Displacement flow diffusers - TROX

Displacement flow diffusers - TROX

Displacement flow diffusers - TROX

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1/10/US/3<br />

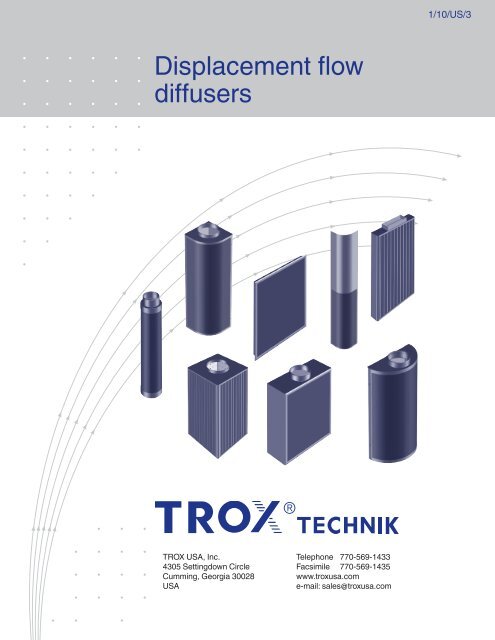

<strong>Displacement</strong> <strong>flow</strong><br />

<strong>diffusers</strong><br />

<strong>TROX</strong> USA, Inc.<br />

4305 Settingdown Circle<br />

Cumming, Georgia 30028<br />

USA<br />

Telephone 770-569-1433<br />

Facsimile 770-569-1435<br />

www.troxusa.com<br />

e-mail: sales@troxusa.com

Application - Construction - Performance Notes<br />

Application<br />

<strong>TROX</strong> displacement <strong>flow</strong> <strong>diffusers</strong> have been developed<br />

specially for air supply in displacement <strong>flow</strong> ventilation<br />

systems. A wide range of different shapes ensures that they can<br />

be effectively integrated into the interior design. They are maintenance-free<br />

because they do not use filter material.<br />

<strong>TROX</strong> displacement <strong>flow</strong> <strong>diffusers</strong> are used where good<br />

ventilation efficiency is very important, i.e. the lowest possible<br />

pollutant contamination in combination with optimum thermal<br />

comfort in occupied spaces and work areas.<br />

Construction<br />

<strong>TROX</strong> displacement <strong>flow</strong> <strong>diffusers</strong> in standard construction are<br />

made of galvanized sheet steel. The face plate is perforated with<br />

3 mm holes. All visible areas are painted white but other colors<br />

are available upon request. Customized<br />

versions are available. Size tolerances ± 2.5 mm.<br />

<strong>TROX</strong> displacement <strong>flow</strong> <strong>diffusers</strong> are supplied ready to install.<br />

The special nozzles with integral air deflector scoops are<br />

constructed of UL 94-rated plastic.<br />

Model QL-WH-RO<br />

<strong>TROX</strong> X30 and X60 nozzles utilized in all of the products<br />

in this leaflet provide optimal <strong>flow</strong> equalization across<br />

the diffuser face by extracting and turning the supply air <strong>flow</strong><br />

perpendicular to the diffuser face. Designs which<br />

incorporate only a distribution plate often provide<br />

inadequate <strong>flow</strong> equalization which results in larger<br />

adjacent zones and reduced space utilization.<br />

K SP<br />

A EFF<br />

1 2 3 5<br />

L 0.2<br />

12 x 18 x 12<br />

654 3.15<br />

Contents<br />

ød<br />

a<br />

B-35 | H-35<br />

b<br />

Page 4<br />

B-35 / H-35<br />

B<br />

T<br />

Type QL-WE-E/<br />

½ B<br />

Page 6<br />

T<br />

1500 h<br />

ød<br />

H h<br />

H<br />

Δh<br />

2000<br />

a<br />

B<br />

Page 21<br />

ød<br />

Type QL-WV-RO/.../K<br />

B<br />

Page 22<br />

a<br />

Type QL-WE-RO/<br />

½ B ½ B<br />

T<br />

Type QL-WS-RO/.../K<br />

T<br />

T<br />

a<br />

½ B<br />

ød<br />

B<br />

D<br />

a<br />

B-35 / H-35<br />

Page 8<br />

Type QL-WE-O/<br />

B<br />

b<br />

Page 10<br />

Type QL-WF-E/<br />

B + 2<br />

Page 12<br />

B + 2<br />

½B<br />

T<br />

T<br />

Type QL-WF-RO/<br />

Page 14<br />

Type QL-WR-RO/<br />

Page 16<br />

a<br />

Type QL-WH-RO/<br />

ød<br />

B<br />

b<br />

ød<br />

B<br />

H h<br />

ød<br />

b<br />

B<br />

H h<br />

B<br />

H h<br />

H h<br />

H h<br />

B<br />

H h<br />

ød<br />

B<br />

d<br />

a<br />

T<br />

B<br />

Page 24<br />

Type QL-WFM...<br />

b<br />

B<br />

½ B<br />

Page 30<br />

Page 32<br />

Type QL-WQT-RO-2/<br />

Type QL-WQT-RO-3/<br />

B<br />

Type QL-WQT-RO-4/<br />

½B<br />

B<br />

T<br />

Type<br />

B<br />

QL-WFT-RO/<br />

b<br />

Type QL-WFT-E/<br />

d<br />

a<br />

T<br />

B<br />

½B<br />

...-E/<br />

...-E-2L/<br />

...-E-3/<br />

...-E-2R/<br />

T<br />

B<br />

B<br />

½B<br />

Page 18<br />

ød<br />

Type QL-WV-RO/<br />

Page 20<br />

a<br />

Type QL-WH-RO/.../K<br />

IMPORTANT:<br />

This leaflet lists only the most common standard sizes.<br />

Other dimensions are available on request.<br />

B<br />

B<br />

½B<br />

B<br />

Technical information...............................................................34<br />

<strong>Displacement</strong> chilled beams....................................................36<br />

Temperature relationships - Nomenclature..............................37<br />

Design nomograph - Supply air determination.........................38<br />

Design examples.....................................................................39<br />

Mounting details......................................................................40<br />

Flow rate control options..........................................................41<br />

Specification text.................................................................... 42<br />

Order details............................................................................44<br />

3

Dimensional Information<br />

Type QL-WE-E<br />

<strong>Displacement</strong> terminal for flush mounting within a framed wall<br />

Rectangular inlet connection<br />

Single direction air<strong>flow</strong> discharge pattern<br />

a + 1<br />

a<br />

D<br />

b<br />

H<br />

QL-WE-E chart.ai<br />

W<br />

Product Features<br />

• Designed for flush mounting in a framed wall<br />

(3 3 /4”cavity)<br />

• Face is removable, no visible fasteners<br />

• Rectangular inlet sized for maximum performance<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Plenum box galvanized steel<br />

• Perforated face is 20% free area<br />

• All visible surfaces powder coat white<br />

Units listed below are standard sizes, other sizes available upon request.<br />

Listed Size<br />

CFM Rangeª<br />

Nominal Size<br />

Inlet<br />

W x H x D NC = 25 NC = 30 W H D<br />

b x a<br />

15 x 16 x 3 3 /4 80 90 15 16 3 3 /4 12 x 2 1 /4<br />

15 x 18 x 3 3 /4 95 105 15 18 3 3 /4 12 x 2 1 /4<br />

15 x 24 x 3 3 /4 130 155 15 24 3 3 /4 12 x 2 1 /4<br />

15 x 30 x 3 3 /4 145 170 15 30 3 3 /4 12 x 2 1 /4<br />

15 x 36 x 3 3 /4 150 180 15 36 3 3 /4 12 x 2 1 /4<br />

23 x 24 x 3 3 /4 215 250 23 24 3 3 /4 20 x 2 1 /4<br />

23 x 30 x 3 3 /4 240 285 23 30 3 3 /4 20 x 2 1 /4<br />

23 x 36 x 3 3 /4 260 300 23 36 3 3 /4 20 x 2 1 /4<br />

23 x 42 x 3 3 /4 260 305 23 42 3 3 /4 20 x 2 1 /4<br />

31 x 24 x 3 3 /4 305 360 31 24 3 3 /4 26 x 2 1 /4<br />

31 x 30 x 3 3 /4 350 410 31 30 3 3 /4 28 x 2 1 /4<br />

31 x 36 x 3 3 /4 365 430 31 36 3 3 /4 28 x 2 1 /4<br />

31 x 42 x 3 3 /4 370 435 31 42 3 3 /4 28 x 2 1 /4<br />

46 x 24 x 3 3 /4 495 580 46 24 3 3 /4 42 x 2 1 /4<br />

46 x 30 x 3 3 /4 535 630 46 30 3 3 /4 42 x 2 1 /4<br />

46 x 36 x 3 3 /4 555 650 46 36 3 3 /4 42 x 2 1 /4<br />

Actual inlet dimensions b and a are 1/8" less then nominal values stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

