REVERSE CYCLE HEAT PUMP-CHILLER

REVERSE CYCLE HEAT PUMP-CHILLER

REVERSE CYCLE HEAT PUMP-CHILLER

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

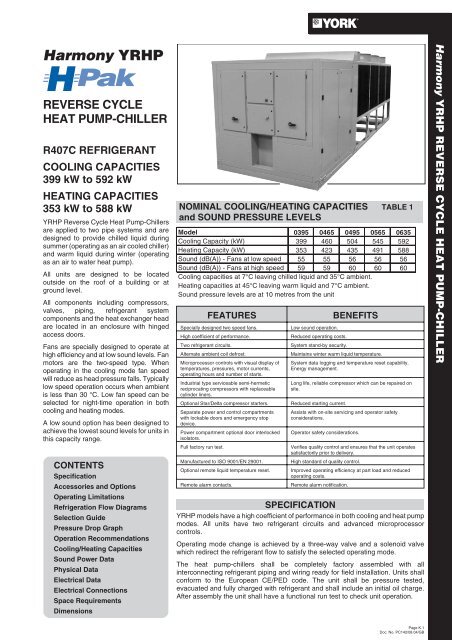

<strong>REVERSE</strong> <strong>CYCLE</strong><br />

<strong>HEAT</strong> <strong>PUMP</strong>-<strong>CHILLER</strong><br />

R407C REFRIGERANT<br />

COOLING CAPACITIES<br />

399 kW to 592 kW<br />

<strong>HEAT</strong>ING CAPACITIES<br />

353 kW to 588 kW<br />

YRHP Reverse Cycle Heat Pump-Chillers<br />

are applied to two pipe systems and are<br />

designed to provide chilled liquid during<br />

summer (operating as an air cooled chiller)<br />

and warm liquid during winter (operating<br />

as an air to water heat pump).<br />

All units are designed to be located<br />

outside on the roof of a building or at<br />

ground level.<br />

All components including compressors,<br />

valves, piping, refrigerant system<br />

components and the heat exchanger head<br />

are located in an enclosure with hinged<br />

access doors.<br />

Fans are specially designed to operate at<br />

high efficiency and at low sound levels. Fan<br />

motors are the two-speed type. When<br />

operating in the cooling mode fan speed<br />

will reduce as head pressure falls. Typically<br />

low speed operation occurs when ambient<br />

is less than 30 °C. Low fan speed can be<br />

selected for night-time operation in both<br />

cooling and heating modes.<br />

A low sound option has been designed to<br />

achieve the lowest sound levels for units in<br />

this capacity range.<br />

CONTENTS<br />

Specification<br />

Accessories and Options<br />

Operating Limitations<br />

Refrigeration Flow Diagrams<br />

Selection Guide<br />

Pressure Drop Graph<br />

Operation Recommendations<br />

Cooling/Heating Capacities<br />

Sound Power Data<br />

Physical Data<br />

Electrical Data<br />

Electrical Connections<br />

Space Requirements<br />

Dimensions<br />

NOMINAL COOLING/<strong>HEAT</strong>ING CAPACITIES TABLE 1<br />

and SOUND PRESSURE LEVELS<br />

Model 0395 0465 0495 0565 0635<br />

Cooling Capacity (kW) 399 460 504 545 592<br />

Heating Capacity (kW) 353 423 435 491 588<br />

Sound (dB(A)) - Fans at low speed 55 55 56 56 56<br />

Sound (dB(A)) - Fans at high speed 59 59 60 60 60<br />

Cooling capacities at 7°C leaving chilled liquid and 35°C ambient.<br />

Heating capacities at 45°C leaving warm liquid and 7°C ambient.<br />

Sound pressure levels are at 10 metres from the unit<br />

FEATURES<br />

Specially designed two speed fans.<br />

High coefficient of performance.<br />

Two refrigerant circuits.<br />

Alternate ambient coil defrost.<br />

Microprocessor controls with visual display of<br />

temperatures, pressures, motor currents,<br />

operating hours and number of starts.<br />

Industrial type serviceable semi-hermetic<br />

reciprocating compressors with replaceable<br />

cylinder liners.<br />

Optional Star/Delta compressor starters.<br />

Separate power and control compartments<br />

with lockable doors and emergency stop<br />

device.<br />

Power compartment optional door interlocked<br />

isolators.<br />

Full factory run test.<br />

Manufactured to ISO 9001/EN 29001.<br />

Optional remote liquid temperature reset.<br />

Remote alarm contacts.<br />

BENEFITS<br />

Low sound operation.<br />

Reduced operating costs.<br />

System stand-by security.<br />

Maintains winter warm liquid temperature.<br />

System data logging and temperature reset capability.<br />

Energy management.<br />

Long life, reliable compressor which can be repaired on<br />

site.<br />

Reduced starting current.<br />

Assists with on-site servicing and operator safety<br />

considerations.<br />

Operator safety considerations.<br />

Verifies quality control and ensures that the unit operates<br />

satisfactorily prior to delivery.<br />

High standard of quality control.<br />

Improved operating efficiency at part load and reduced<br />

operating costs.<br />

Remote alarm notification.<br />

SPECIFICATION<br />

YRHP models have a high coefficient of performance in both cooling and heat pump<br />

modes. All units have two refrigerant circuits and advanced microprocessor<br />

controls.<br />

Operating mode change is achieved by a three-way valve and a solenoid valve<br />

which redirect the refrigerant flow to satisfy the selected operating mode.<br />

The heat pump-chillers shall be completely factory assembled with all<br />

interconnecting refrigerant piping and wiring ready for field installation. Units shall<br />

conform to the European CE/PED code. The unit shall be pressure tested,<br />

evacuated and fully charged with refrigerant and shall include an initial oil charge.<br />

After assembly the unit shall have a functional run test to check unit operation.<br />

