<br />

Camstore Unit, S/N 55131H55W-0002<br />

CAN’T ATTEND? BID ON-LINE AT<br />

www.michaelfox.com

Makino Mdl. MC-100 <strong>CNC</strong> Horizontal Machining Center<br />

Machining Center<br />

Tombstones<br />

(1 of 2) Okamoto Mdl. HMC-3000 4-Axis <strong>CNC</strong><br />

Horizontal Machining Centers<br />

Cincinnati-Milacron Mdl. 10HC-2500 <strong>CNC</strong> Horizontal<br />

Machining Center<br />

Hardinge Mdl. Conquest GT Super-Precision <strong>CNC</strong><br />

Precision Turning Center<br />

<strong>CNC</strong> PRECISION TURNING CENTER<br />

HARDINGE MDL. CONQUEST GT Super-Precision <strong>CNC</strong><br />

Gang Tool Lathe, 11.76” Swing Over Bed, X-11.96”, Z-11” Travels,<br />

1” Round Collet Capacity, 8000 RPM Max Spindle Speed, 5 HP Drive<br />

Motor, Collet Closer, Parts Catcher, Air Filter, Bar Feed Interface, W/<br />

GE-Fanuc 18T <strong>CNC</strong> W/ RS-232 Interface, S/N GTA-994B [1996]<br />

Above Machine Equipped W/ Bar Feed: HARDINGE HAR-MATIC<br />

MDL. VALU-SERVE 27, Hydrodynamic Bar Feed [1997]<br />

<strong>CNC</strong> 4TH AXIS ROTARY TABLES<br />

(2) 31.5” TSUDAKOMA MDL. RCV-800R, .001 Degree<br />

Indexing, 360,000 Positions, S/N’s 407231, 407232<br />

16” TSUDAKOMA MDL. RNCV-400R (Twin Tables), .001<br />

Degree Indexing, 360,000 Positions, Tailstocks, S/N 511581<br />

(2) 12” TSUDAKOMA MDL. NCT-3201, .001 Degree Indexing,<br />

360,000 Positioning, S/N’s 112 & 113<br />

<strong>CNC</strong> 4th Axis Rotary Tables<br />

NEW<br />

1996<br />

TUBE BENDER<br />

TELEDYNE PINES MDL. 1400 Series 101 Hydraulic<br />

Rotary Tube Bender, S/N 10100-80085, Max OD 1 ¼”, Max<br />

Radius 8 ¾”, Max Bend Radius 180º, 5 HP Hydraulic Unit<br />

OVENS<br />

GEHNRICH 2-Door Walk-In Oven<br />

DESPATCH MDL. LDB-1-69, 30” X 18” X 22” Chamber, 6.9’<br />

Capacity, 400 Degrees Maximum Temperature, 120 Volts, 2,400<br />

Heater Watts, 21.6 AMPS, 50/60 HZ, 1 Phase, 9-Shelf Positions,<br />

Double Door Entry, S/N 161610 [1998]<br />

3

4<br />

Hardinge Mdl. HC-AT Automatic Precision Chucker<br />

12.5”<br />

SPINDLE<br />

BORE<br />

32” x 72” Lodge & Shipley MDL. 3220 Hollow-Spindle<br />

Engine Lathe<br />

FINISHING MACHINES<br />

GYROMATIC Model V-20 6’L X 20” Dia. Vibratory Finishing<br />

Machine, 15 HP Motor, S/N 476<br />

ZERO Blast-N-Peen 2-Hole Bead Blast Cabinet W/ Dust<br />

Collector<br />

CYCLO-BLAST MDL. 4836-F Dry Honer, 2-Hole Blast<br />

Cabinet W/ Dust Collector<br />

RIVETERS<br />

