The Magazine Of The Hilti Group

The Magazine Of The Hilti Group

The Magazine Of The Hilti Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

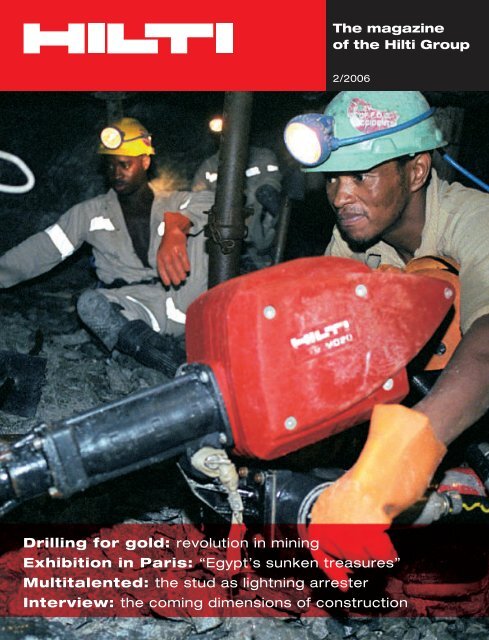

<strong>The</strong> magazine<br />

of the <strong>Hilti</strong> <strong>Group</strong><br />

2/2006<br />

Drilling for gold: revolution in mining<br />

Exhibition in Paris: “Egypt’s sunken treasures”<br />

Multitalented: the stud as lightning arrester<br />

Interview: the coming dimensions of construction

Contents<br />

Page 2<br />

Worldwide<br />

4 Paris: a clean sleeve for a waste plant<br />

4 Clothes make the <strong>Hilti</strong> people on the construction<br />

site<br />

5 Monaragala, Sri Lanka: the future begins here<br />

5 Leipzig: the travels of a railway station<br />

Engineering<br />

16 <strong>The</strong> stud as lightning arrester<br />

Interview<br />

20 Hans-Ulrich Litzner: the coming dimensions<br />

of construction<br />

Construction<br />

6 Essen: a world heritage site in a rock wool coat<br />

Company<br />

8 <strong>The</strong> “Egypt’s sunken treasures” exhibition<br />

Mining<br />

10 Drilling for gold<br />

Innovation<br />

24 18 volts in top form<br />

24 Through the ceiling and wall<br />

25 <strong>The</strong> cordless technology of tomorrow<br />

26 Complete measuring technology<br />

26 Convincing a skeptical professional<br />

26 Strongest in its class<br />

8 An exhibition shows<br />

Egypt’s treasures that<br />

were once on the ocean<br />

floor.<br />

10 A revolution in mining is<br />

about to take place. A<br />

trip down the deepest<br />

gold mine in the world.<br />

16 A stud proves to make<br />

a fine lightning arrester<br />

and also serves to<br />

ground electric equipment.<br />

20 Hans-Ulrich Litzner:<br />

“We have to learn<br />

different methods of<br />

construction.”<br />

Impressum<br />

Publisher: <strong>Hilti</strong> Corporation,<br />

Corporate Communications,<br />

Postbox 333, FL-9494 Schaan,<br />

Principality of Liechtenstein<br />

Editor-in-chief: Ursula Trunz,<br />

phone: +423 234 26 30,<br />

ursula.trunz@hilti.com<br />

Distribution: Tamara Eberle,<br />

tamara.eberle@hilti.com<br />

Layout / design: milano-graphic,<br />

CH-8640 Rapperswil, Switzerland<br />

Composition / lithos / printing: Buchs<br />

Medien AG, CH-9471 Buchs, Switzerland<br />

Publication frequency: twice a year<br />

Circulation: 36,000 (17,000 English,<br />

10,500 German, 3,000 Spanish,<br />

2,500 French, 2,000 Japanese,<br />

1,000 Italian)<br />

Cover photo: Tau Tona gold mine,<br />

South Africa (Photo: Luca Zanetti)<br />

<strong>The</strong> <strong>Magazine</strong> is also available<br />

in electronic form under<br />

www.hilti.com/magazine<br />

<strong>The</strong> articles published in this magazine<br />

may be regarded as official statements<br />

by the Executive Board only when expressly<br />

marked as such. In the event of<br />

differing interpretation, the original text<br />

shall apply.<br />

<strong>Hilti</strong> is a registered trademark of the<br />

<strong>Hilti</strong> Corporation.<br />

© <strong>Hilti</strong> Corporation, September 2006

<strong>Magazine</strong> 2/2006<br />

Editorial<br />

Page 3<br />

A tradition of<br />

innovation<br />

It was one of her most impressive<br />

professional experiences, explained<br />

Ursula Trunz, the editor of<br />

our corporate magazine, after she<br />

returned from Johannesburg. Together<br />

with photographer Luca<br />

Zanetti and three colleagues from<br />

<strong>Hilti</strong> South Africa she went into the<br />

deepest gold mine in the world to<br />

see the world’s first explosion-protected,<br />

hand-held rotary hammer<br />

made expressly for underground<br />

mining in action.<br />

With the development of the completely<br />

new <strong>Hilti</strong> TE MD20 rotary<br />

hammer system for underground<br />

mining we not only made headway<br />

into a new application area, we also<br />

once again proved one of our<br />

strengths, namely innovation. A<br />

passing remark by one of our customers<br />

pointed up a need. This triggered<br />

an exemplary research and<br />

development project that may very<br />

well end up being revolutionary. I<br />

don’t like to use this word as it is<br />

generally used to describe political<br />

upheaval. But specialists who have<br />

seen this tool actually call it revolutionary<br />

in terms of underground<br />

mining.<br />

I admit that this success did not<br />

take place overnight. An international<br />

and interdisciplinary team<br />

worked very hard over many<br />

years in South Africa, in Germany<br />

and at our corporate headquarters<br />

in Liechtenstein. <strong>The</strong>y experienced<br />

moments when they doubted<br />

their own efforts. But they never<br />

lost faith in the revolutionary power<br />

of innovation that was inherent<br />

in the <strong>Hilti</strong> TE MD20 rotary hammer.<br />

Innovation requires courage, teamwork<br />

and a great deal of commitment.<br />

<strong>The</strong> integrity of the individual<br />

team members among themselves<br />

also generates energy. <strong>The</strong>se basic<br />

human factors form the foundation<br />

of our corporate culture. This is why<br />

innovation and a will to create new<br />

things enjoy a long tradition at <strong>Hilti</strong>.<br />

We intend to keep this tradition<br />

alive.<br />

Pius Baschera<br />

Chief Executive <strong>Of</strong>ficer

Worldwide<br />

Page 4<br />

A clean sleeve for a<br />

Parisian waste plant<br />

<strong>The</strong> waste incineration plant will largely function underground and<br />

won’t have any chimneys.<br />

<strong>The</strong> city of Issy-les-Moulineaux,<br />

near Paris, is constructing<br />

a waste incineration plant<br />

designed to dispose of 480,000 tons<br />

of waste a year. <strong>The</strong> garbage will<br />

come from one million residents<br />

in the western end of the French<br />

capital.<br />

<strong>The</strong> plant, located in the middle of<br />

the city and only a few kilometers<br />

from the Eifel Tower, has been designed<br />

to be as environmentally<br />

friendly as possible. <strong>The</strong> architecture<br />

of the complex is very austere<br />

and modern and two-thirds of the<br />

plant will be located below ground.<br />

<strong>The</strong> height of the plant above<br />

ground is limited to 21 meters<br />

(68.9 ft), or about the height of a<br />

six-story building. This will do<br />

away with a large amount of the<br />

noise the plant will generate. <strong>The</strong>re<br />

will be no chimneys shooting into<br />

the air and belching vapor. A special<br />

system has been designed to<br />

suppress the emissions.<br />

But in the middle of the building,<br />

ovens will heat up and conveyor<br />

belts will cause vibrations. It will<br />

be very humid. This type of demanding<br />

environment calls for<br />

<strong>Hilti</strong> fastening solutions.<br />

As the facility will be placed in the<br />

ground at the groundwater level,<br />

and while the Seine River is only<br />

ten meters distant, piles had to be<br />

driven down for the foundation and<br />

an 80,000 square meter concrete<br />

wall (861,112 sq ft) had to be<br />

poured that reached some 50 meters<br />

down (164 ft). Some 95,000 cubic<br />

meters of concrete (3,354,893<br />

cu ft) were reinforced with 6000<br />

tons of steel. To ensure that everything<br />

remained watertight, engineers<br />

selected <strong>Hilti</strong> HIT-RE 500<br />

injectable adhesive mortar for additional<br />

work on the wall.<br />

I know that shirt!<br />

<strong>The</strong> famous red toolbox will<br />

remain the unmistakable<br />

<strong>Hilti</strong> trademark, <strong>Hilti</strong> employees<br />

having direct customer contact<br />

have had an additional identifying<br />

trait for the last few weeks. <strong>The</strong>y<br />

wear the same clothes. Because<br />

the clothing is so practical and<br />

robust, but also smart and fashionable,<br />

the company’s managers<br />

are also interested. <strong>The</strong> presentation<br />

of the clothing line to employees<br />

was made by the heads<br />

of the worldwide sales regions<br />

and Executive Board member<br />

Marco Meyrat, who all served as<br />

models.<br />

Now <strong>Hilti</strong> salespeople will be more easily identifiable on construction sites, thanks to <strong>Hilti</strong> attire. But managers<br />

also like the clothing and even suited up as models.