Page K.1<br />

Doc. No. PC142/08.04/GB

The unit structure and acoustic enclosure<br />

are galvanised steel coated with<br />

baked-on powder paint (Desert Sand<br />

(RAL 1019)).<br />

Compressors<br />

The unit shall have accessible,<br />

semi-hermetic, reciprocating compressors.<br />

All rotating parts are statically and<br />

dynamically balanced. Isolating valves shall<br />

be provided.<br />

Motor - The compressor motors are<br />

refrigerant gas cooled, with integral<br />

temperature-sensing solid state overload<br />

protection in each phase. The terminal<br />

boxes are to IP55 weather protection.<br />

Starting is by Part Winding or optional<br />

Star/ Delta.<br />

Housing - The compressor housing is<br />

cast iron, and contains: removable<br />

cylinder heads with internal muffling,<br />

suction and discharge service valves,<br />

crankcase sight glass and heater, oil and<br />

suction strainers, and internal relief<br />

valves.<br />

Crankshaft - The crankshaft is ductile<br />

(nodular) iron, drilled for positive oil<br />

distribution, with integral counterweights<br />

for balancing. The main bearings are<br />

insert type, steel-backed babbitt. The<br />

thrust bearing is bronze.<br />

Cylinder Assemblies - Suction and<br />

discharge valves are high-quality,<br />

non-flexing, stainless steel. The pistons<br />

are aluminium alloy with two piston rings.<br />

The connecting rods are aluminium alloy<br />

with integral bearing surfaces on both<br />

ends. Cylinder liners are removable.<br />

Lubrication - The lubrication is force-fed<br />

by a reversible oil pump to all crankshaft<br />

and bearing surfaces through a fine mesh<br />

stainless steel oil strainer.<br />

Capacity Control - Capacity control is<br />

provided by solenoid-actuated, capacity<br />

control valves, which are controlled by the<br />

microprocessor centre. This method<br />

efficiently and effectively matches low<br />

load conditions as required. Gas flow is<br />

sufficient at all times to cool the motor.<br />

Isolation - Each compressor is mounted<br />

on isolator pads to reduce vibration<br />

transmission to the structure.<br />

Refrigerant circuits<br />

An independent refrigerant circuit shall be<br />

provided for each compressor. Each<br />

circuit will use copper refrigerant pipe<br />

formed on bending machines to reduce<br />

the number of brazed joints to provide a<br />

reliable and leak resistant system.<br />

Each circuit shall incorporate all<br />

components necessary for the designed<br />

operation including: liquid refrigerant<br />

accumulator, solenoid, three way,<br />

charging and thermostatic expansion<br />

valves, sight glasses and filter drier.<br />

Refrigerant/Water Heat Exchanger<br />

The heat exchanger is the direct<br />

expansion type, with the refrigerant in the<br />

tubes and water flowing through the<br />

baffled shell. The refrigerant side is<br />

constructed and tested in accordance<br />

with the European CE code.<br />

The water baffles are constructed of<br />

galvanised steel to resist corrosion. The<br />

removable head allows access to the<br />

internally enhanced, seamless, copper<br />

tubes. Flanged liquid connections and<br />

vent and drain connections are included.<br />

The heat exchanger is equipped with a<br />

heater mat controlled by a separate<br />

thermostat. The heater provides freeze<br />

protection down to -29°C ambient. The<br />

heat exchanger is covered with 19 mm<br />

flexible, closed-cell, foam insulation.<br />

Ambient Coils<br />

Coils: Separate ambient coil for each<br />

refrigerant circuit. Each coil shall be<br />

manufactured from seamless, internally<br />

enhanced, copper tubes arranged in<br />

staggered rows and mechanically<br />

expanded into aluminium alloy fins with<br />

full height fin collars. The design working<br />

pressure shall be 31 bar g and tested to<br />

34 bar g.<br />

Fans: Shall be dynamically and statically<br />

balanced, direct drive with corrosion<br />

resistant glass reinforced composite<br />

blades moulded having a full airfoil cross<br />

section, providing vertical air discharge<br />

from extended orifices for efficiency and<br />

low sound. Each fan shall be located in a<br />

separate compartment to prevent cross<br />

flow during fan cycling. Fan guards shall<br />

be of heavy gauge, PVC (polyvinyl<br />

chloride) coated galvanised steel.<br />

Motors: Shall be the high efficiency direct<br />

drive two speed, current overload<br />

protected, totally enclosed (TEAC) type<br />

with double sealed, permanently<br />

lubricated, ball bearings.<br />

Defrost: During winter operation the<br />

ambient coils may be affected by frosting.<br />

Defrost is performed by reversing the<br />

action of the refrigerant circuit into the<br />

cooling mode to allow the ice to be melted<br />

by high pressure refrigerant vapour in a<br />

very short time period. Ambient coils<br />

defrosted alternatively so that one<br />

refrigerant circuit provides heat while the<br />

ambient coil on the other circuit is<br />

defrosted.<br />

Power and Control Panel<br />

All controls and motor starting equipment<br />

necessary for unit operation shall be<br />

factory wired and function tested. The<br />

panel enclosure shall be designed to IP55<br />

(rain/dust tight) and be manufactured<br />

from powder painted galvanised steel.<br />

The panel shall be divided into a common<br />

input section, a power section for each<br />

electrical system and a control section.<br />

Models with Standard Single Point<br />

Power Supply Connection<br />

The common input section shall contain:<br />

A master door interlocked non-fused<br />

disconnect switch for connection of the<br />

customer provided single power supply.<br />

Internal factory wiring to two fuse<br />

protected power sections. The control<br />

supply is derived internally from the door<br />

interlocked non-fused disconnect switch.<br />

(Refer to "Electrical Connection Options"<br />

for details).<br />

The common input section also contains<br />

the control circuit switch disconnect/<br />

emergency stop device, 24 V transformer<br />

for the power supply board, control fuses,<br />

residual current circuit breaker, and<br />

terminals for a remote emergency stop<br />

device.<br />

Each power section contains:<br />