CHICAGO Pneumatic MDL. CP625 C-Frame Compression<br />

Riveter, Throat 32”, S/N H-218650<br />

CHICAGO Pneumatic MDL. CP450, C-Frame Compression<br />

Riveter, Throat 24”, S/N H-572928<br />

DRILL PRESSES<br />

LELAND-GIFFORD, 4 Spindle Box Column Sliding Head Table-Type<br />

ALZMETALL MDL. ST AB4 Box Column Drill Press,<br />

S/N 42320J<br />

DELTA 4-Spindle Table Type Drill Press, S/N’s 140814,<br />

140471-140473<br />

GRINDER<br />

Covel MDL. 12, S/N 12/172,Tool & Cutter Grinder<br />

A 10% BUYER’S PREMIUM APPLIES TO<br />

ALL ON-SITE PURCHASES<br />

18” x 60” LeBlond Servo-Shift Engine Lathe<br />

AUTOMATIC PRECISION CHUCKER<br />

HARDINGE MDL. HC-AT, 1.06” Collet Capacity, 6” Chuck<br />

Capacity, 2.18” Spindle Nose Diameter, 4.5” Cross Slide<br />

Travel, 14” Turret Face To Spindle, 6” OD / 5” ID Max<br />

Threading Diameter, 1.75” Max Threading Length, 125-3000<br />

RPM Spindle Speeds, W/ Automatic Overhead Threading, 7-<br />

Position Turret, Splash Guard S/N HC-4235P [1975]<br />

HOLLOW-SPINDLE ENGINE LATHE<br />

32” X 72” LODGE & SHIPLEY MDL. 3220, 31.5”<br />

Swing Over Carriage, 21” Swing Over Cross Slide, 72”<br />

Distance Between Centers, Front & Rear 31.5” 3-Jaw<br />

Hydraulic Chucks W/ 12” Hole, 12.5” Spindle Bore Diameter,<br />

Spindle Speeds to 1527 RPM, 4-Pos. Turret, Tailstock, 14”<br />

Diameter Steady Rest, 40 HP Main Drive Motor, S/N 46320<br />

[1966]<br />

ENGINE LATHES<br />

18” X 60” LEBLOND Servo-Shift, 12” 4-Jaw Chuck, 7.5<br />

HP Motor, 40-1600 RPM Spindle Speeds, Tailstock, S/N 6E<br />

683<br />

20” X 48” LEBLOND, 12” Chuck, 2” Hole<br />

SPINNING LATHES<br />

HAAG, 122” Swing, Spinning Lathe,156” Bed Length<br />

DRIVE ALL 20” Swing Spinning Lathe<br />

Haag Spinning Lathe

Amada Mdl. RG-50 Precision Hydraulic Press Brake<br />

Pacific Mdl. 375R12 Hydraulic Squaring Shear<br />

NEW<br />

1999<br />

Armstrong-Blum Marvel Series 8 Mark II<br />

Universal Band Saw<br />

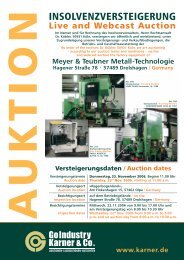

PRESS BRAKES<br />

PACIFIC MDL. 300-16, 300-Ton Hydraulic Press<br />

Brake, S/N 3592, Overall Bed Length 16’, Bending 14’,<br />

Distance Between Uprights 173”, Throat 10”, HURCO<br />

Autobend <strong>CNC</strong> Programmable Back Gauge<br />

AMADA MDL. RG-50, 55-Ton Hydraulic Press<br />

Brake, S/N 506115 (1987), Bed Length 78.8”, Distance<br />

Between Uprights 59.9”, Throat 15.76” Stroke 3.94”,<br />

AMADA NC9-EX 3-Axis <strong>CNC</strong> Control, <strong>CNC</strong> Back Gauge<br />