<strong>Magazine</strong> 2/2006<br />

Worldwide<br />

Page 5<br />

<strong>The</strong> future<br />

begins here<br />

Each kilometer that a <strong>Hilti</strong> team covered in a mountain bike race<br />

in Belgium brought money for the vocational training center.<br />

<strong>The</strong> vocational training center in Monaragala,<br />

in the quiet southeastern part of Sri Lanka,<br />

the financing of which is being made possible<br />

by <strong>Hilti</strong> employees around the globe, is filling<br />

with life. Workshops and classrooms offer<br />

space for 150 young people.<br />

<strong>The</strong> first vocational courses<br />

that began were the carpentry<br />

courses. Other vocations offered at<br />

the center are mechanic, welder<br />

and electrician. Other students venture<br />

into the world of computer<br />

hardware and software. <strong>The</strong> study<br />

of English is also planned for all<br />

students.<br />

“<strong>The</strong> project is promising,” reports<br />

Cedric de Silva, National Director<br />

of SOS Children's Villages of Sri<br />

Lanka. <strong>The</strong> <strong>Hilti</strong> employees trust<br />

the specialist knowledge of SOS<br />

Children's Villages to establish and<br />

operate the vocational training<br />

center. “We are training an equal<br />

number of girls and boys, and that<br />

is rather unusual for a vocational<br />

training center in Sri Lanka. We are<br />

very grateful to <strong>Hilti</strong> employees.<br />

<strong>The</strong> professional training and<br />

knowledge gained here by the students<br />

will prepare them to earn a<br />

reasonable living.”<br />

<strong>Hilti</strong> employees continue to collect<br />

and donate money as they also<br />

want to finance the annual operation<br />

and upkeep costs of the vocational<br />

training center. <strong>The</strong>y sell<br />

homemade cakes to their colleagues,<br />

organize auctions and lotteries<br />

and continue to come up<br />

with new ideas. Stefan Ehrnborg, a<br />

<strong>Hilti</strong> employee in the United Arab<br />

Emirates says “It is great to see<br />

how the team is willing to share the<br />

success for a good cause.” Building<br />

a better future for young<br />

people is indeed a wonderful feeling.<br />

<strong>The</strong> travels<br />

of a railway station<br />

<strong>The</strong> German city of Leipzig<br />

needs additional room for<br />

the construction of the new City<br />

Tunnel. This required moving the<br />

gate of the Bavarian Station. <strong>The</strong><br />

historical gate, stemming from the<br />

mid-19th century, has rail tracks<br />

running through each of its four<br />

arches. It is 20 meters high (65.6<br />

ft), 30 meters wide (98.4 ft) and<br />

weighs 2800 tons. <strong>The</strong> foundation<br />

was wrapped in concrete and then<br />

steel beams were attached that<br />

would serve as the handles by<br />

which the gate was lifted. To stabilize<br />

it for transportation, the work-<br />

Short yet costly<br />

trip. <strong>The</strong> almost<br />

3000 ton portal<br />

of Leipzig’s<br />

Bavarian Station<br />

was moved some<br />

30 meters.<br />

ers used <strong>Hilti</strong> HZA loading claws<br />

that they anchored in the stone of<br />

the gate with <strong>Hilti</strong> HIT-RE 500 injectable<br />

adhesive mortar. <strong>The</strong> old<br />

foundation was attached to the new<br />

one with anchor rods and with<br />

<strong>Hilti</strong> HIT-HY 150 and <strong>Hilti</strong> HIT-<br />

RE 500 injectable adhesive mortars.<br />

Concrete was then poured<br />

over the anchor rods to make the<br />

new foundation. Once the City<br />

Tunnel is completed at the Bavarian<br />

Station in 2008, the gate will<br />

again be placed in its original position.

Construction<br />

Page 6<br />

Rock wool coat for a<br />

<strong>The</strong> German city of Essen has been named the cultural capital of Europe for<br />

2010. <strong>The</strong> hallmark of the metropolis in the Ruhr is the hauling framework<br />

for shaft XII of the Zollverein Coal Mine. By the end of 2007 the mine’s<br />

grounds, and the massive building housing the former coal wash, will be<br />

completely renovated.<br />

<strong>The</strong> coal mine grounds, designed<br />

in 1932 by Bauhaus<br />

architects Fritz Schupp and Martin<br />

Kremmer, were designated as a<br />

UNESCO World Heritage Site in<br />

2001. <strong>The</strong> grounds stand as a symbol<br />

of the structural shift in the<br />

Ruhr, an area that was once characterized<br />

by heavy industry.<br />

Having a foundation of 34 x 91 meters<br />

(112 x 299 ft) and a height of<br />

about 50 meters (164 ft), the coal<br />

wash is the largest building on the<br />

mine grounds. <strong>The</strong> complex, which<br />

was permanently shut down in<br />

1986, was where the coal was transported<br />

to from 12 different shafts,<br />

and then washed and prepared for<br />

further processing. Until the fall of<br />

2003 visitors could see the coal<br />

wash in its original condition and<br />

be transported into the past through<br />

the atmosphere made black by<br />

decades of coal dust. Since then the<br />

building has been comprehensively<br />

renovated at a cost of about 42 million<br />

euro. When completed it will<br />

house both the Zollverein Coal<br />

Mine visitor center and the new<br />

Ruhr Museum.<br />

Sustainable protection<br />

In order to maintain the original<br />

character of the building and the<br />

entire facility, while meeting the<br />

strict requirements of UNESCO<br />

and landmark protection authorities,<br />

the renovation work had to<br />

balance care with sustainability. To<br />

protect the renovated architectural<br />

core against future weather influences<br />

and to ensure that future museum<br />

guests enjoy a pleasant indoor<br />

climate, the contractor and<br />

the responsible architects from<br />

Heinrich Böll, of Essen, decided<br />

on a thermal-insulating compound<br />

system (WDVS) having a rock<br />

wool core. <strong>The</strong> permeable rock<br />

wool, that allows diffusion to take<br />

place, avoids the development of<br />

condensate and thereby guarantees<br />

rapid drying in addition to out-<br />

Once characterized by heavy industry,<br />

Germany’s Ruhr has undergone a massive<br />

structural shift. <strong>The</strong> coal mine grounds in<br />

Essen with its hauling framework (left) is a<br />

symbol of the change.<br />

<strong>The</strong> largest building on the coal mine<br />

grounds is the coal wash (right).<br />

It is being renovated and will later house a<br />

visitor center and museum.<br />

<strong>The</strong> façade of the coal wash will maintain its original character. It contains rock wool insulation that was fastened with <strong>Hilti</strong> composite insulation anchors.

