Polyester Production, POY Spinning, Texturising & Twisting Plant ...

Polyester Production, POY Spinning, Texturising & Twisting Plant ...

Polyester Production, POY Spinning, Texturising & Twisting Plant ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

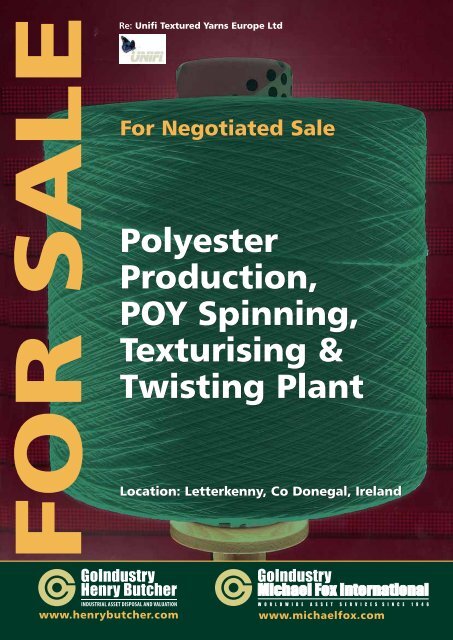

FOR SALE<br />

www.henrybutcher.com<br />

Re: Unifi Textured Yarns Europe Ltd<br />

For Negotiated Sale<br />

<strong>Polyester</strong><br />

<strong>Production</strong>,<br />

<strong>POY</strong> <strong>Spinning</strong>,<br />

<strong>Texturising</strong> &<br />

<strong>Twisting</strong> <strong>Plant</strong><br />

Location: Letterkenny, Co Donegal, Ireland<br />

www.michaelfox.com

POLYMER PLANTS<br />

2 Lurgi 140 tonnes/week PET granule<br />

production plants each comprising<br />

4500 kg batch size, 315 - 325<br />

mins/batch 6000 kg/hr. Chipping plant<br />

with Automatik UWG 36 36 strand<br />

chipping unit with water separator<br />

Zimmer/Davy McKee 220 tonnes/week<br />

PET granule production plant (Zimmer<br />

engineering design and Davy McKee<br />

construction and installation) (1991).<br />

Comprising 5200 kg batch size, 235 -<br />

245 mins/batch, Paste premixing tank<br />

with pump transfer. Zimmer 7250 kg/hr<br />

Chipping plant with Automatik USG<br />

600, 66 strand chipping unit with<br />

water separator<br />

Polymer <strong>Plant</strong> - shared services Catalyst<br />

make up system with centrifuge.<br />

Titanium dioxide preparation with<br />

mixing tanks and pearl mill. Chipping<br />

water preparation and storage.<br />

Ethylene glycol recovery distillation<br />

column (for Lurgi Lines 1 & 2). 2 No<br />

Contrapol 14 million BTU/hr Heavy fuel<br />

oil fired thermal oil boilers. Beel<br />

Industrial Boilers 7110 kW Heavy fuel<br />

oil fired boiler (2000). 3 No - 200<br />

tonnes Stainless Steel Teraphthalic Acid<br />

storage silos<br />

2 No - 100 tonnes Stainless Steel<br />

Ethylene Glycol storage tanks<br />

2 No - 180 tonnes Aluminium alloy wet<br />

chip storage and blending silos. 2 No -<br />

200 tonnes Aluminium alloy wet chip<br />

storage and blending silos<br />

POLYESTER SPINNING PLANTS<br />

4 No Barmag 8.5 tonnes/day <strong>Polyester</strong><br />

<strong>Spinning</strong> and Winding <strong>Plant</strong> for 64<br />

threadlines each comprising: Karl<br />

