BOMAG Original Cutting Tools.

BOMAG Original Cutting Tools.

BOMAG Original Cutting Tools.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

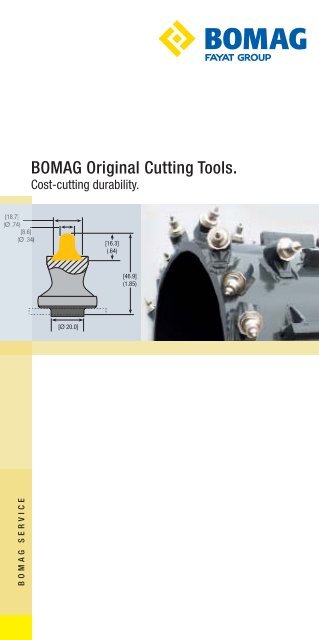

<strong>BOMAG</strong> <strong>Original</strong> <strong>Cutting</strong> <strong>Tools</strong>.<br />

Cost-cutting durability.<br />

[18.7]<br />

(Ø .74)<br />

[8.6]<br />

(Ø .34)<br />

[16.3]<br />

(.64)<br />

[46.9]<br />

(1.85)<br />

[Ø 20.0]<br />

<strong>BOMAG</strong> SERVICE

Contents<br />

Effects on milling performance and penetration ......................... 6<br />

<strong>Cutting</strong> tool wear patterns ........................................................... 8<br />

<strong>BOMAG</strong> <strong>Original</strong> Economy cutting tools for asphalt ...................... 14<br />

<strong>BOMAG</strong> <strong>Original</strong> cutting tools for asphalt ..................................... 16<br />

<strong>BOMAG</strong> <strong>Original</strong> cutting tools for concrete ................................... 18<br />

Recommendations for use .......................................................... 20<br />

Factors affecting cutting tools selection ..................................... 22<br />

<strong>BOMAG</strong> <strong>Original</strong> cutting tool holders for compact milling machines .. 24<br />

<strong>BOMAG</strong> <strong>Original</strong> cutting tool holders for large milling machines ........ 26<br />

<strong>BOMAG</strong> <strong>Original</strong> cutting tools for recycler/stabilizer ..................... 28<br />

<strong>BOMAG</strong> <strong>Original</strong> cutting tool holders for recycler/stabilizer .......... 30<br />

<strong>BOMAG</strong> <strong>Original</strong> accessories ...................................................... 32<br />

3

<strong>BOMAG</strong> <strong>Original</strong> <strong>Cutting</strong> <strong>Tools</strong><br />