4

Technical Data<br />

Type Model QL-WE-E<br />

K SP<br />

A EFF<br />

15 x 16 x 3<br />

15 x 18 x 3<br />

15 x 24 x 3<br />

15 x 30 x 3<br />

15 x 36 x 3<br />

2 3<br />

5<br />

Dimensional Information<br />

Type QL-WE-RO<br />

<strong>Displacement</strong> terminal for flush mounting within sidewall<br />

Round inlet connection<br />

Single direction air<strong>flow</strong> discharge pattern<br />

D<br />

d<br />

H<br />

Model QL - WE - RO<br />

W<br />

Product Features<br />

• Designed for flush mounting in a sidewall<br />

• Face is removable, no visible fasteners<br />

• Circular inlet sized for maximum performance<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Plenum box galvanized steel<br />

• Perforated face is 20% free area<br />

• All visible surfaces powder coat white<br />

Units listed below are standard sizes, other sizes are available upon request.<br />

Listed Size<br />

CFM Range a<br />

Nominal Size Inlet<br />

W x H x D<br />

V 0 = 20 FPM V 0 = 60 FPM W H D<br />

d<br />

15 x 16 x 7 75 90 15 16 7 5 *<br />

15 x 18 x 7 85 100 15 18 7 5 *<br />

15 x 24 x 8 130 150 15 24 8 6 *<br />

15 x 30 x 10 175 195 15 30 10 8 *<br />

15 x 36 x 10 215 245 15 36 10 8 *<br />

23 x 24 x 10 215 250 23 24 10 8 *<br />

23 x 30 x 10 235 275 23 30 10 8 *<br />

23 x 36 x 12 340 390 23 36 12 10 *<br />

23 x 42 x 12 375 440 23 42 12 10 *<br />

31 x 24 x 12 320 375 31 24 12 10 *<br />

31 x 30 x 12 355 420 31 30 12 10 *<br />

31 x 36 x 14 495 580 31 36 14 12<br />

31 x 42 x 14 540 635 31 42 14 12<br />

46 x 24 x 12 345 405 46 24 12 10 *<br />

46 x 30 x 14 510 595 46 30 14 12<br />

46 x 36 x 14 520 610 46 36 14 12<br />

* Optional VFL <strong>flow</strong> limiter (see page 41 for details) available for these inlet sizes<br />

Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

6

Technical Data<br />

Model QL-WE-RO<br />

Type QL-WE-RO<br />

15 x 16 x 7<br />

15 x 18 x 7<br />

15 x 24 x 8<br />

15 x 30 x 10<br />

15 x 36 x 10<br />

2 3 5<br />

Dimensional Information<br />

Type QL-WE-O<br />

<strong>Displacement</strong> terminal for flush mounting in a framed wall<br />

Plenum by others<br />

Single direction air<strong>flow</strong> discharge pattern<br />

D<br />

1<br />

H<br />

W<br />

Product Features<br />

• Designed for flush mounting in a framed wall<br />

• Face is removable, no visible fasteners<br />

• Plenum is by others<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Units listed below are standard sizes, other sizes available upon request.<br />

Listed Size<br />

W x H x D<br />

CFM Rangeª<br />

Nominal Size<br />

NC = 25 NC = 30 W H D<br />

15 x 16 x 3 3 /4 70 80 15 16 2 1 /4<br />

15 x 18 x 3 3 /4 85 100 15 18 2 1 /4<br />

15 x 24 x 3 3 /4 125 145 15 24 2 1 /4<br />

15 x 30 x 3 3 /4 150 175 15 30 2 1 /4<br />

15 x 36 x 3 3 /4 190 225 15 36 2 1 /4<br />

23 x 24 x 3 3 /4 195 230 23 24 2 1 /4<br />

23 x 30 x 3 3 /4 240 280 23 30 2 1 /4<br />

23 x 36 x 3 3 /4 305 360 23 36 2 1 /4<br />

23 x 42 x 3 3 /4 360 425 23 42 2 1 /4<br />

31 x 24 x 3 3 /4 295 345 31 24 2 1 /4<br />

31 x 30 x 3 3 /4 360 420 31 30 2 1 /4<br />

31 x 36 x 3 3 /4 455 535 31 36 2 1 /4<br />

31 x 42 x 3 3 /4 540 635 31 42 2 1 /4<br />

46 x 24 x 3 3 /4 465 545 46 24 2 1 /4<br />

46 x 30 x 3 3 /4 565 665 46 30 2 1 /4<br />

46 x 36 x 3 3 /4 720 845 46 36 2 1 /4<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

8

Technical Data<br />

Model QL-WE-O<br />

Type QL-WE-O<br />

15 x 16 x 3<br />

15 x 18 x 3<br />

15 x 24 x 3<br />

15 x 30 x 3<br />

15 x 36 x 3<br />

2 3 5<br />

Dimensional Information<br />

Type QL-WF-E/<br />

<strong>Displacement</strong> terminal for mounting adjacent to sidewall<br />

Rectangular inlet connection<br />

Single direction air<strong>flow</strong> discharge pattern<br />

a + 1<br />

a<br />

D<br />

b<br />

H<br />

W<br />

Product Features<br />

• Designed for mounting to a sidewall<br />

• Face is removable, no visible fasteners<br />

• Rectangular inlet sized for maximum performance<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Inlet Location<br />

• Top inlet (standard)<br />

• Bottom inlet (optional)<br />

Mounting Location<br />

• Mounting base (optional)<br />

• Duct cover (optional)<br />

Units listed below are standard sizes, other sizes available upon request.<br />

Listed Size<br />

CFM Rangeª<br />

Nominal Size Inlet<br />

W x H x D<br />

NC = 25 NC = 30 W H D<br />

b x a<br />

18 x 24 x 6 170 195 18 24 6 14 x 4<br />

18 x 30 x 6 210 235 18 30 6 14 x 4<br />

18 x 36 x 6 260 295 18 36 6 14 x 4<br />

18 x 48 x 8 355 405 18 48 8 14 x 6<br />

18 x 60 x 8 440 512 18 60 8 14 x 6<br />

24 x 30 x 8 310 350 24 30 8 14 x 6<br />

24 x 36 x 8 380 440 24 36 8 14 x 6<br />

24 x 48 x 8 485 565 24 48 8 16 x 6<br />

24 x 60 x 8 525 615 24 60 8 16 x 6<br />

30 x 30 x 8 365 425 30 30 8 14 x 6<br />

30 x 36 x 8 415 490 30 36 8 14 x 6<br />

30 x 48 x 8 655 770 30 48 8 20 x 6<br />

30 x 60 x 8 685 800 30 60 8 20 x 6<br />

36 x 36 x 8 610 690 36 36 8 24 x 6<br />

36 x 48 x 8 780 920 36 48 8 24 x 6<br />

36 x 60 x 8 820 960 36 60 8 24 x 6<br />

Actual inlet dimensions b and a are 1/8" less then nominal values stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

10

Technical Data<br />

Model QL-WF-E<br />

Type QL-WF-E/<br />

18 x 24 x 6<br />

18 x 30 x 6<br />

18 x 36 x 6<br />

18 x 48 x 8<br />

18 x 60 x 8<br />

2 4 6<br />

Dimensional Information<br />

Type QL-WF-RO/<br />

<strong>Displacement</strong> terminal for mounting to sidewall<br />

Round inlet connection<br />

One way air<strong>flow</strong> discharge pattern<br />

D<br />

d<br />

H<br />

W<br />

Product Features<br />

• Designed for mounting to a sidewall<br />

• Face removable, no visible fasteners<br />

• One way discharge pattern<br />

• Round inlet sized for maximum performance<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• Additional sizes available upon request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Inlet Location<br />

• Top inlet (standard)<br />

• Bottom inlet (optional)<br />

Mounting Location<br />

• Mounting base (optional)<br />

• Duct cover (optional, specify ceiling height)<br />

Units listed below are standard sizes, other sizes available upon request.<br />

Listed Size<br />

CFM Rangeª<br />

Nominal Size<br />

Inlet<br />

W x H x D NC = 25 NC = 30 W H D<br />

φd<br />

18 x 24 x 10 170 195 18 24 10 8 *<br />

18 x 30 x 10 205 235 18 30 10 8 *<br />

18 x 36 x 10 240 280 18 36 10 8 *<br />

18 x 48 x 12 350 400 18 48 12 10 *<br />

18 x 60 x 12 410 480 18 60 12 10 *<br />

24 x 30 x 12 305 350 24 30 12 10 *<br />

24 x 36 x 12 360 425 24 36 12 10 *<br />

24 x 48 x 12 395 465 24 48 12 12 *<br />

24 x 60 x 14 560 655 24 60 14 10 *<br />

30 x 30 x 12 345 405 30 30 12 10 *<br />

30 x 36 x 14 470 540 30 36 14 12<br />

30 x 48 x 14 570 670 30 48 14 12<br />

30 x 60 x 16 785 920 30 60 16 14<br />

36 x 36 x 14 525 615 36 36 14 12<br />

36 x 48 x 16 755 885 36 48 16 14<br />

36 x 60 x 16 780 915 36 60 16 14<br />

* Optional VFL <strong>flow</strong> limiter (see page 41 for details) available for these inlet sizes<br />

Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

12

Technical Data<br />

Model QL-WF-RO<br />

Type QL-WF-RO/<br />

18 x 24 x 10<br />

18 x 30 x 10<br />

18 x 36 x 10<br />

18 x 48 x 12<br />

18 x 60 x 12<br />

2 4 6 8<br />

Dimensional Information<br />

Type QL-WR-RO/<br />

<strong>Displacement</strong> terminal for free standing mounting<br />

Round inlet connection<br />

360° air<strong>flow</strong> discharge pattern d<br />

H<br />

D<br />

Product Features<br />

• Designed for free standing mounting<br />

• Circular inlet sized for maximum performance<br />

• Top or bottom inlet location<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Inlet Location<br />

• Top inlet (standard)<br />

• Bottom inlet (optional)<br />

Mounting Location<br />

• Mounting base (optional)<br />

• Duct cover (optional, 2 pc. specify ceiling height)<br />

Units listed below are standard sizes, other sizes are available upon request.<br />

Listed Size<br />

D x H<br />

CFM Rangeª<br />

Nominal Size<br />

NC = 25 NC = 30 D H d<br />

12 x 18 205 235 12 18 8 *<br />

14 x 18 265 300 14 18 10 *<br />

14 x 24 380 440 14 24 10 *<br />

14 x 30 425 500 14 30 10 *<br />

16 x 24 475 540 16 24 12<br />

16 x 30 560 650 16 30 12<br />

16 x 36 640 750 16 36 12<br />

18 x 30 680 775 18 30 14<br />

18 x 36 820 960 18 36 14<br />

18 x 48 930 1190 18 48 14<br />

20 x 36 980 1130 20 36 16<br />

20 x 48 1180 1385 20 48 16<br />

20 x 60 1230 1440 20 60 16<br />

24 x 36 1270 1435 24 36 20<br />

24 x 48 1700 1985 24 48 20<br />

24 x 60 1890 2220 24 60 20<br />

* Optional VFL <strong>flow</strong> limiter (see page 41) available for these inlet sizes<br />

ŧ Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

14

Technical Data<br />

Model QL-WR-RO<br />

Type QL-WR-RO/<br />

12 x 18 x 8<br />

14 x 18 x 10<br />

14 x 24 x 10<br />

14 x 30 x 10<br />

1 2 3<br />

Dimensional Information<br />

Type QL-WH-RO/<br />

<strong>Displacement</strong> terminal for mounting adjacent to sidewall<br />

Round inlet connection<br />

180º air<strong>flow</strong> discharge pattern<br />

C<br />

D<br />

W<br />

d<br />

H<br />

Product Features<br />

• Designed for flush mounting to a sidewall<br />

• 180º discharge pattern<br />

• Round inlet sized for maximum performance<br />

• Directional nozzles provide even air<strong>flow</strong> across<br />

face<br />

• No filter or fabric media requiring periodic<br />

changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Inlet Location<br />

• Top inlet (standard)<br />

• Bottom inlet (optional)<br />

Mounting Accesories<br />

• Mounting base (optional)<br />

• Duct cover (optional, specify ceiling height)<br />

Units listed below are standard sizes, other sizes available upon request.<br />

Listed Size<br />

CFM Rangeª<br />

Nominal Size<br />

C Inlet<br />

W x H x D<br />

NC = 25 NC = 30 W H D φd<br />

12 x 18 x 12 190 215 12 18 12 5 8 *<br />

12 x 24 x 12 245 285 12 24 12 5 8 *<br />

12 x 36 x 12 315 365 12 36 12 6 8 *<br />

12 x 48 x 12 320 375 12 48 12 6 8 *<br />

18 x 18 x 18 305 340 18 18 18 6 10 *<br />

18 x 24 x 18 390 450 18 24 18 6 10 *<br />

18 x 30 x 18 475 555 18 30 18 6 10 *<br />

18 x 36 x 18 620 720 18 36 18 7 12<br />

18 x 48 x 18 870 1020 18 48 18 8 14<br />

24 x 36 x 20 775 875 24 36 20 9 16<br />

24 x 48 x 20 1105 1290 24 48 20 9 16<br />

24 x 60 x 20 1255 1475 24 60 20 9 16<br />

30 x 30 x 28 955 1085 30 30 28 9 16<br />

30 x 36 x 28 1085 1265 30 36 28 9 16<br />

30 x 48 x 28 1270 1490 30 48 28 9 16<br />

30 x 60 x 28 1950 2235 30 60 28 11 20<br />

* Optional VFL <strong>flow</strong> limiter (see page 41 for details) available for these inlet sizes<br />

ŧ Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

16

Technical Data<br />

Type Model QL-WH-RO/ QL-WH-RO<br />

12 x 18 x 12<br />

12 x 24 x 12<br />

12 x 36 x 12<br />

12 x 48 x 12<br />

1 2 3 5<br />

Dimensional Information<br />

Type QL-WV-RO/<br />

<strong>Displacement</strong> terminal for mounting in a corner<br />

Round inlet connection<br />

90º air<strong>flow</strong> discharge pattern<br />

W<br />

C<br />

C<br />

W<br />

d<br />

H<br />

Product Features<br />

• Designed for mounting in a corner<br />

• 90º discharge pattern<br />

• Round inlet sized for maximum performance<br />

• Directional nozzles provide even air<strong>flow</strong> across<br />

face<br />

• No filter or fabric media requiring periodic<br />

changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Inlet Location<br />

• Top inlet (standard)<br />

• Bottom inlet (optional)<br />

Mounting Accesories<br />

• Mounting base (optional)<br />

• Duct cover (optional)<br />

Units listed below are standard sizes, other sizes available upon request.<br />

Listed Size<br />

CFM Rangeª Nominal Size<br />

C Inlet<br />

W x H<br />

NC = 25 NC = 30 W H φd<br />

12 x 18 155 175 12 18 5 8 *<br />

12 x 24 200 225 12 24 5 8 *<br />

12 x 30 250 290 12 30 5 8 *<br />

12 x 36 270 315 12 36 5 8 *<br />

12 x 42 285 335 12 42 5 8 *<br />

18 x 21 245 285 18 21 5 8 *<br />

18 x 24 255 295 18 24 5 8 *<br />

18 x 30 385 450 18 30 6 10 *<br />

18 x 36 410 485 18 36 6 10 *<br />

18 x 48 635 745 18 48 7 12<br />

18 x 60 670 770 18 60 7 12<br />

24 x 27 520 610 24 27 7 12<br />

24 x 30 550 645 24 30 7 12<br />

24 x 36 585 685 24 36 7 12<br />

24 x 48 990 1150 24 48 9 16<br />

24 x 60 1090 1280 24 60 9 16<br />

* Optional VFL <strong>flow</strong> limiter (see page 41 for details) available for these inlet sizes<br />

ŧ Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

18

Technical Data<br />

Model QL-WV-RO<br />

Type QL-WV-RO/<br />

12 x 18<br />

12 x 24<br />

12 x 30<br />

12 x 36<br />

12 x 42<br />

1 3 4 5<br />

Dimensional Information<br />

Type QL-WH-RO/.../K<br />

<strong>Displacement</strong> terminal with duct cover for sidewall mounting<br />

Round inlet connection<br />

180º air<strong>flow</strong> discharge pattern<br />

W<br />

C<br />

D<br />

d<br />

78"<br />

59"<br />

H<br />

Product Features<br />

• Designed for mounting to a sidewall,<br />

180º discharge<br />

• Round (top) inlet sized for maximum performance<br />

• Integral cover extends to 78 inches in height<br />

• Directional nozzles provide even air<strong>flow</strong><br />

across face<br />

• No filter or fabric media requiring periodic<br />

changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Mounting Accessories<br />

• Mounting base (optional)<br />

Performance • Extended duct cover Data (optional, specify<br />

ceiling height)<br />

Units listed below are standard sizes, other sizes available upon request.<br />

CFM Rangeª<br />

Nominal Size<br />

Listed Size<br />

W x H x D NC = 25 NC = 30 W H D<br />

12 x 24 x 12 245 285 12 24 12 5 8 *<br />

18 x 36 x 18 620 720 18 36 18 7 12<br />

24 x 48 x 20 1105 1290 24 48 19 9 16<br />

30 x 48 x 28 1270 1490 30 48 28 11 20<br />

* Optional VFL <strong>flow</strong> limiter (see page 41 for details) available for these inlet sizes<br />

ŧ Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

C<br />

Inlet<br />

φd<br />

K SP<br />

12 x 24 x 12<br />

18 x 36 x 18<br />

24 x 48 x 20<br />

30 x 48 x 28<br />

2 4 7<br />

Technical Data<br />

Type QL-WV-RO/.../K<br />

<strong>Displacement</strong> terminal with duct cover for corner mounting<br />

Round inlet connection<br />

90º air<strong>flow</strong> discharge pattern<br />

W<br />

C<br />

C<br />

d<br />

78"<br />

59"<br />

H<br />

Product Features<br />

• Designed for mounting to a sidewall, 90º discharge<br />

• Round (top) inlet sized for maximum performance<br />

• Integral cover extends to 78 inches in height<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic<br />

changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Mounting Accessories<br />

