Moscow builds a new city A distributor of electricity is ... - Hilti

Moscow builds a new city A distributor of electricity is ... - Hilti

Moscow builds a new city A distributor of electricity is ... - Hilti

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The magazine<br />

<strong>of</strong> the <strong>Hilti</strong> Group<br />

1/2007<br />

<strong>Moscow</strong> <strong>builds</strong> a <strong>new</strong> <strong>city</strong><br />

A <strong>d<strong>is</strong>tributor</strong> <strong>of</strong> electri<strong>city</strong> <strong>is</strong> redefining fire protection<br />

The hammer: like drilling in butter<br />

Reinforcing flat decks, avoiding catastrophes

Contents<br />

Page 2<br />

Worldwide<br />

4 Greenland: the rotary hammer <strong>is</strong> finally purring<br />

4 France: 400 holes per hour<br />

5 Germany: biodiesel plants in demand<br />

5 Switzerland: a test <strong>of</strong> nerves amid the mountains<br />

A US electri<strong>city</strong> <strong>d<strong>is</strong>tributor</strong> <strong>is</strong> sealing cable<br />

10penetrations and redefining fire prevention.<br />

Company<br />

6 Transition at the top: goodbye and hello<br />

8 An honor for three men<br />

9 Corporate strategy: the continuation <strong>of</strong> the three Cs<br />

9 Twelve design awards for products and the toolbox<br />

Construction<br />

10 Fire protection: handing 12,000 volts<br />

Focus on Russia<br />

14 <strong>Moscow</strong> <strong>builds</strong> a <strong>new</strong> <strong>city</strong><br />

Innovation<br />

22 Like drilling in butter<br />

In <strong>Moscow</strong> the hectic pace <strong>of</strong> high-r<strong>is</strong>e building has<br />

14broken out. 15 skyscrapers will get things started.<br />

Engineering<br />

24 Reinforcing flat decks<br />

Innovation<br />

28 Corded saws are redundant!<br />

29 New <strong>Hilti</strong> patent<br />

29 A fine touch<br />

30 Combilaser: one for all<br />

30 Comfortable work<br />

31 The hammer<br />

31 The masonry connection<br />

Successful testing: <strong>Hilti</strong> engineers develop a<br />

24method for reinforcing flat decks.<br />

Impressum<br />

Publ<strong>is</strong>her: <strong>Hilti</strong> Corporation,<br />

Corporate Communications,<br />

Postbox 333, FL-9494 Schaan,<br />

Principality <strong>of</strong> Liechtenstein<br />

Editor-in-chief: Ursula Trunz,<br />

phone: +423 234 26 30,<br />

ursula.trunz@hilti.com<br />

D<strong>is</strong>tribution: Tamara Eberle,<br />

tamara.eberle@hilti.com<br />

Layout / design: milano-graphic,<br />

CH-8640 Rapperswil, Switzerland<br />

Composition / lithos / printing: Buchs<br />

Medien AG, CH-9471 Buchs, Switzerland<br />

Publication frequency: twice a year<br />

Circulation: 36,000 (17,000 Engl<strong>is</strong>h,<br />

10,500 German, 3,000 Span<strong>is</strong>h,<br />

2,500 French, 2,000 Japanese,<br />

1,000 Italian)<br />

Cover photo: <strong>Moscow</strong> City, <strong>Moscow</strong>,<br />

Russia (Photo: <strong>Hilti</strong>)<br />

The Magazine <strong>is</strong> also available<br />

in electronic form under<br />

www.hilti.com/magazine<br />

The articles publ<strong>is</strong>hed in th<strong>is</strong> magazine<br />

may be regarded as <strong>of</strong>ficial statements<br />

by the Executive Board only when expressly<br />

marked as such. In the event <strong>of</strong><br />

differing interpretation, the original text<br />

shall apply.<br />

<strong>Hilti</strong> <strong>is</strong> a reg<strong>is</strong>tered trademark <strong>of</strong> the<br />