<strong>Magazine</strong> 2/2006<br />

Construction<br />

Page 7<br />

world heritage site<br />

standing heat and acoustic insulation.<br />

This protects the building<br />

against damage associated with<br />

moisture. Additionally, the rock<br />

wool insulation has a melting point<br />

above 1000° C, greatly contributing<br />

to fire prevention.<br />

<strong>The</strong> special procedure<br />

Last spring about 7000 square meters<br />

(75,347 sq ft) of the total<br />

façade surface was completely insulated<br />

and plastered. To keep the<br />

original look and charm of the coal<br />

wash, certain geometric irregularities<br />

and uneven spots were left<br />

alone. As a result there were many<br />

detailed tasks. An additional 5000<br />

square meters (53,819 sq ft) of the<br />

façade was newly clinkered at the<br />

same time.<br />

<strong>The</strong> fins selected for the thermalinsulating<br />

compound system are<br />

characterized by a verticallystanding<br />

structure of rock wool<br />

fibers and therefore are very difficult<br />

to rip down. <strong>The</strong>y were additionally<br />

fastened with the <strong>Hilti</strong> XI-<br />

FV 120 composite insulation<br />

anchor to ensure that the thermalinsulating<br />

compound system<br />

would hold through loads generated<br />

by strong wind gusts in buildings<br />

of above-average height. <strong>The</strong><br />

north gable of the coal wash is<br />

about 50 meters high. After the<br />

mechanical reinforcing was finished<br />

in the subsequent step, the<br />

façade received a specially-developed<br />

machine-applied mineral<br />

plaster having a slightly rough surface.<br />

Industrial history for<br />

the senses<br />

<strong>The</strong> Ruhr Museum, which is to be<br />

housed in the coal wash beginning<br />

in 2007, is to become a historical<br />

institution of culture for the entire<br />

region. <strong>The</strong> Zollverein development<br />

company, responsible for establishing<br />

the museum, is not planning<br />

a classic industrial museum,<br />

but a rather unconventional concept<br />

that aims at using a substantial<br />

archive of images, sounds and<br />

tones that will relay the story of the<br />

Ruhr in a vivid manner and trace<br />

the path of the region from prototype<br />

of an industrial landscape to a<br />

city that has fundamentally altered<br />

its history without turning away<br />

from the past.<br />

Detailed service<br />

Suppliers of thermal-insulating compound systems (WDVS) can count on<br />

<strong>Hilti</strong> competence: specialists analyze the base material and record the<br />

individual needs of the customer before studying these and developing<br />

and suggesting the suitable <strong>Hilti</strong> fastening system. Tensile load tests, that<br />

are carried out by the specialists on location and are recorded in detail,<br />

lead to ideal solutions that the customer can then choose from. Depending<br />

on base material and application, either an impact anchor or a composite<br />

insulation anchor is preferred. Construction supervisory authority<br />

approval exists for either one.<br />

For the façade insulation on the largest building of the former Zollverein<br />

Coal Mine in Essen, careful analysis led to the decision to use <strong>Hilti</strong> XI-FV<br />

120 composite insulation anchors. Specialists from <strong>Hilti</strong> Germany have<br />

supported the WDVS supplier in his discussions with the planners<br />

since 2004. A cost comparison for the calculation was included in the <strong>Hilti</strong><br />

service.<br />

<strong>The</strong> company assigned to carry out the work trained their workers, allowing<br />

them to perform the set check on their own. As a matter of course,<br />

material deliveries were made within 24 hours and a <strong>Hilti</strong> salesperson,<br />

specialized in WDVS, appeared directly at the construction site.<br />

About 7000 square meters were completely insulated and plastered.

Company<br />

Page 8<br />

As if on the oc<br />

<strong>The</strong> “Egypt’s sunken treasures” exhibition shows the splendor and magnificence<br />

of antique Egypt and captivates by taking one into the exciting world<br />

discovered and explored by Franck Goddio and his team. After some 500<br />

objects from the spectacular underwater excavations caused a sensation<br />

in Berlin, they will be transferred to the Grand Palais in Paris where they<br />

will be shown beginning on December 8. <strong>The</strong> <strong>Hilti</strong> <strong>Group</strong> and the <strong>Hilti</strong> Foundation,<br />

a supporter of Franck Goddio’s work since 1996, make the exhibitions<br />

possible.<br />

By Manfred Schiefer<br />

Researcher Franck Goddio is amazed every time he stands next to the<br />

monumental statue of a pharaoh at the exhibition.<br />

Placing the object, weighing tons,<br />

required precise work.<br />

<strong>The</strong> charming sphinx lay on<br />

the ocean floor for more than<br />

2000 years before divers glimpsed<br />

him. This is only one of many fascinating<br />

images that have gone<br />

around the world stemming from<br />

Franck Goddio’s discoveries. But<br />

his area of research brings a great<br />

deal more to light than magnificent<br />

objects. His finds have, for example,<br />

proven for the first time that<br />

the Egyptian port city of Heraklion-Thônis,<br />

long shrouded in legend,<br />

actually existed.<br />

As spectacular as the recovery of<br />

the objects was, including monumental<br />

pieces, their transportation<br />

to the exhibition sights was just as<br />

impressive. <strong>The</strong> largest civilian<br />

cargo aircraft, an Airbus Beluga,<br />

was deployed to ensure that the objects,<br />

some of them six meters tall<br />

(19.6 ft) and weighing several tons,<br />

were safely transported from<br />

Egypt to Germany and then on to<br />

Paris. Having wowed archaeologists<br />

and causing Egyptian history<br />

to be redefined, the cultural treasures<br />

unearthed by Franck Goddio<br />

and his team caused astonishment<br />

among visitors at the exhibition<br />

in Berlin’s Martin-Gropius-Bau,<br />

where the impressive objects were<br />

shown to the public for the first<br />

time.<br />

Soft music and sounds of an underwater<br />

world make the Egypt’s<br />

sunken treasures exhibition both<br />

an informative exhibit as well as<br />

one for the senses. Underwater<br />

photos, helpful explanations and<br />

quotes in ancient characters are<br />

projected on the walls of the exhibition<br />

hall. One finds, for example,<br />

that the Roman philosopher<br />

and statesman Seneca warned his<br />

countrymen against visiting the<br />

corrupt city of Canopus, as “there<br />

are no limits to the excesses seen<br />

there,” or how the Arabian explorer<br />

Ibn Battuta expounded on the<br />

“great pearl” of Alexandria, that<br />

“brightens the West with its<br />

beauty.” It was a successful exhibition<br />

launch with the finds divided<br />

into rooms according to the locations<br />

Canopus, Heraklion and<br />

Alexandria. <strong>The</strong> impressive, monumental<br />

statues and steles were<br />

presented in a rather unconventional<br />

manner. <strong>The</strong> visitor walks<br />

past them as if on a procession<br />

while the floor is as uneven as the<br />

floor of the ocean. “This gives a bit<br />

of the impression as to how my<br />

divers and I found the excavation

<strong>Magazine</strong> 2/2006<br />

Company<br />

Page 9<br />

ean floor<br />

Franck Goddio and his team retrieved statues and other treasures from<br />

the sunken cities of Canopus and Heraklion.<br />

Only the Airbus Beluga was large enough to transport the finds from<br />

Egypt to Germany. Now they travel onward to Paris.<br />

sites,” says underwater archaeologist<br />

Franck Goddio.<br />

Although the exhibition is lightened<br />

somewhat by these experience-oriented<br />

elements, the overall<br />

emphasis of the unique finds, presented<br />

over an area of some 3000<br />

square meters (32,291 sq ft), is on<br />

the fascination of the objects and<br />

their scientific refurbishing. “This<br />

is being done in cooperation with<br />

noteworthy scientists and the Oxford<br />

Centre for Maritime Archaeology<br />

of the University of Oxford,”<br />

explains Michael <strong>Hilti</strong>, Chairman<br />

of the <strong>Hilti</strong> Foundation. Although<br />

the monumental antique works of<br />

art can now be viewed by the<br />

public, it will still be decades before<br />

all the secrets have been revealed.<br />

More on the exhibition and on<br />

Franck Goddio on the Internet:<br />

www.aegyptens-versunkeneschaetze.org<br />

www.egypts-sunkentreasures.org<br />

www.franckgoddio.org<br />

A commitment having a sustainable<br />

influence<br />

<strong>The</strong> <strong>Hilti</strong> Foundation is committed to innovative projects that lead to<br />

new findings and have worldwide scope and significance. <strong>The</strong> comprehensive<br />

support of the work of Franck Goddio has been one emphasis<br />

of the <strong>Hilti</strong> Foundation’s cultural commitment for over ten years. <strong>The</strong> finds<br />

and research results are being made available to the public for the<br />

first time in the “Egypt’s Sunken Treasures” exhibition. <strong>The</strong> exhibition<br />

in the Grand Palais in Paris runs from December 8, 2006 to March 16,<br />

2007.