• Mounting base (optional)<br />

• Extended duct cover (optional, specify<br />

ceiling height)<br />

Performance Data<br />

Units listed below are standard sizes, other sizes available upon request.<br />

Listed Size<br />

W x H x D<br />

CFM Rangeª<br />

W<br />

Nominal Size<br />

NC = 25 NC = 30 W H<br />

* Optional VFL <strong>flow</strong> limiter (see page 41 for details) available for these inlet sizes<br />

ŧ Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

C<br />

Inlet<br />

φd<br />

12 x 24 200 225 12 24 5 8 *<br />

12 x 36 270 315 12 36 7 8 *<br />

18 x 36 410 485 18 36 9 10 *<br />

24 x 48 990 1150 24 48 11 16<br />

12 x 24 x 12<br />

12 x 36 x 12<br />

18 x 36 x 18<br />

24x 48 x 24<br />

1 3<br />

4<br />

Dimensional Information<br />

Model Type QL QL-WS-RO/...K<br />

- - / K<br />

<strong>Displacement</strong> terminal for mounting adjacent to sidewall<br />

Round inlet connection<br />

180º air<strong>flow</strong> discharge pattern<br />

C<br />

D<br />

d<br />

78"<br />

59"<br />

H<br />

Product Features<br />

• Designed for mounting adjacent to<br />

sidewall<br />

• 180º discharge pattern<br />

• Round inlet sized for maximum<br />

performance<br />

• Directional nozzles provide even air<strong>flow</strong><br />

across face<br />

• No filter or fabric media requiring<br />

periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Mounting Accesories<br />

• Duct cover extension (optional,<br />

specify ceiling height)<br />

• Mounting base (optional)<br />

Units listed below are standard sizes, other sizes available upon request.<br />

CFM Rangeª<br />

Nominal Size<br />

Listed Size<br />

Inlet<br />

C<br />

W x H x D φd<br />

NC = 25 NC = 30 W H D<br />

16 x 24 x 7 230 255 16 24 7 3 4<br />

16 x 30 x 7 275 310 16 30 7 3 4<br />

16 x 36 x 7 320 365 16 36 7 3 4<br />

16 x 42 x 7 270 430 16 42 7 3 4<br />

20 x 24 x 7 255 290 20 24 7 3 4<br />

20 x 30 x 7 310 350 20 30 7 3 4<br />

20 x 36 x 7 360 410 20 36 7 3 4<br />

20 x 42 x 7 445 525 20 42 7 3 4<br />

24 x 24 x 8 340 380 24 24 8 3 1 /2 5<br />

24 x 30 x 8 415 465 24 30 8 3 1 /2 5<br />

24 x 36 x 8 480 550 24 36 8 3 1 /2 5<br />

24 x 42 x 8 575 675 24 42 8 3 1 /2 5<br />

30 x 24 x 8 395 445 30 24 8 3 1 /2 5<br />

30 x 30 x 8 480 545 30 30 8 3 1 /2 5<br />

30 x 36 x 8 565 640 30 36 8 3 1 /2 5<br />

30 x 42 x 8 680 795 30 42 8 3 1 /2 5<br />

* Optional VFL <strong>flow</strong> limiter (see page 41 for details) available for these inlet sizes<br />

ŧ Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

22

Technical Data<br />

Type Model QL-WS-RO/...K QL-WS-RO / K<br />

16 x 24 x 7<br />

16 x 30 x 7<br />

16 x 36 x 7<br />

16 x 42 x 7<br />

2 3<br />

5<br />

Dimensional Information<br />

Model QL - WFM - E<br />

Type QL-WFM-E/<br />

Model QL - WFM - E<br />

<strong>Displacement</strong> terminal for mounting adjacent to a sidewall<br />

Rectangular inlet connection<br />

One way air<strong>flow</strong> discharge pattern<br />

a<br />

D<br />

b<br />

H<br />

W<br />

Product Features<br />

• Designed for mounting adjacent to a sidewall<br />

• 1 way discharge pattern<br />

• Rectangular inlet sized for maximum performance<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Inlet Location<br />

• Top inlet (standard)<br />

• Bottom inlet (optional)<br />

Mounting Accessories<br />

• Mounting base (optional)<br />

• Duct cover (optional, specify ceiling height)<br />

Units listed below are standard sizes, other sizes are available upon request.<br />

Listed Size<br />

CFM Range a<br />

Nominal Size Inlet<br />

W x H x D NC = 25 NC = 30 W H D b x a<br />

20 x 24 x 12 190 215 20 24 12 16 x 6<br />

20 x 30 x 12 245 275 20 30 12 16 x 8<br />

20 x 36 x 12 300 340 20 36 12 16 x 8<br />

20 x 48 x 14 415 465 20 48 14 16 x 12<br />

20 x 60 x 14 525 595 20 60 14 16 x 12<br />

24 x 30 x 14 325 370 24 30 14 20 x 10<br />

24 x 36 x 14 400 455 24 36 14 20 x 10<br />

24 x 48 x 14 570 645 24 48 14 20 x 12<br />

24 x 60 x 14 725 820 24 60 14 20 x 12<br />

30 x 30 x 14 450 505 30 30 14 24 x 8<br />

30 x 36 x 14 550 620 30 36 14 24 x 8<br />

30 x 48 x 14 715 810 30 48 14 24 x 12<br />

30 x 60 x 14 910 1025 30 60 14 24 x 12<br />

36 x 36 x 14 700 795 36 36 14 24 x 10<br />

36 x 48 x 14 990 1125 36 48 14 24 x 10<br />

36 x 60 x 14 1265 1435 36 60 14 30 x 10<br />

Actual b & a dimensions are 1/8" less then nominal value in the table<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

24

Technical Data<br />

Model QL-WFM-E<br />

Type QL-WFM-E/<br />

K SP<br />

A EFF<br />

20 x 24 x 12<br />

20 x 30 x 12<br />

20 x 36 x 12<br />

20 x 48 x 14<br />

20 x 60 x 14<br />

Air<strong>flow</strong> Rate (CFM)<br />

2 4 6 8 L 0.2<br />

Dimensional Information<br />

Type QL-WFM-E-2/<br />

<strong>Displacement</strong> terminal for mounting adjacent to the sidewall<br />

Rectangular inlet connection<br />

Two way direction air<strong>flow</strong> discharge pattern<br />

a<br />

D<br />

a<br />

D<br />

... - E2- L ... - E2- R<br />

b<br />

H<br />

W<br />

Product Features<br />

• Designed for mounting adjacent to a sidewall<br />

• Heavy duty reinforced face<br />

• Rectangular inlet sized for maximum performance<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Inlet Location<br />

• Top inlet (standard)<br />

• Bottom inlet (optional)<br />

Mounting Accessories<br />

• Mounting base (optional)<br />

• Duct cover (optional, specify ceiling height)<br />

Units listed below are standard sizes, other sizes are available upon request.<br />

Listed Size<br />

CFM Rangeª<br />

Nominal Size<br />

Inlet<br />

W x H x D<br />

NC = 25 NC = 30 W H D<br />

b x a<br />

20 x 24 x 12 280 320 20 24 12 16 x 6<br />

20 x 30 x 12 365 415 20 30 12 16 x 8<br />

20 x 36 x 12 450 510 20 36 12 16 x 8<br />

20 x 48 x 14 685 775 20 48 14 16 x 12<br />

20 x 60 x 14 865 985 20 60 14 16 x 12<br />

24 x 30 x 14 485 540 24 30 14 20 x 10<br />

24 x 36 x 14 585 650 24 36 14 20 x 10<br />

24 x 48 x 14 840 960 24 48 14 20 x 12<br />

24 x 60 x 14 995 1170 24 60 14 20 x 12<br />

30 x 30 x 14 605 670 30 30 14 24 x 8<br />

30 x 36 x 14 720 835 30 36 14 24 x 8<br />

30 x 48 x 14 960 1110 30 48 14 24 x 12<br />

30 x 60 x 14 1215 1410 30 60 14 24 x 12<br />

36 x 36 x 14 900 1020 36 36 14 24 x 10<br />

36 x 48 x 14 1205 1410 36 48 14 24 x 10<br />

36 x 60 x 14 1555 1810 36 60 14 30 x 10<br />

Actual b & a dimensions are 1/8" less then nominal value in the table<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

