Cover FTM en 18mm - Motek

Cover FTM en 18mm - Motek Cover FTM en 18mm - Motek

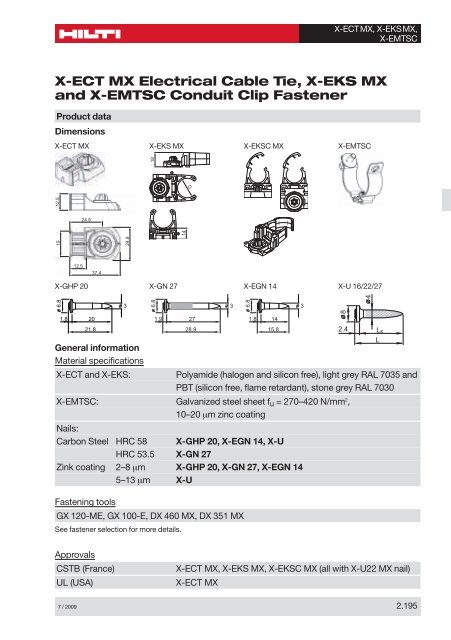

D X-ECTMX, X-EKSMX, X-EMTSC X-ECT MX Electrical Cable Tie, X-EKS MX and X-EMTSC Conduit Clip Fastener Product data Dimensions X-ECT MX X-EKS MX X-EKSC MX X-EMTSC 18 X-GHP 20 X-GN 27 X-EGN 14 X-U 16/22/27 4 12.5 24.5 19 24.9 14 12.5 37.4 o 6.8 1.8 20 21.8 General information Material specifications X-ECT and X-EKS: Polyamide (halogen and silicon free), light grey RAL 7035 and PBT (silicon free, flame retardant), stone grey RAL 7030 X-EMTSC: Galvanized steel sheet f u = 270–420 N/mm 2 , 10–20 μm zinc coating Nails: Carbon Steel HRC 58 X-GHP 20, X-EGN 14, X-U HRC 53.5 X-GN 27 Zink coating 2–8 μm X-GHP 20, X-GN 27, X-EGN 14 5–13 μm X-U Fastening tools o 3 o 6.8 GX 120-ME, GX 100-E, DX 460 MX, DX 351 MX 1.9 See fastener selection for more details. 27 28.9 o 3 o 6.8 1.8 14 15.8 o 3 8 2.4 Ls L Approvals CSTB (France) UL (USA) X-ECT MX, X-EKS MX, X-EKSC MX (all with X-U22 MX nail) X-ECT MX 7 / 2009 2.195

- Page 2 and 3: X-ECTMX, X-EKSMX, X-EMTSC Applicati

- Page 4 and 5: X-ECTMX, X-EKSMX, X-EMTSC Fastener

- Page 6: X-ECTMX, X-EKSMX, X-EMTSC Fastening

D<br />

X-ECTMX, X-EKSMX,<br />

X-EMTSC<br />

X-ECT MX Electrical Cable Tie, X-EKS MX<br />

and X-EMTSC Conduit Clip Fast<strong>en</strong>er<br />

Product data<br />

Dim<strong>en</strong>sions<br />

X-ECT MX<br />

X-EKS MX<br />

X-EKSC MX<br />

X-EMTSC<br />

18<br />

X-GHP 20<br />

X-GN 27<br />

X-EGN 14<br />

X-U 16/22/27<br />

4<br />

12.5<br />

24.5<br />

19<br />

24.9<br />

14<br />

12.5<br />

37.4<br />

o 6.8<br />

1.8<br />

20<br />

21.8<br />

G<strong>en</strong>eral information<br />

Material specifications<br />

X-ECT and X-EKS:<br />

Polyamide (halog<strong>en</strong> and silicon free), light grey RAL 7035 and<br />

