2006 Fall Issue - UAW-Chrysler.com

2006 Fall Issue - UAW-Chrysler.com

2006 Fall Issue - UAW-Chrysler.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

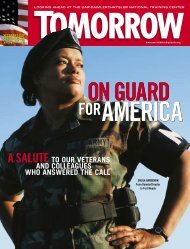

Part of the<br />

Rosetta Jackson sees<br />

changes for the better under<br />

the Lean Warehousing system.<br />

When a loyal customer brings<br />

her Jeep Grand Cherokee<br />

in for maintenance to a<br />

Nashville dealership on a Thursday<br />

afternoon and is told she can pick it up<br />

the next morning, in time for the weekend,<br />

it’s not just good luck. Chances are the<br />

promise will be kept due to the diligence<br />

of a worker at the Memphis Parts<br />

Distribution Center — and a new way<br />

of doing business.<br />

Now that Lean Warehousing is up and<br />

running, dealers in the six-state region<br />

served by Memphis PDC are ordering parts<br />

later, receiving them earlier, and getting<br />

world-class quality, with a small error rate<br />

of close to one error per thousand.<br />

As more PDCs transition to Lean<br />

Warehousing, the impact of this level of<br />

service is being felt by dealers and their<br />

vehicle-buying customers across the<br />

country. “To be <strong>com</strong>petitive, we had to<br />

change the way we do dealer business,”<br />

says Rosetta Jackson, shop chair for<br />

<strong>UAW</strong> Local 1248 at the Detroit PDC.<br />

“Management and union had to <strong>com</strong>e<br />

together on <strong>com</strong>mon ground, which is<br />

customer satisfaction, and implement<br />

new processes. The culture had to change,<br />

but it’s a smarter way to do the job.”<br />

JUST-IN-TIME SUCCESS<br />

Lean Warehousing aims to reduce the time<br />

and resources needed to convert orders into<br />

accurately shipped parts. The “lean” part of<br />

Lean Warehousing is about maintaining justin-time<br />

inventory, cutting waste from order<br />

fulfillment and keeping the process efficient<br />

through constant problem solving.<br />

“Continuous-improvement workshops<br />

are making a difference,” notes Butch<br />

Williams, president of <strong>UAW</strong> Local 1086 at<br />

the Memphis PDC. “When we see a problem,<br />

we do a workshop where we work as a team<br />

to figure out how to fix it. That’s part of what<br />

makes Lean Warehousing different.”<br />

10 TOMORROW FALL <strong>2006</strong> www.uawdcx.<strong>com</strong>