Compressor and fan fuses, compressor<br />

and fan contactors, fan overloads and a<br />

control circuit fuse.<br />

The control section contains:<br />

An On/Off switch, control system keypad<br />

and display, microprocessor board,<br />

power supply board, and relay boards<br />

(which contain the customer connection<br />

terminals).<br />

Microprocessor Controls<br />

The control system uses actual leaving<br />

liquid temperature and the programmed<br />

liquid temperature setpoint and range to<br />

provide chilled and warm liquid<br />

temperature control. The system is<br />

designed to limit compressor/loader<br />

cycling thus saving energy and reducing<br />

wear on mechanical components. The<br />

microprocessor shall have the following<br />

functions and displays:<br />

• A liquid crystal 40 character display with<br />

text provided on two lines and light emitting<br />

diode backlighting for outdoor viewing.<br />

• A colour coded sealed keypad with sections<br />

for Display, Entry, Setpoints, Clock, Print,<br />

Program and Unit On/Off switch.<br />

• The standard controls shall include: mode<br />

change contacts, run signal contacts,<br />

demand load limit from external building<br />

automation system input, remote reset<br />

liquid temperature reset input, unit alarm<br />

contacts, liquid pump control, automatic<br />

and manual reset after power failure,<br />

automatic system optimisation to match<br />

operating conditions, software stored in<br />

non-volatile memory (EPROM) to eliminate<br />

chiller failure due to AC power failure.<br />

• Programmed setpoints shall be retained in<br />

a lithium battery backed RTC memory for a<br />

minimum of 5 years.<br />

The standard unit can be directly<br />

connected to a YORK ISN Building<br />

Automation System via the standard<br />

on-board RS485 communication port.<br />

This option also provides open system<br />

compatibility with other communications<br />

networks (BACNET & LONMARK)<br />

via interface through standard onboard<br />

485 or 232 port and an external YorkTalk<br />

Translator.<br />

Page K.2<br />

Doc. No. PC142/08.04/GB

Electrical Connection Options:<br />

Single Point Power Supply Connection<br />

A terminal block in the common input<br />

section of the panel for connection of the<br />

customer provided single power supply.<br />

Internal factory wiring to two door<br />

interlocked fused disconnect switches or<br />

two door interlocked circuit breakers,<br />

mounted in the power sections. The<br />

control supply is derived internally from<br />

the terminal block.<br />

or<br />

A master door interlocked non-fused<br />

disconnect switch in the common input<br />

section of the panel for connection of the<br />

customer provided single power supply.<br />

Internal factory wiring to two door<br />

interlocked fused disconnect switches or<br />

two door interlocked circuit breakers,<br />

mounted in the power sections. The<br />

control supply is derived internally from<br />

the master non-fused disconnect switch.<br />

Multi Point Power Supply Connection<br />

Two door interlocked fused disconnect<br />

switches, mounted in the power sections,<br />

for connection of the customer provided<br />

power supplies. A non-fused disconnect<br />

switch / emergency stop device<br />

(QCSD/ESD) with termination for the<br />

customer (400 V, 2 Ø, 50 Hz ) control<br />

supply.<br />

or<br />

Two door interlocked circuit breakers,<br />

mounted in the power sections, for<br />

connection of the customer provided<br />

power supplies. A non-fused disconnect<br />

switch / emergency stop device<br />

(QCSD/ESD) with termination for the<br />

customer (400 V, 2 Ø, 50 Hz ) control<br />

supply.<br />

Star/Delta Compressor Starting<br />

Compressors fitted with star/delta wound<br />

motors and contactors for reduced<br />

current starting.<br />

ACCESSORIES AND OPTIONS<br />

Power Factor Correction<br />

Factory mounted passive (static) power<br />

factor correction capacitors to correct<br />

compressor power factors to a target of<br />

0.9 - 0.95 (depending on operating<br />

conditions).<br />

Note: Operating voltage range is reduced<br />

from standard 342 - 440 V to 360 - 440 V<br />

when power factor correction is fitted.<br />

Control Options:<br />

Building Automation System (BAS)<br />

Interface - The addition of a factory<br />

mounted PCB to accept a 4-20 mA,<br />

0-10 Vdc or contact closure input to reset<br />

the leaving liquid temperature from a<br />

building automation system.<br />

The standard unit capabilities include<br />

remote start-stop, remote mode selection,<br />

remote leaving liquid temperature reset<br />

via a PWM input signal or up to two steps<br />

of demand (load) limiting depending on<br />

model.<br />

Note: The standard unit control panel can<br />

be directly connected to a YORK Building<br />

Automated System via the standard on<br />

board RS485 communication port.<br />

Language LCD and Keypad - French,<br />

Italian, Portugese and Spanish unit LCD<br />

read-out and keypad available. Standard<br />

language is English.<br />

Printer - Hand held plug in printer for<br />

obtaining record data of operating and<br />

history data.<br />

Refrigerant/Liquid Circuit Options:<br />

Mechanical Gauge Kit - Factory fitted<br />

mechanical pressure gauges for display<br />

of suction and discharge pressures, one<br />

complete set per system.<br />

10.5 bar (150 PSI) DWP Flow Switch -<br />

Vapour-proof SPDT switch, -29°C to<br />

121°C, with 1" NPT connection for upright<br />

mounting in horizontal pipe (field<br />

mounted).<br />

Refrigerant to Water Heat Exchanger<br />

Mating Flanges - Field installed mating<br />

flanges for heat exchanger water<br />

connections.<br />

Ambient Coil Options:<br />

Copper Fin Ambient Coils - Ambient<br />

coils are constructed with copper fins<br />

(ASTM 287 Test, after 1500 hours 17%<br />

weight loss).<br />

Black Epoxy Coated Aluminium Fin<br />

Ambient Coils - Ambient coils are<br />

constructed with corrosion resistant<br />

epoxy coated aluminium fins (ASTM 287<br />

Test, after 1500 hours 7% weight loss).<br />

Blygold Protective Coating - is<br />

recommended for corrosive applications,<br />

such as coastal locations where salt spray<br />

may hit the ambient coil fins (ASTM 287<br />