4

The correct cutting tool always delivers more power.<br />

Outstanding technology in even the smallest detail.<br />

The result of intensive innovation and continuous development,<br />

we offer you the optimum cutting tool specifically designed to<br />

excel in each job.<br />

Advantages and special features<br />

Fracture-proof and wear resistant carbide tip<br />

High-quality soldered connection between tip and shaft<br />

Large base diameter to protect the cutting tool holder<br />

Pre-tensioned spring sleeve to reduce wear in the receiving<br />

bore<br />

Wear plate to protect the cutting tool holder<br />

Long shaft to protect the receiving bore<br />

5

Effect of the cutting tool condition on milling perfo<br />

New condition<br />

m/min.<br />

If the tool carbide tip wear is advanced, material penetration<br />

will be reduced due to the increase in the cutting tool<br />

What are the reasons for changing a cutting tool?<br />

If the operator sees errors in the milling pattern on the street<br />

If the advance rate can be reduced<br />

Rotation problems are rarely<br />

6

mance and penetration<br />

worn<br />

m/min.<br />

diameter and shorter length. Low penetration in turn reduces<br />

the advance rate or milling performance.<br />

If the operator detects<br />

<br />

<br />

<br />

milling drum and the cutting tool<br />

THE EFFECT OF CUTTING TOOL CONDITION ON PERFORMANCE AND PENETRATION<br />

caused by the cutting tool<br />

7

<strong>Cutting</strong> tool wear patterns –<br />

New condition<br />

Reasons for cutting tool wear<br />

No rotation<br />

Reasons for ...<br />

... flat spots (cat’s claw)<br />

Worn holders<br />

Misaligned holders<br />

Material build up in bore<br />

Excessive heat (inside and outside<br />

temperature)<br />

Insufficient cooling water<br />

8

Causes and solutions<br />

Normal wear<br />

TOOL WEAR PATTERNS<br />

Recommendations<br />

Increase the cooling water volume<br />

<br />

each shift<br />

Replace worn cutting tool holders/have the rotor repaired<br />

9

<strong>Cutting</strong> tool wear patterns –<br />

Reasons for cutting tool wear<br />

Washing out the<br />

cutting tool body<br />

Reasons for …<br />

... Washing out the cutting tool<br />

body<br />

Highly abrasive materials<br />

Worn conveyor belts<br />

Excess accumulation of material<br />

in rotor housing, carbide tip<br />

<br />

Carbide tip<br />

breakage<br />

Reasons for …<br />

... Carbide tip breakage<br />

Large particle sizes (concrete or<br />

asphalt)<br />

Lowering the milling drum onto<br />

hard subsoil<br />

Normal wear No rotation Abrasion Carbide tip<br />

<br />

10

Causes and solutions<br />

Recommendations<br />

New conveyor belts<br />

<br />

<br />

Recommendations<br />

Selecting the right cutting tool<br />

CUTTING TOOL WEAR PATTERNS<br />

11

Run faster ... or save fuel<br />

<br />

with an intact carbide tip cuts the material better and the<br />

machine speed increases. This new shaping process allows us<br />

to use the shape of a “worn” cutting tool, but with the strength<br />

of an unused one.<br />

Cooling the cutting tool increases<br />

the performance of the carbide tip<br />

Mill faster and longer with less<br />

vibration, and lower fuel consumption<br />

<br />

protection and improved cutting tool<br />

rotation<br />

Improved rotation throughout the<br />

life of the cutting tool<br />

Recommendation: Our new Economy series for<br />

asphalt work<br />

Select the best <strong>BOMAG</strong> <strong>Original</strong> Economy cutting tools<br />

for your job from the table. Opt for cost-effectiveness and<br />

performance for all your milling applications.<br />

13

NEW!<br />

<strong>BOMAG</strong> <strong>Original</strong> Economy cutting tool for as<br />