<strong>Hilti</strong> Corporation.<br />

© <strong>Hilti</strong> Corporation, July 2007

Magazine 1/2007<br />

Editorial<br />

Page 3<br />

Change amid<br />

growth<br />

Things come to an end even in<br />

pr<strong>of</strong>essional life. We consciously<br />

say th<strong>is</strong> at <strong>Hilti</strong> and, with<br />

an eye on the future, promote upand-coming<br />

colleagues, allowing<br />

them to prepare for challenging<br />

work early on. Taking the long<br />

view, we feel that th<strong>is</strong> helps to ensure<br />

the subsequent development<br />

<strong>of</strong> our company.<br />

At the beginning <strong>of</strong> th<strong>is</strong> year I assumed<br />

the post <strong>of</strong> Chairman <strong>of</strong> the<br />

Board <strong>of</strong> Directors from Michael<br />

<strong>Hilti</strong>, the son <strong>of</strong> company founder<br />

Martin <strong>Hilti</strong>, and handed the reins<br />

<strong>of</strong> my <strong>of</strong>fice, Chief Executive Officer,<br />

to my successor Bo R<strong>is</strong>berg<br />

after 13 fascinating and fulfilling<br />

years. As a sign <strong>of</strong> th<strong>is</strong> smooth<br />

transition that was carefully introduced<br />

according to plan, we’re<br />

writing th<strong>is</strong> editorial jointly.<br />

The enthusiasm with which you<br />

embrace our products and services,<br />

our innovations that we develop<br />

for you, and our greatly-expanded<br />

sales force, give me more<br />

optim<strong>is</strong>m than ever. I want to thank<br />

you for the loyalty that you show<br />

our company.<br />

Optim<strong>is</strong>m <strong>is</strong> contagious! Ba -<br />

sed on our very solid economic<br />

foundation and thanks to<br />

our committed employees, we all<br />

have a chance to further strengthen<br />

and expand our position within the<br />

market. We also created the strategic<br />

foundation to do so last year:<br />

we will continue to follow our<br />

Champion 3C corporate strategy,<br />

that has focused on Customer,<br />

Competence and Concentration<br />

since 1996, and are also focusing<br />

on growth in addition to other<br />

strategic priorities. In the last year<br />

alone we created more than 1400<br />

<strong>new</strong> positions, about 1100 <strong>of</strong> those<br />

in sales. Around the globe there are<br />

more than 18,000 people working<br />

for you.<br />

Differentiation <strong>is</strong> just as important<br />

to us as growth. By remaining a<br />

step ahead through the products<br />

and services that we <strong>of</strong>fer you, we<br />

provide you with unique added<br />

value that reflects greater performance<br />

and reliability. You as the customer<br />

are the first to pr<strong>of</strong>it from<br />

the strength <strong>of</strong> our innovation!<br />

Pius Baschera<br />

Chairman <strong>of</strong> the Board <strong>of</strong> Directors<br />

Bo R<strong>is</strong>berg<br />

Chief Executive Officer

Wordwide<br />

Page 4<br />

The rotary hammer<br />

<strong>is</strong> finally purring<br />

meter and, sometimes, centimeter<br />

for centimeter,” say Andrea Fichtner<br />

and Chr<strong>is</strong>toph Hainz. “Our<br />

bodies are wet and cold but they<br />

are once again at operating temperature.<br />

But once we stop moving<br />

forward we again begin to freeze.”<br />

Happy and the first ones atop the granite peak: from left<br />

Chr<strong>is</strong>toph Hainz, Roger Schäli and Andrea Fichtner.<br />