PACIFIC MDL.40-6 40-Ton Hydraulic Press<br />

Brake, S/N 4083, Capacity 12 GA x 6’, Bed Length 6”,<br />

Distance Between Uprights 51 ¾” Throat 6”, 24” Front<br />

Operated Manual Back Gauge<br />

HYDRAULIC SHEAR<br />

PACIFIC MDL. 375R12 3/8” X 12’ Cap. Hydraulic<br />

Squaring Shear, S/N 510394, 36” Front Operated<br />

Power Back Gauge, (2) Table Support Arms, 8’ Squaring<br />

Arm, Rake Control<br />

BAND SAWS<br />

ARMSTRONG-BLUM MARVEL Series 8 Mark II<br />

Universal Band Saw, S/N 828552 [1999] Throat 18”,<br />

18” x 20” Cap., Manual Clamping, Coolant System<br />

OLIVER No. 35, 35” Vertical Band Saw, S/N 7415,<br />

W/ Portable Base<br />

30” Vertical Band Saw<br />

GROB Model 4V-18 18” Vertical Band Saw, S/N<br />

1757, Air Hydraulic Table Feed, W/ Butt Welder & Cutoff<br />

DELTA ROCKWELL 14” Vertical Band Saw, S/N<br />

BJ9558<br />

WALKER-TURNER 14” Vertical Band Saw, S/N<br />

CW5885<br />

HACK SAW<br />

ARMSTRONG-BLUM MARVEL Series 9A, Mdl.<br />

9A4/M6/EIA/E16/S Power Hack Saw, S/N 97535,<br />

Capacity 10”, Manual Clamping, 10’ Chain Pulley Type<br />

Feed Table<br />

CHOP SAWS<br />

DORINGER MDL. D-350 14” Miter Cold Saw, S/N<br />

18758, Speeds 27 & 54 RPM, Double Air Vise W/ (2)<br />

Roller Feed Tables<br />

(2) ROCKWELL 12” Miter Cut-Off Saws, 5 HP<br />

Motor W/ Feed Table, S/N’s 1282613, 1491769<br />

RADIAL SAW<br />

DEWALT MDL. GAR-M01, Type B 13” Radial<br />

Arm Saw, S/N 614709, 5 HP Motor<br />

SANDERS<br />

TIMESAVER MDL. 336<br />

M-1 36” Conveyorized<br />

Belt Sander, S/N 6312,<br />

Spindle Motor 25 HP, W/<br />

Dust Collector<br />

(2) Apex MDL. 2CS 20”<br />

Disk Sander, S/N 1382, 1<br />

½ HP Motor<br />

STEPHEN BADER 3”<br />

Belt Grinding Jack<br />

Time Saver Mdl. 336M1 Belt Sander<br />

SOME ITEMS SUBJECT<br />

TO PRIOR SALE<br />

BID LIVE ON-LINE<br />

LIVE INTERNET AUCTIONS<br />

www.michaelfox.com<br />

5

Thermotron Environmental Test Chamber<br />

L.A.B. Mechanical Technology Inc. Drop Test Machine<br />

DEA Mdl. Beta Coordinate Measuring Machine<br />

6<br />

NEW<br />

1997<br />

LATE<br />

1990’S<br />

Ransco Environmental Test Chamber<br />

ENVIRONMENTAL <strong>TEST</strong><br />

THERMOTRON MDL. F-32-CHV-15-15 Environ.<br />

Test Chamber, S/N 26964, [1997], 40”W X 36”H X 40”D,<br />

HONEYWELL Truline Chart Recorder, THERMATRON 7800<br />

Control System, W/ LING MDL. 624V Track Mounted Shaker,<br />

S/N 27, [1997] W/ Cooling Tower<br />

RANSCO MDL. 16635 Environ. Test Chamber, 42”W<br />

X 38”H X 38”D, Temp. Range -73º To 177ºC W/ O Humidity,<br />

4º To 94ºC W/ Humidity, RANSCO Temp/Humidity Control<br />

L.A.B. MECHANICAL TECHNOLOGY 60”Drop Test<br />

Machine & Vibration Test Cell, MTI Lab Controls<br />

Consisting Of: MDL. 8832 Compressor Control, (2) 8834<br />

Multi-Level Programmers, 8838 Level Meter, 487M30<br />

Vibration Meter, 8833 Vibration Monitor, 8836 Signal<br />

Collector, 8835 Dwell Control, 8830 Servocontrol, 8837<br />

Pump Controller, SCIENTIFIC ATLANTA Spectral Dynamics<br />

DS1700 Vibration Controller, WAVETEK Stabilized Function<br />

Generator, WAVETEK Arbitrary Waveform Generator,<br />

NICOLES 3091 Digital Oscilloscope<br />

TENNEY MDL. TH Jr. Bench Top Environ.<br />

Humidity & Temperature Test Chamber, 16”W X<br />

19”H X 14” D, Digital Control, S/N SB10843, Honeywell<br />

Chart Recorder<br />

Environmental Salt Spray Cabinet<br />

<strong>CNC</strong> COORDINATE<br />

MEASURING MACHINES<br />

DEA MDL. BETA, X-70.5”, Y–38.5”, Z – 28.5” Travels,<br />

78.5” X 35.75” Granite Table, W/ Troll Measuring System,<br />