Test, after 1500 hours 0% weight loss).<br />

Defrost Drip Trays - Field fitted drip trays<br />

each with a drain connection, drainage<br />

piping to be installed and supplied by<br />

others. Three trays on each side of the<br />

unit on YRHP0395 and 0465, four trays<br />

on each side of the unit on YRHP0495,<br />

0565 and 0635.<br />

Low Sound Option<br />

Component enclosure lined with acoustic<br />

material.<br />

Unit Enclosures:<br />

Wire Enclosure - Welded wire mesh<br />

guards mounted on the ambient coils<br />

(factory mounted).<br />

Vibration Isolation:<br />

25 mm Spring Isolators - Level<br />

adjustable, spring and cage type isolators<br />

for mounting under the unit base rails<br />

(field mounted).<br />

Service Licence - Allows access to<br />

detailed fault diagnosis data.<br />

OPERATING LIMITATIONS TABLE 2<br />

Chilled<br />

Liquid<br />

Warm<br />

Liquid<br />

Refrigerant/<br />

Liquid Heat<br />

Exchanger<br />

Ambient<br />

Coil<br />

Liquid outlet<br />

temperature<br />

Liquid outlet<br />

MODEL YRHP<br />

Water outlet<br />

Temperature spread<br />

Water outlet<br />

Temperature range<br />

temperature<br />

Flow rate<br />

Liquid pressure drop<br />

Maximum refrigerant working pressure<br />

Maximum liquid working pressure<br />

Air entering Cooling Mode<br />

temperature Heat Pump Mode<br />

Fan available static pressure<br />

Power supply voltage 400V, 3 ,50Hz (nominal) (1)<br />

Recommended minimum system water volume<br />

0395 0465 0495 0565 0635<br />

min. max. min. max. min. max. min. max. min. max.<br />

°C<br />

5to15<br />

3.3to8.0<br />

°C<br />

35 to 50<br />

3.3to8.0<br />

l/s<br />

8.6 to 42.6<br />

kPa 5.9 118 5.9 118 5.9 122 5.9 122 5.9 122<br />

barg<br />

31<br />

10<br />

°C<br />

-4 to 42<br />

-12 to 20 (fans full speed), -8 to 24 (fans slow speed)<br />

Pa<br />

0<br />

V<br />

342 to 440<br />

l 2139 2511 2696 2310 2570<br />

Note: (1) Power supply limit is 360 to 440 V when Power Factor Correction Option is fitted.<br />

Page K.3<br />

Doc. No. PC142/08.04/GB

FIGURE 1<br />

Ambient Coil<br />

Refrigerant Circuit No 2<br />

REFRIGERANT FLOW DIAGRAM - COOLING MODE<br />

TEV<br />

NRV<br />

OPEN<br />

CLOSED<br />

High pressure<br />

sub-cooled liquid<br />

High Pressure<br />

superheated vapour<br />

Compressor<br />

Accumulator<br />

OPEN CLOSED<br />

3-Way Valve<br />

OPEN<br />

Cooling Mode<br />

Low pressure liquid refrigerant enters the<br />

refrigerant to water heat exchanger and is<br />

evaporated and superheated by the heat<br />

energy absorbed from the chilled water<br />

passing through the heat exchanger shell.<br />

Low pressure vapour passes through the<br />

three way valve and accumulator before<br />

entering the compressor where pressure<br />

and superheat are increased. Heat is<br />

rejected via the ambient coil and fans.<br />

The fully condensed and subcooled liquid<br />

refrigerant then enters the expansion<br />

valve where pressure reduction and<br />

further cooling takes place before<br />

returning to the heat exchanger.<br />

Low pressure superheated vapour<br />

TEV<br />

Low pressure<br />

sub-cooled<br />

liquid<br />

Refrigerant Circuit No 2<br />

Refrigerant to Water<br />

Heat Exchanger<br />

Heating Mode<br />

Liquid refrigerant enters the ambient coil<br />

and is fully evaporated and superheated<br />

by the energy absorbed from the ambient<br />

air. Low pressure superheated refrigerant<br />

vapour passes through the three way<br />

valve and accumulator and enters the<br />

compressor, where pressure and<br />

superheat are increased. High pressure<br />

superheated refrigerant vapour enters the<br />

refrigerant to water heat exchanger tubes<br />

where heat is rejected to the water<br />

circulating through the shell. The high<br />

pressure liquid refrigerant, leaving the<br />

heat exchanger, enters the thermostatic<br />

expansion valves where the refrigerant<br />

pressure is reduced and subsequently<br />

cooled before returning to the ambient<br />

coil.<br />

Defrost Mode<br />

When ice builds up on the ambient coils<br />

defrost is initiated by operating the<br />

machine in a cooling mode. Each of the<br />

two refrigerant circuits will be defrosted<br />

one at a time. When defrost is operative<br />

the circuit operating in heat pump mode is<br />

in balance with the circuit operating in<br />

defrost (cooling). Therefore, heat energy<br />

is not removed from the hot water system.<br />

FIGURE 2<br />

Ambient Coil<br />

Refrigerant Circuit No 2<br />

Low pressure TEV<br />

sub-cooled<br />

liquid<br />

REFRIGERANT FLOW DIAGRAM - <strong>HEAT</strong>ING MODE<br />

High pressure<br />

sub-cooled liquid<br />

NRV<br />

TEV<br />

CLOSED<br />

OPEN<br />

Low pressure superheated vapour<br />

Compressor<br />

High Pressure<br />

superheated vapour<br />

Refrigerant Circuit No 2<br />

Refrigerant to Water<br />

Heat Exchanger<br />

Accumulator<br />

OPEN<br />

OPEN<br />

3-Way Valve<br />

CLOSED<br />

Page K.4<br />

Doc. No. PC142/08.04/GB

DATA REQUIRED<br />

To select a YORK YRHP Reverse Cycle Heat Pump-Chiller, the<br />

following information is required:<br />

1. Required cooling/heating capacity.<br />

2. Design chilled liquid entering and leaving temperatures.<br />

3. Design hot liquid leaving temperature.<br />

4. Design liquid flow rate if one of the temperatures in item 2 are<br />

unknown.*<br />

5. Summer and winter design entering air temperatures.<br />

6. Altitude above sea level.<br />

7. Design refrigerant/water heat exchanger water side fouling<br />

factor.<br />

*Item 4:The same refrigerant to water heat exchanger is used for<br />

chilled liquid in the summer and hot liquid in the winter. The<br />

YRHP cooling capacity normally exceeds the heating capacity at<br />

design ambient conditions. Therefore the water flow should be<br />

calculated using items 1 and 2 and the following formulae:<br />

Cooling capacity kW = l/s chilled liquid x °C range<br />

0.2392<br />

Where:<br />

Range = Entering liquid temperature - Leaving liquid<br />

temperature.<br />

The hot liquid range is calculated as follows:<br />

Hot liquid range °C = Heating capacity x 0.2392<br />

l/s hot liquid<br />

<strong>REVERSE</strong> <strong>CYCLE</strong> <strong>HEAT</strong> <strong>PUMP</strong>-<strong>CHILLER</strong> SELECTION<br />