A lonesome, nameless chunk <strong>of</strong> granite in<br />

Greenland, three people and one rotary<br />

hammer. The story <strong>of</strong> a spectacular and<br />

demanding first ascent.<br />

In the far, far north, summer<br />

nights are generally light. But<br />

now heavy clouds and thick fog are<br />

hanging over Greenland and it’s<br />

raining without interruption. In<br />

spite <strong>of</strong> th<strong>is</strong> Andrea Fichtner, from<br />

Germany, Chr<strong>is</strong>toph Hainz, from<br />

Italy, and Roger Schäli, from<br />

Switzerland, have sought refuge in<br />

the wall <strong>of</strong> th<strong>is</strong> nameless mountain.<br />

The only thing that can be heard in<br />

the dark <strong>is</strong> the clinking <strong>of</strong> snap<br />

hooks. Roger Schäli <strong>is</strong> fighting up<br />

a wet crevasse while Andrea Fichtner<br />

and Chr<strong>is</strong>toph Hainz are literally<br />

hanging around, freezing and<br />

waiting until they can climb again.<br />

Finally the rotary hammer begins<br />

to purr. “Stand,” says Roger Schäli.<br />

“We work ahead quickly, meter for<br />

The stand locations are outfitted<br />

with two spring hooks each. And<br />

after a total <strong>of</strong> 16 rope lengths the<br />

trio are at the top and in the sun.<br />

“We could only gauge our luck<br />

after an hour <strong>of</strong> deep sleep in the<br />

warming rays <strong>of</strong> the sun,” wrote the<br />

extreme climbers. “Asta nunaat” <strong>is</strong><br />

the name given the mountain,<br />

meaning “white granite <strong>of</strong> the<br />

best quality.” The route for th<strong>is</strong><br />

first ascent receives the Italian<br />

name Tartaruga, or torto<strong>is</strong>e.<br />

400 holes an hour<br />

<strong>Hilti</strong> France gets an ass<strong>is</strong>t for helping set a record.<br />

A single worker can drill 400 holes in one hour. Innovative<br />

engineers from the special developments<br />

unit have designed and developed a system that<br />

drills four holes at the same time. Th<strong>is</strong> enhances<br />

efficiency and, in a positive ancillary effect, saves<br />

consumables.<br />

The story began on the day<br />

that the French company<br />

Satras came to <strong>Hilti</strong> with a special<br />

request. Satras specializes in the<br />

repair <strong>of</strong> concrete construction<br />

and, as a result, in the injection <strong>of</strong><br />

synthetic mortars and cement<br />

masses. A particular project required<br />

that 400,000 holes be<br />

drilled into a floor. In a joint d<strong>is</strong>cussion<br />

with the <strong>Hilti</strong> pr<strong>of</strong>essionals<br />

the idea <strong>of</strong> the four-hole drilling<br />

system was born.<br />

The result: the number <strong>of</strong> holes<br />

drilled per hour and worker quintupled<br />

thanks to the system. The<br />

time <strong>of</strong> doing th<strong>is</strong> type <strong>of</strong> hard<br />

work on the knees <strong>is</strong> also over.<br />

And instead <strong>of</strong> the 1000 rotary<br />

hammers that customer thought<br />

they would need, they now only<br />

require 250. The system can be<br />

outfitted with a number <strong>of</strong> various<br />

<strong>Hilti</strong> rotary hammers and <strong>is</strong><br />

suitable for the repair <strong>of</strong> floors in<br />

industrial operations, warehouses<br />

and supermarkets.<br />

Four-hole drilling system with the<br />

<strong>Hilti</strong> TE 16. Pure efficiency.

