Drives&Controls; - Capsule-group.com

Drives&Controls; - Capsule-group.com

Drives&Controls; - Capsule-group.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DRIVES & CONTROLS www.drives.co.uk MARCH 2010<br />

Drives&<strong>Controls</strong><br />

THE LEADING MAGAZINE FOR AUTOMATION, POWER TRANSMISSION AND MOTION CONTROL<br />

Drives&<strong>Controls</strong><br />

MARCH 2010<br />

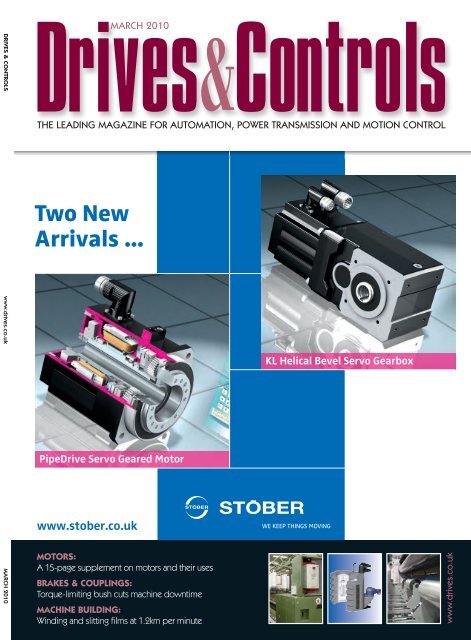

Two New<br />

Arrivals ...<br />

PipeDrive Servo Geared Motor<br />

www.stober.co.uk<br />

MOTORS:<br />

A 15-page supplement on motors and their uses<br />

BRAKES & COUPLINGS:<br />

Torque-limiting bush cuts machine downtime<br />

MACHINE BUILDING:<br />

Winding and slitting films at 1.2km per minute<br />

KL Helical Bevel Servo Gearbox<br />

WE KEEP THINGS MOVING<br />

www.drives.co.uk

PipeDrive Servo Geared Motor<br />

with flange mount hollow bore.<br />

Also available without integrated<br />

gear unit.<br />

KL Ultra Compact Helical<br />

Bevel Geared Servo Motor<br />

WELCOME TO THE FAMILY<br />

Servo Geared Motors<br />

Backlash from 1 Arc Min,<br />

Torques upto 13,500 Nm<br />

with or without Motors<br />

Intelligent Power<br />

Electronics<br />

with STOBERS 5 th Generation<br />

Digital Servo and AC Inverter<br />

ranges we offer inbuilt drive<br />

intelligence delivering flexible<br />

and user friendly motion<br />

platforms<br />

AC Geared Motors<br />

Motor Power 0,12 – 45 kW<br />

Gear Motor Range 4 – 682<br />

www.stober.co.uk<br />

Phone +44 (0)1992 709710<br />

YEARS<br />

WE KEEP THINGS MOVING

DRIVES & CONTROLS<br />

Editor<br />

Tony Sacks, BA, BSc<br />

t/f: 01732 465367<br />

tony@drives.co.uk<br />

Production Manager<br />

Sarah Blake<br />

t: 01233 770781<br />

sarah@dfamedia.co.uk<br />

Customer Liaison<br />

Katherine Cairns<br />

t: 01732 370340<br />

katherine@dfamedia.co.uk<br />

Financial<br />

Clare Jackson<br />

tel: 01732 370340<br />

clare@dfamedia.co.uk<br />

ADVERTISING<br />

Sales Director<br />

Doug Devlin<br />

t: 01922 644766<br />

f: 01922 633730<br />

m: 07803 624471<br />

doug@drives.co.uk<br />

Display Sales Manager<br />

London & South, & Recruitment<br />

Simon Langston<br />

t/f: 01353 863383<br />

m: 07962 402454<br />

simon@dfamedia.co.uk<br />

Germany Victoria Hufmann<br />

Meck Str. 3-5, D-90762 Furth, Germany<br />

t: +49 (0) 911 939 764 42<br />

f: +49 (0) 911 939 764 59<br />

victoria@hufmann.info<br />

Eastern US<br />

Karen C Smith-Kernc<br />

karenkcs@aol.<strong>com</strong><br />

t: +1 717 397 7100<br />

f: +1 717 397 7800<br />

Western US and Canada<br />

Alan A Kernc<br />

alankcs@aol.<strong>com</strong><br />

t: +1 717 397 7100<br />

f: +1 717 397 7800<br />

Publisher<br />

Ian Atkinson<br />

t: 01732 370340<br />

ian@dfamedia.co.uk<br />

Circulation<br />

Andy Kirk<br />

t: 0845 602 7390<br />

f: 0845 604 2327<br />

info@capsule-<strong>group</strong>.<strong>com</strong><br />

HEAD OFFICE<br />

DFA Media Ltd<br />

Cape House, 60A Priory Road,<br />

Tonbridge, Kent TN9 2BL<br />

t: 01732 370340 f: 01732 360034<br />

generalinfo@dfamedia.co.uk<br />

http://www.drives.co.uk<br />

Drives & <strong>Controls</strong> is a controlled circulation publication. If<br />

you live in the UK and want to subscribe phone 0845 602<br />

7390, or fax 0845 604 2327. Alternatively for both UK and<br />

overseas subscriptions please subscribe online at<br />

www.drives.co.uk. If you have any enquiries regarding your<br />

subscription, please use these numbers.<br />

The content of this magazine, website and newsletters do<br />

not necessarily express the views of the Editor or<br />

publishers. The publishers accept no legal responsibility<br />

for loss arising from information in this publication. All<br />

rights reserved. No part of this publication may be<br />

produced or stored in a retrieval system without the<br />

written consent of the publishers<br />

Paid subscriptions<br />

Europe: £90 per annum<br />

Rest of World: £105 per annum<br />

Printing: Garnett Dickinson Print Ltd.<br />

Wath-upon-Dearne, Rotherham, S63 5DL<br />

ISSN 0950 5490<br />

Copyright DFA Media Ltd 2010<br />

UPDATE<br />

3 NEWS<br />

A round-up of the latest business and industry developments from<br />

around the world.<br />

10 TECHNOLOGY<br />

Cutting-edge innovations in motion, power transmission, controls and<br />

related technologies.<br />

IN DEPTH<br />

18 Machine Safety<br />

The delayed demise of EN 954-1 has created confusion in the world of<br />

machine safety. An expert looks at the implications and how the safety market<br />

may be affected.<br />

21 Motors<br />

In a special 15-page<br />

supplement, we report<br />

on the many and varied<br />

ways in which electric<br />

motors are being used,<br />

and offer advice on how<br />

to reduce noise levels in<br />

stepper motor<br />

installations.<br />

36 Brakes and Couplings<br />

How hydraulic brakes are playing a critical role in a novel subsea power<br />

generation technology, and how torque-limiting bushes have cut downtime<br />

on blow-moulding machinery.<br />

41 Machine Building<br />

A look at a machine that rolls and slits thin films at speeds of up to 1.2km per<br />

minute, and a report on how a servo-controlled insertion machine has<br />

speeded up the production of automotive parts.<br />

REGULARS<br />

9 Comment<br />

45 ABB Back to Basics<br />

46 Design Data<br />

48 Multimedia<br />

Software<br />

50 Products<br />

58 Workspace<br />

59 Products & Services<br />

64 Appointments<br />

NEXT ISSUE<br />

The April issue of Drives & <strong>Controls</strong> will<br />

contain our annual supplement on<br />

machine safety, plus reports on water industry applications<br />

and what’s happening in the world of bearings, belts and chains.<br />

IN THIS ISSUE March 2010 Vol 26 No 3<br />

Drives&<strong>Controls</strong><br />

Two New<br />

Arrivals ...<br />

PipeDrive Servo Geared Motor<br />

www.stober.co.uk<br />

MARCH 2010<br />

MOTORS:<br />

A 15-page supplement on motors and their uses<br />

BRAKES & COUPLINGS:<br />

Torque-limiting bush cuts machine downtime<br />

MACHINE BUILDING:<br />

Winding and slitting films at 1.2km per minute<br />

KL Helical Bevel Servo Gearbox<br />

WE KEEP THINGS MOVING<br />

6<br />

THE LEADING MAGAZINE FOR AUTOMATION, POWER TRANSMISSION AND MOTION CONTROL<br />

www.drives.co.uk<br />

www.drives.co.uk<br />

6<br />

12<br />

18<br />

36<br />

42<br />

50<br />

52<br />

53<br />

CONTENTS

automation<br />

See us on<br />

Stand D2336<br />

Drives & <strong>Controls</strong> 2010<br />

NEC, Birmingham<br />

8-10 June 2010<br />

PSS4000 –<br />

Simplify your Automation.<br />

Imagine an automation system that <strong>com</strong>bines the areas of safety, standard,<br />

motion control, visualisation and diagnostics in one system. An ideal system for<br />

all sectors, whether in mechanical engineering or the manufacturing industry.<br />