1. Determine the correct size of unit by selecting the model<br />

which most closely matches the required capacity at the<br />

design conditions of leaving liquid temperatures and entering<br />

air temperatures (Tables 5 and 6).<br />

2. Apply the relevant correction factors for fouling factors and<br />

altitude (Tables 3 and 4) to the cooling and heating capacities<br />

and power values (Tables 5 and 6). Ensure the corrected<br />

capacity is still sufficient for requirements.<br />

3. Using the corrected capacity of the selected unit adjust the<br />

design temperature range, or flow rate, to balance the<br />

formulae shown in "Data Required".<br />

4. Physical and electrical data can now be determined from<br />

Tables 8 and 9.<br />

5. Always re-check that selections fall within the design<br />

limitations specified (Table 2).<br />

FOULING FACTORS TABLE 3<br />

Refrigerant to Water Heat Exchanger<br />

Fouling Factor m² °C/kW Capacity Factor Power Factor<br />

0.044 1.000 1.000<br />

0.088 0.987 0.995<br />

0.176 0.964 0.985<br />

0.352 0.995 0.962<br />

ALTITUDE FACTORS TABLE 4<br />

Altitude (m) Capacity Factor Power Factor<br />

0 1.000 1.000<br />

600 0.987 1.010<br />

1200 0.973 1.020<br />

1800 0.958 1.029<br />

2400 0.943 1.038<br />

SELECTION GUIDE<br />

YRHP SAMPLE SELECTION<br />

A YRHP Reverse Cycle Heat Pump-Chiller operating at 35°C<br />

ambient, is required to cool liquid from 12°C to 7°C having a<br />

cooling capacity of 440 kW. A heating capacity of 300 kW is<br />

required at design conditions of 0°C ambient and a leaving hot<br />

liquid temperature of 45 °C.<br />

The liquid fouling factor is 0.044 m² °C/kW and the unit will be<br />

operating at sea level.<br />

A model YRHP0495 gives approximately the required capacity<br />

(table 5). No correction factors apply, therefore, after calculating<br />

the flow rate, the conditions will be as follows:<br />

Cooling capacity<br />

= 445 kW<br />

Cooling mode input power = 154 kW<br />

Chilled liquid temperature = 12°C to 7°C (5°C range)<br />

Chilled and hot liquid flow rate = 21.3 l/s<br />

Heating capacity<br />

= 317 kW<br />

Heating mode input power = 133kW<br />

Hot leaving temperature = 45°C<br />

Hot liquid range = 3.6 °C<br />

Return hot liquid temperature = 41.4 °C.<br />

All values are within the operating limits in Table 2.<br />

From figure 3 pressure drop = 32.2 kPa at 21.3 l/s.<br />

REFRIGERANT/WATER <strong>HEAT</strong> FIGURE 3<br />

EXCHANGER PRESSURE DROP GRAPH<br />

Pressure Drop (kPa)<br />

120<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

5 10 15 20 25 30 35 40 45<br />

Flow Rate (l/s)<br />

Model<br />

0395<br />

0465<br />

0495<br />

0565<br />

0635<br />

Pressure Drop Calculation<br />

Pressure Drop [kPa] = 0.1057 x (Flow Rate [l/s] 1.8697 )<br />

Pressure Drop [kPa] = 0.0850 x (Flow Rate [l/s] 1.9362 )<br />

Page K.5<br />

Doc. No. PC142/08.04/GB

OPERATION RECOMMENDATIONS<br />

The following recommendations ensure that the maximum cooling/heating duty of the unit is obtained quickly and that nuisance trips<br />

are prevented:<br />

When starting the unit in the ‘Cooling Mode’ or changing from ‘Heating‘ to ‘Cooling’ the operation of any cooling appliance within the<br />

circuit must be inhibited/bypassed, until the chilled liquid returning to the unit has fallen to 20°C.<br />

When starting the unit in the ‘Heat Pump Mode’ or changing from ‘Cooling’ to ‘Heating‘ the operation of any heating appliance within<br />

the circuit must be inhibited/bypassed, until the warm liquid returning to the unit has risen to 35°C.<br />

TABLE 5<br />

YRHP COOLING CAPACITIES<br />

Ambient Coil Entering Air Temperature oC<br />

LWT 20 25 30 35 38 40<br />

42<br />

Model<br />

o C Cool Power Cool Power Cool Power Cool Power Cool Power Cool Power Cool Power<br />