Drilling for g

<strong>Magazine</strong> 2/2006<br />

old<br />

<strong>The</strong><br />

<strong>Hilti</strong> TE MD20 rotary hammer is beginning to conquer South Africa.<br />

According to specialists the first electro pneumatic drilling system<br />

in the world, operated by hand in spite of the comprehensive explosion<br />

protection system, will revolutionize underground mining. A look into<br />

the Tau Tona gold mine, one of the deepest in the world<br />

By Ursula Trunz (text) and Luca Zanetti (photos)

Mining<br />

Page 12<br />

Those hand signals again.<br />

Hardly a word is spoken,<br />

only hand signals and a few telling<br />

glances. A pointing index finger<br />

draws attention to something.<br />

Thumbs up - understood, everything<br />

OK. Only an hour ago, I was<br />

urged along by a hand on my back<br />

before being ushered into the corner<br />

of the cage. <strong>The</strong> roll-up door,<br />

pulled down from the outside,<br />

closed with a clatter.<br />

Packed to capacity, each of the<br />

cage’s four floor levels held thirty<br />

persons. <strong>The</strong>re was no lighting in<br />

this giant elevator-like metal contraption.<br />

A rumble and a shudder<br />

signaled the start of our descent.<br />

Dropping at a rate of 18 meters<br />

(59 ft) per second, the cage accelerated<br />

to a speed of 60 kilometers (37<br />

mi) per hour as it plummeted down<br />

the shaft in almost total darkness.<br />

90 pairs of rubber boots soon shuffled<br />

hastily along the tunnel connecting<br />

the main shaft to the sub<br />

shaft. We squeezed into the next<br />

cage and our descent continued.<br />

Having reached the third, or tertiary<br />

shaft, the cage door again clattered<br />

loudly as it was closed, followed<br />

once more by a slightly<br />

uneasy silence as we patiently<br />

waited, a little apprehensively, for<br />

the cage to be set in motion.<br />

Extreme heat and<br />

humidity<br />

We arrived at a depth of 3,600 meters<br />

(11,811 ft) at our initial destination<br />

– level 116 of the Tau Tona<br />

mine, one of the deepest in the<br />

world. At this point, our distance<br />

from the earth’s surface is almost<br />

equal to the height of Japan’s<br />

Mount Fujiyama. No more cool<br />

rock down here. It’s hot – like the<br />

Sahara sand in summer – more than<br />

50 degrees centigrade or 122 degrees<br />

Fahrenheit. A wall of heat and<br />

humidity greets us. Together with<br />

the photographer and three colleagues<br />

from <strong>Hilti</strong>, all three experi-<br />

enced mining specialists, we climb<br />

aboard the train that will take us<br />

four kilometers closer to the gold.<br />

Our group is accompanied by<br />

Barend Strydom. As an overseer,<br />

he is responsible for the 400 mine<br />

workers of a section. After returning<br />

from the mine with us he’ll retrace<br />

our journey on the huge chart<br />

on the wall of his office, showing<br />

all the shafts, galleries and sections<br />

worked. Between 4,500 and 5,000<br />

mine workers descend every day of<br />

the year into this seemingly endless<br />

labyrinth-like underground world -<br />

a potentially dangerous world with<br />

laws all of its own.<br />

Tau Tona is operated by AngloGold<br />

Ashanti, one of the world’s leading<br />

gold producers. <strong>The</strong> mine has been<br />

a hive of activity for the past forty<br />

years. It’s an underground tower of<br />

Babylon, going down rather than<br />

up, with tunnels and galleries now<br />

extending to more than 1700 kilometers<br />

(1056 mi). Three to four<br />

further kilometers are added each<br />

month and several thousand tons<br />

of ore are extracted every day. A<br />

ton of ore from the main reef at the<br />

Tau Tona Mine – which runs<br />

north-to-south at a 21° angle –<br />

yields an average of thirty grams<br />

of gold – a little more than an<br />

ounce. Other mines have to be<br />

content with only about 10 grams.<br />

Up to 600 earthquakes<br />

each month<br />

<strong>The</strong> brakes squeal and the train<br />

comes to a stop. We climb out over<br />

loose rock and rubble. At this<br />

point, the gallery leading to the<br />

section we’re making for is only<br />

head-high. Heat and dampness<br />

simply can’t escape, making the atmosphere<br />

even more obtrusive<br />

than before. Glasses steam up constantly<br />

and we drip with sweat.<br />

<strong>The</strong>n a finger points to the wooden<br />

beams. Tons of these are transported<br />

into new galleries every day<br />

where they are used as props.<br />

Stacked one on top of the other,

<strong>Magazine</strong> 2/2006<br />

Mining<br />

Page 13<br />

<strong>The</strong> gallery leading to the stope face begins to rise more steeply<br />

and its height drops to between sixty and eighty centimeters. <strong>The</strong> underground<br />

work is extremely taxing. A hand-held drilling tool, that is<br />

quieter and produces less vibration, is therefore greatly welcomed.<br />

Compressed air drills (far left) release an oily vapor.<br />

<strong>The</strong> <strong>Hilti</strong> TE MD20 keeps the air clean. Additionally, electricity<br />

is easier to supply than compressed air.<br />

they support the billions of tons of<br />

rock above our heads. Without<br />

these wooden props, the galleries<br />

would simply cave in.<br />

Even so, falling rock is one of the<br />

biggest hazards faced by mine<br />

workers. Besides, South Africa’s<br />

mines are situated in a zone of frequent<br />

seismic activity. Up to 600<br />

earthquakes are registered every<br />

month in the Tau Tona Mine, some<br />

of which reach a force of up to 3.5<br />

on the Richter scale. Barend Strydom<br />

will never forget the moment<br />

in his life when a rock fall in the<br />

gallery blocked his way back from<br />

the section. It took him five hours<br />

to free himself. “You learn to handle<br />

the rough, arduous conditions<br />

down here,” he had assured us<br />

while we were still on the train.<br />

“And at home, do you speak to<br />

your wife about your experiences?”<br />

– “No, not usually.”<br />

<strong>The</strong> gallery begins to rise more<br />

steeply and its height drops to between<br />

about 60 and 80 centimeters<br />

(23.6 – 31.5 in). As walking upright<br />

is impossible, we crawl on all<br />

fours toward the stope face. I suddenly<br />

realize that it’s becoming<br />

increasingly difficult to gathering<br />

a few crystal clear thoughts. <strong>The</strong><br />

deeper the stope, the higher the<br />

temperature and thus the greater<br />

the danger of being unable to concentrate<br />

properly. How can anyone<br />

work under these conditions for<br />

three and a half hours without a<br />

break? <strong>The</strong> answer is simple: Without<br />

the air-cooling system it would<br />

be impossible. <strong>The</strong> fresh air certainly<br />

brings down the temperature<br />

at this depth of 3,600 meters, but<br />

it’s still probably well over thirty<br />

degrees. <strong>The</strong> heat, the dampness<br />

and the cramped conditions are unpleasant,<br />

to say the least. But then<br />

there’s the noise – the deafening<br />

drilling noise.<br />

Mine workers consider the job of<br />

the driller to be something of an<br />

honor. Working with extremely<br />

More holes with less energy<br />

“A study has shown that energy losses in a pneumatic system can reach<br />

90 percent, whereas losses in the electrical system would typically be<br />

around 8 percent. This means that one can power ten times as many electric<br />

drills than pneumatic drills for the same energy output.”<br />

“Water is circulated through the motor of the <strong>Hilti</strong> TE MD20 electric rotary<br />

hammer to keep temperature down, after which it is directed through the<br />

drill steel and out at the bit, lubricating the rock face, suppressing the<br />

dust and flushing the drill hole. <strong>The</strong> rotary hammer does not need inline<br />

lubrication, which is a major economic and health benefit.” (Editor’s note:<br />

conversely, pneumatic hammer drills must be lubricated every day and release<br />

an oily vapor when used.) “In the mine Mining Mirror visited, full electric<br />

drilling would eliminate the need for lubricating grease, thereby saving<br />

one mine company roughly 1 million liters of grease per year. It would<br />

also keep all of that grease out of the water reticulation system and out of<br />