A system that's easy to use and always considers the requirements for safety<br />

of man and machine from the outset. Imagine that this system is here!<br />

PSS4000. The new automation system from Pilz.<br />

Pilz Automation Technology<br />

Pilz Willow GmbH House, & Co. KG, Medlicott 73760 Ostfildern Close, Corby, Northants NN18 9NF<br />

0711 Tel: 01536 3409-0, 460766, pilz.gmbh@pilz.de, pss4000@pilz.co.uk, www.pilz.de www.pilz.co.uk

Components such as MCCBs are tested in open-air<br />

rigs that do not represent real conditions when<br />

operating as part of an assembly<br />

Controlgear<br />

assemblies ‘could<br />

pose a fire risk’<br />

GAMBICA, the trade body that represents the UK’s control and<br />

automation sector, is warning that a new series of IEC standards<br />

covering low-voltage switchgear and controlgear assemblies will<br />

not eliminate the need to exercise skill and caution when choosing<br />

the ratings of <strong>com</strong>ponents used in assemblies. If care is not taken,<br />

it cautions, the assemblies could overheat, possibly causing injuries<br />

or leading to fires.<br />

Gambica’s Controlgear Group technical <strong>com</strong>mittee has<br />

wel<strong>com</strong>ed the long-awaited publication of IEC 61439 – soon to be<br />

implemented in the UK as BS EN 61439. But it is worried that the<br />

nominal current ratings of circuit-breakers and other <strong>com</strong>ponents –<br />

such as contactors, overload relays and even variable speed drives<br />

– relate to tests carried out in “free air”. For these tests, the<br />

<strong>com</strong>ponent is mounted on an open framework with air all around<br />

it, which helps to dissipate excess heat.<br />

Unfortunately, the <strong>com</strong>mittee says, these test conditions are very<br />

different from those in which the <strong>com</strong>ponent will operate when<br />

installed in a power switchgear or controlgear assembly (PSC). As a<br />

result, substantial derating may be needed to ensure safe<br />

operation and to <strong>com</strong>ply with the temperature rise requirements of<br />

the IEC 61439 standard.<br />

If PSCs operate above their limiting temperatures, they can<br />

suffer progressive insulation breakdown, leading ultimately to short<br />

circuits. Users can suffer burns and the risk of the equipment<br />

catching fire is increased significantly. Furthermore, the equipment<br />

cannot be declared as <strong>com</strong>pliant with IEC 61439.<br />

Gambica’s <strong>com</strong>mittee warns that nominal <strong>com</strong>ponent ratings<br />

should be considered only as a starting point for making<br />

sound engineering decisions relating to PSC design and<br />

construction.<br />

It points out that reputable PSC manufacturers are aware of<br />

these issues and will undertake the testing needed to determine<br />

ratings that are appropriate to the use of particular <strong>com</strong>ponents in<br />