Special features:better fuel economyeconomicalhigher<br />

BMT 01E<br />

BMT 02E<br />

Overview of cutting tool dimensions<br />

BMT 01E<br />

[mm]<br />

(inch)<br />

BMT 02E<br />

[mm]<br />

(inch)<br />

[Ø 15.9]<br />

(Ø .62)<br />

[Ø 7.8]<br />

(Ø .31)<br />

[16.3]<br />

(.64)<br />

[Ø 18.7]<br />

(Ø .74)<br />

[Ø 8.6]<br />

(Ø .34)<br />

[16.3]<br />

(.64)<br />

[46.9]<br />

(1.85)<br />

[46.9]<br />

(1.85)<br />

[Ø 20.0]<br />

[Ø 20.0]<br />

BMT 01E<br />

BMT 02E<br />

TN Box (60 pcs.) 300 261 28C60 300 261 29C60<br />

TN Pallet (3,600 pcs.) 300 261 28C3600 300 261 29C3600<br />

Characteristics<br />

Premium carbide tip for longer life<br />

Improved rotational properties<br />

Improved tool holder life<br />

14

phalt<br />

performance<br />

[Ø 18.7]<br />

(Ø .74)<br />

[Ø 10.2]<br />

(Ø .40)<br />

BMT 03E<br />

BMT 03E<br />

[Ø 20.0]<br />

[18.8]<br />

(.74)<br />

[mm]<br />

(inch)<br />

[49.4]<br />

(1.95)<br />

[Ø 18.7]<br />

(Ø .74)<br />

[Ø 11.5]<br />

(Ø .45)<br />

BMT 04E<br />

BMT 04E<br />

[Ø 20.0]<br />

[19.0]<br />

(.75)<br />

[mm]<br />

(inch)<br />

[49.7]<br />

(1.96)<br />

<strong>BOMAG</strong> ORIGINAL ECONOMY CUTTING TOOLS FOR ASPHALT<br />

BMT 03E<br />

BMT 04E<br />

TN Box (60 pcs.) 300 261 30C60 300 261 31C60<br />

TN Pallet (3,600 pcs.) 300 261 30C3600 300 261 31C3600<br />

15

<strong>BOMAG</strong> <strong>Original</strong> cutting tools for asphalt<br />

BMT 18<br />

Universal<br />

BMT 24<br />

Universal<br />

Overview of cutting tool dimensions<br />

BMT 18<br />

Universal<br />

[mm]<br />

(inch)<br />

BMT 24<br />

Universal<br />

[mm]<br />

(inch)<br />

[Ø 15.9]<br />

(Ø .62)<br />

[Ø 7.8]<br />

(Ø .31)<br />

[16.3]<br />

(.64)<br />

[Ø 18.7]<br />

(Ø .74)<br />

[Ø 10.2]<br />

(Ø .40)<br />

[17.0]<br />

(.67)<br />

[49.0]<br />

(1.93)<br />

[47.6]<br />

(1.87)<br />

[Ø 20.0] [Ø 20.0]<br />

BMT 18 BMT 24<br />

TN Box (50 pcs.) 300 261 18C50 350 100 014C50<br />

TN Pallet (3,000 pcs.) 300 261 18C3000 350 100 014C3000<br />

Characteristics<br />

Universal cutting tool<br />

Robust carbide tip for highest loads<br />

Pull-out groove for cutting tool change<br />

16

[Ø 18.7]<br />

(Ø .74)<br />

[Ø 10.2]<br />

(Ø .40)<br />

BMT 16<br />

Universal Plus<br />

BMT 16<br />

Universal Plus<br />

[18.0]<br />

(.74)<br />

[mm]<br />

(inch)<br />

[49.4]<br />

(1.95)<br />

[Ø 18.7]<br />

(Ø .74)<br />

[Ø 11.5]<br />

(Ø .45)<br />

BMT 20TP<br />

Premium<br />

BMT 20TP<br />

Premium<br />

[19.0]<br />

(.75)<br />

[mm]<br />

(inch)<br />

[49.7]<br />

(1.96)<br />

<strong>BOMAG</strong> ORIGINAL CUTTING TOOLS FOR ASPHALT<br />

[Ø 20.0]<br />

[Ø 20.0]<br />

BMT 16<br />

BMT 20TP<br />

TN Box (50 pcs.) 300 261 16C50 300 261 20C50<br />

TN Pallet (3,000 pcs.) 300 261 16C3000 300 261 20C3000<br />

17

<strong>BOMAG</strong> <strong>Original</strong> cutting tools for concrete<br />