kW kW kW kW kW kW kW kW kW kW kW kW kW kW<br />

5 451 120 430 125 402 131 371 136 354 138 336 140 318 142<br />

6 469 122 445 126 416 132 385 138 364 140 349 142 334 144<br />

YRHP 7 486 124 460 128 429 134 399 139 374 143 363 144 349 146<br />

0395 8 502 126 478 130 448 136 420 143 386 145 378 150 255 148<br />

10 520 130 495 134 468 139 441 145 406 147 392 149 265 99<br />

12 539 134 514 138 489 142 463 147 427 150 284 100 276 101<br />

5 520 150 496 156 464 163 428 170 408 173 388 175 367 178<br />

6 541 153 513 158 479 165 444 172 420 175 403 177 386 180<br />

YRHP 7 561 155 530 160 495 167 460 174 431 178 419 180 403 182<br />

0465 8 579 158 551 163 517 170 485 178 445 181 436 188 294 122<br />

10 600 162 571 167 540 174 509 181 468 184 452 186 306 124<br />

12 622 167 593 172 564 178 534 184 493 187 327 125 318 126<br />

5 571 146 543 151 514 158 486 165 457 170 434 175 413 177<br />

6 594 147 561 153 528 159 495 167 470 172 452 175 434 179<br />

YRHP 7 617 149 580 155 544 161 504 169 483 174 469 177 454 181<br />

0495 8 650 152 611 158 571 164 520 172 507 177 489 180 304 184<br />

10 680 158 642 164 600 171 557 178 530 183 508 186 328 190<br />

12 712 165 671 171 629 178 594 185 555 189 527 192 500 196<br />

5 629 168 594 176 559 185 507 192 493 195 483 198 473 201<br />

6 653 171 615 180 578 188 526 195 507 198 494 202 483 205<br />

YRHP 7 678 175 635 183 596 191 544 198 522 202 507 206 493 209<br />

0565 8 701 179 658 186 615 194 563 202 538 207 521 210 514 213<br />

10 748 185 699 193 651 201 598 208 568 213 536 215 407 154<br />

12 797 192 742 199 688 202 633 215 599 219 449 155 436 159<br />

5 683 205 646 215 608 225 551 234 536 238 525 241 514 244<br />

6 710 209 668 219 628 229 571 238 551 242 537 246 525 249<br />

YRHP 7 736 214 691 223 648 233 592 242 567 246 551 249 536 253<br />

0635 8 762 218 715 227 668 236 612 246 584 253 566 259 411 194<br />

10 813 226 760 235 708 245 650 254 617 260 462 195 443 198<br />

12 866 234 807 243 748 252 689 262 652 267 489 200 474 205<br />

Performance with capacity set-back due to head pressure control. Set-back will also occur at all<br />

ambient exceeding 42°C.<br />

Fans are factory set to operate at low speed at 10 barg refrigerant discharge pressure. This is generally<br />

when operating at all ambients below 20°C.<br />

Fan operation/staging is controlled by head pressure, at ambients below 35°C all fans may not operate.<br />

The total unit fan power, when fans are operating at full speed, is 8 kW for YRHP 0395 and 0465,<br />

or 10.5 kW for YRHP 0495, 0565 and 0635.<br />

Power kW is compressor power only.<br />

Page K.6<br />

Doc. No. PC142/08.04/GB

YRHP <strong>HEAT</strong>ING CAPACITIES TABLE 6<br />

Ambient Coil Entering Air Temperature o C<br />

-6<br />

-4<br />

-2<br />

0<br />

2<br />

4<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

18<br />

Model YRHP 0395 YRHP 0465 YRHP 0495 YRHP 0565 YRHP 0635<br />

LHLT °C 35 40 45 50 35 40 45 50 35 40 45 50 35 40 45 50 35 40 45 50<br />

Heat kW 216 206 197 259 247 236 266 254 243 301 286 274 360 343 328<br />

Power kW 79 81 83 120 124 127 120 123 126 133 137 140 165 170 174<br />

Heat kW 236 226 217 284 271 260 292 279 267 329 315 301 394 377 361<br />

Power kW 98 101 103 122 125 129 121 125 128 134 138 142 167 172 177<br />

Heat kW 257 247 236 226 308 296 284 271 317 304 292 278 357 343 329 314 428 411 394 376<br />

Power kW 100 102 105 109 124 128 131 135 123 127 130 135 137 141 145 149 170 175 180 186<br />

Heat kW 278 255 257 245 333 321 308 294 343 330 317 303 387 372 357 342 463 446 428 409<br />

Power kW 101 104 107 111 126 130 134 138 126 129 133 137 139 143 148 153 173 178 184 190<br />

Heat kW 304 293 281 271 364 351 338 325 374 361 347 334 423 407 392 377 506 488 469 451<br />

Power kW 103 106 110 114 129 133 137 143 128 132 136 142 142 146 151 157 177 182 188 196<br />

Heat kW 333 320 308 296 400 384 369 356 411 395 380 366 463 446 428 412 555 534 513 494<br />

Power kW 106 109 114 118 133 136 142 147 132 135 141 146 146 150 157 162 182 187 195 202<br />

Heat kW 363 349 337 325 436 418 405 390 448 430 416 401 505 485 469 453 605 581 562 461<br />

Power kW 110 113 118 122 137 141 148 153 136 140 147 152 151 156 163 168 188 194 203 172<br />

Heat kW 397 379 368 356 477 455 441 427 490 468 454 439 553 528 512 421 662 632 613 504<br />

Power kW 114 118 123 128 142 147 154 160 141 146 153 159 157 162 170 146 195 202 212 181<br />

Heat kW 426 410 395 326 511 492 474 392 525 506 487 403 593 571 549 454 710 684 658 544<br />

Power kW 118 123 129 111 147 153 161 138 146 152 160 137 162 169 178 153 202 211 222 190<br />

Heat kW 449 433 418 345 539 519 501 414 554 534 515 426 625 602 581 480 748 721 696 575<br />

Power kW 122 128 135 116 153 160 168 145 152 159 167 144 168 176 186 160 210 220 232 199<br />

Heat kW 472 455 439 362 566 546 527 434 582 561 542 446 656 633 611 504 786 758 732 603<br />

Power kW 127 133 140 121 158 167 176 151 157 166 174 150 175 184 194 167 218 230 242 208<br />

Heat kW 494 477 461 380 593 572 554 456 610 588 569 468 688 664 642 529 824 795 769 633<br />

Power kW 131 139 146 126 164 174 183 158 163 173 182 157 181 192 202 174 226 240 253 217<br />

Heat kW 517 499 483 468 621 599 580 562 638 616 596 577 720 695 672 554 862 832 805 663<br />

Power kW 135 145 152 159 169 181 191 200 168 180 189 198 187 200 210 181 233 250 263 226<br />

Maximum hot leaving liquid temperature of 45°C to prevent excessive discharge temperatures.<br />

468 Unit capacity and power reduced due to high discharge pressure limiting.<br />

At ambient temperatures less than +4°C defrost operation is included in the data and capacities are therefore<br />

an average of normal operation and defrost.<br />

Defrost operates on one refrigerant circuit at a time. The fans of the circuit being defrosted do not operate.<br />