their enclosures. Alternatively, the manufacturers may adopt<br />

another approach permitted by IEC 61439, which relies on<br />

calculations that incorporate generous safety margins.<br />

Gambica stresses that specifiers and purchasers of PSCs must<br />

insist on guarantees from their suppliers that issues relating to<br />

<strong>com</strong>ponent ratings have been addressed.<br />

Gambica has published a free technical guide, called Current<br />

Rating of Low-Voltage Electrical Switchgear Assemblies, which is<br />

available as a download from www.gambica.org.uk<br />

NEWS<br />

Yaskawa chooses Drives & <strong>Controls</strong> show<br />

to re-establish its UK presence<br />

YASKAWA is the latest major supplier to<br />

sign up to exhibit at the Drives & <strong>Controls</strong><br />

Show at the NEC in June. Following the<br />

ending of its joint venture with Omron last<br />

year, the Japanese motion engineering<br />

giant is using the show as part of its<br />

campaign to re-establish its presence in<br />

the UK as an independent supplier.<br />

“We are using the show to re-establish<br />

Yaskawa in the UK with its own brand,”<br />

says Paul Seale, the <strong>com</strong>pany’s key<br />

account manager. “We think that the<br />

Drives & <strong>Controls</strong> Show is great<br />

opportunity to do that.”<br />

Yaskawa will be showing a wide range<br />

of its latest products, including inverters,<br />

servo drives and linear motors. For<br />

example, it will be demonstrating: the<br />

energy savings possible with its IE3-rated<br />

EcoIPM motors; the anti-vibration<br />

performance of its Sigma-5 servo drives;<br />

and the high levels of repeatability<br />

possible with its linear motors. There will<br />

also be new <strong>com</strong>munications and safety<br />

option modules for Sigma-5, as well as a<br />

new IEC control platform.<br />

Yaskawa is one of a stream of <strong>com</strong>panies<br />

that that have booked to attend the<br />

exhibition in recent weeks. The show’s sales<br />

director, Doug Devlin, says that the number<br />

of <strong>com</strong>panies signing up reflects a<br />

widespread optimism about the future.<br />

“There’s confidence in the marketplace,” he<br />

says, pointing out that many exhibitors are<br />

appearing at the show for the first time.<br />

For example, IDEM Safety Switches, set<br />

up in Leigh, near Manchester, in 2003, by<br />

former employees of EJA Guardmaster, will<br />

be showing items from its portfolio of light<br />

curtains, interlocks, safety relays, rope<br />

switches, and other safety-related products.<br />

A highlight on the IDEM stand will be a<br />

range of IP69K stainless-steel interlock<br />

switches suitable for use in food, beverage<br />

and pharmaceutical environments.<br />

The show is also attracting first-time<br />

exhibitors from<br />

elsewhere in Europe,<br />

Seale:<br />

“a great<br />

including the German<br />

opportunity”<br />

<strong>com</strong>puter simulation<br />

specialist, CST, and the<br />

Italian power transmission<br />

manufacturer, Chiaravalli.<br />

Other recent signings include the<br />

Warwickshire sensor specialist, Techni<br />

Measure, the small motors manufacturer,<br />

Dunkermotoren, and the electromechanical<br />

<strong>com</strong>ponents supplier, Stocko<br />

(which will also be exhibiting items from<br />

Wieland Electric’s portfolio).<br />

Harting, which had already signed up to<br />

exhibit at the Drives & <strong>Controls</strong> Show, has<br />

recently taken a second stand at the show<br />

taking its total floor area to 36m 2 .<br />

If you would like to attend the show, you<br />

can register online at www.drives2010.<strong>com</strong>.<br />

If you are interested in exhibiting, please<br />

contact Doug Devlin on 01922 644766 or<br />

email him at doug@drives.co.uk<br />

www.drives.co.uk March 2010 3

NEWS<br />

IN BRIEF<br />

A US report says that Emerson<br />

Electric has been approached by an<br />

unnamed potential buyer of its<br />

Commercial and Industrial Motors<br />

and Appliance Motors & <strong>Controls</strong><br />

operations. The businesses, which<br />

employ around 6,000 people, are part<br />

of Emerson’s Appliance and Tools<br />

division. Last month, Emerson CEO<br />

David Farr said he plans to divest<br />

“non-core” businesses worth $1bn<br />

over the next two to three years, and<br />

$2bn within five years. He does not<br />

regard Appliance and Tools as a<br />

“cornerstone” division and says it will<br />

contract. But Emerson has not decided<br />

whether to sell the motor businesses.<br />

Sales of manufacturing technology in<br />

the US during 2009 totalled $1.77bn<br />

– a drop of 60.4% from 2008. The<br />

figures were <strong>com</strong>piled jointly by the<br />

Association for Manufacturing<br />

Technology and the American<br />

Machine Tool Distributors’<br />

Association. Although sales figures<br />

for December 2009 were 22.9% up<br />

on November, they were 5.7% lower<br />

than in December 2008.<br />

Oracle is the latest IT systems<br />

supplier to join Mitsubishi Electric’s<br />

e-F@ctory initiative which links<br />

control hardware and networks with<br />

IT systems from strategic partners<br />

(already including IBM and<br />

Microsoft). Mitsubishi is the first<br />

hardware vendor with an approved<br />

and tested connection to Oracle’s<br />

Manufacturing Operations Center<br />

software, which gives users real-time<br />

information about plant production.<br />

Birmingham-based Luso Electronics<br />

has been appointed a distributor for<br />

products from Warner Electric, TB<br />

Woods and Boston Gear, which are<br />

all part of the Altra Industrial<br />

Motion Group. Contact Luso on<br />

0121 321 2144 or at<br />

yvonne.g@lusoelectronics.<strong>com</strong><br />

Caersys-based Olsen Engineering<br />

has reported a record turnover for<br />

the past year, which saw it expand<br />

into new premises and employ two<br />

new members of staff.<br />

Rittal has launched a service to<br />

modify its enclosures to UK users’<br />

specifications, adding features such<br />

as holes, cut-outs and engraving. The<br />

service will offer delivery in five<br />

working days.<br />

Since the start of 2010, around 60<br />

<strong>com</strong>panies have booked to exhibit at<br />

the MACH manufacturing<br />

technologies exhibition, which will<br />

run alongside the Drives & <strong>Controls</strong><br />

show at the NEC in June. The new<br />

bookings add 1,200m 2 of stand<br />

space to the show which is now<br />

almost 90% full, according to its<br />

organiser, the Manufacturing<br />

Technologies Association.<br />

Siemens’ drives and automation<br />

divisions get new leaders<br />

SIEMENS HAS announced two<br />

key appointments at the top<br />

of its Industry Automation &<br />

Drives Technologies (IA&DT)<br />

division in the UK. It has also<br />

joined forces with several<br />

industrial <strong>com</strong>panies to form a<br />

“drive train partnership”.<br />

Andrew Peter has been<br />

appointed director of the Drive<br />

Technologies division, while<br />

Brian Halliday is taking on a<br />

similar role in the Industry<br />

Automation division. They are<br />

charged with leading the<br />

future strategic direction and<br />

operational delivery in their<br />

businesses, and will report to<br />

IA&DT managing director,<br />

Juergen Maier.<br />

“The UK IA&DT business is<br />

going from strength to<br />

strength,” says Maier. “The<br />

individual merits of our<br />

industry automation and drive<br />

technologies solutions are<br />

strong and well-proven, but<br />

working more closely together<br />

we can offer an enhanced and<br />

powerful <strong>com</strong>bination of<br />

broad-based expertise,<br />

technical solutions and<br />

innovative thinking to provide<br />

real and tangible answers for<br />

industry.” The IA&DT<br />

operation employs around<br />

2,000 people in the UK.<br />

In a separate move, Siemens<br />

Drives Technology (DT) has<br />

linked up with a number of<br />

industry suppliers and<br />

distributors to form a “drive<br />

train partnership” aimed at<br />

promoting the <strong>com</strong>pany’s<br />

capability and delivering<br />

ABB is buying the Swedish machine safety<br />

specialist, Jokab Safety International, for an<br />

undisclosed sum. Jokab, which was founded<br />

in 1988, employs around 120 people in<br />

Sweden, the US, Canada, Italy, France and the<br />

UK. Its turnover in 2008 was worth around<br />

€25 million.<br />

Jokab will join ABB’s Swedish-based Cewe-<br />

Control business in its Low Voltage Products<br />

division.<br />

“This investment is fully in line with our<br />

strategy to diversify by offering value-creating<br />

Taking charge: Siemens’ new divisional directors,<br />

Brian Holliday and Andrew Peters<br />

products and systems faster.<br />

The <strong>com</strong>panies involved are<br />

Brammer, Hayley, Fraser &<br />

Macdonald, Southern &<br />

Redfern, Dorlec, Anstee Ware,<br />

CPM and MR Engineering.<br />

The products covered by the<br />

partnership include variable<br />

speed drives, induction<br />

motors, geared motors and<br />

gearboxes.<br />

“This new partnership<br />

enables Siemens to deliver its<br />

DT products and services<br />

through a strong national and<br />

regional parts network to its<br />

large and varied customer<br />

base,” says Paul Dudley,<br />

Siemens’ channel manager for<br />

Drives Technology. “Customers<br />

will see an immediate and longterm<br />

benefit from this move.”<br />

Siemens has also improved<br />

its service operation and now<br />

provides a 24-hour, seven-daya-week<br />

call-out service for all<br />

of its motors. It has also<br />

increased and widened its UK<br />

ABB adds Jokab Safety to its LV division<br />

stock levels to meet the<br />

additional demand it expects<br />

the partnership to create. The<br />

<strong>com</strong>pany can now supply Eff1<br />

industrial motors up to 200kW<br />

directly from its Bradford site,<br />

while the new partners will be<br />

able to supply motors up to<br />

90kW from stock, as well as<br />

offering other services such as<br />

installation and motor repair<br />

facilities.<br />

• In Germany, Theo Maas has<br />

succeeded Manfred Egelwisse<br />

as head of Siemens’<br />

mechanical drives business.<br />

Egelwisse was with Flender for<br />

more than 20 years before<br />

Siemens acquired the business<br />

in 2005. He managed the<br />

integration of Flender into<br />

Siemens which will be<br />

<strong>com</strong>pleted with its imminent<br />

legal absorption into Siemens.<br />

Maas has been COO of<br />

Siemens’ global industrial<br />

gears business since 2008.<br />

acquisitions,” says Tom Sjökvist, head of<br />

ABB's Low Voltage division. “We are pleased<br />

to have acquired one of the strongest product<br />

portfolios in machine safety for<br />

manufacturing.<br />

“The acquisition strengthens both ABB and<br />

Jokab Safety’s offering,” he adds. “Together,<br />

we can better meet customers' growing<br />

demands for low-voltage and machine<br />

safety.”<br />

The transaction is scheduled to be<br />

<strong>com</strong>pleted by 10 March.<br />

4 March 2010 www.drives.co.uk

get<br />

all your<br />

devices<br />

on the same page.<br />

Data Station Plus. Protocol conversion. Ethernet gateway. IT-ready data logging. It’s all here.<br />

Red Lion’s Data Station Plus is the single-device solution for protocol conversion. One remarkable device bridges the<br />

<strong>com</strong>munication gap between serial only, fieldbus, and Ethernet devices—unlocking untold information from PLCs,<br />

drives, motion controllers, and more. Red Lion’s free, robust Crimson ® software enables drag-and-drop register<br />

mapping that lets a Siemens ® PLC to talk to an Allen Bradley ® drive in just seconds. The built-in Ethernet gateway<br />

lets you network-enable serial or fieldbus machines onto a <strong>com</strong>mon <strong>com</strong>munications backbone in minutes, and<br />

convert your old PLC’s and drive’s proprietary protocol into a single modern and open standard.<br />

But that’s just the beginning. Use the integrated web server to quickly set up secure,<br />

real-time remote monitoring, operation, diagnostics and data acquisition from any web-enabled PC,<br />

PDA or phone. Easily create a web based HMI depiction of your machine or process with the included<br />

5000+ image graphics package. Receive alarms or event notification remotely via e-mail or SMS text.<br />

Collect performance data, display it, store it for evaluation, or trigger PLC functions—live or remotely.<br />

And seamlessly port logged “IT-ready” trending data to web pages, e-mail, ftp sites or other applications.<br />

The no-risk asset and data management solution.<br />

Data Station Plus is the evolutionary, non-invasive device and software platform that expands and unifies the<br />

capabilities of your legacy processes into a modern, <strong>com</strong>pletely integrated control solution. And it does it for literally<br />

tens-of-thousands less. See what Data Station Plus can mean to your process at www.redlion.net/DSP<br />

Operator Interface Protocol Conversion Signal Conditioning Panel Meters Data Acquisition<br />

Red Lion <strong>Controls</strong> Phone: +31 (0) 33-4723-225 Fax: +31 (0) 33-4893-793<br />

europe@redlion.net Toll Free from UK and France: (00800 733 54667)<br />

Trademarks used herein are property of their respective owners.