BMT 22<br />

Concrete<br />

BMT 21<br />

Concrete<br />

Overview of cutting tool dimensions<br />

BMT 22<br />

Concrete<br />

[mm]<br />

(inch)<br />

BMT 21<br />

Concrete<br />

[mm]<br />

(inch)<br />

[Ø 9.1]<br />

(Ø .36)<br />

[Ø 12.2]<br />

(Ø .48)<br />

[26.1]<br />

(1.03)<br />

[26.7]<br />

(1.05)<br />

[48.5]<br />

(1.91)<br />

[48.6]<br />

(1.91)<br />

[Ø 20.0]<br />

[Ø 20.0]<br />

BMT 22 BMT 21<br />

TN Box (50 pcs.) 300 261 27C50 300 261 21C50<br />

TN Pallet (3,000 pcs.) 300 261 27C3000 300 261 21C3000<br />

Characteristics<br />

Extremely robust, cylindrical carbide tip<br />

Reinforced steel body<br />

Pull-out groove for cutting tool change<br />

18

19<br />

<strong>BOMAG</strong> ORIGINAL CUTTING TOOLS FOR CONCRETE

Application guide for Bomag <strong>Original</strong> cutting tools<br />

Tool type<br />

Carbide<br />

diameter<br />

Carbide<br />

foot<br />

Carbide<br />

length<br />

BM 500/15 BM 600/15<br />

BMT 01E 7,8 mm 15,9 mm 16,3 mm<br />

BMT 18 7,8 mm 15,9 mm 16,3 mm<br />

BMT 02E 8,6 mm 18,7 mm 16,3 mm<br />

Asphalt<br />

BMT 24 10,2 mm 18,7 mm 17,0 mm<br />

BMT 16 10,2 mm 18,7 mm 18,0 mm<br />

BMT 03E 10,2 mm 18,7 mm 18,8 mm<br />

BMT 20TP 11,5 mm 18,7 mm 19,0 mm<br />

BMT 04E 11,5 mm 18,7 mm 19,0 mm<br />

Concrete<br />

BMT 22 9,1 mm 9,1 mm 26,1 mm<br />

BMT 21 12,2 mm 12,2 mm 26,7 mm<br />

<strong>BOMAG</strong> <strong>Original</strong> cutting tools suitable for other<br />

20

BM 1000/30 BM 1200/30 BM 1300/30 BM 1500/50 BM 2000/50 BM 2000/60<br />

Recommended<br />

Recommended for<br />

soft materials<br />

machine types<br />

21

Factors for best cutting tool selection<br />

Small carbide tip diameter<br />

High penetration performance<br />

Low machine power<br />

Softness of material<br />

High area output<br />

Influence of carbide tip diameter on penetration pe<br />

Penetration performance<br />

[Ø 7.8]<br />

(Ø .31)<br />

[Ø 8.6]<br />

(Ø .34)<br />

Short carbide tip length<br />

<br />

Low penetration performance<br />

Low area output<br />

Low penetration performance<br />

22

Large carbide tip diameter<br />

Low penetration performance<br />

Higher machine power<br />

Increasing hardness of material<br />

Low area output<br />

rformance and breakage resistance.<br />

Breakage resistance<br />

[Ø 10.2]<br />

(Ø .40)<br />

[Ø 11.5]<br />

(Ø .45)<br />

Long carbide tip length<br />

<br />

High penetration performance<br />

High area output<br />

Long lifetime<br />

23

<strong>BOMAG</strong> <strong>Original</strong> cutting tool holders for compact<br />

milling machines<br />

Standard milling drum<br />

BMS 03<br />

BMS 05<br />

Fine milling drum<br />

BMS 03<br />

POWER-DRUM milling drum<br />

BMS 05<br />

BMS 03<br />

24

Holder system BMS 05<br />

BMS 05<br />

TN (pcs.) 882 222 05<br />

Holder system BMS 03<br />

For all cutting tools with<br />

<br />

Weld-on, high-strength cutting<br />

tool holder<br />

For all tools with a 20 mm<br />

<br />

Weld-on, high-strength cutting<br />

tool holder<br />

<strong>BOMAG</strong> ORIGINAL CUTTING TOOL HOLDERS FOR COMPACT MILLING MACHINES<br />

