CNC Special Machines CM 27 - Mecro

CNC Special Machines CM 27 - Mecro

CNC Special Machines CM 27 - Mecro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>CNC</strong> <strong>Special</strong> <strong>Machines</strong><br />

<strong>CNC</strong> <strong>Special</strong> <strong>Machines</strong><br />

Technical Data <strong>CM</strong> <strong>27</strong> Standard<br />

Details<br />

Controller<br />

Siemens 840 D with integrated PC in mobile control cabinet<br />

Routing spindle<br />

HSK F 63, water-cooled, power max. 16 kW<br />

infinitely variable speed regulation up to 24,000 rpm<br />

Working unit universal robot unit with Z axis, A 540°, B +/- 98°<br />

A/B mounted at an angle of 50°<br />

Extraction<br />

chip collecting basket vertically adjustable via <strong>CNC</strong><br />

extraction connection 1 x dia. 300<br />

<strong>CM</strong> <strong>27</strong><br />

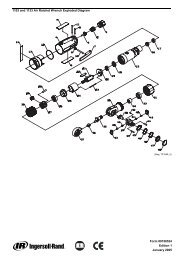

Axis drives<br />

X-axis toothed rack<br />

Y-axis toothed rack<br />

Z-axis recirculating ball screws<br />

Machine table<br />

top steel table with plane surface, 40 mm thick<br />

Clamping station<br />

vacuum clamping device, 1 vacuum clamping circuit per table<br />

Protection device<br />

revolving doors at the front, protection device with access door on<br />

the rear side, safety blind between the tables, roller shutters<br />

Working envelope in 3- and 5-axis operation<br />

Condition<br />

tool dia. 160 mm, total tool length 160 mm<br />

X = 1,500 mm, Y = 1,500 mm, Z = 800 mm<br />

Travel speeds<br />

X = 45 m/min, Y = 45 m/min, Z = 24 m/min, A/B = 10,000 °/min<br />

Driving dynamics<br />

Acceleration X, Y, Z idle running 3 m/sec 2 , operation feed 1.5 m/sec 2<br />

Tool changer<br />

Data<br />

Installation details<br />

Machine weight<br />

Required space <strong>CM</strong> <strong>27</strong>t<br />

chain-type tool magazine with 12 tool places (standard) or optionally<br />

16, 24, 32 tool places; dia. 160 mm, total length 160 mm<br />

(max. dia. 90 mm with 24, 32 places); tool weight max. 6 kg<br />

a saw blade with a dia. of max. 350 mm,<br />

pick-up tool place for saw blade dia. 450 mm<br />

approx. 13,000 kg with Y axis stroke 1,500 mm<br />

approx. 8,000 x 8,500 x 4,400 (w x d x h) incl. operation and safety space<br />

Subject to technical alterations. 04/2006/3120<br />

<strong>CNC</strong> Machining Centre<br />

with 5-Axis-technology<br />

for the high-speed machining<br />

of large aluminium castings<br />

MAKA – Max Mayer Maschinenbau GmbH<br />

P.O.Box 8008 · 89218 Neu-Ulm · Germany · Tel. ++49-(0)7308/813-0 · Fax ++49-(0)7308/813-170 · www.maka.com<br />

and technical profiles

<strong>CM</strong> <strong>27</strong><br />

<strong>CNC</strong> Machining Centre with 5-Axis-technology<br />

for the high-speed machining of large aluminium castings<br />

and technical profiles<br />

2<br />

Fields of application<br />

The 5-axis machining <strong>CM</strong> <strong>27</strong> has become<br />

a synonym for first class routing<br />

operations. This MAKA series allows the<br />

three-dimensional machining of any kind<br />

of material to be used in the pattern and<br />

model making industry as well as<br />

castings and light metals. This series<br />

combines sector-specific features with the<br />

advantages of a light machine tool and<br />

is used wherever economical heavy-duty<br />

machining is required: by manufacturers<br />

of prototypes, in the automotive and<br />

railvehicle industry as well as by<br />

manufacturers of large-scale wooden<br />

mouldings or patterns.<br />

Outstanding feature of the machine is the<br />

high flexibility: Routing, sawing,<br />

drilling, cutting threads can be performed<br />

in almost any angle; a rigid and dynamic<br />

design, a high Z axis, a heavy-duty routing<br />

unit as well as well-proven MAKA<br />

5-axis technology are only some of the<br />

advantages. The large tool magazine with<br />

a de-posit for a saw blade allows<br />

complete machining operations with only<br />

one clamping.<br />

The classical design of the machine with<br />

stationary Gantry where the X and Y axes<br />

are allocated to the working unit and to<br />

the machine table is the optimum precondition<br />

for dynamics and precision.<br />

4<br />

1<br />

Required space <strong>CM</strong> <strong>27</strong>t:<br />

approx. 8,000 x 8,500 x 4,400 (w x d x h)<br />

Machine weight: approx. 13,000 kg<br />

with Z stroke 1,500 mm<br />

3<br />

8,500<br />

1 2<br />

8,000<br />

3<br />

4<br />

Routing unit<br />

As standard-type spindle we<br />

offer the HSK F 63 spindle.<br />

Other spindle types are available<br />

on request<br />

Tool magazine<br />

Chain-type tool magazines<br />

with 12, 16, 24, 32 tool places<br />

are possible<br />

Machine table<br />

Plane steel table<br />

with plane surface,<br />

40 mm thick<br />

<strong>CNC</strong> controller<br />

Latest controller generation:<br />

Siemens 840 D<br />

Pattern making<br />

High Z axis stroke<br />

up to 1,000 mm<br />

Profile Machining<br />

High-duty cutting with<br />

thick-wall aluminium profile