the ore enrichment process, which will eliminate the need for whatever<br />

chemicals are used to eliminate the oil from the ore.”<br />

Henri-John Kock, Mining Mirror

Mining<br />

Page 14<br />

Underground<br />

efficiency<br />

Twenty minutes of drilling instead of eight hours: a new elevator shaft<br />

being prepared in a South African Mine.<br />

Ventilation curtains direct fresh air into the<br />

mines. For their assembly and for other<br />

work, as in the elevator shaft, specialists<br />

depend on <strong>Hilti</strong>.<br />

Gerrie Pienaar counts the possibilities<br />

on his fingers. Fastening wires<br />

to the gallery walls for attaching<br />

ventilation curtains: It takes time.<br />

Adhesive: It takes time. <strong>Hilti</strong> direct<br />

fastening: That’s the answer! He<br />

smacks his fist into the palm of his<br />

hand. “Two, three seconds – finished.<br />

Six of my men put up<br />

320 meters of curtain in three<br />

days. With other methods it would<br />

have taken them two and a half<br />

weeks!”<br />

Gerrie Pienaar, ventilation specialist<br />

of the Driefontein Gold Mine,<br />

points out the importance of ensuring<br />

that these installations are<br />

not only efficient but also effective:<br />

“<strong>The</strong> temperature in the mine also<br />

depends on the speed of the incoming<br />

fresh air flow. We can double<br />

the flow speed with the ventilation<br />

curtains we install using the<br />

<strong>Hilti</strong> direct fastening system.<br />

Where the air was previously coming<br />

through at 0.4 meters per second,<br />

it’s now flowing at between<br />

0.8 and 1 meter per second. Keeping<br />

the temperatures as low as<br />

possible makes it easier to work in<br />

the mines, lowers the risk of accidents<br />

and improves quality. A<br />

strong air flow also distributes any<br />

gases better and reduces the risk<br />

of explosions accordingly.” <strong>The</strong><br />

South African authorities and the<br />

U.S. Department of Mine Safety<br />

and Health have approved the <strong>Hilti</strong><br />

powder-actuated direct fastening<br />

system for use in underground<br />

mining.<br />

Working with a pneumatic jackhammer,<br />

it took two workers eight<br />

hours to break out a recess for anchoring<br />

a steel beam, for a new lift<br />

shaft, in the concrete wall. “With<br />

the <strong>Hilti</strong> DD 250 diamond core<br />

drilling system, we do it in twenty<br />

minutes,” they said. “Noise and<br />

vibration are also much lower.”<br />

heavy, noisy pneumatic hammer<br />

drills, they drill the blasting holes<br />

a few centimeters above and below<br />

the gold vein, which is hardly discernible<br />

to the untrained eye. Compressed<br />

air hoses and water hoses<br />

stretch in confusion across the<br />

stope face and the drillers and their<br />

assistants, always close at hand, almost<br />

disappear behind the thick,<br />

stinking oily mist that fills the air.<br />

But what if one of the metal drill<br />

bits suddenly, unexpectedly breaks<br />

through into a pocket of methane<br />

gas? <strong>The</strong> gas would escape through<br />

the hole being drilled. At that moment,<br />

a spark could be lethal. In a<br />

concentration of up to 5 percent,<br />

methane begins to burn. In concentrations<br />

above 5 percent, it explodes.<br />

A methane explosion can<br />

form a fireball that incinerates<br />

everything in its path. Accordingly,<br />

the methane concentration is<br />

measured at regular intervals, a<br />

somewhat risky process in itself.<br />

Highly explosive methane gas, together<br />

with the extremely arduous<br />

conditions faced in the mines, have<br />

been a hindrance to technical advances<br />

in gold mining - up to now.<br />

In the low gallery, dimly lit by the<br />

workers’ head torches, the air is<br />

noticeably clearer in an area alongside<br />

where conventional pneumatic<br />

drills are in use. Two drillers<br />

here are working with a new approach<br />

- the <strong>Hilti</strong> approach. <strong>The</strong><br />

tool they are using is the <strong>Hilti</strong> TE<br />

MD20, the first electric hammer<br />

drill that can be guided by hand,<br />

despite being equipped with comprehensive<br />

explosion-protection<br />

systems. According to the experts,<br />

it will revolutionize underground<br />

mining. <strong>The</strong> fact that the workers<br />

no longer have to breath in oily vapors<br />

from the air is only one of the<br />

benefits of this new tool.<br />

Better performance<br />

with less energy<br />

Asked about the advantages of the<br />

<strong>Hilti</strong> TE MD20 hammer drill, a<br />

driller spontaneously mentions the<br />

much lower noise – the <strong>Hilti</strong> drill<br />

is quieter. <strong>The</strong> level of vibration<br />

emitted by the tool is also much<br />

lower than with conventional pneumatic<br />

drills. <strong>The</strong> risk of damage<br />

to the hearing, or of the operator<br />

suffering white finger syndrome<br />

as a result of vibration-induced<br />

blood circulation problems in the<br />

hands, can now be much better controlled.<br />

<strong>The</strong> next driller is obviously impressed<br />

by the new hammer drill’s<br />

performance. With the <strong>Hilti</strong> TE<br />

MD20 he can position the drill bit<br />

more easily and more precisely<br />

when starting a hole and control<br />

the drilling operation more exactly.<br />

It also takes less effort to pull the<br />

drill bit back out of the hole. He<br />

doesn’t really need an assistant any<br />

more.<br />

<strong>The</strong> two drillers are part of Barend<br />

Strydom’s team of 400 workers. As<br />

overseer he’s not only responsible<br />

for his team’s safety, but also for<br />

productivity in his section. <strong>The</strong><br />

deeper a section, the more difficult<br />

it becomes to ensure safety while<br />

maintaining productivity and efficiency.<br />

But safety must never be<br />

neglected in pursuit of higher efficiency.<br />

Up to now, the <strong>Hilti</strong> TE<br />

MD20 is almost certainly the only<br />

mining drill that can meet all of<br />

these demands. <strong>The</strong> most important<br />

point, as far as productivity<br />

and efficiency is concerned, is that<br />

the <strong>Hilti</strong> TE MD20 needs no compressed<br />

air supply. <strong>The</strong> greater the<br />

distance over which compressed<br />

air has to be supplied, the greater<br />

the drop in pressure. And the lower<br />

the air pressure, the lower the performance<br />

of the pneumatic drill.<br />

“In the depths of the mine,” Barend<br />

Strydom reminds us, “air becomes<br />

a highly valued and costly commodity.”<br />

Electric power can be<br />

supplied more easily and at significantly<br />

lower cost than compressed<br />

air. <strong>The</strong> high performance of the<br />

<strong>Hilti</strong> TE MD20 also remains con-

<strong>Magazine</strong> 2/2006<br />

Mining<br />

Page 15<br />

stant, irrespective of the depth underground<br />

at which the drilling<br />

work is taking place.<br />

We leave the stope face and crawl<br />

backwards down to the point<br />

where the gallery offers more<br />

headroom. At midday, at the end of<br />

the early shift, the workforce<br />

leaves the mine. <strong>The</strong> hoists run flat<br />

out to bring the workers to the surface.<br />

Explosives placed in the<br />

newly-drilled holes by the blasting<br />

specialists are detonated, causing a<br />

shockwave to thunder through the<br />

galleries. <strong>The</strong>n the hard work begins<br />

all over again. <strong>The</strong> ore has to<br />

be transported to the surface,<br />

where it disappears behind the<br />

high walls and locked doors of the<br />

gold production plant. .<br />

<strong>The</strong> mine empties after the end of the early shift and the workers ride in cage-like elevators to the surface.<br />

<strong>The</strong> drilled holes are now filled with explosives and the ore containing the gold will be blasted free.<br />