NEWS<br />

£2m cash injection will fund<br />

Deritend’s expansion plans<br />

In the early days,<br />

bearings were<br />

assembled by hand<br />

SKF notches up a<br />

century in the UK<br />

SKF IS CELEBRATING its 100th anniversary in the UK this year. The<br />

<strong>com</strong>pany was founded in Sweden in 1907 by Sven Wingqvist, inventor<br />

of the double-row, self-aligning ball bearing. Three years later, in 1910,<br />

it opened a sales office in Lower Regent Street, London.<br />

The following year, SKF inaugurated a production site in Luton.<br />

Initially, the factory employed 150 people and produced around<br />

180 bearings a day. By the end of the First World War, this figure<br />

had risen to 24,000 bearings per month.<br />

In 1936, a new factory was opened in Sundon, a few miles from<br />

the first plant, where production continued until 1977 when all<br />

operations were centralised at Sundon, now SKF’s UK headquarters.<br />

The site makes spherical and toroidal roller bearings for heavy<br />

industrial applications, as well as offering support services.<br />

SKF has several other facilities in the UK including a plant in<br />

Gloucestershire which manufactures high-performance bearings for<br />

the aerospace sector.<br />

Phil Burge, SKF’s UK marketing manager, says that the UK has<br />

always played an important role in SKF. “Even during the recent<br />

economic recession,” he adds, “we have still managed to maintain<br />

a strong level of output, which we anticipate will grow in future<br />

years as the pace of global recovery picks up. As a result, we<br />

anticipate continued investment and development of our UK<br />

manufacturing operations”.<br />

• SKF is setting up a University Technology Centre on tribology in<br />

Imperial College London's Department of Mechanical Engineering. The<br />

initial contract is for five years and will focus on research into modelling<br />

tribological systems with the aim of reducing friction and wear, and<br />

thus extending the service lives and environmental performance of<br />

products such as bearings. SKF’s first University Technology Centre was<br />

established at the University of Cambridge last year.<br />

DERITEND HAS secured a £2m<br />

cash injection to fund the<br />

expansion of its business. The<br />

Wolverhampton-based<br />

industrial maintenance, service<br />

and repair <strong>group</strong> has received<br />

the funding from the Capital<br />

for Enterprise Fund (CfE), a<br />

Government initiative to<br />

attract capital for successful<br />

UK businesses.<br />

The investment will support<br />

Deritend’s growth strategy,<br />

which includes developing its<br />

energy efficiency consultancy<br />

services for industrial<br />

customers.<br />

Deritend Industries’ <strong>group</strong><br />

managing director, Richard<br />

Hale, says the investment will<br />

underpin the <strong>group</strong>’s growth<br />

strategy. “It provides us with<br />

the stability to further develop<br />

our business close on the<br />

heels of development of our<br />

engineering centre of<br />

excellence in West Bromwich,<br />

and site services business in<br />

Ashby,” he explains.<br />

The funding is being<br />

provided by Maven Capital<br />

Partners, which jointly<br />

manages the CfE fund.<br />

Andrew Ferguson, a partner<br />

at Maven, says that “Deritend<br />

Industries has an impressive<br />

record as a national business<br />

introducing innovative valueadded<br />

services to an<br />

impressive blue chip client<br />

base. The senior management<br />

team have exciting plans for<br />

the business and Maven is<br />

delighted to be able to<br />

provide this investment from<br />

the CfE Fund at a critical time<br />

in the <strong>com</strong>pany’s<br />

development.”<br />

Funding will help<br />

Deritend to expand<br />

Eff logo gets a stay of execution<br />

Peter Still, industry<br />

standards manager at<br />

Schneider Electric, has been<br />

appointed chairman of the<br />

Cenelec TC44X <strong>com</strong>mittee<br />

which is responsible for the<br />

electrical safety of<br />

machinery. Still, who has<br />

been on the <strong>com</strong>mittee for<br />

14 years, says a key role will<br />

be to ensure that standards<br />

can be harmonised under<br />

the Machinery Directive.<br />

CEMEP, the body that represents<br />

European motor-makers, has<br />

announced that motor<br />

manufacturers will be allowed to<br />

continue using the Eff motor<br />

efficiency logo until the new<br />

mandatory IEC efficiency classes<br />

<strong>com</strong>e into force from June 2011.<br />

The Eff logo was originally<br />

registered as a trademark by the<br />

French electrical trade body<br />

Gimélec, acting on behalf of<br />

Cemep, on 10 February 2000.<br />

Motor manufacturers wanting to<br />

use the logo had to sign a<br />

licencing agreement which expires<br />

on 10 February, 2010.<br />

Sign of things to <strong>com</strong>e: an ABB motor<br />

nameplate showing the new IE classification<br />

Cemep has now decided to<br />

offer a temporary licence to<br />

registered motor manufacturers,<br />

allowing them to continue using<br />

the Eff logo until 15 June 2011. It<br />

says it has done this because<br />

many OEMs are still running<br />

energy efficiency campaigns<br />

based on Eff1 motors, while more<br />

users are choosing Eff1 motors.<br />

The extended licences will<br />

expire the day before the new IEC<br />

class IE2 efficiency motors (similar<br />

to Eff1) be<strong>com</strong>e the mandatory<br />

minimum for low-voltage threephase<br />

motors sold in Europe.<br />

Despite extending the Eff logo<br />

licences, Cemep re<strong>com</strong>mends that<br />

motor manufacturers should now<br />

be starting to use the new IEC<br />

efficiency classes – as defined in IEC<br />

60034-30, and using test methods<br />

laid out in IEC 60034-2-1 (2007).<br />

6 March 2010 www.drives.co.uk

www.crossmorse.<strong>com</strong><br />

Cross+Morse Shady Lane Great Barr Birmingham B44 9EU England<br />

Tel +44 121 360 0155 Fax +44 121 325 1079 Email sales@crossmorse.<strong>com</strong>

COMMENT<br />

HITTING THE<br />

RIGHT TARGET?<br />

According to a new poll conducted for the Carbon Trust, British<br />

manufacturers are almost as worried by rising energy prices as<br />

they are about the state of the economy. The survey of 700 UK<br />

businesses with annual energy bills between £50,000 and £3m,<br />

revealed that 53% of manufacturers are worried by energy<br />

price hikes – only slightly behind the 57% whose biggest<br />

concern is the economy. Just 19% of the manufacturers<br />

surveyed were worried about environmental legislation, and<br />

16% about a possible change of government.<br />

The poll was conducted to promote a new Carbon Trust<br />

campaign that offers free on-site energy surveys to <strong>com</strong>panies<br />

that spend £50,000–£3m a year on energy. The Trust says that<br />

these surveys will typically identify potential savings of 20–30%<br />

on a <strong>com</strong>pany’s energy costs. It hopes that the campaign,<br />

called Best Advice*, will persuade British <strong>com</strong>panies to stop<br />

wasting more than £3bn worth of energy a year.<br />

Businesses that spend less than £50,000 a year on energy will<br />

have to make do with an online tutorial, including a video,<br />

telling them how to calculate their potential savings and how to<br />

develop a plan to achieve these savings.<br />

But surely, it is the smaller businesses that would benefit most<br />

from free on-site surveys? Although the larger businesses<br />

could probably generate larger savings, they are more likely to<br />

have the internal resources to conduct their own surveys. And<br />

because they have such big energy bills, the large potential<br />

savings give them the incentive to investigate where they could<br />

make savings.<br />

Smaller organisations are less likely to have the resources or<br />

the time to organise their own energy surveys. And although<br />

the amount that each <strong>com</strong>pany could save is probably less, on<br />

average, than the larger organisations, there are many more<br />

small <strong>com</strong>panies in the UK and their <strong>com</strong>bined savings could<br />

outweigh those of the larger businesses.<br />

The Carbon Trust reports that 13% of the manufacturers it<br />

surveyed “admitted that no one within their organisation was<br />

responsible for managing their energy consumption and<br />

controlling costs”. But this suggests that 87% of <strong>com</strong>panies do<br />

have someone in this role. This is probably a much higher<br />

figure than even a few years ago and shows that the vast<br />

majority of organisations now realise that managing energy is a<br />

vital aspect of their business.<br />

In the past, the Carbon Trust has been criticised for placing too<br />

much emphasis on publicity-grabbing initiatives such as its<br />

campaigns to cut the energy wasted by domestic appliances<br />

on standby. More recently, however, it has been more visibly<br />

active in the industrial sector with high-profile initiatives such<br />

its Big Business Refit scheme that gives interest-free loans to<br />

replace inefficient, old equipment with newer technologies<br />

such as variable speed drives and high-efficiency motors.<br />

The Trust says that, since 2001, its initiatives have delivered<br />

energy savings worth more than £1.4bn, and it hopes to<br />

achieve a further £1bn of savings in the <strong>com</strong>ing three years.<br />