BMS 03<br />

TN (pcs.) 882 222 03<br />

25

<strong>Cutting</strong> ool holders for large milling machines<br />

NEW!<br />

Exchange holder system BMS 15<br />

For all cutting tools with<br />

<br />

Additional, robust interchangeable<br />

holder as wear element<br />

<br />

wear part<br />

Weld-on, high-strength interchangeable<br />

holder base<br />

Low tightening torque of<br />

100 Nm<br />

BMS 15 BMS 15<br />

4 mm<br />

shorter<br />

BMS 15<br />

8 mm<br />

shorter<br />

BMS 15<br />

Complete<br />

BMS 15<br />

Fastening<br />

kit<br />

TN (pcs.) 883 010 33 883 010 34 883 010 35 883 010 37 883 010 36<br />

26

<strong>Cutting</strong> tool holders for large milling machines<br />

Interchangeable holder system BTS 303<br />

For all cutting tools<br />

<br />

Additional, robust interchangeable<br />

holder as wear element<br />

No screws needed for<br />

mounting<br />

Weld-on, high-strength interchangeable<br />

holder base<br />

BTS 303 exchange holder BTS 303 exchange holder base<br />

TN (pcs.) 350 100 020 350 100 030<br />

<strong>BOMAG</strong> ORIGINAL CUTTING TOOL HOLDERS FOR LARGE MILLING MACHINES<br />

27

<strong>BOMAG</strong> <strong>Original</strong> cutting tools for recycler/stabilizer<br />