Simply revolutionary<br />

<strong>The</strong> customer and their needs are the trigger<br />

for innovation. A provocative question led to<br />

the development of the TE MD20.<br />

<strong>The</strong> question was somewhat<br />

provocative: “Why can’t you<br />

equip the hammer drills we use in<br />

the gold mines with electric motors?”<br />

But Wayne Sterley of <strong>Hilti</strong><br />

South Africa pricked up his ears and<br />

accepted the challenge when this<br />

question was put to him by a member<br />

of the managerial staff at Anglo-<br />

Gold Ashanti. He passed the question<br />

on and it started the ball rolling<br />

– all the way to <strong>Hilti</strong>’s Corporate<br />

Headquarters in Liechtenstein.<br />

An international team took up the<br />

question for closer examination<br />

and held discussions with representatives<br />

of AngloGold Ashanti to<br />

ensure that the needs of the customer<br />

could flow directly into the<br />

project. An entirely new hammer<br />

drill system would have to be “invented”,<br />

all the way from the cable<br />

and plug to the explosion-protected<br />

modular motor section and<br />

sturdy drill bit. Ideas already existed<br />

and some concepts had previously<br />

been realized by the specialists<br />

in <strong>Hilti</strong>’s research and<br />

development departments. “But it<br />

took courage to combine these<br />

with the required technical perfection,<br />

safety and reliability,” says<br />

mechanical engineer Karl Neuper<br />

in recollection. Within a few<br />

months, Martin Richter and his development<br />

team at Kaufering, the<br />

site of <strong>Hilti</strong> Germany’s head office,<br />

had built a functional model.<br />

It was a fascinating and exciting<br />

moment. Wayne Sterley remembers<br />

that the telephone lines sometimes<br />

ran very hot. “<strong>The</strong>re were<br />

days when I was on the phone for<br />

up to five hours. We experienced<br />

moments of elation as well as deep<br />

disappointment, but we were convinced<br />

that the idea would be a<br />

success.” This joint effort did come<br />

to a successful conclusion: <strong>The</strong><br />

world’s first explosion-protected,<br />

hand-guided electric hammer drill<br />

for underground mining - the <strong>Hilti</strong><br />

TE MD20 – has reached the serial<br />

production stage. Nevertheless, as<br />

Wayne Sterley admits, “<strong>The</strong> tool<br />

looks entirely different from what<br />

was originally planned.”<br />

Although built to withstand extremely<br />

hard use, the <strong>Hilti</strong> TE<br />

MD20 is still compact and convenient.<br />

<strong>The</strong> more than twenty patents<br />

combined in this machine give<br />

some indication of the number of<br />

innovations it incorporates. <strong>The</strong><br />

workers are no longer required to<br />

breath in the oily vapors released<br />

by conventional pneumatic hammer<br />

drills. In addition, the cost of<br />

supplying power for the new machine<br />

is significantly lower than<br />

with compressed air. As the experts<br />

agree, this tool isn’t only innovative,<br />

it’s simply revolutionary

<strong>Magazine</strong> 2/2006<br />

Engineering<br />

Page 17<br />

A stud as lightning<br />

arrester<br />

<strong>The</strong> stainless steel <strong>Hilti</strong> X-BT threaded stud has turned out to be a<br />

versatile fastener. Its range of applications continues to grow. An innovative<br />

customer uses it as a fastener for lightning protection systems.<br />

Tests have also pointed up its suitability for grounding electric tools or<br />

equipment.<br />

By Michael Siemers*<br />

<strong>The</strong> <strong>Hilti</strong> X-BT threaded stud<br />

has a blunt end. Developed<br />

and optimized for simple fastening<br />

in a corrosive environment, it is<br />

used where welding is impractical<br />

or where the welding would require<br />

a significant amount of rework.<br />

<strong>The</strong> stainless steel stud ensures<br />

a secure fastening in highly<br />

corrosive environments and does<br />

not damage the protective anti-corrosion<br />

coating of steel construction.<br />

Additionally, it can also be set<br />

exactly on the location desired as a<br />

small hole must be drilled in advance.<br />

<strong>The</strong> <strong>Hilti</strong> X-BT is therefore<br />

also suitable for fastenings on very<br />

thin base materials.<br />

Lightning protection<br />

A new application for the X-BT<br />

stud is to aid in lightning protection<br />

atop mobile telephone antennas<br />

on high structures, such as<br />

grain silos. When antennae are<br />

mounted on such exposed places<br />

they tend to attract lightning<br />

strikes.<br />

arrester systems, excess voltage<br />

protection and industrial safety.<br />

<strong>The</strong>y see an ideal system, in the<br />

combination of the <strong>Hilti</strong> X-BT and<br />

Ferroscan PS 200, for using existing<br />

rebars in silos as lightning arrester<br />

systems.<br />

Once the rebar that are detected<br />

and localized with the Ferroscan<br />

are exposed with a <strong>Hilti</strong> breaker<br />

and a TE percussion core bit, the<br />

stud is driven into the rebar. This<br />

finishes off the fastening point in<br />

the shortest time, allowing the<br />

lightning arrester to be mounted on<br />

the rebar. As the <strong>Hilti</strong> X-BT can be<br />

placed in a very exact manner, it<br />

can also be used on very thin rebar.<br />

<strong>The</strong> minimum diameter of rebar<br />

for a proper fastening is 8 mm<br />

(5/16 in).<br />

Each fastening point or each <strong>Hilti</strong><br />

X-BT can withstand a lightning<br />

strike equal to a maximum of<br />

50,000 amperes, directing the energy<br />

through the rebar.<br />

Steel and<br />

concrete towers,<br />

such as grain<br />

silos, attract<br />

lightning strikes.<br />

<strong>The</strong> <strong>Hilti</strong> X-BT<br />

threaded stud<br />

is placed on<br />

rebars, on which<br />

connections for<br />

lightning arresters<br />

and measuring<br />

points are<br />

fastened.<br />

To protect the antenna a relatively<br />

inexpensive, efficient and effective<br />

solution is required to direct the<br />

lightning strike to the grounding<br />

system. <strong>The</strong> German company<br />

Dehn + Söhne in Bavaria’s Neumarkt,<br />

are specialists for lightning<br />

Before the system is operational,<br />

and to aid running tests of the<br />

lightning arrester system, measurements<br />

must show a continuous<br />

flow of electricity. <strong>The</strong> required<br />

measuring points can be fastened<br />

to the rebar with the <strong>Hilti</strong> X-BT, as

Engineering<br />

Page 18<br />

Stainless steel,<br />

easy to set and<br />

suitable for fastening<br />

on a very thin base<br />

material. <strong>The</strong><br />

<strong>Hilti</strong> X-BT threaded<br />

stud underscored<br />

its talents in the<br />

construction of a<br />

tram station roof<br />

in the Swiss city<br />

of Zurich.<br />

with the connections for the lightning<br />

arrester system.<br />

Grounding electric<br />

tools and equipment<br />

<strong>The</strong> <strong>Hilti</strong> X-BT is also suitable for<br />

grounding electrical tools and<br />

equipment such as switching<br />

boxes, gas detectors or pipes on oil<br />

platforms and in industrial installations.<br />

<strong>The</strong> ground cable is fastened to the<br />

X-BT stud between two nuts. This<br />

ensures the safe arresting of electricity<br />

even in coated steel construction<br />

without damaging the<br />

corrosion protection. On oil platforms<br />

and other installations that<br />

are subject to aggressive environmental<br />

influences, this translates<br />

into a significant time advantage<br />

versus welded grounding studs.<br />

<strong>The</strong> fastening point alone is threeto-four<br />

times faster to create compared<br />

to welding, with all the additional<br />

work involved such as<br />

removing the coating. Added to<br />

this, corrosion protection must be<br />

reapplied once welding work is<br />

completed. This can take anywhere<br />

between two-to-four days, depending<br />

on the required layers of protective<br />

coating, before the grounding<br />

cable can be completely<br />

installed.<br />

Technical data<br />

Tests have proven the suitability of<br />

the <strong>Hilti</strong> X-BT threaded stud as a<br />

grounding stud.<br />

Literature<br />

For usage as a lightning arrester<br />

tests were conducted according to<br />

European standard EN 50164-1,<br />

“Lightning protection components.<br />

Requirements for connection<br />

components,” in the labs of<br />

Dehn + Söhne. In the tests the <strong>Hilti</strong><br />

X-BT was fastened to 8 mm-thick<br />

rebar. <strong>The</strong> test on steel plates corresponds<br />

to the typical fastening as<br />

used in grounding electric equipment.<br />

Two additional testing series were<br />

carried out to monitor the suitability<br />

of the X-BT stud for grounding<br />

electric equipment. <strong>The</strong>se highlighted<br />

the differences between<br />

continuous electricity, that the connection<br />

must withstand, and a brief<br />

electrical impulse. As representative<br />

of the many possible requirements,<br />

the tests took place according<br />

to European and American<br />

standards. In both cases the <strong>Hilti</strong><br />

X-BT was fastened to a steel plate<br />

and the cable attached to the stud<br />

with two nuts.<br />

<strong>The</strong> German Technical Inspection<br />

Association, TÜV, carried out the<br />

continuous electricity test in accordance<br />

with European standard IEC<br />

60204-1:1997, “Safety of machinery.<br />

Electrical equipment of machines.”<br />

Underwriter Laboratories<br />

Inc. conducted the electrical impulse<br />

test in the USA according to<br />

U.S. standard UL 467, “Standard<br />

for Grounding and Bonding Equipment,”<br />

and the corresponding<br />

[1] Technical Report No. 70064671; TÜV Product Service, Test Center<br />

Frankfurt, Germany; February 2004 (XE_04_15)<br />

[2] UL Approval – File E257069; X-BT for Grounding and Bonding Equipment<br />

according to UL 467 and CSA C22.2 No. 41; December 2005<br />

(XE_06_24)<br />

[3] Test Report No. CF-791; Dehn and Söhne, Neumarkt, Germany;<br />

March 2006 (XE_06_31)