S/N 010474<br />

DEA MDL. OMICRON A001, X-26”, Y-18”, Z-14” Travels,<br />

W/ Heidennain Scales, Omni 3D Software [1995]<br />

Tenney Mdl. TH Junior Environmental Test<br />

Chamber

CI Systems Infrared Electro-Optical Test Station<br />

Hollis Mdl. 206911 Wave Solder System<br />

DEA Mdl. Omnicron A001 <strong>CNC</strong> CMM<br />

NEW<br />

1999<br />

LATE<br />

1990’S<br />

Environmental Salt Spray Cabinet<br />

OPTICAL <strong>TEST</strong> STATION<br />

CI SYSTEMS MDL. AN/TAS-4 Infrared<br />

Electro-Optical Test Station; Testing<br />

Include Narrow Field Of View (NFOV); Wide Field<br />

Of View (WFOV); HP54503A Digitizing<br />

Oscilloscope; IR Radiation Source Controller<br />

W/Automatic Flir Testing Software; 2 Digital<br />

Readouts; TMC Optical Table<br />

OPTICAL COMPARATOR<br />

30” SCHERR-TUMICO MDL. P-2500, 30”<br />

Dia. Screen, 35” X 8” T-Slot Table, W/ Profile,<br />

Surface, & Scale Illumination, S/N 449<br />

WAVE SOLDER SYSTEM<br />

HOLLIS MDL. 206911 Wave Solder<br />

System, S/N SF10041, Alpha Metals 7B Robotic<br />

(Solder Md-202-TL), Alpha Metals Robotic Aging<br />

System Md-ST-2<br />

30” Scherr-Tumico Mdl. P-2500 Optical<br />

Comparitor<br />

CAN’T ATTEND? BID ON-LINE AT<br />

www.michaelfox.com<br />

7

View of (3) Alliant Mdl. 42VC Vertical Mills<br />

VERTICAL MILLS<br />

(2) FRITZ WERNER MDL. FV-3, 71” X 14” T-Slotted<br />

Table, 35–1800 RPM Spindle Speeds, 10 HP Motor<br />

(2) BRIDGEPORT MDL 2J 1 1/2 HP Variable Speed<br />

Universal Vertical Mills, 42” X 9” Table, S/N 185278,<br />

165642<br />

ALLIANT MDL 48VC 2 HP Universal Vertical Mill,<br />

48” X 9” Power Table, W/ DRO, 60–4500 RPM Spindle<br />

Speed, S/N 75067646<br />

(3) ALLIANT MDL 42VC 2 HP Universal Vertical<br />

Mills, 42” X 9” Table, 60–4500 RPM Spindle Speeds<br />

S/N 75057472 (W/ Power Feed) S/N 75057471(W/ Power<br />

Feed, DRO) S/N 75057470 (W/ DRO)<br />

KEARNEY & TRECKER MDL. 10 HP–3CH, 65” X 13.5”<br />

T-Slotted Table, 15-1500 RPM Spindle Speeds, 10 HP Motor,<br />

S/N 7420<br />

Gardner Denver Rotary Screw Air Compressor<br />

8<br />

NEW<br />

1997<br />

Baron Blakeslee Mdl. MLR-120LE Vapor Degreaser<br />

(Description On Pg. 10)<br />

HORIZONTAL MILLS<br />

(2) CINCINNATI HYDROMATIC Rise & Fall Production<br />

Mills, MDL.’s 3-36 & 3-24, 12” X 50”, 27-200 RPM,10 HP Motor<br />

WHITNEY HAND MILLING MACHINE<br />

AIR COMPRESSORS<br />

GARDNER DENVER MDL. ECMOKA 50 HP Rotary Screw<br />

Air Compressor, S/N 802733 W/ Sound Enclosure<br />

CURTIS 2-Stage Air Compressor, S/N C98 57-2232<br />

25 HP Horizontal Tank-Mounted Air Compressor<br />

ARROW PNEUMATIC MDL. 4021 Pneumatic Compressed<br />

Air Dryer, S/N 50003<br />

UNABLE TO ATTEND? BID LIVE ONLINE WITH GoWebcast<br />

FOR DETAILS VISIT OUR WEBSITE: www.michaelfox.com<br />

Arrow Pneumatic Mdl. 4021 Pneumatic<br />

Compressed Air Dryer

View of Miller Welders<br />

SPOT WELDER<br />

SCIAKY MDL. PMC04ST-200-36<br />

200 KVA Press Type Spot Welder,<br />

S/N 6228, Throat 36”, Water Cooled,<br />

Welding Control<br />

WELDERS<br />

(3) MILLER MDL. Synchrowave<br />

500 AC/CD Gas Tungsten-Arc Or<br />

Shielded Metal Arc 500 Amp Welding<br />

Power Source, S/N’s JH305649,<br />

JH305650, JH637185<br />

(4) MILLER MDL. Pulstar 450<br />

Constant Potential Pulsed DC Arc<br />

450 AMP Welding Power Source, S/N JD<br />

700173 W/ Millermatic S-520 Digital Wire<br />

Feeder; SN’s JF933731, JH207804 W/<br />

Miller S-60 24 V Constant Speed Wire<br />

Feeder<br />

(2) MILLER MDL. Maxtron 450<br />