Fischer Granule crystalliser/dryer,<br />

Barmag 12E4-24D 120mm 24:1<br />

extruder, Brunswick CPF polymer filter<br />

32 No Barmag double spinning pumps<br />

with jet packs and 70mm spinnerettes,<br />

16 No Barmag SW4SLD 2-spindle takeup<br />

2 No Barmag 4.25 tonnes/day <strong>Polyester</strong><br />

<strong>Spinning</strong> and Winding <strong>Plant</strong> for 32<br />

threadlines each comprising: Karl<br />

Fischer Granule crystalliser/dryer,<br />

Barmag 9E4-24D 90mm 24:1 extruder,<br />

Brunswick CPF polymer filter, 16 No<br />

Barmag double spinning pumps with<br />

jet packs and 70mm spinnerettes,<br />

8 No Barmag SW4SLD 2-spindle takeup<br />

winders<br />

Barmag 1 tonne/day <strong>Polyester</strong> Pilot<br />

<strong>Spinning</strong> and Winding <strong>Plant</strong> for 8<br />

threadlines comprising: Karl Fischer<br />

Granule crystalliser/dryer, Barmag 4E4-<br />

24D 40mm 24:1 extruder, Brunswick<br />

CPF polymer filter, 4 No Barmag double<br />

spinning pumps with jet packs and<br />

70mm spinnerettes, 8 No Barmag<br />

SW4SLD 2-spindle take-up winders<br />

Zimmer Batch crystalliser/dryer with<br />

vibratory fluidised bed fines removal,<br />

(32 tonnes/day)<br />

Automatik/Toray 9.5 tonnes/day <strong>Polyester</strong><br />

<strong>Spinning</strong> and Winding <strong>Plant</strong> for 144<br />

threadlines comprising: Automatik E1-<br />

105-30L 105mm 30:1 extruder,<br />

Brunswick CPF Polymer filter, 12 No<br />

FOR SALE BY PRIVATE TREATY<br />

Zimmer 7250 kg/hr Chipping plant with Automatik USG 600, 66 strand chipping unit with water separator<br />

Beel Industrial Boilers 7110 kW at 21.7 bar Heavy fuel oil fired boiler Fuel 3500 SR1 oil (42333 kJ/kg) 729 kg/hr<br />

at full output Serial No 10880<br />

Zimmer Batch crystalliser/dryer with vibratory<br />

fluidised bed fines removal (32 tonnes/day)<br />

Qty 2<br />

Approx 200 tonnes capacity Aluminium alloy wet<br />

chip storage and blending silos with dense phase<br />

chip conveyor<br />

Further Information @ www.henrybutcher.com<br />

2000<br />

1991

Further Information @ www.henrybutcher.com<br />

Qty 20<br />

Barmag FK6M-700, 700 m/min 216 position false twist texturising machines<br />

Toray TW536/M1/6 2-spindle turret type take-up winders with (inset) auto doffing with Auto doff travelling<br />