<strong>Magazine</strong> 2/2006<br />

Engineering<br />

Page 19<br />

<strong>The</strong> <strong>Hilti</strong> X-BT grounds switch<br />

boxes, pipes and gas detectors.<br />

<strong>The</strong> stud is assembled on a<br />

steel plate and the cable is fastened<br />

between two nuts.<br />

Canadian standard CSA C22.2<br />

No.41. <strong>The</strong> results of these tests<br />

and the corresponding test parameters<br />

are summarized in the tables<br />

at right. <strong>The</strong> UL approval, granted<br />

on the basis of the UL tests, is available<br />

on the UL Website: http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/index.ht<br />

m, UL file number: E257069.<br />

<strong>The</strong> tests showed that the <strong>Hilti</strong> X-<br />

BT threaded stud is suitable to<br />

serve as a fastening point in lightning<br />

arrester systems up to a current<br />

of 50,000 amperes and can tolerate<br />

continuous electricity for<br />

grounding electrical equipment of<br />

up to 60 amperes and up to an electrical<br />

impulse of 1530 amperes<br />

over six seconds. This places a<br />

quick and precise fastening solution<br />

that meets the highest requirements<br />

for safety and corrosion<br />

protection at the disposal of technicians.<br />

Lightning arrester test<br />

Connection point Class Imax Time<br />

1<br />

2<br />

X-BT M10-24-6 SN12-R<br />

Continuous current test<br />

Connection point<br />

X-BT M10-24-6 SN12-R<br />

With cable between two nuts<br />

Impulse test<br />

On rebar with connecting<br />

plate<br />

On steel base material with<br />

two nuts<br />

Connection point Cable designation /<br />

Cable type and size<br />

1<br />

2<br />

X-BT M10-24-6 SN12-R /<br />

X-BT W10-24-6 SN12-R<br />

With cable between two nuts<br />

Cable<br />

Material<br />

copper<br />

copper<br />

Size<br />

_> 10 mm 2<br />

_> 16 mm 2 Continuous<br />

current<br />

40 A<br />

60 A<br />

Maximum<br />

temperature<br />

49 °C<br />

78 °C<br />

3<br />

/4 , 1 (21. 27 metric) /<br />

copper 6 AWG (13.3 mm 2 )<br />

3<br />

/4 , 1 (21. 27 metric) /<br />

aluminum 6 AWG (13.3 mm 2 )<br />

N<br />

N<br />

50 kA<br />

50 kA<br />

Electrical current<br />

t d _< 2 ms<br />

t d _< 2 ms<br />

Time<br />

1530 A 6 Seconds<br />

* Michael Siemers, <strong>Hilti</strong> Consulting<br />

Engineer in the area of direct<br />

fastening, is responsible for the<br />

application technology. For additional<br />

information please contact<br />

michael.siemers@hilti.com

Interview<br />

Page 20<br />

<strong>The</strong> coming<br />

dimensions of<br />

construction<br />

<strong>The</strong> construction industry is overcoming what is often though to be an unjustified<br />

poor reputation. Today, construction means creating sustainable<br />

values and including future economic aspects in the planning stages. In this<br />

comprehensive view, construction requires looking at things from new<br />

perspectives, research and new abilities. Ursula Trunz spoke with Dr. Hans-<br />

Ulrich Litzner about this. As the Managing Director of the German Concrete<br />

Society and General Manager of the German Builders Federation for technology,<br />

technology policy and divisional policy, he’s a proven expert on the<br />

branch in Europe.<br />

Construction is by definition<br />

three dimensional. In a poor joke<br />

the three Ds stand for dirty, difficult<br />

and dangerous. How can the<br />

construction industry lose this<br />

image?<br />

Hans-Ulrich Litzner: A construction<br />

engineer doesn’t merely walk<br />

around a construction site in steeltoed<br />

rubber boots. A construction<br />

engineer creates unique specimens.<br />

Additionally, his work is no<br />

longer merely technical in nature.<br />

Construction continues to develop<br />

to where the entire lifetime scope<br />

of a project must be taken into consideration.<br />

How must a commercial<br />

or residential building be created<br />

to ensure that it uses as little<br />

energy as possible during its lifetime<br />

while keeping maintenance<br />

costs low? <strong>The</strong> wild market, that is<br />

solely fixated on the cost of con-<br />

struction, doesn’t exist any more.<br />

Construction therefore consists of<br />

much more than finite elements.<br />

We need to get this point across.<br />

“Construction continues to<br />

develop into something that<br />

deserves lifetime consideration.”<br />

This comprehensive view of construction<br />

is also aimed at three<br />

Ps: public, private, partnership.<br />

In this business model the public<br />

sphere transfers not only the<br />

construction but also the operation<br />

to private companies for a<br />

certain period of time. <strong>The</strong><br />

private sector functions as a<br />

system provider and investor<br />

vis-à-vis the state and compensates<br />

or overcompensates the<br />

invested amount with an operation<br />

that is as low-cost as possible.<br />

PPP requires new capabilities.<br />

Hans-Ulrich Litzner: <strong>The</strong> trend is<br />

heading in the direction that the<br />

customer, whether private or public,<br />

only defines the framework,<br />

leaving everything else to the<br />

group carrying out the project. To<br />

be successful within this model<br />

one must also know something<br />

about financing and maintenance<br />

issues and project management, as<br />

well as being fluent in foreign languages<br />

while having very high social<br />

abilities. <strong>The</strong>se and other socalled<br />

soft skills must be highly<br />

developed. <strong>The</strong> professional environment<br />

of the construction engineer<br />

and his training are changing<br />

greatly.<br />

Speaking of private enterprise<br />

as a system provider, one would<br />

imagine that research has a central<br />

role.<br />

Hans-Ulrich Litzner: We really do<br />

have to develop new technologies<br />

and find solutions, for example,<br />

for the interface between rough<br />

construction work and the technical<br />

outfitting of a building. Today,<br />

rough construction contributes<br />

about 20-to-30 percent of added<br />

value while the remaining building<br />

manufacturing costs are on the

<strong>Magazine</strong> 2/2006<br />

Interview<br />

Page 21<br />

Hans-Ulrich Litzner: “<strong>The</strong> type of wild market solely fixated on the cost of construction no longer exists.<br />

Construction is therefore made up of much more than finite elements.”