26

Technical Data<br />

Type Model QL-WFM-E-2/ QL-WFM-E-2<br />

K SP<br />

A EFF<br />

20 x 24 x 12<br />

2 3 5 7<br />

L 0.2<br />

Dimensional Information<br />

Model<br />

Model<br />

QL - WFM<br />

QL -<br />

-<br />

WFM<br />

E - 3<br />

- E - 3<br />

Type QL-WFM-E-3/<br />

<strong>Displacement</strong> terminal for mounting adjacent to a sidewall<br />

Rectangular inlet connection<br />

Three way air<strong>flow</strong> discharge pattern<br />

a<br />

D<br />

b<br />

H<br />

W<br />

Product Features<br />

• Designed for mounting adjacent to a sidewall<br />

• 3 way discharge pattern<br />

• Rectangular inlet sized for maximum performance<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Inlet Location<br />

• Top inlet (standard)<br />

• Bottom inlet (optional)<br />

Mounting Accesories<br />

• Mounting base (optional)<br />

• Duct cover (optional, specify ceiling height)<br />

Units listed below are standard sizes, other sizes are available upon request.<br />

Listed Size<br />

CFM Range a<br />

Nominal Size Inlet<br />

W x H x D NC = 25 NC = 30 W H D b x a<br />

20 x 24 x 12 375 425 20 24 12 16 x 6<br />

20 x 30 x 12 490 550 20 30 12 16 x 8<br />

20 x 36 x 12 590 675 20 36 12 16 x 8<br />

20 x 48 x 14 930 1075 20 48 14 16 x 12<br />

20 x 60 x 14 1080 1270 20 60 14 16 x 12<br />

24 x 30 x 14 650 735 24 30 14 20 x 10<br />

24 x 36 x 14 800 905 24 36 14 20 x 10<br />

24 x 48 x 14 1065 1250 24 48 14 20 x 10<br />

24 x 60 x 14 1185 1390 24 60 14 20 x 12<br />

30 x 30 x 14 770 870 30 30 14 24 x 8<br />

30 x 36 x 14 925 1065 30 36 14 24 x 8<br />

30 x 48 x 14 1270 1450 30 48 14 24 x 12<br />

30 x 60 x 14 1535 1790 30 60 14 24 x 12<br />

36 x 36 x 14 1080 1235 36 36 14 24 x 10<br />

36 x 48 x 14 1330 1560 36 48 14 24 x 10<br />

36 x 60 x 14 1735 2035 36 60 14 30 x 10<br />

Actual b & a dimensions are 1/8" less then nominal value in the table<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

28

Technical Data<br />

Model QL-WFM-E-3<br />

Type QL-WFM-E-3/<br />

K SP<br />

A EFF<br />

20 x 24 x 12<br />

20 x 30 x 12<br />

2 4<br />

6 7<br />

2 3 5 7 L 0.2<br />

Dimensional Information<br />

Model QL - WFT - …..<br />

Type QL-WFT...<br />

<strong>Displacement</strong> terminal for mounting to sidewall<br />

Rectangular (QL-WFT-E) or round (QL-WFT-RO) inlet<br />

Heavy duty reinforced face<br />

One way air<strong>flow</strong> discharge pattern<br />

a + 1<br />

a<br />

b<br />

D<br />

Model QL-WFT-E<br />

d<br />

D<br />

Model QL-WFT-RO<br />

H<br />

W<br />

Product Features<br />

• Designed for mounting to a sidewall<br />

• Rectangular (QL-WFT-E) or round (QL-WFT-RO)<br />

inlets sized for maximum performance<br />

• One way discharge pattern<br />

• Heavy duty reinforced face for industrial applications<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• Additional sizes available on request<br />

• No filter or fabric media requiring periodic changeout<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 18% free area<br />

• All surfaces powder coat white<br />

Accessories/Options<br />

Inlet Location<br />

• Top inlet (standard)<br />

• Bottom inlet (optional)<br />

Units listed below are standard sizes, other sizes are available upon request.<br />

Model QL-WFT-E<br />

Listed Size<br />

CFM Range a<br />

Nominal Size<br />

W x H x D NC = 25 NC = 30 W H D<br />

24 x 48 x 10 415 470 24 48 10 24 x 8<br />

31 x 36 x 10 375 425 30 1 /2 36 10 24 x 8<br />

31 x 48 x 10 520 585 30 1 /2 48 10 24 x 8<br />

31 x 60 x 10 715 805 30 1 /2 60 10 24 x 8<br />

31 x 72 x 10 835 950 30 1 /2 72 10 24 x 8<br />

36 x 48 x 10 625 705 36 48 10 28 x 8<br />

36 x 60 x 10 855 970 36 60 10 28 x 8<br />

36 x 72 x 10 1000 1140 36 72 10 28 x 8<br />

Model QL-WFT-RO<br />

Listed Size<br />

CFM Range a<br />

Nominal Size<br />

W x H x D NC = 25 NC = 30 W H D<br />

Inlet<br />

b x a<br />

24 x 48 x 14 460 525 24 48 14 8 *<br />

31 x 36 x 14 405 460 30 1 /2 36 14 8 *<br />

31 x 48 x 16 580 660 30 1 /2 48 16 14<br />

31 x 60 x 19 775 880 30 1 /2 60 19 16<br />

31 x 72 x 19 880 1015 30 1 /2 72 19 16<br />

36 x 48 x 19 700 795 36 48 19 16<br />

36 x 60 x 19 890 1035 36 60 19 16<br />

36 x 72 x 19 975 1145 36 72 19 16<br />

* Optional VFL <strong>flow</strong> limiter (see page 41 for details) available for these inlet sizes<br />

ŧ Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

Inlet<br />

d<br />

30

Technical Data<br />

Model QL-WFT-E<br />

Type QL-WFT-E<br />

24 x 48 x 10<br />

31 x 36 x 10<br />

31 x 48 x 10<br />

31 x 60 x 10<br />

3 6<br />

9 11<br />

Dimensional Information<br />

Type QL-WQT-RO<br />

<strong>Displacement</strong> terminal for free standing mounting<br />

Heavy duty reinforced face<br />

Round inlet connection<br />

Two, three or four way air<strong>flow</strong> discharge pattern<br />

W<br />

WQT-RO-2 WQT-RO-3 WQT-RO-4<br />

d<br />

H<br />

W<br />

Product Features<br />

• Designed for free standing or sidewall mounting<br />

• 2, 3 or 4 way discharge pattern<br />

• Round inlet sized for maximum performance<br />

• Heavy duty industrial construction<br />

• Directional nozzles provide even air<strong>flow</strong> across face<br />

• No filter or fabric media requiring periodic changeout<br />

• Additional sizes available on request<br />

Construction / Finish<br />

• Front face is 18 ga. steel<br />

• Plenum box and nozzle plate 20 ga. steel<br />

• Perforated face is 20% free area<br />

• All surfaces powder coat white<br />

Units listed below are standard sizes, other sizes are available upon request.<br />

Listed Size<br />

CFM Rangeª Nominal Size Inlet<br />

W x H<br />

NC = 25 NC = 30 W H<br />

d<br />

QL-WQT-RO-2<br />

30 x 48 1040 1175 30 48 26<br />

30 x 60 1430 1615 30 60 26<br />

36 x 60 1715 1940 36 60 32<br />

36 x 72 2025 2290 36 72 32<br />

QL-WQT-RO-3<br />

30 x 48 1560 1765 30 48 26<br />

30 x 60 2140 2420 30 60 26<br />

36 x 60 2570 2905 36 60 32<br />

36 x 72 3035 3435 36 72 32<br />

QL-WQT-RO-4<br />

30 x 48 2075 2345 30 48 26<br />

30 x 60 2745 3175 30 60 26<br />

36 x 60 3410 3870 36 60 32<br />

36 x 72 4000 4540 36 72 32<br />

ŧ Actual inlet diameter (φd) is 1/8" less then nominal value stated in the table.<br />

ª NC values include 10 dB room absorption in each octave band (125-4000 Hz)<br />

32

Technical Data<br />

Type QL-WQT-RO-2<br />

K SP<br />

A EFF<br />

30 x 48<br />

30 x 60<br />

36 x 60<br />

36 x 72<br />

2 5 7<br />

Technical Information<br />

General technical information regarding<br />

displacement ventilation systems<br />

Mixed air systems, widely used in North American nonresidential<br />

HVAC systems, discharge supply air at relatively<br />

high velocities in an attempt to create high levels of room air<br />

entrainment. The resultant room air mixture is homogenous<br />

with respect to both temperature and airborne (gaseous) contaminant<br />

levels. Heat gains are well distributed resulting in<br />

their sum having to be treated by the conditioned air passing<br />

through the space. Due to the outlets’ relatively high discharge<br />

velocities, they are generally located at the ceiling or otherwise<br />

separated from the occupied zone (stationary residents).<br />

Unlike mixed air systems, displacement conditioning systems<br />

discharge conditioned air at low velocities (typically 60 fpm or<br />

less) in an attempt to minimize entrainment and mixing with<br />

room air. As such the supply air stream quickly falls to the floor<br />

and spreads across the lower level of the space similar to a<br />

liquid spill. This conditioned air is confined to the lower part of<br />

the space by warmer ambient air above it.<br />

Convective heat sources transferring heat to the ambient<br />

air around them create natural convection plumes that rise<br />

vertically above them. These plumes will rise to the level where<br />

they either encounter equally warm air or a physical boundary<br />

such as a ceiling. Air from beneath the heat source is drawn<br />

upward to replenish that displaced by the rising convection<br />

plume. If a heat source is near the supply air layer, it is this<br />

conditioned air that is drawn up over it, making a single vertical<br />

pass through the space. The entrained air conditions the<br />

heat source and transports any respiratory and/or olfactory<br />

contaminants associated with the source to the upper part of<br />

the space where the return air inlet is located.<br />

<strong>Displacement</strong> outlets are generally positioned in the floor or<br />

