3180 3190 3280 3290 for Varian 3000 Sputtering Systems - Ferrotec

3180 3190 3280 3290 for Varian 3000 Sputtering Systems - Ferrotec 3180 3190 3280 3290 for Varian 3000 Sputtering Systems - Ferrotec

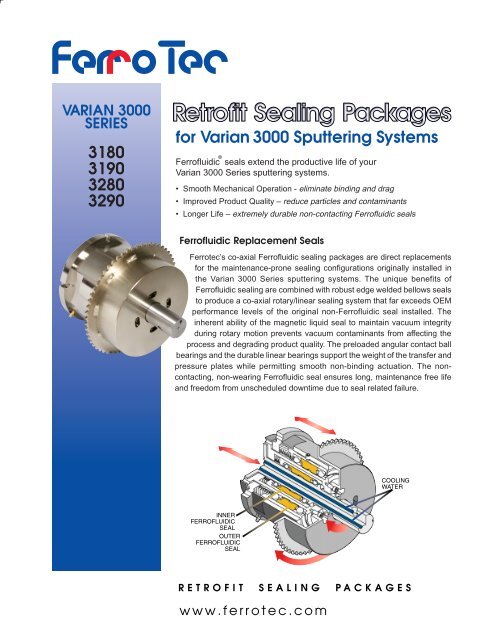

VARIAN 3000 SERIES 3180 3190 3280 3290 for Varian 3000 Sputtering Systems seals extend the productive life of your Varian 3000 Series sputtering systems. Ferrofluidic ® • Smooth Mechanical Operation - eliminate binding and drag • Improved Product Quality – reduce particles and contaminants • Longer Life – extremely durable non-contacting Ferrofluidic seals Ferrofluidic Replacement Seals Ferrotec’s co-axial Ferrofluidic sealing packages are direct replacements for the maintenance-prone sealing configurations originally installed in the Varian 3000 Series sputtering systems. The unique benefits of Ferrofluidic sealing are combined with robust edge welded bellows seals to produce a co-axial rotary/linear sealing system that far exceeds OEM performance levels of the original non-Ferrofluidic seal installed. The inherent ability of the magnetic liquid seal to maintain vacuum integrity during rotary motion prevents vacuum contaminants from affecting the process and degrading product quality. The preloaded angular contact ball bearings and the durable linear bearings support the weight of the transfer and pressure plates while permitting smooth non-binding actuation. The noncontacting, non-wearing Ferrofluidic seal ensures long, maintenance free life and freedom from unscheduled downtime due to seal related failure. RETROFIT SEALING PACKAGES www.ferrotec.com

VARIAN <strong>3000</strong><br />

SERIES<br />

<strong>3180</strong><br />

<strong>3190</strong><br />

<strong>3280</strong><br />

<strong>3290</strong><br />

<strong>for</strong> <strong>Varian</strong> <strong>3000</strong> <strong>Sputtering</strong> <strong>Systems</strong><br />

seals extend the productive life of your<br />

<strong>Varian</strong> <strong>3000</strong> Series sputtering systems.<br />

Ferrofluidic ®<br />

• Smooth Mechanical Operation - eliminate binding and drag<br />

• Improved Product Quality – reduce particles and contaminants<br />

• Longer Life – extremely durable non-contacting Ferrofluidic seals<br />

Ferrofluidic Replacement Seals<br />

<strong>Ferrotec</strong>’s co-axial Ferrofluidic sealing packages are direct replacements<br />

<strong>for</strong> the maintenance-prone sealing configurations originally installed in<br />

the <strong>Varian</strong> <strong>3000</strong> Series sputtering systems. The unique benefits of<br />

Ferrofluidic sealing are combined with robust edge welded bellows seals<br />

to produce a co-axial rotary/linear sealing system that far exceeds OEM<br />

per<strong>for</strong>mance levels of the original non-Ferrofluidic seal installed. The<br />

inherent ability of the magnetic liquid seal to maintain vacuum integrity<br />

during rotary motion prevents vacuum contaminants from affecting the<br />

process and degrading product quality. The preloaded angular contact ball<br />

bearings and the durable linear bearings support the weight of the transfer and<br />

pressure plates while permitting smooth non-binding actuation. The noncontacting,<br />

non-wearing Ferrofluidic seal ensures long, maintenance free life<br />

and freedom from unscheduled downtime due to seal related failure.<br />

RETROFIT SEALING PACKAGES<br />

www.ferrotec.com

USA<br />

Tel: (603) 883 9800<br />

Email: info@ferrotec.com<br />

www.ferrotec.com<br />

® Ferrofluidic is a registered trademark of <strong>Ferrotec</strong> Corporation<br />

Principle of Magnetic Liquid Sealing<br />

Ferrofluidic sealing technology takes advantage of the response of a<br />

magnetic fluid to an applied magnetic field. It uses a magnet with magnetically<br />

permeable north and south pole pieces and a magnetically<br />

permeable shaft to create a permanent magnetic circuit. The magnetic<br />

flux is concentrated in the gap under each pole and when ferrofluid is<br />

applied to this gap it assumes the shape of a liquid o-ring and produces<br />

a hermetic seal.<br />

Ferrofluidic feedthroughs offer many benefits including hermetic sealing,<br />

long life, virtually 100% torque transmission and smooth<br />

operation. They are non-contaminating, highly reliable and can<br />

operate at high speeds.<br />

Repair and Exchange Program<br />

Even Ferrofluidic seals need proper maintenance and repair and you should<br />

always return your Ferrofluidic seals to <strong>Ferrotec</strong> <strong>for</strong> expert repair or exchange<br />

services. Only <strong>Ferrotec</strong> guarantees that your seal will be re-built to the same<br />

specifications and quality as when it was first manufactured and only direct<br />

replacement or the latest improved components are ever used. Most importantly,<br />

only <strong>Ferrotec</strong> manufactures the ferrofluid selected specifically <strong>for</strong> this<br />

magnetic seal design and product application.<br />

With 30 years’ experience in the semiconductor industry, we understand the<br />

importance of maximum uptime and eliminating unscheduled downtime. That<br />

is why we have further developed our exchange program. Rather than simply<br />

repairing your seal, which takes days or even weeks depending on the replacement<br />

part requirements, we keep a stock of exchange seals in house and can<br />

dispatch one the same day or the next working day from receipt of your order.<br />

This means that you maximize uptime and know that your feedthrough is either<br />

new or fully remanufactured and supplied as new. Remanufactured products<br />

are completely disassembled, every part cleaned, all worn and consumable<br />

parts replaced and the fluid replenished. Finally, once re-assembled, they are<br />

required to pass exactly the same stringent dynamic vacuum, leak and QC<br />

tests and inspection as new products. Any feedthrough from our exchange program<br />

is returned to you with the same warranty that it had when new – a full 12<br />

months.<br />

Ordering is simple – just contact your local customer<br />

service representative and ask <strong>for</strong> part number 116533X.<br />

Germany and Mainland Europe<br />

Tel: +49 7022 9270 0<br />

Email: gmbh@ferrotec.com<br />

www.ferrotec.com<br />

UK and Ireland<br />

Tel: +44 1869 363200<br />

Email: info@ferrotec.co.uk<br />

www.ferrotec.com