BRT 01<br />

Premium<br />

BRT 02<br />

Concrete<br />

Overview of cutting tool dimensions<br />

BRT 01<br />

Premium<br />

[mm]<br />

(inch)<br />

BRT 02<br />

Concrete<br />

[mm]<br />

(inch)<br />

[Ø 22.2]<br />

(Ø .88)<br />

[Ø 11.2]<br />

(Ø .44)<br />

[Ø 12.2]<br />

(Ø .48)<br />

[19.0]<br />

.75<br />

[26.7]<br />

1.05<br />

[52.1]<br />

2.05<br />

[52.1]<br />

2.05<br />

[Ø 22.0]<br />

[Ø 22.0]<br />

BRT 01 BRT 02<br />

TN Box (40 pcs.) 300 263 01C40 300 263 02C40<br />

TN Pallet (2,400 pcs.) 300 263 01C2400 300 263 02C2400<br />

Characteristics<br />

Stabilization/asphalt<br />

pulverization<br />

Ideal for:<br />

– Cohesive soils<br />

– Gravel/sand<br />

– Asphalt<br />

Concrete carriageways<br />

Ideal for:<br />

– Concrete<br />

28

[Ø 19.0]<br />

(Ø .75)<br />

[Ø 11.5]<br />

(Ø .45)<br />

BRT 03<br />

Universal<br />

BRT 03<br />

Universal<br />

[Ø 22.0]<br />

[21.3]<br />

.84<br />

[mm]<br />

(inch)<br />

[52.0]<br />

2.05<br />

[15.9]<br />

(Ø .62)<br />

BRT 04<br />

Standard<br />

BRT 04<br />

Standard<br />

[Ø 22.0]<br />

BRT 03 BRT 04<br />

TN Box (40 pcs.) 300 263 03C40 300 263 04C40<br />

TN Pallet (2,400 pcs.) 300 263 03C2400 300 263 04C2400<br />

[13.5]<br />

.53<br />

[52.1]<br />

2.05<br />

[mm]<br />

(inch)<br />

<strong>BOMAG</strong> ORIGINAL CUTTING TOOLS FOR RECYCLER/STABILIZERS<br />

Soil stabilization<br />

Ideal for:<br />

– Cohesive soils<br />

– Gravel/sand<br />

Soil stabilization<br />

Ideal for:<br />

– Cohesive soils<br />

29

<strong>Cutting</strong> tool holders for recycler/stabilizer<br />

Holder system BRS 02<br />

1<br />

2<br />

for all tools<br />

with a<br />

<br />

weld-on,<br />

high-strength<br />

steel holder<br />

Nr. 1 Nr. 2<br />

BRS 02 holder<br />

BRS 02 repair kit<br />

TN (pcs.) 591 702 81 079 911 03<br />

Exchange holder system BRS 05<br />

3<br />

special holder shape<br />

<br />

resistant to dirt and<br />

corrosion<br />

2<br />

1<br />

Thread in the wear<br />

element<br />

Transfer of forces via<br />

positive connection<br />

High wear resistant<br />

materials for extra life<br />

Nr. 1 Nr. 2 Nr. 3<br />

BRS 05<br />

Exchange holder<br />

BRS 05<br />

Basic holder<br />

BRS 05<br />

Screw fitting<br />

TN (pcs.) 591 705 76 591 705 75 071 520 37<br />

30

31<br />

<strong>BOMAG</strong> ORIGINAL CUTTING TOOL HOLDERS FOR RECYCLERS/STABILIZERS

<strong>BOMAG</strong> <strong>Original</strong> accessories ...<br />

<strong>BOMAG</strong> <strong>Original</strong> accessory parts are designed for everyday<br />

<br />

<br />

damage and enhance site safety.<br />

2<br />

3<br />

1<br />

4<br />

TN (pcs.)<br />

Nr. 1 Copper mallet 1000g 079 060 10<br />

Nr. 2 Flat chisel 079 060 11<br />

Nr. 3 Chipping hammer 1500 g 972 019 26<br />

Nr. 4 Impact protection 079 911 21<br />

... for milling machines<br />

2<br />

1 3 4<br />

5<br />

TN (pcs.)<br />

Nr. 1 Extractor for cutting tool holders - starter 079 911 22<br />

Nr. 2 Extractor for cutting tool holders - finisher 079 911 23<br />

Nr. 3 Extractor for cutting tools 079 911 24<br />

Nr. 4 Extractor for cutting tools 350 220 014<br />

Nr. 5 Knockout punch for cutting tools 836 801 98<br />

32

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

TN (pcs.)<br />

Nr. 1 Torque wrench for BMS 15 079 060 09<br />

Nr. 2 Special tool ring spanner for BMS 15 883 110 76<br />

Nr. 3 Hydraulic cutting tool hammer 836 110 59<br />

Nr. 4 Pointed chisel for hydraulic cutting tool hammer 065 110 16<br />

Nr. 5 Square-nosed chisel for hydraulic cutting tool hammer 065 110 15<br />

Nr. 6<br />

<strong>Cutting</strong> tool knockout punch for hydraulic cutting tool<br />

hammer<br />

... for recycler/stabilizer<br />

1<br />

2<br />

883 111 43<br />

<strong>BOMAG</strong> ORIGINAL ACCESSORIES<br />

TN (pcs.)<br />

Nr. 1 Device - welding 591 703 83<br />

Nr. 2 Device - flame cutting 591 703 82<br />

ohne Abb. Hydraulic cutting tool hammer 065 110 17<br />

ohne Abb.<br />

ohne Abb.<br />

ohne Abb.<br />

33<br />

Square-nosed chisel long for hydraulic cutting tool<br />

hammer<br />

Square-nosed chisel short for hydraulic cutting tool<br />

hammer<br />

<strong>Cutting</strong> tool knockout punch for hydraulic cutting tool<br />

hammer<br />

590 043 68<br />

065 110 18<br />

590 046 06

Meißelhalter Maintenance/parts für Recycler/Stabilisierer<br />

service<br />

Specialist support teams are available to you in Germany, Europe and<br />

other markets. This highly focused network maintains close contact with<br />

users around the world.<br />

Parts for maintenance, service and repairs are readily available from our<br />

branch offices and dealers.<br />

<strong>BOMAG</strong> guarantees the long-term availability of standard parts.<br />

Clearly arranged catalogues provide easy orientation, accurate<br />

identification and ordering of parts.<br />

Use only genuine <strong>BOMAG</strong> spare parts. They are precisely matched to<br />

specific machines to avoid operating problems and unnecessary downtime.