Let’s hope that industrial technologies play a significant role in<br />

generating these savings.<br />

Tony Sacks<br />

Editor<br />

* For more details, call 01865 885788 or visit<br />

www.thebestadvice.co.uk

TECHNOLOGY<br />

Powerful piezo actuator<br />

‘could replace motors’<br />

PARKER HANNIFIN has developed a<br />

piezoelectric-based actuator which, it<br />

claims, produces 50–100 times the<br />

deflection and force of traditional piezo<br />

stack devices. One possible application<br />

for the Advanced Technology Actuator<br />

would as a simple, direct-drive<br />

replacement for less efficient electric<br />

motors.<br />

Parker says the technology will open<br />

up applications that are unsuitable for<br />

conventional piezo actuators, as well as<br />

improving the performance of existing<br />

applications.<br />

The actuator consists of a proprietary<br />

temperature-<strong>com</strong>pensating frame, an<br />

amplifier body, and a piezo ceramic<br />

stack. It is said to be particularly<br />

suitable for serial bus and batterypowered<br />

applications.<br />

Rich McDonnell, Parker’s product<br />

manager, says that initial feedback on<br />

THE SWITCHED reluctance drives specialist SR<br />

Drives is part of a consortium which has won<br />

a £15m award from the Technology Strategy<br />

Board to help develop a lightweight, gasturbine-based<br />

range extender for future<br />

electric vehicles.<br />

The consortium, which also includes<br />

Jaguar Land Rover and Bladon Jets, aims to<br />

produce the world’s first <strong>com</strong>mercially viable,<br />

« Parker Hannifin’s piezoelectric<br />

actuator delivers more force<br />

and moves further<br />

the device from designers “has exceeded our<br />

expectations. We're looking forward to choosing<br />

several beta applications from among many<br />

interested parties who wish to have early access to<br />

the technology for use in their equipment and<br />

devices.”<br />

www.parker.<strong>com</strong>/pneumatics<br />

Turbine-based EV generator will use SR technology<br />

and environmentally friendly, gas turbine<br />

generator specifically for automotive<br />

applications.<br />

The system will couple an axial-flow gas<br />

turbine engine to a high-speed generator,<br />

based on SR Drives’ proprietary switchedreluctance<br />

technology.<br />

Harrogate-based SR Drives is owned by<br />

Emerson Electric.<br />

Automation<br />

giants back<br />

integration<br />

scheme<br />

A GROUP of leading automation<br />

organisations and suppliers has decided<br />

to expand the scope of the EDDL Cooperation<br />

Team to accelerate the<br />

deployment of FDI (Field Device<br />

Integration) technology. A new team<br />

called FDI Co-operation will take over<br />

the work of harmonising the EDDL and<br />

FDT/DTM technologies, which began in<br />

2007 and is now expected to result in a<br />

final FDI specification by mid-2010.<br />

The organisations backing the move<br />

include the FDT Group, the Profibus<br />

Users Association, the Fieldbus<br />

Foundation and the OPC Foundation.<br />

The <strong>com</strong>panies involved include ABB,<br />

Emerson, Honeywell, Invensys, Siemens<br />

and Yokogawa.<br />

The enlarged team, which will also<br />

develop design and test tools, aims to<br />

produce a system that will allow<br />

devices to be integrated across all host<br />

systems, devices and protocols that<br />

users might need.<br />

Anton Huber, chief executive of<br />

Siemens’ automation division, sees the<br />

development as “a milestone in<br />

achieving an industry-wide<br />

harmonisation of device integration as,<br />

for the first time, a significant number<br />

of vendors have cone together to agree<br />

on such a standard”. He adds that<br />

Siemens will support the FDI technology<br />

in its products as soon as it is available.