at a low sidewall location, but in certain circumstances may<br />

also be located above the occupied zone. As such, a higher<br />

discharge air temperature (typically 62 to 67ºF) is usually<br />

employed where stationary occupants are involved.<br />

Temperature gradients and occupant thermal<br />

comfort in displacement systems<br />

The room air mixture in areas conditioned by displacement<br />

systems remains thermally stratified with the lowest temperature<br />

air remaining at the floor and the warmest in the region<br />

adjacent to the ceiling.<br />

As displacement outlets are generally located within or near<br />

the occupied zone, a certain separation between the outlet<br />

and the occupants should be observed to avoid draft<br />

problems. Stationary occupants should not be located within<br />

the area adjacent to the outlet in which velocities exceeding<br />

40 fpm (0.2 m/s) are likely to be found. This area is referred<br />

to as the outlet’s adjacent or near zone and is denoted by the<br />

nomenclature L 0.2<br />

. The extent of this zone is determined by the<br />

outlet’s height, geometry and face velocity as well as the temperature<br />

difference between the room and supply air.<br />

<strong>TROX</strong> displacement outlets utilize an array of nozzles specifically<br />

designed to maximize the spread of the supply air<strong>flow</strong><br />

across the outlet face. In addition to providing pressure equalization,<br />

these nozzles also serve as turning devices that scoop<br />

the supply air and turn it such that its <strong>flow</strong> direction is perpendicular<br />

to the diffuser face. By doing so, <strong>TROX</strong> is able to offer<br />

the shortest adjacent zones in the industry allowing more efficient<br />

use of the floor space by the occupants.<br />

The performance charts in this leaflet indicate outlet adjacent<br />

zones for a temperature differential (Δt u<br />

) of 10ºF (5.6ºK)<br />

between the room and supply air. Table 1 (page 2) provides L 0.2<br />

correction factors for other Δt u<br />

values.<br />

ANSI/ASHRAE Standard 55-2004 Thermal Environmental<br />

Conditions for Human Occupancy limits the temperature gradient<br />

between the ankle and head level of stationary space<br />

occupants to no more than 3ºK (5.4ºF) if a high level of thermal<br />

comfort (10% or less PPD) is to be maintained. The ankle and<br />

head levels of seated occupants are considered to be 0.1 and<br />

1.1 m (4 and 42 inches) respectively.<br />

Contaminant removal and ventilation effectiveness<br />

with displacement systems<br />

The single vertical passage of air in the vicinity of the occupants<br />

results in enhanced contaminant removal efficiencies<br />

as well as more effective space ventilation. Table 6-1 of ANSI/<br />

ASHRAE Standard 62.1-2004 Ventilation for Acceptable Indoor<br />

Air Quality awards thermal displacement systems a ventilation<br />

effectiveness of 1.2 which essentially means that similar ventilation<br />

effects can be produced by displacement systems delivering<br />

twenty (20) percent less outdoor air than a fully mixed<br />

room air distribution system. A recent ASHRAE research project<br />

(RP-1373) studied the ventilation effectiveness of displacement<br />

systems in various applications and suggests that the<br />

ventilation effectiveness of thermal displacement systems is as<br />

high as 1.35 for offices and classrooms and 2.0 for workshops<br />

and auditoriums.<br />

34

Technical Information<br />

Supply temperature and air<strong>flow</strong> relationships<br />

for displacement systems<br />

Although displacement supply air temperatures are typically<br />

several degrees warmer than those employed in conventional<br />

mixed air systems, the return air temperature is also higher,<br />

resulting in a space supply air<strong>flow</strong> rate that is usually quite<br />

similar.<br />

The design nomograph presented on page 38 affords the<br />

designer a method to easily identify a supply air<strong>flow</strong> rate that<br />

is sufficient to satisfy the space heat gains while maintaining<br />

a high level of occupant thermal comfort. Use of this chart<br />

and the associated air<strong>flow</strong> rate determination procedures will<br />

assure that the required cooling is accomplished while limiting<br />

the space vertical temperature gradient to less than 1ºF<br />

per foot (3.6ºK) as prescribed by ANSI/ASHRAE Standard<br />

55-2004. Design examples for a classroom and an atrium are<br />

provided to assist in the use of this chart.<br />

Common applications favoring displacement conditioning<br />

systems<br />

<strong>Displacement</strong> conditioning is ideal for applications where highly<br />

efficient gaseous contaminant removal is desired. Classrooms,<br />

waiting areas and patient rooms in hospitals commonly rely on<br />

displacement systems to reduce ambient CO 2<br />

levels, thereby<br />

reducing the risk of disease spread by respiratory means.<br />

Industrial applications often rely on displacement systems to<br />

allow warm gases and their associated fumes to escape occupied<br />

levels naturally.<br />

<strong>Displacement</strong> systems are also often used to reduce HVAC<br />

energy requirements. The thermal stratification produced by<br />

displacement systems can be applied to high ceiling areas<br />

such as atriums and transportation halls to isolate rising heat<br />

plumes to the upper levels of the space. This results in higher<br />

supply to return air temperature differentials which require<br />

lower supply air<strong>flow</strong> rates than mixed air systems.<br />

<strong>Displacement</strong> systems can also be effectively employed in<br />

spaces where the removal of odors associated with heat<br />

sources is desired. Applications such as restaurants and casinos<br />

where smoking is allowed are such examples. Odors associated<br />

with space heat sources (food or tobacco smoke) are<br />

transported out of the occupied zone by their thermal plumes<br />

and do not affect the other occupants of the space.<br />

Application recommendations regarding<br />

displacement conditioning systems<br />

Certain limitations should be observed when designing thermal<br />

displacement systems. Among these are,<br />

1. For most applications (well distributed space heat<br />

gains up to about 30 btuh/ft 2 ), displacement <strong>diffusers</strong><br />

are capable of serving an area within about a thirty<br />

foot radius of the diffuser face. This area may be<br />

reduced when greater space heat loads are present or<br />

when high intensity heat sources are located near the<br />

floor and within the coverage radius aforementioned.<br />

2. Supply air temperatures for displacement systems<br />

serving spaces with primarily stationary occupants<br />

should be no more than 14 °F below the room temperature<br />

at the occupants’ head level. In the case of<br />

transient occupancy, this differential can be as high as<br />

20 °F.<br />

3. Average face velocities should be maintained at 60<br />

fpm (0.3 m/s) or less for thermal comfort applications<br />

involving stationary occupants. These may be as high<br />

as 80 fpm (0.4 m/s) when applied to industrial spaces<br />

or to spaces with transient occupancy.<br />

4. When used for thermal comfort applications the space<br />

vertical temperature gradient should not exceed 1 °F<br />

per linear foot (2°K per linear meter).<br />

5. Stationary occupants should not be located within<br />

identified outlet adjacent zones (L 0.2<br />

) in order to assure<br />

that the occupants are not subjected to cold drafts<br />

near their ankles.<br />

6. When used in applications requiring a high degree<br />

of occupant thermal comfort, unit heights should be<br />

limited to no more than five (5) feet as taller units tend<br />

to create a “waterfall” effect which extends adjacent<br />

zones and results in higher associated draft risks.<br />

7. Heating with displacement systems should not be<br />

attempted except in very mild climates, therefore a<br />

separate heating system is generally required. In<br />

cases where heating is done by the displacement <strong>diffusers</strong>,<br />

ventilation effectiveness advantages are offset<br />

by the vertical rise of the warm air near its point of<br />

discharge.<br />

35

<strong>Displacement</strong> Chilled Beams<br />

Although displacement systems are highly regarded for their<br />

contamination removal efficiencies, there are dehumidification<br />

and associated energy issues which have limited their use in<br />

high humidity areas within North America.<br />

<strong>Displacement</strong> outlets systems employ higher discharge air temperatures<br />

(typically 62 to 67°F) than those used for mixed air<br />

systems. In order to satisfy the space latent load, the mixture of<br />

outside and return air being reconditioned by the air handling<br />

unit’s cooling coil must be lowered to a similar dew point temperature,<br />

typically 52 to 54°F (11 to 12°C), as that of a mixed<br />

air system. Conventional cooling/dehumidification systems cool<br />

the supply air mixture to such a dew point temperature, then<br />

somehow reheat it prior to its delivery to the space. Figure 1<br />

illustrates such a process utilizing a bypass of return air around<br />

the cooling coil to reheat the mixture to its desired delivery temperature.<br />