CC/CV 450 AMP DC Inverter Arc<br />

Welder, W/ Miller 60M Series<br />

Microprocessor Controller Wire Feeder,<br />

S/N’s KD505318, KD505317<br />

(3) MILLER MDL. Synchrowave<br />

300 AC/DC Gas-Tungsten Arc Or<br />

Shielded Metal Arc Welders, 300<br />

AMP Welding Power Sources S/N’s<br />

HJ155487, JD694248<br />

(2) MILLER MDL. Synchrowave<br />

351 CC AC/DC 350, AMP Welding<br />

Power Source (1995), S/N’s KF831266,<br />

KF8331267<br />

LEPEL MDL. RWWEX-20 Water<br />

Cooling Recirculator S/N 8545<br />

MILLER MDL. Spectrum 750<br />

DC Plasma Cutter System, S/N<br />

KC206165 (1992)<br />

MILLER MDL. CP-250TS<br />

Constant Voltage DC 250 AMP<br />

Arc Welding Power Source, S/N<br />

KD496658, W/ Miller XR A Extended<br />

Reach Air Cooled Wire Feeder<br />

(12) ACORN Welding Tables<br />

(4) Assorted Smoke Eaters<br />

WELDING<br />

POSITIONERS<br />

RANSOME Size 30: 3,000 Lb.<br />

Cap. Welding Positioner, 42”<br />

Diameter Table, S/N 17745<br />

RANSOME Size 25P 2500 Lb.<br />

Cap. Welding Positioner, 30”<br />

Diameter Table, S/N 1617040<br />

RANSOME Size 25P 2500 Lb.<br />

Cap. Welding Positioner, 30”<br />

Diameter Table, S/N 653019<br />

FOR MORE<br />

INFORMATION,<br />

VISIT OUR WEBSITE<br />

OR CONTACT<br />

AUCTIONEER<br />

<<br />

Raymond<br />

Mdl.<br />

211.T40TT<br />

4,000 Lb. Cap.<br />

Fork Lift<br />

><br />

Clark<br />

Mdl. GPS25MC<br />

4,000 Lb. Cap.<br />

Fork Lift<br />

TURRET PUNCHES<br />

TRUMPF MDL. Trumatic 150 <strong>CNC</strong> Turret<br />

Punching & Nibbling Machine, S/N 604, Max.<br />

Punch Press Force 20-Tons,<br />

16-Station Tool Changer, Max. Punch Dia. 4”, General<br />

Numeric GN5 Series Control<br />

ROTEX MDL. 18-B C-Frame 18-Station<br />

Manual Turret Punch, S/N 12473, Throat 24”<br />

MISC. <strong>FABRICATING</strong> EQUIP.<br />

PECK STOW & WILCOX MDL. 536 Circle<br />

Shear, S/N H8226, Cap. 12 Ga. X 72” Dia., 2 HP<br />

Motor<br />

PECK STOW & WILCOX MDL. 2299-C Circle<br />

Shear, S/N 66787, Capacity 20 Ga. X 48” Dia. ½ HP<br />

Motor<br />

SAN ANGELO 72” X 4” Dia. Initial Type<br />

Power Bending Rolls, 2 HP Motor<br />

PECK STOW & WILCOX MDL. 5-45, 37” Cap.<br />

Foot Shear, S/N 1370, 18 Ga. Cap.<br />

FORK LIFTS<br />

CLARK MDL. GSP25MC 4,000 Lb. LP Gas<br />

Forklift Truck, 189”Vertical Lift, S/N GP138MC-<br />

0180-5534FA<br />

RAYMOND MDL. 211.R40TT 4,000 Lb. Cap.<br />

Electric Stand-Up Riding Reach Forklift, 211”<br />

Vertical Lift, 24” Reach, S/N 021D.88.04000<br />

(2) CROWN MDL. 60PE-27-1 3,000 Lb. Cap.<br />

Pallet Trucks<br />

YALE Electric , 3,000 Lb. Cap. Pallet Trucks<br />

W/ Built-in Charger<br />

BIG JOE’S Electric Lifts, (1) 1,500 lb. cap., (1)<br />

1,000 cap.<br />

9

10<br />

Waste Water Treatment System<br />

<strong>ELECTRONIC</strong> <strong>TEST</strong> & MEASUREMENT<br />

Hewlett Packard MDL. 3585A Spectrum Analyzer<br />

Hewlett Packard MDL. 6253A Dual DC Power Supply<br />

Hewlett Packard MDL. 8903B Audio Analyzer<br />

Hewlett Packard MDL. 6060B Electronic Load<br />

Associated Research Voltage Tester, MDL. 35601 HY-<br />

Pot II<br />

MDL. 3650-5 Power Supply<br />

(3) MD TW5005 Power Design, Dual Power Supply<br />

MDL. 3240 Power Design, Transistorized Power Supply<br />

Hewlett Packard MDL. 54602B Oscilloscope<br />

Hewlett Packard MDL. 6177C DC Current Source<br />

Hewlett Packard MDL. 8111A Pulse/Funtion Generator<br />

Fluke MDL. 8050 Digital Multimeter<br />

General Radio MDL. 1863 Megohmmeter<br />

Sorensen DCR 40-70B Power Supply W/ Tex Lab Cart<br />

MDL. 4<br />