At 0°C ambient dry bulb and 85% relative humidity defrost occurs for a total of 6 minutes in each hour.<br />

High speed fan operation can be inhibited manually, at the unit, or remotely.<br />

Low speed fan operation will reduce the heating capacity by 5% and increase the total kW input by 2%<br />

(due to increases in compressor power minus 4.8 kW reduction in fan power).<br />

SOUND POWER DATA TABLE 7<br />

Model YRHP<br />

0395 0465 0495 0565 0635<br />

Standard Unit Fans at Nominal Low Speed (705 rpm) 96 96 97 97 97<br />

Fans at Nominal High Speed 540 rpm) 98 98 99 99 99<br />

Low Sound Unit Fans at Nominal Low Speed (705 rpm) 88 88 89 89 89<br />

Fans at Nominal High Speed 540 rpm) 92 92 93 93 93<br />

Sound Power has been calculated from sound pressure measurements in free field conditions.<br />

Page K.7<br />

Doc. No. PC142/08.04/GB

TABLE 8<br />

PHYSICAL DATA<br />

YRHP<br />

0395 0465 0495 0565 0635<br />

Number of refrigerant circuits<br />

2 2 2 2 2<br />

Unit refrigerant charge (per circuit = Unit / 2)<br />

kg 110 110 130 130 130<br />

Model<br />

PC632Q PC642S PC642S PC833S PC843T<br />

Quantity 2 2 2 2 2<br />

Compressor<br />

Number of cylinders each 6 6 6 8 8<br />

Speed rpm 1450 1450 1450 1450 1450<br />

Oil capacity each I 13.3 13.3 13.3 13.3 13.3<br />

Unit capacity steps 6 6 6 8 8<br />

Model 790 790 920 920 920<br />

Heat Exchanger<br />

Quantity 1 1 1 1 1<br />

Number of circuits 2 2 2 2 2<br />

Water capacity I 230 230 214 214 214<br />

Ambient Coil<br />

Face area m 2 17.84 17.84 23.78 23.78 23.78<br />

Nuber of tube rows 4 4 4 4 4<br />

Number of fans 6 6 8 8 8<br />

Nominal high speed rpm 705 705 705 705 705<br />

Fans<br />

Total air flow at high speed m 3 /s 37.5 37.5 50 50 50<br />

Nominal low speed rpm 540 540 540 540 540<br />

Total air flow at low speed m 3 /s 30 30 40 40 40<br />

Weight<br />

Shipping kg 5590 5590 6380 6380 6380<br />

Operating kg 5820 5820 6594 6594 6594<br />

Length mm 6021 6021 7240 7240 7240<br />

Dimensions (1) Width mm 2330 2330 2330 2330 2330<br />

Height mm 2489 2489 2489 2489 2489<br />

(1) Length does not include door interlocked disconnect switch/circuit breaker handles.<br />

(1) Width does not include drip trays or header enclosure.<br />

(1) Height does not include anti-vibration mounts.<br />

TABLE 9<br />

ELECTRICAL DATA<br />

Nominal Running Amps Maximum Running Amps<br />

Locked Rotor Conditions (2)<br />

@ 380 V @ 400 V @ 380 V @ 400 V @Min.V (1)<br />

Star for Star/Delta Part Wind<br />

Model<br />

Without Power Factor Correction<br />

Current Amps Current Amps<br />

YRHP With Optional Power Factor Correction fitted<br />

@ 380V @ 400V @ 380V @ 400V<br />

0395<br />

0465<br />

0495<br />

0565<br />

0635<br />

261<br />

325<br />

324<br />

350<br />

438<br />

263<br />

321<br />

322<br />

346<br />

430<br />

333<br />

381<br />

414<br />

434<br />

518<br />

327<br />

373<br />

404<br />

422<br />

502<br />

392<br />

442<br />

491<br />

519<br />

603<br />

229<br />

289<br />

290<br />

316<br />

392<br />

223<br />

281<br />

280<br />

306<br />

378<br />

301<br />

347<br />

378<br />

400<br />

470<br />

291<br />

333<br />

364<br />

384<br />

450<br />

346<br />

394<br />

439<br />

463<br />

535<br />

207<br />

247<br />

247<br />

247<br />

304<br />

218<br />

260<br />

260<br />

260<br />

320<br />

458<br />

549<br />

549<br />

549<br />

689<br />

482<br />

578<br />

578<br />

578<br />

725<br />

Note: (1) Voltage limits (Min. V) on units without Power Factor Correction is 342-440 V<br />

Note: (1) Voltage limits (Min. V) on units with Optional Power Factor Correction is 360-440 V<br />

Figures in table based on the higher of the two modes - Nominal: Cooling, - Maximum: Heating<br />

