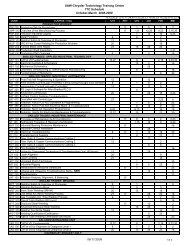

TTC Skilled Trades Training - UAW-Chrysler.com

TTC Skilled Trades Training - UAW-Chrysler.com

TTC Skilled Trades Training - UAW-Chrysler.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Industrial Automation:<br />

ROBOTICS: FANUC RJ2-RJ3 ELECTRICAL<br />

MAINTENANCE & TROUBLESHOOTING (FRT 350)<br />

2 hours<br />

Course Description<br />

This course prepares participants with the necessary skills needed to troubleshoot the Fanuc<br />

RJ2 and RJ3 style controllers, and Fanuc Manipulators.<br />

Learning Out<strong>com</strong>e<br />

Upon <strong>com</strong>pletion of this course, participants should be able to:<br />

1. locate and identify the functions of all electrical and mechanical <strong>com</strong>ponents of the<br />

robot system teach pendant buttons and jog the robot;<br />

2. connect, troubleshoot, and replace all <strong>com</strong>ponents of the robot system;<br />

3. use position, alarms, and status screens, and indicators for troubleshooting;<br />

4. locate robot inputs and outputs screen to determine equipment status; remove motor,<br />

replace master and calibrate the robot system; and<br />

5. file utilities for program backup, loading and software restoration.<br />

Course Objective<br />

To provide the participant with the skills to diagnose, troubleshoot, and carry out electrical<br />

maintenance on the Fanuc RJ2 and RJ3 robotic equipment.<br />

Major Topics Covered<br />

• Robotic Basics Review: Safety guidelines, fault recovery, power up controller using<br />

various methods, jogging the robot using different methods for troubleshooting.<br />

• Robot Setup: Zero position and single axis mastering and calibration, Tool Center<br />

Point (TCP), Application specific setup screens and Inputs and Outputs.<br />

• Communication: Robot Communications to peripheral equipment.<br />

• Component Identification, removal and replacement: Install, remove, and identify<br />

the functions of all robot system <strong>com</strong>ponents.<br />

• Troubleshooting: Position, alarm and status screens, LEDs, robot inputs and outputs<br />

screen location, PLC to robot <strong>com</strong>munications, <strong>com</strong>mon electrical <strong>com</strong>ponents issues,<br />

and UOP input and output utilization.<br />

• File Utilities: Robot Core Software files and configuration, Teach pendant programs,<br />

application programs and system variables.<br />

Prerequisites<br />

Fanuc RJ2-RJ3 Operation and Programming (FRT 300) or training that includes a general<br />

understanding of automation, <strong>com</strong>puters and electrical troubleshooting.<br />

Class Size<br />

6<br />

Course Duration<br />

40 hours<br />

29