(5) Hewlett Packard Oscillator Plugin MDL.’s<br />

8695AH48, 8692 B<br />

(3) Hewlett Packard Oscillator Plugin MDL. 8693B<br />

(8) Hewlett Packard Frequency Plugin MDL.’s 8692-B,<br />

J532A, G532A, 536A, H532A, X532B, P532A, P537A<br />

Hewlett Packard Signal Generator, MDL. 620A<br />

Hewlett Packard Signal Generator, MDL. H09-61B<br />

Scientific Atlanta Rectangular Recorder, MDL. 1520<br />

(4) Hewlett Packard Variable Attenuator, MDL.’s<br />

5382A, X382A, P382A, G382A<br />

Gould 2 Channel Chart Recorder, MDL. 2202<br />

Hewlett Packard SWR Meter MDL. 415B<br />

Hewlett Packard Power Meter, MDL. 432A<br />

Hewlett Packard Milliohmeter, MDL. 4328A<br />

Hewlett Packard Square Wave Generator, MDL. 211B<br />

Cel Digital Impulse Sound Meter, MDL. 354<br />

Hewlett Packard Oscilloscope, MDL. 1740A<br />

Hewlett Packard RMS Voltsmeter, MDL. 3400A<br />

Hewlett Packard Frequency Function Generator, MDL.<br />

3311A<br />

Hewlett Packard Frequency Counter, MDL. AC0082<br />

Hewlett Packard MultiMeter, MDL. AC0089<br />

(2) Hewlett Packard Switch Controls, MDL. 3488A<br />

Hewlett Packard Synthesizer/Function Generator,<br />

MDL. 3325A<br />

Hewlett Packard SWR Meter, MDL. 415E<br />

Empire Devises Antenna Equipment, MDL. LP-105<br />

Micro-Dot RF Unit 500/1000 MHz, MDL. M187<br />

Hewlett Packard SWR Indicator, MDL. 415B<br />

Hewlett Packard Thermistor Mount, MDL. 478A<br />

WASTE TREATMENT<br />

& PLATING<br />

Plating Area Consisting Of (8) Stainless<br />

Steel Tanks, Gantry Hoist System, Misc.<br />

Racks And Baskets<br />

Waste Treatment System, Including JWI<br />

Filter Press, Vapor Degreaser, Holding Tanks<br />

SAMSCO Water Evaporator, Series 500 Gas.<br />

S/N 1658, Footprint 5’ X 5’ By 22” By 2” Mdl. 500<br />

CRA Processing An Estimated 30 Gal. Per Year<br />

Operating At 33% Capacity Based On A 24 Hours<br />

Day, 250 Days A Year.<br />

VAPOR DEGREASER<br />

BARON BLAKESLEE MDL. MLR-120LE,<br />

Tank Dimensions: 21” X 12” X 21”, Solvent<br />

Capacity: 5.5 Gallons (Boil & Rinse Tanks), 2.5<br />

Gallons (Spray Tank), 1.5 KW Electric Heater, 120<br />

Volts, 25 AMPS, 1 Phase, 60 HZ, W/ Drop-In<br />

Vaportrap Freeboard Chiller; Temperature Range -<br />

40 To 60 Degrees, S/N 27060 [1997]<br />

(Photo On Pg. 8)<br />

FOR A COMPLETE LISTING OF<br />

EQUIPMENT, DETAILED<br />

DESCRIPTIONS, PHOTOS & MORE,<br />

VISIT OUR WEBSITE AT<br />

www.michaelfox.com<br />

(3) Hewlett Packard Dectector’s, MDL. 1164<br />

Sorensen Power Supply, MDL. QRB30-1<br />

W.Kerr LCR Motor, MDL. 4225<br />

Yew Me Gohn Motor, MDL. 2404<br />

General Radio Sound Level Calibrator, MDL. 1987<br />

Westinghouse Amps. Meter, MDL. PA-14<br />

Krohn-Hite Frequency Viable Filter, MDL. 3323-4<br />

Hewlett Packard Directional Coupler, MDL. 1169D<br />

PRD Directional Coupler, MDL. 408<br />

(2) Hewlett Packard Dual Directional Couplers,<br />

MDL.’s P752C, 11592D<br />

(2) FXR Slotted Line, MDL.’s. H115A, X115A<br />

Harrison Labs Power Supply, MDL. 865A<br />

Hewlett Packard Impedence Bridge, MDL. 803A<br />

Textronic Dual Trace Amp, MDL. 7A18<br />

Textronic Oscilloscope, MDL. 7603<br />

Textronic Time Base, MDL. 7B53A<br />

Julie Research Voltage Divider, MDL. VDR-127<br />

SA Microwave Received, MDL. 1711<br />

Hewlett Packard Signal Generator, MDL. 8614A<br />

Hewlett Packard Dual Output +50 MHz Pulse<br />

Generator, MDL. 8015A<br />

Hewlett Packard Sweep Amp Analyzer Display, MDL.<br />

180TR<br />

Hewlett Packard Oscilloscope MDL. 130C<br />

Hewlett Packard XY Recorder MDL. 7035B<br />