Note: (2) Locked rotor conditions are per compressor<br />

Page K.8<br />

Doc. No. PC142/08.04/GB

ELECTRICAL CONNECTIONS - POWER SUPPLIES<br />

Standard Single Point Power Supply<br />

One supply to master non-fused disconnect switch (XCSISD)<br />

with internal power distribution to fuses, control supply to non-fused<br />

disconnect switch (QCSD/ESD) derived internally.<br />

1PS<br />

FFF<br />

2PS<br />

CIS<br />

FFF<br />

QCSISD<br />

U V W<br />

QCSD/ESD<br />

PE 3 4<br />

PE<br />

L1 L2 L3<br />

QRESB<br />

3 50 Hz 380/400 V<br />

DESIGNATION<br />

AMB<br />

ARB<br />

CS<br />

CIS<br />

F<br />

PE<br />

PS<br />

QCSD/ESD<br />

QCB<br />

QCSISD<br />

QCSITB<br />

QRESB<br />

QSDF<br />

EMS<br />

DESCRIPTION<br />

MICROPROCESSOR BOARD<br />

RELAY BOARD<br />

CONTROL SECTION<br />

COMMOMN INPUT SECTION<br />

FUSE<br />

PROTECTIVE EARTH<br />

POWER SECTION<br />

CONTROL CIRCUIT SWITCH DISCONNECT<br />

/ EMERGENCY STOP DEVICE<br />

CIRCUIT BREAKER<br />

COMMON SUPPLY INPUT SWITCH DISCONNECT<br />

COMMON SUPPLY INPUT TERMINAL BLOCK<br />

REMOTE EMERGENCY STOP BUTTON<br />

SWITCH DISCONNECT FUSED<br />

EMS INTERFACE CARD (OPTION)<br />

Single Point Power Supply (Option)<br />

One supply to a common terminal block (QCSITB) with<br />

internal power distribution to fused disconnect switches (QSDF)<br />

or circuit breakers (QCB),<br />

control supply to non-fused<br />

disconnect switch (QCSD/ESD) derived internally.<br />

Single Point Power Supply (Option)<br />

One supply to master non-fused disconnect switch (QCSISD)<br />

with internal power distribution to fused disconnect<br />

switches (QSDF) or circuit breaker (QCB),<br />

control supply<br />

to non-fused disconnect switch (QCSD/ESD) derived internally.<br />

1PS<br />

2PS<br />

1PS<br />

2PS<br />

QSDF/QCB<br />

CIS<br />

QSDF/QCB<br />

QSDF/QCB<br />

CIS<br />

QSDF/QCB<br />

U V W<br />

QCSITB<br />

U V W<br />

U V W<br />

QCSISD<br />

U V W<br />

U V W<br />

PE<br />

QCSD/ESD<br />

3 4<br />

U V W<br />

PE<br />

QCSD/ESD<br />

3 4<br />

L1 L2 L3<br />

PE<br />

QRESB<br />

L1 L2 L3<br />

PE<br />

QRESB<br />

3 50 Hz 380/400 V<br />

3 50 Hz 380/400 V<br />

Multi Point Power Supply (Option)<br />

Two supplies to fused disconnect switches (QSDF) or circuit breakers (QCB)<br />

with separate control supply to non-fused disconnect switch (QCSD/ESD).<br />

+5V<br />

GND<br />

RXD<br />

TXD<br />

DSR<br />

DTR<br />

RS232<br />

1PS<br />

CS<br />

AMB ARB<br />

EMS<br />

2PS<br />

QSDF<br />

or<br />

QCB<br />

CIS<br />

3<br />

4<br />

QSDF<br />

or<br />

QCB<br />

PE<br />

U V W<br />

PE<br />

QCSD/ESD<br />

PE<br />

U V W<br />

QRESB<br />

PE<br />

L1 L2<br />

3 50Hz<br />

380/400V<br />

L3<br />

PE<br />

L1 L3<br />

2 50Hz<br />

380/400V<br />

PE<br />

L1 L2 L3<br />

3 50Hz<br />

380/400V<br />

Page K.9<br />

Doc. No. PC142/08.04/GB

ELECTRICAL CONNECTIONS - CONTROL<br />

1PS<br />

CS<br />

AMB<br />

CIS<br />

ARB<br />

EMS<br />

2PS<br />

34<br />

33<br />

36<br />

35<br />

37<br />

38<br />

39<br />

30<br />

31<br />

32<br />

41<br />

40<br />

}<br />

}<br />

}<br />

}<br />

}<br />

}<br />

}<br />

Liquid Pump Start<br />

Unit Run Signal<br />

Open on Alarm<br />

Close on Alarm<br />

Open on Alarm<br />

Close on Alarm<br />

Bivalent Heat Signal<br />

}<br />

}<br />

System<br />

N° 1<br />

System<br />

N° 2<br />

16 13 14 13 17 15 13 11 13 12 10 13<br />

Flow Switch<br />

System 2 Remote Run Interlock<br />

Fan Full Speed Inhibit<br />

System 1 Remote Run Interlock<br />

PWM Remote Temperature Reset or<br />

Remote Unload Second Stage<br />

Remote Mode Selection Closed for Heating<br />

Remote Unload First Stage<br />

SPACE REQUIREMENTS<br />

2.0 m<br />

1.3 m<br />

1.3 m<br />

2.0 m<br />

2.0 m<br />

2.0 m<br />

2.0 m<br />

2.0 m<br />

1.3 m<br />

2.0 m 3.0 m<br />

2.0 m<br />

2.0 m<br />

2.0 m<br />

Page K.10<br />

Doc. No. PC142/08.04/GB

DIMENSIONS<br />

YRHP 0395 and 0465<br />

523<br />

2330<br />

761<br />

1118<br />

CL<br />

VESSEL<br />

VIEW A<br />

SEE DETAIL A<br />

VIEW B<br />

A<br />

2169<br />

2489<br />

B<br />

2694<br />

2224<br />

INLET<br />

SEE DETAIL B<br />

6021<br />

12 HOLES Ø 22 EQUI. SPACED<br />

ON P.C.D. OF 295mm<br />

OUTLET<br />

SEE DETAIL B<br />

Ø 340<br />

Ø 209,1<br />

DETAIL A<br />

POWER SUPPLY CABLE ENTRY<br />

GLAND PLATE 286 X 235<br />

2 x DIN 200/PIN 16<br />

DETAIL B<br />

Page K.11<br />

Doc. No. PC142/08.04/GB

DIMENSIONS (continued)<br />

YRHP 0495, 0565 and 0635<br />

523<br />

2330<br />

761<br />

1118<br />

CL<br />

VESSEL<br />

VIEW A<br />

SEE DETAIL A<br />

VIEW B<br />

A<br />

2169<br />

2489<br />

B<br />

2694<br />

2224<br />

INLET<br />

SEE DETAIL B<br />

7240<br />

12 HOLES Ø 22 EQUI. SPACED<br />

ON P.C.D. OF 295mm<br />

OUTLET<br />

SEE DETAIL B<br />

Ø 340<br />

Ø 209,1<br />

DETAIL A<br />

POWER SUPPLY CABLE ENTRY<br />

GLAND PLATE 286 X 235<br />

2 x DIN 200/PIN 16<br />

DETAIL B<br />

Page K.12<br />

Doc. No. PC142/08.04/GB