Magazine 1/2007<br />

Worldwide<br />

Page 5<br />

Biodiesel plants<br />

in demand<br />

“Th<strong>is</strong> installation system allows us to flexibly implement small changes,” says special<strong>is</strong>t project manager Armin Bredel (middle photo).<br />

Increasing ecological considerations have generated<br />

a demand for alternative fuels. To meet th<strong>is</strong><br />

demand, Lurgi <strong>is</strong> quickly building <strong>new</strong> biodiesel<br />

plants worldwide. The market leader in plant construction<br />

and process engineering <strong>is</strong> using the<br />

<strong>Hilti</strong> MI and MQ installation systems.<br />

Asmall portion <strong>of</strong> nerves <strong>is</strong><br />

part <strong>of</strong> a splendid view. Th<strong>is</strong><br />

may very well have been what the<br />

head <strong>of</strong> Formula 1, Bernie Ecclestone,<br />

was thinking. He’s one <strong>of</strong> the<br />

<strong>new</strong> owners <strong>of</strong> the glacial ski area<br />

“Glacier 3000” that <strong>is</strong> situated between<br />

Gstaad and Les Diablerets in<br />

Switzerland. A total <strong>of</strong> 118 million<br />

Sw<strong>is</strong>s francs have been invested,<br />

some 12 million francs <strong>of</strong> that in artificial<br />

snow. A toboggan run has<br />

been created at an elevation <strong>of</strong><br />

Lurgi, a technology company<br />

operating worldwide and<br />

based in Frankfurt am Main, Germany,<br />

has built the most biodiesel<br />

plants in the last few years – in Germany,<br />

France and Spain as well as<br />

in Argentina, Malaysia, Indonesia<br />

and Australia. Demand remains<br />

high and the timeframe correspondingly<br />

tight. Th<strong>is</strong> requires efficient<br />

planning, processing and installation.<br />

Lurgi can count on <strong>Hilti</strong><br />

in all these phases.<br />

Plant Design System (PDS) s<strong>of</strong>tware,<br />

from s<strong>of</strong>tware developer Intergraph,<br />

<strong>is</strong> used to plan the<br />

biodiesel plants along with the pipe<br />

support tool that was developed at<br />

the request <strong>of</strong> <strong>Hilti</strong>. Lurgi engineers<br />

construct a plant in the form <strong>of</strong> a 3D<br />

model, including all the required<br />

about 3000 meters (9842 ft) above<br />

sea level, that can be operated in either<br />

winter or summer. For the exact<br />

alignment <strong>of</strong> construction, with<br />

wind velocities <strong>of</strong> up to 80 kilometers<br />

per hour (50 mi), temperatures<br />

<strong>of</strong> -10°C and more than a meter<br />

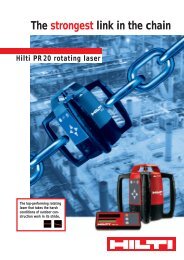

<strong>of</strong> powder snow, the <strong>Hilti</strong> PR 25<br />

rotating laser was called for. The<br />

toboggan course runs a length <strong>of</strong><br />

800 meters (2952 ft) and has a<br />

height difference <strong>of</strong> 200 meters<br />

(738 ft).<br />

components, up to the pipes and<br />

supports, and the correct dimensions.<br />

The s<strong>of</strong>tware allows for controls<br />

to ensure that the supports do<br />

not intersect with other plant components,<br />

increasing planning quality.<br />

By linking the planning s<strong>of</strong>tware<br />

and the Lurgi materials management<br />

system, where all required<br />

<strong>Hilti</strong> products are l<strong>is</strong>ted, all components<br />

needed can be ordered at the<br />

touch <strong>of</strong> a button.<br />

The efficiency <strong>of</strong> the planning continues<br />

at the construction site.<br />

“The <strong>Hilti</strong> installation systems<br />

allow our installers to make little<br />

adjustments without a great deal <strong>of</strong><br />

The assembly takes place at temperatures below zero.<br />

effort,” says Armin Bredel, special<strong>is</strong>t<br />

project manager for bio -<br />

diesel plants in Enns, Austria.<br />

“Th<strong>is</strong> helps us to meet the deadlines<br />

as the construction progresses.”<br />

The international <strong>Hilti</strong><br />

service network <strong>is</strong> just as important<br />

for worldwide cooperation<br />

as proximity to the customers. “We<br />

appreciate the short delivery periods<br />

for badly-needed parts and<br />

consulting on location,” says Bülent<br />

Atik, site engineer for the<br />

biodiesel plant at the Höchst industrial<br />

park near Frankfurt am<br />

Main.<br />

A test <strong>of</strong> nerves in the mountains

Company<br />

Page 6<br />

Bo R<strong>is</strong>berg (left) has been CEO since January 1. Marco Meyrat (second from left)<br />