Historian module keeps<br />

an eye on machine<br />

performance<br />

ROCKWELL<br />

AUTOMATION has<br />

announced a<br />

machine-level data<br />

historian that helps<br />

manufacturers to<br />

reduce the risk of<br />

machine downtime<br />

and achieve<br />

continuous process<br />

improvements. The<br />

FactoryTalk Historian<br />

ME application is a<br />

solid-state module,<br />

hardened for onmachine<br />

data<br />

collection, which<br />

has no moving parts<br />

and a low risk of<br />

data loss due to<br />

network or other system interruptions.<br />

The module fits into an Allen-Bradley<br />

ControlLogix backplane. Its software<br />

detects controllers automatically and<br />

configures all relevant tags.<br />

Communicating via the backplane<br />

makes data collection quicker and<br />

provides more detailed information<br />

than is possible with traditional,<br />

network-connected plant historians.<br />

The application is part of a<br />

distributed, tiered architecture that<br />

allows employees in different locations<br />

and at different levels to view and<br />

« Rockwell’s Historian ME module can<br />

be used to produce trend data<br />

depicting factory operations<br />

analyse historical data<br />

tailored to their roles.<br />

Operators, for<br />

example, can view<br />

data from the machine<br />

they are using, while<br />

plant-level supervisors<br />

can view individual<br />

machines or <strong>com</strong>plete<br />

lines to build real-time<br />

<strong>com</strong>parisons.<br />

Senior management<br />

can use the technology<br />

to develop executive<br />

dashboards that<br />

<strong>com</strong>pare key<br />

performance indicators<br />

of production activity<br />

across several<br />

locations.<br />

The software “improves<br />

manufacturing intelligence by<br />

providing a new level of visibility into<br />

production operations,” says product<br />

manager, Jan Pingel. “By integrating<br />

data from a machine-level historian<br />

with data from a plant-level historian,<br />

operations can now locate and<br />

correct sources of inefficiencies more<br />

quickly to improve manufacturing<br />

consistency, energy use and first-pass<br />

quality.”<br />

http://discover.rockwellautomation.<strong>com</strong><br />

/historian<br />

Displacement sensors<br />

promise long ranges<br />

at a low cost<br />

THE GERMAN sensor specialist Micro-Epsilon has<br />

<strong>com</strong>e up with a low-cost technology for<br />

measuring displacement which, it claims, offers<br />

high sensitivity and long operating ranges.<br />

Unlike Hall Effect sensors, the patented<br />

Magnetic Displacement Sensor (MDS) is based on<br />

a linear relationship between the position of a<br />

target magnet and the output signal. It uses<br />

printed coils, thus avoiding the need for<br />

semiconductor manufacturing processes and<br />

making customer-specific adaptations easier.<br />

The MDS uses much smaller magnets than Hall<br />

sensors, cutting costs and simplifying installation.<br />

It also supports considerably longer measuring<br />

distances – currently up to 60mm.<br />

Because the sensors are extremely sensitive,<br />

simple, low-cost evaluation circuits can be used.<br />

The output can be in the form of a PWM signal<br />

which can be read by a microcontroller. Using an<br />

eddy current sensor as the technological core,<br />

fast, high-resolution versions are possible.<br />

Micro-Epsilon developed the technology for use<br />

in appliances such as washing machines where it<br />

allows loads to be measured with a high<br />

resolution, while monitoring spin cycles with high<br />

dynamics. It could be applied anywhere needing<br />

long measuring ranges and high resolution.<br />

Micro-Epsilon’s patented sensing technology allows<br />

long-distance measurements at a low cost<br />

TECHNOLOGY

TECHNOLOGY<br />

Monitor your<br />

PLCs on a<br />

BlackBerry<br />

USERS OF Mitsubishi FX PLCs<br />

can now monitor and adjust<br />

their installations remotely from<br />

a BlackBerry mobile phone. A<br />

German <strong>com</strong>pany called Schad,<br />

which specialises in Blackberrybased<br />

automation software,<br />

has joined Mitsubishi’s e-<br />

F@ctory Alliance scheme, and is<br />

offering support for the PLCs<br />

via its Extend 7000 mobile<br />

SCADA system.<br />

The software allows<br />

BlackBerry users to change<br />

production schedules remotely,<br />

and to diagnose and make<br />

adjustments to their control<br />

systems, based on alarms<br />

triggered by preset parameters<br />

or fault conditions.<br />

The main innovation in the<br />

Extend 7000 system is crossplatform<br />

integration. A SCADA<br />

layer hosted on a local server<br />

connects to factory PLCs and<br />

provides a secure connection<br />

via the BlackBerry enterprise<br />

server to the Internet and out<br />

to a mobile network via a<br />

stable, secure 256-bit encrypted<br />

signal.<br />

This allows real-time<br />

interaction with PLC functions<br />

using simple <strong>com</strong>mands. The<br />

system has already proved<br />

popular with large production<br />

sites and businesses such as<br />

utilities where engineering and<br />

maintenance teams need to<br />

monitor and maintain remote<br />

sites such as pumping stations.<br />

Schad aims to be<strong>com</strong>e a<br />

global leader in mobile systems<br />

for operating and monitoring<br />

machine and plant controls.<br />

“We hope the Extend 7000<br />

solution will be established as<br />

the standard for mobile access<br />

« Schad’s technology allows PLCs to be monitored and adjusted<br />

remotely via secure BlackBerry connections<br />

to Mitsubishi PLCs,” says<br />

Christian Schad, the <strong>com</strong>pany’s<br />

MD and the originator of its<br />

technology. “We have been<br />

able to convince users<br />

[including Volkswagen and<br />

Cologne-Bonn Airport] that the<br />

system really does save time for<br />

solving problems and improving<br />

plant uptime, while freeing<br />

operators to move around and<br />

take care of other management<br />

issues, without being shackled<br />

to a PC and a hardwired<br />

Ethernet link.”<br />

The Schad system currently<br />

works with any Mitsubishi FX<br />

PLC connected to a network<br />

with Internet access. There are<br />

plans to extend the support to<br />

other Mitsubishi products such<br />

as its System Q, iQ Automation<br />

Platform, inverters and servo<br />

drives.<br />

Chris Hazlewood, the<br />

originator of Mitsubishi’s e-<br />

F@ctory Alliance, believes that<br />

the Schad system “offers our<br />

end-users the opportunity to<br />

make better use of personnel<br />

and make improvements to<br />

<strong>com</strong>munications and<br />

productivity.<br />

“We are also looking for<br />

future potential and believe this<br />

platform has the potential to be<br />

extended to include the<br />

majority of Mitsubishi<br />

automation products,” he adds.<br />

www.schad-automation.de<br />

www.mitsubishiautomation.co.uk<br />

Cranfield<br />

technology<br />

will help to<br />

manufacture<br />

micro-scale<br />

devices<br />

≈ These piezoelectric micro-valve <strong>com</strong>ponents on a 50mm<br />

wafer, can change shape when an electrical signal is applied.<br />

They are just 100µ thick – twice as thick as a human hair.<br />

RESEARCHERS AT Cranfield University have<br />

developed a technology that could slash the<br />

cost of manufacturing <strong>com</strong>plex micromechanical<br />

and micro-optical devices. The<br />

project, part of a €3.2m EU-supported research<br />

consortium called Q2M (Quality to Micro), has<br />

examined some of the key issues with existing<br />

micro-fabrication processes, which are limited<br />

by the conflicting requirements of different<br />

materials.<br />

“Standard micro-fabrication techniques are<br />

often in<strong>com</strong>patible with high-quality transducer<br />

materials, such as shape memory alloys and<br />

functional ceramics,” explains Stephen Wilson,<br />

a senior research fellow in microsystems<br />

technology at Cranfield. “This is one of the<br />

major bottlenecks for the development of novel<br />

micro-scale systems.<br />

“The new technology enables multi-material<br />

devices to be made that do not conform to the<br />

usual silicon MEMS stereotype,” he continues.<br />

“It will bring down the cost of genuinely new<br />

systems considerably.”<br />

The new methods could be used to<br />

manufacture items ranging in size from a few<br />

hundred nanometres to a few millimetres.<br />

Potential applications include: biomedical<br />

devices that can diagnose disease and<br />

administer drugs electronically; electronic noses<br />

to sniff out explosives or dangerous chemicals;<br />

and environmental control systems for personal<br />

healthcare. The technology could also open up<br />

new applications in <strong>com</strong>munications because it<br />

allows previously in<strong>com</strong>patible non-silicon<br />

materials to be incorporated in radio-frequency<br />

circuits.<br />

The three-year Q2M project involved 12<br />

academic partners and industrial <strong>com</strong>panies, as<br />

well as several end-users to ensure the work<br />

addressed real industrial needs.<br />

The Drives and <strong>Controls</strong><br />

Exhibition & Conference 2010<br />

8-10 June 2010 - NEC - Birmingham<br />

Contact us now for your FREE exhibition pack and be<strong>com</strong>e part of the<br />