Dedicated outdoor air systems (DOAS) with desiccant<br />

capabilities can provide lower dew point temperatures without<br />

such reheat but cost much more than conventional air handling<br />

equipment.<br />

Outdoor<br />

Air<br />

Return Air<br />

(80 to 85°F)<br />

Figure 1: AHU configuration for an all-air displacement<br />

system in humid climate<br />

Supply Air<br />

(62 to 67°F)<br />

<strong>TROX</strong> QLCI series displacement chilled beams combine the<br />

energy savings of an air water system with the acoustical and<br />

contamination removal benefits of a displacement system. Primary<br />

air is delivered from the air handling unit at a conventional<br />

supply air temperature (53 to 57 °F) and injected though a series<br />

of nozzles which entrain room air through the face of the beam<br />

and an integral heat transfer coil. This entrained air is reconditioned<br />

then mixed with the primary air. This mixture is discharged<br />

to the space at a air temperature that varies according to the<br />

instantaneous space cooling requirement. The heat transfer coil<br />

utilizes chilled water supplied at a temperature at or above the<br />

room dew point temperature in order to prevent condensation on<br />

its surfaces.<br />

<strong>Displacement</strong> chilled beams remove approximately 60% of<br />

the space sensible heat gain by means of their chilled water,<br />

enabling the primary air<strong>flow</strong> rate to be reduced accordingly.<br />

The use of conventional ducted air temperatures eliminates the<br />

need for reheat on the AHU. Coupled with the primary air<strong>flow</strong><br />

reduction affected by their sensible cooling coil, displacement<br />

chilled beams offer significant reductions in ductwork and air<br />

handling unit size as well as operational cost savings.<br />

Primary air from AHU<br />

(53 to 57°F)<br />

Chilled water supply<br />

Induced room air<br />

(74 to 76°F)<br />

<strong>Displacement</strong> chilled beams are ideal for use in classrooms and<br />

healthcare applications. In the latter case, a MERV-8 filter can be<br />

supplied if required. For more information on QLCI displacement<br />

chilled beams, please contact <strong>TROX</strong> USA or visit our website at<br />

www.troxusa.com.<br />

Supply air to space<br />

(62 to 68°F)<br />

Figure 2: <strong>TROX</strong> QLCI series displacement chilled beams<br />

36

Temperature relationships - Nomenclature<br />

Q Btuh/ft² Heat load (per square foot of floor area)<br />

CFM<br />

Supply <strong>flow</strong> rate<br />

/A CFM/ft² Supply <strong>flow</strong> rate per ft² floor area<br />

ρ lb/ft³ Air density<br />

c p btuh/lb - °F Specific heat of air<br />

h R ft Room height<br />

t Z °F Supply air temperature<br />

t h1 °F Air temperature at approx. 4 in (0.1 m) above the floor<br />

t h2 °F Room temperature at approx. 42 in (1.0 m) above the floor<br />

t A °F Extract air temperature<br />

Δt °F Difference between extract air temperature and supply air temperature<br />

Δt 1 °F Difference between floor air temperature t h1 and supply air temperature t Z<br />

Δt u °F Difference between room temperature t h2 and supply air temperature t Z<br />

Δt C °F Temperature gradient (t h2 – t h1 ) within the occupied zone<br />

L 0.2 ft Radius of diffuser adjacent zone<br />

Design chart on page 38 is based on standard air at sea level<br />

ρ = .075 lb/ft 3<br />

c p = 0.24 btu/lb-°F<br />

37

Design Nomograph Supply air<strong>flow</strong> determination<br />

ρ = .075 lb/ft 3<br />

c p = 0.24 btu/lb-°F<br />

t<br />

°F<br />

34<br />

CFM/ft 2<br />

0.2 0.4 0.6 0.8 1.0 1.2 1.4<br />

t u<br />

°F<br />

20<br />

16 15<br />

14<br />

13<br />

t 1<br />

°F<br />

32<br />

19<br />

12<br />

30<br />

1.6<br />

18<br />

28<br />

26<br />

1.8<br />

17<br />

16<br />

2<br />

11<br />

10<br />

24<br />

2.0<br />

2<br />

15<br />

14<br />

9<br />

22<br />

20<br />

2.2<br />

2.4<br />

13<br />

12<br />

rH<br />

16 ft<br />

1<br />

8<br />

18<br />

16<br />

14<br />

2.6<br />

2.8<br />

3.0<br />

1<br />

fpm<br />

11<br />

10<br />

9<br />

8<br />

rH = 14 ft<br />

rH = 12 ft<br />

rH = 10 ft<br />

7<br />

6<br />

5<br />

12<br />

7<br />

1<br />

2<br />

4<br />

10<br />

6<br />

rH = 8 ft<br />

3<br />

8<br />

1<br />

2 1 2<br />

5<br />

6<br />

4<br />

3<br />

4<br />

2<br />

2<br />

0<br />

0 8 16 24 32 40<br />

48<br />

8<br />

10 12 14<br />

16<br />

0.5 1.0 1.5 2.0 2.5 3.0<br />

Sensible Heat Gain Q SENS (Btuh/ft 2 )<br />

Room Height rH (ft.)<br />

Air<strong>flow</strong> Rate (CFM/ft 2 )<br />

Procedure for supply air<strong>flow</strong> rate determination<br />

1. Enter the center section of the design chart and draw a vertical line that coincides with the ceiling height (rH).<br />

2. Identify where the vertical line intersects the desired under temperature (Δt u<br />

). The under temperature is the<br />

temperature differential between the room and supply air.<br />

3. Draw a horizontal line through the intersection that spans all three sections of the design chart. The resultant<br />

temperature differential (Δt) between the supply and exhaust air is indicated on the left side of the chart.<br />

4. Draw a vertical line (coincident with the space sensible heat gain) through the left section of the chart. Identify the point<br />

where this line intersects with the horizontal line drawn in step 3. The intersection of these lines identifies the required<br />

supply air<strong>flow</strong> rate for the under temperature (Δt u<br />

) specified.<br />

5. Enter the right section of the chart and draw a vertical line corresponding to the supply air<strong>flow</strong> rate identified in step 4.<br />

The intersection of this and the horizontal line (from step 3) will identify the value of Δt 1<br />

.<br />

6. If the intersection point is left of the curve relating to the applicable ceiling height, a good comfort level (T R<br />

– T B<br />

≤ 3.6 ºF)<br />

will be achieved. The actual value of T R<br />

– T B<br />

can be determined by subtracting Δt 1<br />

from Δt u.<br />

38

Design Examples<br />

Example 1:<br />

A 900 square foot classroom is to be served by displacement<br />

ventilation with a supply air temperature of 64 ºF. The classroom<br />

ceiling height is 10 feet.<br />

The design criteria are as follows:<br />

Q SENS<br />

= 27,000 Btuh = 30.0 Btuh/ft 2<br />

T R<br />

= 76 ºF<br />

T R<br />

– T B<br />

≤ 3.6 ºF<br />

Δt u<br />

= T ROOM<br />

– T SUPPLY<br />

= 76 – 64 = 12 ºF<br />

Determine the supply air<strong>flow</strong> rate that will satisfy the design<br />

requirements.<br />

Solution:<br />

1. At (Δt u<br />

) of 12 ºF and rH = 10 feet, Δt = 17.9 ºF<br />

2. The intersection of the vertical line running through<br />

Q SENS<br />

= 30 Btuh/ft 2 and the horizontal line at Δt =<br />

17.9ºF indicates that the required supply air<strong>flow</strong> rate<br />

will be 1.55 CFM/ft 2 .<br />

3. A vertical line drawn through the supply air<strong>flow</strong> rate<br />

of 1.55 CFM/ft 2 intersects the horizontal line at Δt 1<br />

=<br />

8.8 ºF. The occupied zone temperature differential<br />

(T R<br />

– T B<br />

) is approximately 3.2 ºF (see step 6 of the<br />

procedures above). This is compliant with the design<br />

criteria.<br />

Diffuser selection:<br />

Two (2) QL-WV-RO <strong>diffusers</strong> will be placed in the corners of<br />

the classroom opposite its outside wall. ANSI S12.60 stipulates<br />

that the background noise level for the classroom not exceed<br />

NC27.<br />

The supply air<strong>flow</strong> requirement for the classroom is 1.55 CFM/<br />

ft 2 or 1,395 CFM, thus each unit must supply 698 CFM.<br />

The performance data for the QL-WV-RO on page 19 indicates<br />

that a size 24 x 48 terminal can supply the required air<strong>flow</strong> at<br />

an NC less than 25. The inlet static pressure (ΔP S) for this <strong>flow</strong><br />

rate can be calculated by inserting and the KSP factor (2,927)<br />

into the formula on page 2:<br />

ΔP S = (698/2,927) 2 = .057 in.w.g.<br />

The near zone value (7 feet) must be multiplied by the correction<br />

factor for Δt U (1.14) in table 2, indicating occupants should<br />

not be located within eight (8) feet of the corner mounted <strong>diffusers</strong>.<br />