PBT (silicon free, flame retardant), stone grey RAL 7030<br />

X-EMTSC: Galvanized steel sheet f u = 270–420 N/mm 2 ,<br />

10–20 μm zinc coating<br />

Nails:<br />

Carbon Steel HRC 58 X-GHP 20, X-EGN 14, X-U<br />

HRC 53.5 X-GN 27<br />

Zink coating 2–8 μm X-GHP 20, X-GN 27, X-EGN 14<br />

5–13 μm X-U<br />

Fast<strong>en</strong>ing tools<br />

o 3<br />

o 6.8<br />

GX 120-ME, GX 100-E, DX 460 MX, DX 351 MX<br />

1.9<br />

See fast<strong>en</strong>er selection for more details.<br />

27<br />

28.9<br />

o 3<br />

o 6.8<br />

1.8<br />

14<br />

15.8<br />

o 3<br />

8<br />

2.4<br />

Ls<br />

L<br />

Approvals<br />

CSTB (France)<br />

UL (USA)<br />

X-ECT MX, X-EKS MX, X-EKSC MX (all with X-U22 MX nail)<br />

X-ECT MX<br />

7 / 2009 2.195

X-ECTMX, X-EKSMX,<br />

X-EMTSC<br />

Applications<br />

Examples<br />

Flexible or rigid cable conduits<br />

with cable ties<br />

Rigid conduits<br />

Cable conduits or light duty<br />

pipes<br />

Load data<br />

Design data<br />

Recomm<strong>en</strong>ded loads<br />

Service load 1 )<br />

Fast<strong>en</strong>er<br />

[kN]<br />

X-ECT MX 0.04<br />

X-EKS MX 0.02<br />

X-EMTSC MX 0.05<br />

1<br />

) The recomm<strong>en</strong>ded service load is determined by the serviceability of the plastic part.<br />

Test data (Examples)<br />

Important note: test data are for information only.<br />

Load capacity of the nails:<br />

The nail resistance is not controlling the failure of the fast<strong>en</strong>er.<br />

Fast<strong>en</strong>ings to concrete<br />

Average t<strong>en</strong>sile Scatter Embedm<strong>en</strong>t Concrete<br />

failure load depth str<strong>en</strong>gth<br />

Nail N u,m [kN] [%] h ET [mm] f cc [N/mm 2 ]<br />

X-GHP 20 MX 1.61 52.0 14.0 52.2<br />

X-GN 27 MX 1.91 47.1 19.2 23.7<br />

X-U 22 MX 3.18 37.8 20.1 54.7<br />

X-U 27 MX 4.04 35.4 24.5 30.9<br />

2.196 7 / 2009

X-ECTMX, X-EKSMX,<br />

X-EMTSC<br />

Application requirem<strong>en</strong>ts<br />

Thickness of base material<br />

Concrete<br />

X-U:<br />

X-GHP, X-GN:<br />

h min =80mm<br />

h min =60mm<br />

Steel<br />

t Il ≥ 4mm<br />

tII<br />

Spacing and edge distances<br />

50–100 cm along the cable tie. Adjust spacing as needed to achieve stability of cable tie<br />

Corrosion information<br />

These zinc-coated fast<strong>en</strong>ers are not suitable for long-term service outdoors or in otherwise<br />

corrosive <strong>en</strong>vironm<strong>en</strong>ts.<br />

For further detailed information on corrosion see relevant chapter in Direct Fast<strong>en</strong>ing<br />

Principles and Technique section.<br />

Application limits<br />

No g<strong>en</strong>eral restrictions exist<strong>en</strong>t. Limitations are dep<strong>en</strong>ding on application and user requirem<strong>en</strong>ts.<br />