UK’s largest and most successful manufacturing event<br />

www.drives2010.<strong>com</strong><br />

CONTACT:<br />

Doug Devlin on<br />

E: doug@drives.co.uk<br />

+44(0)1922 644766 M: 07803 624471<br />

Simon Langston on<br />

E: simon@dfamedia.co.uk<br />

+44(0)1353 863383 M: 07962 402454

TECHNOLOGY<br />

Wavepower generator relies on<br />

low-friction bearing materials<br />

NOVEL BEARING and seal technologies are<br />

playing a vital role in a new UK-developed<br />

wave energy generator due to start testing<br />

off Orkney later this year.<br />

Engineers at Edinburgh-based Pelamis<br />

Wave Power have been developing wave<br />

power devices for more than a decade and<br />

have over<strong>com</strong>e the challenge of continuous<br />

operation in the punishing marine<br />

environment. Building on their experience<br />

of producing the world’s first offshore<br />

wave energy converter, the team has now<br />

developed a second-generation design<br />

which is more efficient and cost-effective.<br />

Crucial to the new design are the bearings<br />

and seals. The P2 generator consists of a<br />

series of floating, linked tubes with four<br />

hydraulic rams at each main joint pivoting<br />

on precision bearings to drive hydraulic<br />

motors coupled to electric generators.<br />

“Our biggest challenge has always been<br />

how we manage the loads and motions<br />

from such an active and constantly variable<br />

environment, whilst at the same time<br />

extracting as much power as possible,”<br />

explains Mike Woods, Pelamis’ senior<br />

engineer and bearings <strong>group</strong> leader. “The<br />

working forces generated across each joint<br />

can be several hundred tonnes, which can<br />

present huge problems for the bearings as<br />

they have to take up the reactive forces<br />

<strong>com</strong>ing back through the joints.”<br />

Pelamis’ first wave energy converter (P1)<br />

was a simpler design with separate hinged<br />

joints. Although this arrangement allowed<br />

useful working space between the axes, it<br />

had to carry high transferred loads and was<br />

unable to manage the <strong>com</strong>bined motions<br />

needed for the P2 configuration. Also, the<br />

bearings themselves were relatively high<br />

friction, affecting efficiency.<br />

“Our engineering team had been trying<br />

to work out a way of over<strong>com</strong>ing this<br />

problem and eventually came up with the<br />

idea of bringing the axes, or joints,<br />

together,” Woods continues. “However,<br />

this meant a <strong>com</strong>pletely new bearing<br />

solution which was able to manage<br />

<strong>com</strong>bined angles in a single package.”<br />

Pelamis turned to Schaeffler for help and<br />

support. Key to the new joint is a low-friction<br />

material developed by Schaeffler. The<br />

modified PTFE fabric liner effectively<br />

eliminates the “stick-slip” effect, allowing<br />

the machine to perform better than standard<br />

bearing materials would have done.<br />

The Pelamis P2 wave power device, which builds on the experience<br />

gained operating the first-generation P1 system (shown above),<br />

relies on novel bearings for its connection structures (below)<br />

“Now that we have been able to put all<br />

the bearings in one place, we have taken a<br />

major technological step forward,” says<br />

Woods. “As well as being a much more<br />

efficient bearing mechanism, the new<br />

design is a self-contained, modular unit. It’s<br />

a bit like being able to take an engine out<br />

of a car in one go; it allows us to improve<br />

our inspection procedures and reduce our<br />

exposure to technological risk.”<br />

The first P2 wave generator, ordered by<br />

Eon, is now nearing <strong>com</strong>pletion. Its first<br />

190-tonne tubes were launched in Leith<br />

Docks last month. These will be linked to<br />

form a 180m-long wave power station<br />

capable of generating 750kW which is due<br />

to be deployed at the European Marine<br />

Energy Centre, Orkney, later this year.<br />

Last month, Pelamis and Eon were<br />

awarded £4.8m of funding from the UK<br />

government’s Marine Renewable Proving<br />

Fund, which will allow them to increase the<br />

scope and pace of their trials.<br />

Pelamis has also formed a joint venture<br />

with the Swedish utility Vattenfall with the<br />

aim of installing an array of up to 26 P2<br />

generators off the coast of Shetland, to<br />

generate up to 20MW.<br />

Solid-state memory drives set to oust hard disks from industrial PCs<br />

Solid-state memory drives<br />

(SSDs) are likely to replace<br />

traditional hard disk drives<br />

(HDDs) in industrial PCs<br />

within a decade, a new<br />

forecast suggests. The<br />

market analyst IMS Research<br />

reports that the use of SSDs<br />

in IPCs has already increased<br />

substantially in the past two<br />

years.<br />

“SSDs now offer similar<br />

levels of storage capacity to a<br />

HDD, but without the<br />

rotating parts that can<br />

be<strong>com</strong>e vulnerable in<br />

environments where vibration<br />

is <strong>com</strong>mon,” points out IMS<br />

senior analyst, Mark Watson.<br />

“The higher level of reliability<br />

offered by SSDs has made<br />

them a popular choice for<br />

critical applications.<br />

“SSDs are currently more<br />

expensive than HDDs,” he<br />

adds, “but, whereas HDDs<br />

have little room for prices to<br />

fall further, SSD prices have<br />

decreased significantly over<br />

the past two years. A 16GB<br />

SSD would have cost an IPC<br />

manufacturer approximately<br />

$200 in 2007. In 2009, the<br />

same <strong>com</strong>ponent would have<br />

cost closer to $50.”<br />

www.imsresearch.<strong>com</strong><br />

AIR-TECH 2010<br />

8-10 June 2010 - NEC - Birmingham<br />

Brochures available NOW!<br />

www.airtech2010.<strong>com</strong><br />

In association with<br />

CONTACT:<br />

Ryan Fuller<br />

E: ryan@dfamedia.co.uk<br />

+44 (0)1732 370344<br />

M: 07720 275097<br />

Roberto Tondina<br />

E: roberto@dfamedia.co.uk<br />

+44 (0)1732 370348<br />

M: 07886 119897

Market leading<br />

Temperature and Position sensors!<br />

Infra Red non-contact<br />

Temperature sensors & imagers<br />

Extensive 56 page catalogue describes sensors for almost all<br />

applications and environments: -40 to +3300 °C; upto 250 °C<br />

ambient without cooling; built in laser sighting;<br />

from 1µm to 14 µm; wavelengths for specific materials,<br />

including Metals, Glass, Plastics.<br />

New: Inline fixed mount and handheld thermal imagers.<br />

Market leading specifications at very <strong>com</strong>petitive prices<br />

LVDT, Inductive, Eddy current<br />

and Draw wire sensors<br />

Large range of over 250 different models available from stock!<br />

No matter what your process – we have a sensor<br />

to suit your requirement.<br />

Measurement ranges from 0.5mm to 60m!<br />

Extremely robust and stable in the<br />

most demanding applications.<br />

Call now to request your selection guide<br />

Laser sensors<br />

Using either Laser Triangulation or Time of Flight sensors<br />

enable measurements from single microns to 3Km!<br />

Compact and robust sensors with integrated controllers.<br />

Low cost OEM and entry level models<br />

to highest precision in class.<br />

Select analogue, serial, BUS interfaces.<br />

Largest selection of sensors worldwide.<br />

Visit us: Maintec<br />

2nd - 4th March 2010,<br />

NEC. Stand C3<br />

Call to speak to a sensor expert +44 (0) 151 355 6070<br />

or visit<br />

or visit www.micro-epsilon.co.uk

TECHNOLOGY<br />

IN BRIEF<br />

NSK has developed a new<br />

stainless steel for use in highhumidity,<br />

chemical or hygienic<br />

environments where corrosion<br />

can shorten the lives of rolling<br />

bearings. The ES1 steel is said<br />

to provide better corrosion<br />

resistance and rolling contact<br />

fatigue life than the AISI 440C<br />

steel usually employed in wet<br />

and aggressive environments.<br />

This helps to cut maintenance,<br />

downtime and replacement<br />

bearing costs.<br />

The German chip-maker iC-<br />

Haus has designed a highresolution<br />

sine-to-digital<br />

converter chip with 13-bit realtime<br />

interpolation that supports<br />

the BiSS C protocol which<br />

enables bidirectional data<br />

exchange at the same time as<br />

the cyclic output of<br />

measurement data. The iC-NQC<br />

chip can be used for<br />

incremental or absolute<br />

encoders as well as for<br />

magnetic linear position<br />

measuring systems and optical<br />

linear scales. It offers binary<br />

resolutions from 8–8,192 angle<br />

steps, or decimal resolutions<br />

from 25–25,000 angle steps.<br />

The US motion control specialist<br />

Magnetek has received an<br />

initial production order worth<br />

almost $1.5m for a new liquidcooled<br />

inverter for wind<br />

turbines. The inverters, which<br />

transform the DC output of the<br />

turbines’ generators into utilitygrade<br />

AC power, are aimed at<br />

sealed-structure applications<br />

such as near-shore wind<br />

turbines, or those operating in<br />

corrosive environments or in<br />

high ambient temperatures.<br />

National Instruments is<br />

collaborating with Denso<br />

Robotics to integrate NI<br />

measurement and vision<br />

technology into Denso’s robotic<br />

arms. NI partner ImagingLab<br />

has produced a library of<br />

graphical functions that<br />

<strong>com</strong>municate with Denso’s<br />

controllers to control robotic<br />

arms via NI’s LabView software.<br />

The library allows one software<br />

environment to control and<br />

integrate every aspect of a<br />

machine, from part-handling to<br />

measurements and vision.<br />

Mobile link delivers field<br />

service invoices ‘in hours’<br />

A DUBLIN-based <strong>com</strong>pany which<br />

specialises in vehicle tracking<br />

systems, has branched into field<br />

service management with a<br />

system that automates service<br />

call management, job dispatch,<br />

signature capture and invoicing.<br />

FleetMatics’ Field Service<br />

Manager system allows service<br />

departments to <strong>com</strong>municate<br />

with their field engineers via<br />

smartphones, PDAs or other<br />

mobile devices.<br />

The <strong>com</strong>pany says the<br />

software can boost productivity,<br />

cut overheads, ensure faster<br />

receipt of payments, and make it<br />

easier for field engineers to<br />

<strong>com</strong>plete forms. According to<br />

sales director Derek Bryan, the<br />

system can reduce invoicing<br />

times from an average of six<br />

weeks, “to a matter of hours”.<br />

The software runs on any<br />

handheld device using the<br />

Windows Mobile 6 or Google<br />

Android operating systems. It<br />

connects to the service<br />

department’s back-office system<br />

via the GPRS network, and<br />

appears as a dashboard accessed<br />

via the Web.<br />

From the dashboard, jobs can<br />

be logged and issued to the<br />

engineers. After finishing a job,<br />

the engineer <strong>com</strong>pletes the<br />

Metal-free air motor can<br />

be used in MRI scanners<br />

THE GERMAN air motor specialist Deprag has<br />

developed a motor with no metallic<br />

<strong>com</strong>ponents for use in MRI (magnetic<br />

resonance imaging) scanners where the<br />

presence of metal can interfere with the<br />

machine’s operation.<br />

In response to a request, the <strong>com</strong>pany’s<br />

development department has <strong>com</strong>e up with<br />

an air vane motor made entirely from ceramic<br />

and synthetic materials. The 40mm-diameter,<br />

78mm-long pneumatically-driven prototype<br />

achieves an output of 150W at 14,000 rpm.<br />

« FleetMatics’ software can generate a variety of reports on field service operations<br />