Head Office/Hauptsitz:<br />

<strong>BOMAG</strong><br />

Hellerwald<br />

56154 Boppard<br />

GERMANY<br />

Tel.: +49 6742 100-0<br />

Fax: +49 6742 3090<br />

e-mail: info@bomag.com<br />

<strong>BOMAG</strong><br />

Maschinenhandelsgesellschaft m.b.H.<br />

Porschestraße 9<br />

1230 Wien<br />

AUSTRIA<br />

Tel.: +43 1 69040-0<br />

Fax: +43 1 69040-20<br />

e-mail: austria@bomag.com<br />

<strong>BOMAG</strong> (CANADA), INC.<br />

3455 Semenyk Court<br />

Mississauga, Ontario L5C 4P9<br />

CANADA<br />

Tel.: +1 905 361 9961<br />

Fax: +1 905 361 9962<br />

e-mail: canada@bomag.com<br />

<strong>BOMAG</strong> (CHINA)<br />

Compaction Machinery Co. Ltd.<br />

No. 2808 West Huancheng Road<br />

Shanghai Comprehensive Industrial Zone<br />

(Fengxian)<br />

Shanghai 201401<br />

CHINA<br />

Tel.: +86 21 33655566<br />

Fax: +86 21 33655508<br />

e-mail: china@bomag.com<br />

BOMA Equipment Hong Kong LTD<br />

Room 1003,<br />

10/F Cham Centre<br />

700, Castle Peak<br />

Road, Kowloon<br />

HONG KONG<br />

Tel: +852 2721 6363<br />

Fax: +852 2721 3212<br />

e-mail: bomahk@bomag.com<br />

<strong>BOMAG</strong> FRANCE S.A.S.<br />

2, avenue du Général de Gaulle<br />

91170 Viry-Châtillon<br />

FRANCE<br />

Tel.: +33 1 69578600<br />

Fax: +33 1 69962660<br />

e-mail: france@bomag.com<br />

<strong>BOMAG</strong> (GREAT BRITAIN), LTD.<br />

Sheldon Way<br />

Larkfield, Aylesford<br />

Kent ME20 6SE<br />

GREAT BRITAIN<br />

Tel.: +44 1622 716611<br />

Fax: +44 1622 718385<br />

e-mail: gb@bomag.com<br />

<strong>BOMAG</strong> ITALIA Srl.<br />

Via Roma 50<br />

48011 Alfonsine<br />

ITALIA<br />

Tel.: +39 0544 864235<br />

Fax: +39 0544-864367<br />

e-mail: italy@bomag.com<br />

FAYAT <strong>BOMAG</strong> Polska Sp. z o.o.<br />

Ul. Szyszkowa 52<br />

02-285 Warszawa<br />

POLAND<br />

Tel.: +48 22 482 0400<br />

Fax: +48 22 482 04 01<br />

e-mail: poland@bomag.com<br />

FAYAT <strong>BOMAG</strong> RUS OOO<br />

141400, RF, Moscow region<br />

Khimki, Klayazma block, h. 1-g<br />

RUSSIA<br />

Tel: +7 (495) 287 92 90<br />

Fax: +7 (495) 287 92 91<br />

e-mail: russia@bomag.com<br />

<strong>BOMAG</strong> GmbH<br />

300 Beach Road<br />

The Concourse, #18-06<br />

Singapore 199555<br />

SINGAPORE<br />

Tel.: +65 6 294 1277<br />

Fax: +65 6 294 1377<br />

e-mail: singapore@bomag.com<br />

<strong>BOMAG</strong> Americas Inc.<br />

2000 Kentville Road<br />

Kewanee, Illinois 61443<br />

U.S.A.<br />

Tel.: +1 309 8533571<br />

Fax: +1 309 8520350<br />

e-mail: usa@bomag.com

01/13 PRE 115 007 Errors excepted and subject to change without notice.