THE ECHO - Ferrostaal

THE ECHO - Ferrostaal

THE ECHO - Ferrostaal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

20<br />

projects & contracting<br />

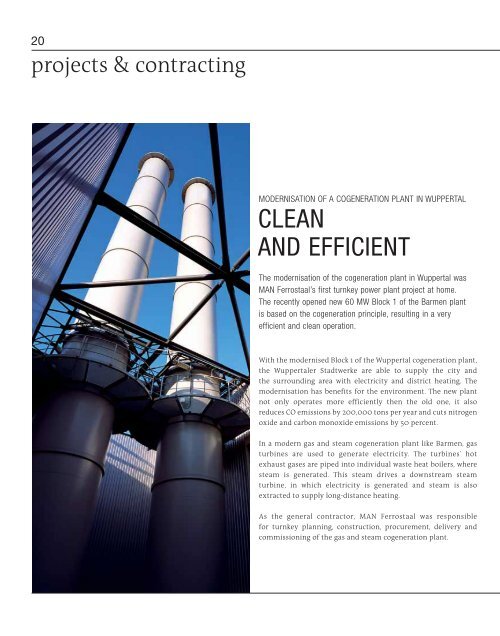

MODERNISATION OF A COGENERATION PLANT IN WUPPERTAL<br />

CLEAN<br />

AND EFFICIENT<br />

The modernisation of the cogeneration plant in Wuppertal was<br />

MAN <strong>Ferrostaal</strong>’s first turnkey power plant project at home.<br />

The recently opened new 60 MW Block 1 of the Barmen plant<br />

is based on the cogeneration principle, resulting in a very<br />

efficient and clean operation.<br />

With the modernised Block 1 of the Wuppertal cogeneration plant,<br />

the Wuppertaler Stadtwerke are able to supply the city and<br />

the surrounding area with electricity and district heating. The<br />

modernisation has benefits for the environment. The new plant<br />

not only operates more efficiently then the old one, it also<br />

reduces CO emissions by 200,000 tons per year and cuts nitrogen<br />

oxide and carbon monoxide emissions by 50 percent.<br />

In a modern gas and steam cogeneration plant like Barmen, gas<br />

turbines are used to generate electricity. The turbines’ hot<br />

exhaust gases are piped into individual waste heat boilers, where<br />

steam is generated. This steam drives a downstream steam<br />

turbine, in which electricity is generated and steam is also<br />

extracted to supply long-distance heating.<br />

As the general contractor, MAN <strong>Ferrostaal</strong> was responsible<br />

for turnkey planning, construction, procurement, delivery and<br />

commissioning of the gas and steam cogeneration plant.