relevant forms on their mobile<br />

device and sends the<br />

information back to the service<br />

department for immediate<br />

invoicing.<br />

“Our product is unique,”<br />

Bryan asserts, “as it allows<br />

engineers to get on with the<br />

job and <strong>com</strong>plete the necessary<br />

forms regardless of whether<br />

they are online or not, unlike<br />

most field service management<br />

software solutions, which offer<br />

Web-based forms. This is<br />

critical when service engineers<br />

are in basements or lift shafts,<br />

or where network coverage is<br />

patchy – it means job<br />

processing does not stop even<br />

when the mobile network is<br />

down.” Once the device is back<br />

online, the <strong>com</strong>pleted forms<br />

are sent to the service<br />

department.<br />

Field Service Manager is<br />

based on the “cloud<br />

<strong>com</strong>puting” concept, with<br />

customers paying a monthly<br />

subscription of around £70 per<br />

engineer per month. It is<br />

suitable for businesses of all<br />

sizes. Free trials are available.<br />

The industry analyst, Gartner,<br />

predicts that the proportion of<br />

technicians with wireless access<br />

to field service management<br />

systems will increase from 12%<br />

to 40% over the <strong>com</strong>ing two<br />

years.<br />

www.fieldservicemanager.<strong>com</strong><br />

Yaskawa’s North<br />

American operation<br />

has developed a free<br />

application that runs<br />

on Apple’s iPhone or<br />

iPod Touch handheld<br />

devices to estimate<br />

the energy savings<br />

that are possible<br />

when using variable<br />

speed drives to<br />

control pumps or<br />

fans. The $avings<br />

Predictor calculates<br />

the savings in five<br />

steps. It is available<br />

from Apple’s iTunes<br />

app store.<br />

IFPEX 2010<br />

8-10 June 2010 - NEC - Birmingham<br />

Brochures available NOW!<br />

www.ifpex2010.<strong>com</strong><br />

In association with<br />

CONTACT:<br />

Ryan Fuller<br />

E: ryan@dfamedia.co.uk<br />

+44 (0)1732 370344<br />

M: 07720 275097<br />

Alistair McKay<br />

E: alistair@dfamedia.co.uk<br />

+44 (0)1732 370347<br />

M: 07799 333961

CORPORATE PROFILE<br />

FACT FILE<br />

Company Focus:<br />

From Pioneer to Technical Leader<br />

We keep things moving<br />

For more than seven decades the name<br />

STOBER has stood for innovation in<br />

drive technology, particularly for system<br />

solutions. To be right out in front with<br />

technological leadership, multifaceted<br />

excellence is required in the total drive<br />

solution.<br />

Along with the development of new<br />

products, this statement refers also to<br />

the ability to be able to exactly tailor<br />

solutions to customers’ requirements.<br />

STOBER supplies perfectly matched<br />

<strong>com</strong>ponents of digital servo drives and<br />

frequency inverters, gear units, motors<br />

and user software. These products are<br />

available as <strong>com</strong>plete assemblies or<br />

separate <strong>com</strong>ponents.<br />

We work to provide best in class<br />

products and solutions with full backup<br />

of support, training and a worldwide<br />

service network.<br />

Our thinking and activities are always<br />

focused on people – on the one hand<br />

the customer with very individual<br />

requirements and on the other the<br />

employee who requires the <strong>com</strong>petence<br />

and technical knowledge.<br />

This reflects another important corporate<br />

strength of STOBER - a value system<br />

which is consciously nurtured and passed<br />

on from generation to generation.<br />

This efficient <strong>com</strong>pany structure with its<br />

close customer relationship and the<br />

innovative products make it possible for<br />

STOBER, as a family business with<br />

approx. 620 employees, to be successful<br />

in the global gearbox and drives market.<br />

Energetically preserve traditions, actively<br />

shape the future: Nothing is as constant at<br />

STOBER as change – and that always with the<br />

promise of using innovations to give<br />

customers an advantage in their highly<br />

<strong>com</strong>petitive markets.<br />

As a system supplier for digital drive<br />

technology, STOBER keeps setting new<br />

standards for integrated hardware and<br />

software products in this market.<br />

The decision to concentrate on three core<br />

target sectors has been made consciously<br />

to be able to operate in the market as a<br />

specialist with a very clear know-how profile.<br />

Company Profile:<br />

Year founded: 1934<br />

Employees: Approx 620 worldwide<br />

Turnover: 80 million € / year<br />

Target Markets::<br />

Packaging<br />

Automation & Robots<br />

Machine Tool<br />

Products:<br />

Servo Motor with Drive Electronics<br />

Frequency Inverters<br />

Geared Motors with Servo/AC Motors<br />

Planetary Gearboxes<br />

Inline<br />

Right Angle<br />

Low Backlash<br />

Shaft and Hollow Bore<br />

Helical Inline and Bevel Gearboxes<br />

Servo and AC Motor <strong>com</strong>patible<br />

Torques up to 13,000 Nm<br />

ATEX / Food Grades<br />

Controller Software<br />

STOBER DRIVES Ltd. – Essex UK<br />

Martin Preece – Sales Director<br />

www.stober.co.uk<br />

A major ac<strong>com</strong>plishment of STOBER is<br />

that it made its vision a reality by<br />

making the conscious decision not just<br />

to be a leader in gearbox technology.<br />

But couple this with being a leader in<br />

servo motor technology – the<br />

foundation for our success in geared<br />

solutions.<br />

STOBER – WE KEEP THINGS MOVING<br />

Tel: 01992 709710<br />

mail@stober.co.uk<br />

martin.preece@stober.co.uk

MACHINE SAFETY<br />

Three<br />

standards,<br />

one<br />

objective<br />

The delayed demise of EN 954-1 has created<br />

confusion in the world of machine safety.<br />

Dr Martin Payn, conformance officer at Parker<br />

SSD Drives, tries to discern a few simple truths<br />

that will define machine safety from now on.<br />

Legislation and conformance have<br />

mushroomed over the past decade or two,<br />

and have reached a point where many larger<br />

<strong>com</strong>panies employ specialist engineers to keep<br />

on top of things. But the trouble with this is that<br />

these specialists can easily find themselves adrift<br />

from the mainstream engineering issues that<br />

concern their colleagues.<br />

An example of this occurred towards the end<br />

of 2009, when the European Union decided<br />

suddenly to delay withdrawing the ageing EN<br />

954-1 safety standard, even though its successor<br />

had already been introduced. The reason for the<br />

delay wasn’t entirely clear, but one factor was<br />

that many <strong>com</strong>panies had been focusing on the<br />

economic situation and had not <strong>com</strong>pleted their<br />

plans for the switchover. In fact, there are two<br />

new standards, EN 13849 and 62061 – the<br />

former for general machines, the latter for<br />

electronic ones – in addition to EN 954-1.<br />

On the face of it, this was a sensible decision<br />

that would be wel<strong>com</strong>ed by the general<br />

engineering populace because it would give<br />

them more time to get ready for the new regime.<br />

However a major problem has arisen from the<br />

delay in that some <strong>com</strong>panies now want to stick<br />

with the existing standard, others want to adopt<br />

the new ones, while a third set don’t know what<br />

to do! Many organisations that had invested<br />

considerable amounts of time and money to<br />

prepare for the changeover, now feel aggrieved.<br />

EN 954 is nearly 20 years old and was due to<br />

be discontinued at the end of 2009. Its<br />

retirement has now been pushed back by two<br />

years to 2011. During this period, engineers will<br />

be able to choose whether to <strong>com</strong>ply with the<br />

old or the new standards.<br />

(EN 62061 is appropriate for electrical and PLC<br />

type applications, while EN 13849 is suitable for<br />

all types of machinery, including pneumatic and<br />

hydraulic. Based on Safety Integration Levels, or<br />

SILs, this is attractive because it is an established<br />

standard with which many engineers are already<br />

familiar. But it should be recognised that while<br />

EN 62061 is appropriate for some applications,<br />

EN 13849 is suitable for all production machinery<br />

work, particularly for those involving drive<br />

systems and sub-systems.)<br />

> Pragmatic approach<br />

As the 2009 deadline approached, many <strong>com</strong>panies<br />

had not decided which route to follow. Instead they<br />

were planning to go with the flow, watching other<br />

<strong>com</strong>panies and taking expert advice if necessary –<br />

but never taking the initiative, in case they were<br />

wrong. In truth, this is a pragmatic approach and<br />

may be the best one for the many organisations<br />

that do not have the resources to develop their own<br />

strategies and to be<strong>com</strong>e leaders in the field.<br />

The extension means that, in theory, engineers<br />

can relax and carry on as before until December<br />

2011. But the reality is that those <strong>com</strong>panies that<br />

weren’t ready in December, probably won’t be<br />

ready in two years’ time either. They will wait it<br />

out and hope to find a leader to follow.<br />

Organisations that were ready in December are<br />

pushing to make the changeover now.

The result will be confusion in the market,<br />

with several standards vying for dominance.<br />

This is messy, frustrating and expensive, and<br />

could lead ultimately to lower safety levels<br />

until a single new regime is established.<br />

Before we examine the differences<br />

between the standards, let us first look at<br />

recent history for some guidance. There is<br />

always a transition period before new<br />

standards are introduced to give <strong>com</strong>panies<br />

time to get ready. But while some do<br />

prepare, others are content to follow.<br />

Directives relating to EMC<br />