(3) Hewlett Packard Oscilloscope Plugin MDL.’s<br />

8695A, 8692B, 8694B<br />

Hewlett Packard Frequency Counter, MDL. 5383A<br />

Hewlett Packard Universal Counter, MDL. 5314A<br />

(2) Sivers Slotted Line, MDL.’s PM7135J, 7135P<br />

Hewlett Packard Slotted Line, MDL. 805C<br />

Omega Slotted Line, MDL. 500<br />

(2) Omega Conductivity Electrode, MDL. CDH 4060,<br />

CDH 40<br />

Omega Flow Meter, MDL. FC451

Large Quantity of Tool Holders<br />

Large Quantity of Inspection Tooling<br />

SHOP & FACTORY<br />

SOUTHWORTH 1,000 Lb. Scissor Lift Cart<br />

CECOR Model MD-CA-5 Portable Sump<br />

Cleaner/Filter And Coolant Dispenser, FAIRBANKS<br />

1000 Lb. Cap. Platform Scale S/N F770490, BINKS<br />

Paint Pots W/ Spray Guns And Hoses, Bench Vises,<br />

Work Benches, Shop Fans, Arbor Presses,<br />

Pneumatic Hand Tools, Electric Hand Tools, Drill<br />

Presses, Pedestal Grinders, Die Lift Table, Scissor<br />

Lift Tables, Shop Carts, Ladders, WELDON<br />

Pneumatic Pumps, Stock Carts, Steel Stock Racks,<br />

Steel Supply Shelving, CHATILION 50 Lb. Bench<br />

Scale, Chain Hoists, Electrical Supplies, Plumbing<br />

Supplies, Electric Motors, (4) Stackable Modular<br />

Spill Pallets, C-Clamps, Woodworking Clamps,<br />

Chain Slings, Belt Slings, Cable Slings, Etc.<br />

TOOL HOLDERS<br />

BT-40 (213), BT-45 (226), BT-50 (146), CAT-50 (287)<br />

(11) Tool Holder Racks<br />

Tool Carts<br />

MACHINE ACCESSORIES<br />

Approx. Walter 25” Rotary Talbe, Yasa 19” Rotary<br />

Table, (20) Assorted Machine Vises, Angle Plates,<br />

Risers, Hold Down Tooling, Quick Change Tool<br />

Post Sets, Offset Boring Heads, Collet Sets, Die<br />

Sets, Perishable Tooling, Including: Carbine<br />

Inserts, End Mills, Drills, Taps, Reamers, Etc.<br />

Large Quantity of Vidmar Cabinets<br />

OGP Mdl. VQ2418 Vidicom Qualifier<br />

VIDEO INSPECTION SYSTEM<br />

OGP MDL. VQ2418 Non-Contact Vidicom Qualifier,<br />

X-24”, Y-18”, Z-6” Travels, 26” X 17.5” Screen, Air Bearings,<br />

X/Y-Axis Servo Motors, Z-Axis Stepper Motor, 115V/50/60 Cycle,<br />

12 AMPS, 1440 Max Watts, S/N VQ2418113 [1986]<br />

PRECISION INSPECTION<br />

Large Granite Surface Plate 8’ x 16’ W/4” X 16’ Straight<br />

Edge, Base<br />

(8) Granite Surface Plates from 12” x 24” to 36” x 48”<br />

(4) Steel Surface Plates from 16” x 22” to 18” x 24”<br />

Assorted Micrometers, Calipers, Height Gauges, Dial<br />

Gauges, Hole Gauges, Pin Gauges, Cadillac Plate Check<br />

Gauge, Federal Air Gauge, Etc.<br />

MISC. EQUIPMENT<br />

EKSTRAM Carlson No. 156 Overarm Router, S/N 156, Throat<br />

16”, 1.5 HP Motor<br />

K.R. WILSON MDL. 37FB-9 S/N 1075, 300 Amp Constant<br />

Current AC/DC Welding Power Source<br />

Approx. 30 Stanley Vidmar Tool Cabinets; Walker-Turner<br />

Floor-Type Drill Press, Dayton Double End Pedestal<br />

Grinder, Branch Hand Tapper, Aloris Quick Change Tool<br />

Post Set, Hand Tools<br />

CAMMANN Tap Disintegrater, S/N 100186<br />

LP Gas Hot High Pressure Steam Unit [1993]<br />

(4) LANGE Portable Die Lift Tables<br />

11

TERMS OF SALE<br />

NO WARRANTIES: Every item and lot in the "Auction" is sold: (a) "AS IS,<br />

WHERE IS, AND WITHOUT RECOURSE," and (b) with no warranties,<br />

guarantees or representation of any kind or variety, whether expressed,<br />

implied or otherwise.<br />

PAYMENT: A 10% buyer's premium applies to the purchase price of all onsite<br />

purchases. A 13-½ % buyer's premium applies to the purchase price of<br />

all on-line purchases. Cash or certified funds required in full at the time and<br />