7 / 2009 2.197

X-ECTMX, X-EKSMX,<br />

X-EMTSC<br />

Fast<strong>en</strong>er selection<br />

Suitable cables with X-ECT MX fast<strong>en</strong>er<br />

Cable type Cable measure [∅ mm] No. of cables<br />

NYM 3x1.5 8 14<br />

NYM 5x1.5 10 10<br />

Suitable conduits with X-EKS / X-EKSC MX fast<strong>en</strong>er<br />

Conduit type Conduit size [mm] No. of conduits<br />

Plastic conduit 16–40 1<br />

Suitable conduits with X-EMTSC MX fast<strong>en</strong>er<br />

Conduit type Conduit size [inch] No. of conduits<br />

Metal conduit 1<br />

/2”–1” 1<br />

Fast<strong>en</strong>er program<br />

Nail<br />

Shank Ø *) Shank l<strong>en</strong>gth*)<br />

Base material Designation Technology d s [mm] L s [mm] L [mm<br />

Concrete X-U 22 MX DX 4.0 22 –<br />

Concrete X-U 27 MX DX 4.0 27 –<br />

Steel X-U 16 MX DX 4.0 16 –<br />

Concrete X-GHP 20 MX GX 3.0 20 21.8<br />

Concrete or masonry X-GN 27 MX GX 3.0 27 28.9<br />

Steel X-EGN 14 MX GX 3.0 14 15.8<br />

*) Standard chank diameters and shank l<strong>en</strong>gths. Other combinations available on special order.<br />

Tools:<br />

DX technology: DX 460-MX, DX 351-MX<br />

GX technology: GX 120-ME, GX 100-E<br />

2.198 7 / 2009

X-ECTMX, X-EKSMX,<br />

X-EMTSC<br />

X-EKS<br />

Item no.<br />

Designation<br />

285719 X-EKS 16 MX<br />

285720 X-EKS 20 MX<br />

285721 X-EKS 25 MX<br />

285722 X-EKS 32 MX<br />

285723 X-EKS 40 MX<br />

X-ECT<br />

Item no.<br />

Designation<br />

285709 X-ECT MX<br />

285710 X-ECT UV MX<br />

285711 X-ECT FR MX<br />

X-EMTSC<br />

Item no.<br />

Designation<br />

228338 X-EMTSC 1 /2” MX<br />

228339 X-EMTSC 3 /4” MX<br />

228340 X-EMTSC 1” MX<br />

GX nails<br />

Item no.<br />

Designation<br />

338872 X-EGN 14 MX<br />

340229 X-GHP 20 MX<br />

34541 X-GN 27 MX<br />

DX Nails<br />

Item no.<br />

Designation<br />

237344 X-U 16 MX<br />

237346 X-U 22 MX<br />

237347 X-U 27 MX<br />

X-EKSC<br />

Item no.<br />

Designation<br />

274083 X-EKSC 16 MX<br />

274086 X-EKSC 20 MX<br />

274087 X-EKSC 25 MX<br />

386469 X-EKSC 32 MX<br />

386470 X-EKSC 40 MX<br />

System recomm<strong>en</strong>dation<br />

DX tools: Steel: 6.8/11M red cartridge<br />

Concrete: 6.8/11M yellow cartridge on gre<strong>en</strong>/fresh and standard concrete<br />

6.8/11M red cartridge on precast, old and hard concrete<br />

Masonry: 6.8/11M gre<strong>en</strong> cartridge<br />

GX 120 tool:<br />

GX 100 tool:<br />

Tool <strong>en</strong>ergy adjustm<strong>en</strong>t by setting tests on site.<br />

Gas can GC 21 (GC 22 in USA)<br />

Gas can GC 11 (GC 12 in USA)<br />

7 / 2009 2.199

X-ECTMX, X-EKSMX,<br />

X-EMTSC<br />

Fast<strong>en</strong>ing quality assurance<br />

Installation<br />

1.<br />

Load X-EKS,X-ECT or<br />

X-EMTSC in the tool.<br />

2.<br />

Apply X-EKS,X-ECT or<br />

X-EMTSC to surface<br />

with tool, compress<br />

the tool and pull the<br />

trigger.<br />

3.<br />

Turn down the X-EKS<br />

clip or assemble a<br />

cable binder into the<br />

X- ECT<br />

(Example: X-EKS)<br />

4.<br />

Fast<strong>en</strong> the cable to the<br />

X-EKS clip, the X-ETC<br />

or the X-EMTSC<br />

(Example: X-EKS)<br />

Spacing:<br />

• 50–100 cm along the cable tie<br />

• Adjust spacing as needed to achieve stability of cable tie<br />

2.200 7 / 2009