Example 2:<br />

A 2,000 square foot atrium is to be served by displacement<br />

ventilation with a supply air temperature of 62 ºF. The ceiling<br />

height is 20 feet.<br />

The design criteria are as follows:<br />

Q SENS<br />

= 90,000 Btuh = 45 Btuh/ft 2<br />

T R<br />

= 76 ºF<br />

T R<br />

– T B<br />

≤ 3.6 ºF<br />

Δt u<br />

= T ROOM<br />

– T SUPPLY<br />

= 76 – 62 = 14 ºF<br />

Determine the supply air<strong>flow</strong> rate that will satisfy the design<br />

requirements.<br />

Solution:<br />

1. At (Δt u<br />

) of 14 ºF and rH = 16+ feet, Δt = 23.2 ºF<br />

2. The intersection of the vertical line running through<br />

Q SENS<br />

= 45 Btuh/ft 2 and the horizontal line at Δt =<br />

23.2ºF indicates that the required supply air<strong>flow</strong> rate<br />

will be 1.78 CFM/ft 2 .<br />

3. A vertical line drawn through the supply air<strong>flow</strong> rate<br />

of 1.78 CFM/ft 2 intersects the horizontal line at Δt 1<br />

=<br />

11 ºF. The occupied zone temperature differential (T R<br />

– T B<br />

) is approximately 3 ºF (see step 6 of the determination<br />

procedures). This is compliant with the design<br />

criteria.<br />

Diffuser selection:<br />

Three (3) QL-WH-RO <strong>diffusers</strong> will be spaced equally along an<br />

inside wall. As this is an atrium and its occupants are primarily<br />

transient, NC levels up to 40 will be considered acceptable.<br />

The supply air<strong>flow</strong> requirement for the classroom is 1.78 CFM/<br />

ft 2 or 3,560 CFM, thus each unit must supply 1,187 CFM.<br />

The performance data for the QL-WH-RO on page 17 indicates<br />

that a size 20 x 48 x 20 terminal can supply the required air<strong>flow</strong><br />

at an NC of around 32 . The inlet static pressure (ΔP S) for<br />

this <strong>flow</strong> rate can be calculated by inserting and the KSP factor<br />

(3,152) into the formula on page 2:<br />

ΔP S = (1,187/3,152) 2 = 0.14 in.w.g.<br />

The near zone value (7 feet) must be multiplied by the correction<br />

factor for Δt U (1.62) in table 2, but the fact that occupants<br />

are transient makes this value relatively unimportant.<br />

39

Mounting details<br />

4<br />

Installation and Mounting<br />

Models QL-WE-E, QL-WE-RO and QL-WE-O<br />

3<br />

1. Remove face from unit (face snaps out).<br />

2. Insert plenum/nozzle assembly between wall studs.<br />

3. Fasten plenum/nozzle assembly to wall studs.<br />

2<br />

4. Install and connect inlet ductwork.<br />

6<br />

5. Complete drywall installation.<br />

6. After all drywall installation is complete, re-install face.<br />

Hatch as wood stud<br />

5<br />

7<br />

mouting-1.ai<br />

Installation and Mounting<br />

Models QL-WV-RO/…, QL-WH-RO/…,<br />

and QL-WS-RO/K<br />

1. If applicable, attach mounting base to floor.<br />

2. Attach lower mounting angles to drywall.<br />

3. Place unit on base (where applicable) and attach to<br />

lower angles.<br />

6<br />

4. If applicable, cut upper angles to extend above the<br />

ceiling plane.<br />

3<br />

5. If applicable, attach upper mounting angles to wall.<br />

2<br />

1<br />

3<br />

6. Attach inlet ductwork.<br />

7. If applicable, attach duct cover to upper mounting angles.<br />

4<br />

mouting-2.ai<br />

Installation and Mounting<br />

Models QL-WF-E, and QL-WF-RO<br />

7<br />

5<br />

6<br />

5<br />

7<br />

1. If applicable, attach mounting base to floor.<br />

2. Remove face (snaps out) and nozzle plate.<br />

3. Fasten unit to floor (or mounting base) and wall as shown.<br />

4. If applicable, cut mounting angles to extend above<br />

the ceiling.<br />

5. If applicable, attach mounting angles to wall.<br />

2<br />

2<br />

6. Attach inlet ductwork.<br />

7. If applicable, attach duct cover to mounting angles.<br />

3<br />

1<br />

40<br />

mouting-3.ai

Volume Flow Limiter<br />

4<br />

1<br />

4<br />

Installation and Mounting<br />

Models QL-WFM-E/…, and QL-WFT-E<br />

1. Attach mounting angles to wall.<br />

2. Position unit between mounting angles.<br />

3. Fasten unit to mounting angles.<br />

4. Attach inlet ductwork.<br />

2<br />

3<br />

mouting-4.ai<br />

Volume control options<br />

Installation and Mounting<br />

<strong>TROX</strong> model VFL <strong>flow</strong> regulators can be fitted directly to the<br />

round inlet connection on certain displacement units. This limiter<br />

is fully self-contained and requires no power or control connections.<br />

It may be field set to maintain a constant volume <strong>flow</strong> rate<br />

to the unit. The VFL compensates for system pressure changes<br />

to maintain the beam’s design air<strong>flow</strong> rate.<br />

VFL <strong>flow</strong> limiters require a minimum of 0.15 inches H 2<br />

O differential<br />

static pressure to operate. This must be added to the<br />

catalogued pressure loss of the displacement unit to arrive at<br />

an appropriate inlet static pressure requirement. For acoustical<br />

reasons, the inlet static pressure should not exceed 1.0 inches<br />

H 2<br />

O. More information on VFL <strong>flow</strong> limiters may be found in<br />

<strong>TROX</strong> leaflet 5/9.2/EN/3.<br />

41

Specification text<br />

General information<br />

<strong>TROX</strong> displacement <strong>flow</strong> <strong>diffusers</strong> for optimum discharge of conditioned air to the room using the displacement <strong>flow</strong> principle. Completely<br />

uniform velocity profile with special nozzles with integral air deflection scoops.<br />

Type QL-WE-E/ for flush installation in a framed wall<br />

Air distribution face plate with integral geometrically arranged plastic<br />

nozzles with deflection scoops. Every nozzle provides a constant<br />

<strong>flow</strong> rate from the passing airstream and directs it to<br />

the face plate. Perforated flat sheet metal face providing a<br />

low-turbulence low velocity discharge, galvanized sheet steel,<br />

powder-coated, standard color white, other colors optional.<br />

Rectangular air inlet.<br />

Type QL-WE-RO/ for flush installation in a framed wall<br />

Air distribution face plate with integral geometrically arranged plastic<br />

nozzles with deflection scoops. Every nozzle provides a constant<br />

<strong>flow</strong> rate from the passing airstream and directs it to<br />

the face plate. Perforated flat sheet metal face providing a<br />

low-turbulence low velocity discharge, galvanized sheet steel,<br />

powder-coated, standard color white, other colors optional.<br />

Round air inlet.<br />

Type QL-WE-O/ for flush installation in a framed wall<br />

Air distribution face plate with integral geometrically arranged plastic<br />

nozzles with deflection scoops. Every nozzle provides a constant<br />

<strong>flow</strong> rate from the passing airstream and directs it to<br />

the face plate. Perforated flat sheet metal face providing a<br />

low-turbulence low velocity discharge, galvanized sheet steel,<br />

powder-coated, standard color white, other colors optional.<br />

Plenum by others.<br />

Type QL-WF-E/ and Type QL-WF-RO/ for sidewall installation,<br />

one way discharge, available with base and duct cover<br />

Air distribution face plate with integral geometrically arranged plastic<br />

nozzles with deflection scoops. Every nozzle provides a constant<br />

<strong>flow</strong> rate from the passing airstream and directs it to the face<br />

plate. Compact welded construction. Perforated flat sheet metal<br />

face providing a low-turbulence low velocity discharge, galvanized<br />

sheet steel, powder-coated, standard color white, other colors optional.<br />

Type QL-WF-E has rectangular inlet<br />

connection. Type QL-WF-RO has round inlet connection.<br />

Options: base and/or duct cover.<br />

Type QL-WH-RO/ and Type QL-WH-RO/.../K semi circular unit<br />

for sidewall installation, available with base<br />

Air distribution face plate with integral geometrically arranged<br />

plastic nozzles with deflection scoops. Every nozzle provides a<br />

constant <strong>flow</strong> rate from the passing airstream and directs it to the<br />

face plate. Perforated sheet metal face providing a lowturbulence<br />

low velocity discharge, galvanized sheet steel,<br />

powder-coated, standard color white, other colors optional. Round<br />

air inlet.<br />

Type QL-WH-RO/ without a duct cover<br />

Type QL-WH-RO/.../K with a duct cover (78’’ tall), base and/or<br />

duct cover extension on request.<br />

Type QL-WV-RO/ and Type QL-WV-K-RO/.../K<br />

quarter-round unit for corner installation, available with<br />

base<br />