place of auction. Non-certified checks will NOT be accepted unless<br />

accompanied by a valid bank letter of guarantee, which must be in the<br />

following format: This bank guarantees payment to Michael Fox<br />

International, Inc. from (name of customer) on account #_______ up to the<br />

amount of $ _____. This letter is valid for purchases at the auction held at<br />

Ainslie Corporation on November 18.<br />

INSPECTION<br />

Monday, November 17 from 10:00 A.M. to 4:00 P.M. or by appointment.<br />

REMOVAL<br />

ALL equipment must be removed no later than Friday, December 19.<br />

OVERNIGHT ACCOMMODATIONS<br />

Marriott Hotel Quincy........................................................... (617) 472-1000<br />

Holiday Inn Express............................................................... (781) 848-1260<br />

Hampton Inn ........................................................................ (781) 380-3300<br />

Sheraton ............................................................................... (781) 848-0600<br />

This Sale will be a 'Webcast' auction, which enables you to bid securely in real-time from<br />

the comfort of your own computer. To utilize this service, register with Michael Fox<br />

International at www.michaelfox.com. To learn more about how a webcast works, please go<br />

to the Support section on our homepage and choose "Webcast Instructions".<br />

DIRECTIONS<br />

From Logan<br />

International Airport:<br />

Exit via “Airport Exit”<br />

toward Rte-1A South/<br />

Sumner Tunnel (I-93)/<br />

Boston. Continue<br />

onto East Boston Expy.<br />

(becomes East Boston<br />

Expy./ Sumner Tunnel).<br />

Bear right on Cross<br />

Street. Make sharp<br />

left & take I-93 South<br />

towards Mass. Pike/<br />

Quincy (Go 11.2<br />

miles). Take Exit #6<br />

(Rte-37) toward<br />

Braintree/ Holbrook.<br />

Bear right on Granite<br />

St. (becomes Pond St.)<br />

& proceed to site at<br />

(531 Pond St.).<br />

AIRPORT & TRANSPORTATION<br />

The area is served by the Logan International Airport,<br />

approximately 17 miles north of the auction site.<br />

LEASE FINANCING AVAILABLE<br />

Maximize your bidding power! Get PRE-APPROVED for up to $75,000 (USD) in lease<br />

financing. For more information call the AuctionLea$e Department at 800-438-1470,<br />

or apply online at: www.AuctionLease.com<br />

INFORMATION PROVIDED IS BELIEVED TO BE ACCURATE, BUT IS NOT GUARANTEED.<br />

PLANT CLOSED<br />

AUCTION<br />

<strong>CNC</strong> <strong>MACHINING</strong>/<strong>FABRICATING</strong> EQUIPMENT & <strong>ELECTRONIC</strong> <strong>TEST</strong> <strong>FACILITY</strong><br />

EXECUTIVE OFFICES:<br />

11425 CRONHILL DRIVE, OWINGS MILLS, MARYLAND 21117<br />

(410) 654-7500 (800) 722-3334 FAX (410) 654-5876<br />

531 POND STREET<br />

BRAINTREE, MASSACHUSETTS<br />

TUESDAY, NOVEMBER 18 AT 10:00 A.M. (EST)<br />

MFI-7084<br />

39 OFFICES IN 20 COUNTRIES<br />

GoIndustry · Michael Fox International · Henry Butcher International · Karner & Co · Appelboom<br />

http://www.michaelfox.com<br />

email: info@michaelfox.com<br />

FIRST CLASS MAIL<br />

POSTMASTER: Dated Material.<br />

Please Deliver Promptly.<br />

AUCTION SITE<br />

AIRPORT<br />

PRESORTED<br />

First Class Mail<br />

U.S. Postage PAID<br />

Hyattsville, MD<br />

Permit No. 5394

![UTILITY PIPE BENT EASEMENT AGREEMENT [PE-UB5] THIS ...](https://img.yumpu.com/5265493/1/190x245/utility-pipe-bent-easement-agreement-pe-ub5-this-.jpg?quality=85)