doffing cart<br />

Automatik E1-105-30L 105mm 30:1 extruder Brunswick CPF Polymer filter<br />

Qty 24<br />

FOR SALE BY PRIVATE TREATY<br />

Feinpruef 4-spindle spinning pumps<br />

with jet packs and 80mm spinnerettes,<br />

24 No Toray CRD401614 Godet roll<br />

sets, 24 No Toray TW536/M1/6 2spindle<br />

turret type take-up winders<br />

with auto doffing<br />

Automatik/Toray 20 tonnes/day <strong>Polyester</strong><br />

<strong>Spinning</strong> and Winding <strong>Plant</strong> for 144<br />

threadlines comprising: Automatik E1-<br />

150-30L 150 mm 30:1 extruder,<br />

Brunswick CPF Polymer filter, 12 No<br />

Feinpruef 4-spindle spinning pumps<br />

with jet packs and 80mm spinnerettes,<br />

24 No Toray CRD401614 Godet roll<br />

sets, 24 No Toray TW536/M1/6 2spindle<br />

turret type take-up winders<br />

with auto doffing<br />

Automatik/Toray 1.5 tonnes/day <strong>Polyester</strong><br />

Pilot <strong>Spinning</strong> and Winding <strong>Plant</strong> for 12<br />

threadlines comprising: Automatik<br />

extruder, Brunswick CPF Polymer filter,<br />

Feinpruef 4-spindle spinning pump<br />

with jet packs and 80mm spinnerettes,<br />

2 No Toray CRD401614 Godet roll sets,<br />

2 No Toray TW536/M1/6 2-spindle<br />

turret type take-up winders each<br />

TEXTURISING<br />

20 No Barmag FK6M-700, 700 m/min<br />

216 position false twist texturising<br />

machines (1988 and 1989) each with M<br />

profile with 2 m, 3.4 kW thermex<br />

heated primary heaters, Temco On line<br />

tension monitoring (1991).<br />

Karl Fischer Granule crystalliser/dryer with fines<br />

removal Barmag 12E4-24D 120mm 24:1 extruder<br />

Brunswick CPF polymer filter<br />

Qty 16<br />

Barmag SW4SLD 2-spindle take-up winders<br />

Qty 3<br />

Stähle RMT-D 12 position air jet texturising machines<br />

each with primary heater unit to each position

FAG 471 Friction twist units (1991) with<br />

6 mm PU discs and metal guide discs,<br />

air interlacing to each position, 18 - 24<br />

end rotating creels<br />

2 No Stähle RMT-D 12 position air jet<br />

texturising machines each with 12 x 24<br />

end rotating creels (1999)<br />

3 No Stähle RMT-D 12 position air jet<br />

texturising machines each with primary<br />

heater unit to each position and 12 x<br />

24 end rotating creels (1999)<br />

TWISTING<br />

25 ICBT type DT360E 108 spindle 2 for 1<br />

twisting machines each with type<br />

DTM235 spindles in 9 sections (1 –<br />

1995, 24 – 1996)<br />

3 No ICBT type DT350EH 96 spindle 2 for<br />

1 twisting machine each with type<br />

DTM260 spindles in 12 sections (2 –<br />

1995 and 1 - 1998)<br />

GENERAL<br />

J C Lagarde 8940 lt, Steam autoclave<br />

(1996)<br />

Welker 7000 lt, Steam autoclave (1990)<br />

J C Lagarde 8940 lt Steam autoclave<br />

(2000)<br />

2 No Gardner Denver EAUSRD Packaged<br />

screw type air compressors, 150 psi,<br />

300 HP (1991)<br />

Atlas Copco GA-250-FF Packaged screw<br />

type air compressor, 13 bar, 250 kW<br />

(2001), with built in refrigerant type air<br />

dryer<br />

7 No Atlas Copco GA-250 Packaged<br />

screw type air compressor, 250 kW<br />

(1993-99)<br />

2 No Trane CVGD045 water cooled chiller<br />

plants with 306kW centrifugal<br />

compressor (R134a – 1993)<br />

2 No Trane RTAA322 Air cooled chiller<br />

plants with 3 x 150kW screw<br />

compressors (R22 – 1997)<br />

Scaglia Vacugrip SB 120 kg Vacuum<br />

lifting<br />

4 No Lawson Hemphill Circular check<br />

knitting machines<br />

Well equipped Textile and Polymer<br />

Laboratories<br />

FOR SALE BY PRIVATE TREATY<br />

A list of the principal plant items together with photographs is available on our webpage<br />

www.henrybutcher.com/unifi<br />

Viewing is Strictly by Appointment Only<br />

For further information or appointment to view please contact:<br />

Email: unifi@henrybutcher.com<br />

www.henrybutcher.com<br />

New London Bridge House,<br />

25 London Bridge Street, London SE1 9BQ, UK<br />

Tel: +44 (0)20 7098 3700<br />

Fax: +44 (0)20 7098 3795<br />

email: sales@henrybutcher.com<br />

25 ICBT type DT360E 108 spindle 2 for 1 twisting machines<br />

J C Lagarde 8940 lt Steam autoclave<br />

A Buyer’s Premium of 12.5% + VAT will be charged on all sales.<br />

www.michaelfox.com<br />

11424 Cronhill Drive,<br />

Owings Mills (Baltimore), Maryland 21117, USA<br />

Tel: +1 (410) 654 7500<br />

Fax: +1 (410) 654 5876<br />

email: sales.support@michaelfox.com<br />

LOCAL SERVICE – GLOBAL REACH<br />

GoIndustry • Henry Butcher International • Michael Fox International • Karner & Co • Appelboom<br />

The details within this brochure are for guidance only and do not form any part of any contract.

![UTILITY PIPE BENT EASEMENT AGREEMENT [PE-UB5] THIS ...](https://img.yumpu.com/5265493/1/190x245/utility-pipe-bent-easement-agreement-pe-ub5-this-.jpg?quality=85)