Interview<br />

Page 22<br />

Photos: Pia Zanetti<br />

“<strong>The</strong> question of how buildings can be constructed to withstand terrorist<br />

attacks is also one of interest in today’s world.”<br />

technical side. <strong>The</strong> construction<br />

engineer is challenged to develop<br />

corresponding systems with other<br />

specialists. Private enterprise is<br />

challenged as a whole.<br />

According to the so-called Lisbon<br />

Agreement of 2000, the nations of<br />

the European Union should spend<br />

three percent of their Gross Domestic<br />

Product on research. Onethird<br />

of this amount comes from<br />

the state and the rest from private<br />

enterprise. <strong>The</strong> construction industry,<br />

as an important economic sector<br />

in Europe, should also profit<br />

from this. As a result of the Lisbon<br />

Agreement the European Union’s<br />

seventh framework program for research<br />

and technological development<br />

will begin in January 2007.<br />

Up until 2013 the program will<br />

“We must learn to build<br />

differently. I see a great need<br />

for research.”<br />

spend some 40 billion euro on the<br />

overall economy. We, the German<br />

and the European construction industries,<br />

want to take advantage<br />

of this and move ahead of the US<br />

and Japan. In doing so we want to<br />

play to our strengths of performance<br />

and quality.<br />

To meet these goals the European<br />

Construction Technology Platform<br />

(ECTP) was founded in 2004 and it,<br />

in turn, generated a strategic research<br />

agenda. <strong>The</strong> ECTP has the<br />

task of defining future-oriented<br />

research projects and forming associated<br />

consortiums together with<br />

the European construction industry.<br />

This also offers a chance to manufacturers<br />

of high-tech products.<br />

What are the trends in<br />

research?<br />

Hans-Ulrich Litzner: Clear application<br />

research. <strong>The</strong> collapse of<br />

several buildings last winter has<br />

raised the issue of stability. Other<br />

examples for important research<br />

topics are how buildings use energy,<br />

construction involving existing<br />

buildings or fire safety in tunnels.<br />

<strong>The</strong> question of how buildings<br />

must be constructed to withstand<br />

terrorist attacks is also one of interest<br />

in today’s world. We have to<br />

learn how to build differently and,<br />

once again, shift our way of thinking<br />

so that we do not merely look at<br />

a construction material but at an entire<br />

building when we think of a<br />

product. Today construction is<br />

streamlined but I’m convinced that<br />

in the future greater robustness will<br />

be in demand. Additionally, how do<br />

we deal with climate and environmental<br />

changes or with the increasing<br />

frequency of flooding and<br />

earthquakes? As I mentioned at the<br />

outset of our discussion, the topic<br />

of durability also requires a different<br />

way of thinking. I see a tremendous<br />

need for research.<br />

If we speak of durability and<br />

sustainability we must also include<br />

the environment.<br />

Hans-Ulrich Litzner: Environmental<br />

protection is a hot topic. Subjecting<br />

construction workers to sil-

<strong>Magazine</strong> 2/2006<br />

Interview<br />

Page 23<br />

ica dust or vibrations caused by<br />

tools are real issues. If the permissible<br />

levels of silica dust are significantly<br />

lowered, construction according<br />

to what are now normal<br />

methods will no longer be possible<br />

because there is no natural construction<br />

material that doesn’t contain<br />

this material.<br />

Ecological sustainability includes<br />

the longevity of the building, possibilities<br />

for renovation and dismantling<br />

and the recycling of materials.<br />

I believe there is still much<br />

to be done, particularly in light of<br />

the fact that people in Germany, for<br />

And this means…?<br />

Hans-Ulrich Litzner: We have to<br />

get subsequent generations interested<br />

in construction. In 1995<br />

there were 12,500 students in Germany<br />

who registered to study construction<br />

engineering. This was<br />

immediately after reunification<br />

and Germany experienced a significant<br />

boom. In 2005, the number<br />

of students in their first semester<br />

of construction engineering<br />

was 5,000. But it will get worse.<br />

According to our statistics, about<br />

half of the students drop out. But<br />

the career of a construction engineer<br />

has never been more exciting.<br />

And the construction industry in<br />

Germany has developed standards<br />

for teaching the broad-based<br />

knowledge that is needed in today’s<br />

construction industry.<br />

“<strong>The</strong> profession of construction<br />

engineer, is more exciting now<br />

than ever.”<br />

example view the environment and<br />

its protection as their third most<br />

significant problem.<br />

Construction is becoming more<br />

complex through this comprehensive<br />

view while the actual<br />

competence on the construction<br />

site is decreasing…<br />

Hans-Ulrich Litzner: <strong>The</strong> confidence<br />

and optimism that formerly<br />

prevailed on construction sites,<br />

that the people there would fix<br />

whatever needed fixing, is no<br />

longer valid. We have to develop<br />

construction processes and materials<br />

that are functional and easy to<br />

use by people who have more limited<br />

qualifications. Take self-compacting<br />

concrete for example. It is<br />

sensitive and needs twice as much<br />

effort as normal, vibrated concrete.<br />

So there is a substantial requirement<br />

for improvement here as<br />

well.<br />

Having a passion for construction.<br />

How and where did you<br />

discover this passion?<br />

Hans-Ulrich Litzner: I also experienced<br />

a construction boom in the<br />

years following the Second World<br />

War. In the 50s and 60s cranes<br />

were seen everywhere in Germany.<br />

When I studied in Aachen, I made<br />

calculations under Professor Jürgen<br />

Kammenhuber for the Felsenau<br />

Bridge in Bern, Switzerland,<br />

which was designed by Christian<br />

Menn. That bridge and its dimensions<br />

were the things that once<br />

and for all awakened my fascination!<br />

“We have to develop construction processes and materials<br />

that are functional and easy to use by people who have more<br />

limited qualifications.”

Innovation<br />

Page 24<br />

18 volts in top form<br />

<strong>The</strong> new cordless hammer drill/driver<br />

and drill/driver from <strong>Hilti</strong> impress through<br />

their incredible power and unequalled<br />

efficiency<br />

Through ceiling<br />

and wall<br />

It pays to know the exit point. A completely<br />

new system, the <strong>Hilti</strong> PX 10 transpointer, gives<br />

construction professionals a real inside view.<br />

Suitable for<br />

all wall or ceiling<br />

penetrations.<br />

<strong>The</strong> <strong>Hilti</strong> PX 10<br />

transpointer.<br />

For powerful hammer drilling in masonry and lightweight concrete.<br />

<strong>The</strong> <strong>Hilti</strong> SFH 181-A cordless hammer drill/driver.<br />

Capable of tackling countless<br />

jobs ranging from<br />

hammer drilling to fast hole-sawing<br />

in wood and metal or highspeed<br />

drilling in sheet metal or<br />

wood, these powerful new tools<br />

are, of course, also ideal for driving<br />

large-diameter screws. <strong>The</strong>y<br />

even make short work of heavy,<br />

repetitive drilling work in wood.<br />

Delivering the highest torque and<br />

best speed in the 18-volt class, the<br />

<strong>Hilti</strong> SFH 181-A cordless hammer<br />

drill/driver sets the standard<br />

for drilling in brick, masonry and<br />

cellular concrete as well as demanding<br />

screwdriving work. Its<br />

new high-performance motor and<br />

highly efficient 3-speed planetary<br />

gearing ensure optimum performance<br />

in each demanding application.<br />

Almost identical in design and<br />

lacking only the hammer drilling<br />

function, the <strong>Hilti</strong> SF 181-A<br />

is a thoroughbred cordless drill/<br />

driver. <strong>Of</strong>fering a torque of up<br />

to 12 Nm, finely adjustable in<br />

15 increments, this tool knows<br />

virtually no limits in countless<br />

applications. Despite this high<br />

torque, it can be gripped and controlled<br />

safely by its adjustable<br />

side handle. Featuring a sturdy<br />

glass-fiber reinforced, impactresistant<br />

casing.<br />

<strong>The</strong> unique system consists of<br />

a transmitter and receiver. It<br />

is capable of transferring reference<br />

points through concrete or masonry<br />

walls having a thickness of<br />

up to 1.35 meters (4.4 ft) while also<br />

giving an accurate reading of the<br />

wall thickness. One knows in advance<br />

the position of the drill bit<br />

exit point and can also determine<br />

the suitable drill bit type and<br />

length.<br />

This new and handy system is suitable<br />

for penetrations of all walls<br />

and floors. In many situations,<br />

overhead drilling becomes completely<br />

unnecessary because, after<br />

transposing the hole-starting point<br />

from the desired exit point on the<br />

opposite side, the hole can be<br />

drilled from the side that’s most<br />

convenient to work from.<br />

<strong>The</strong> transmitter is attached to the<br />

surface at the reference point with<br />

the special adhesive putty supplied.<br />

<strong>The</strong> receiver can then be<br />

used to find the target point on the<br />

opposite side of the floor or wall<br />

within seconds. A practical point<br />

for diamond professionals: the<br />

unique oblique drilling adapter allows<br />

the drill bit exit point or holestarting<br />

point to be determined for<br />

a given angle or, alternatively, the<br />