has been in the Executive Board since the beginning <strong>of</strong> 2005. Chr<strong>is</strong>toph Loos (third from left)<br />

and Stefan Nöken (right) joined the Executive Board on January 1

Magazine 1/2007<br />

Company<br />

Page 7<br />

The <strong>Hilti</strong> Group underwent the largest shift in upper management in<br />

13 years at the beginning <strong>of</strong> 2007. Michael <strong>Hilti</strong>, previously Chairman<br />

<strong>of</strong> the Board <strong>of</strong> Directors, handed th<strong>is</strong> <strong>of</strong>fice to Pius Baschera, the<br />

former Chief Executive Officer, as <strong>of</strong> January 1 and now serves as a<br />

board member. Bo R<strong>is</strong>berg, until now a member <strong>of</strong> the Executive<br />

Board, was named the <strong>new</strong> Chief Executive Officer. H<strong>is</strong> former position<br />

in the Executive Board was filled by Stefan Nöken. Chr<strong>is</strong>toph Loos<br />

also joined the Executive Board in January 2007, replacing Egbert Appel<br />

who was named a Trustee <strong>of</strong> the Martin <strong>Hilti</strong> Family Trust. Bo R<strong>is</strong>berg,<br />

Chr<strong>is</strong>toph Loos and Stefan Nöken, together with ex<strong>is</strong>ting Executive<br />

Board member Marco Meyrat, form the <strong>new</strong> Executive Board.<br />

Goodbye<br />

and hello<br />

Pius Baschera’s statement <strong>is</strong><br />

surpr<strong>is</strong>ing: “From our point<br />

<strong>of</strong> view the transition was nothing<br />

revolutionary.” The transition was<br />

announced in 2005 and all participants<br />

carefully prepared for their<br />

<strong>new</strong> positions in 2006 as the shift<br />

began. “Perhaps,” Pius Baschera<br />

continues, “the spectacular <strong>is</strong> simply<br />

the smoothness <strong>of</strong> th<strong>is</strong> transition,<br />

which was long in the planning,<br />

and that it went <strong>of</strong>f without a<br />

hitch.”<br />

Continuity at the <strong>Hilti</strong> Group, as<br />

mentioned repeatedly by both Michael<br />

<strong>Hilti</strong> and Pius Baschera, <strong>is</strong><br />

not based on individual names but<br />

on the transfer <strong>of</strong> knowledge and<br />

on promoting colleagues who then<br />

grow into their demanding positions.<br />

It's really about the development<br />

<strong>of</strong> the employee and, thereby,<br />

the company. “So we said goodbye<br />

to one function and hello to ano -<br />

ther,” resumed Pius Baschera. H<strong>is</strong><br />

successor, Bo R<strong>is</strong>berg, and h<strong>is</strong><br />

Executive Board colleagues Chr<strong>is</strong>toph<br />

Loos, Marco Meyrat and Stefan<br />

Nöken, have known the company<br />

for years, and know it well<br />

through the various positions they<br />

have held. And - even more importantly<br />

- they live out the corporate<br />

culture. From their point <strong>of</strong> view<br />

it's the bas<strong>is</strong> for success.<br />

Turn the page and read how the<br />

change in the Executive Management<br />

moved hundreds and thousands<br />

<strong>of</strong> people.<br />

Bo R<strong>is</strong>berg<br />

Bo R<strong>is</strong>berg (born 1956 in Sweden)<br />

has been CEO since 1 January<br />

2007. H<strong>is</strong> predecessor in <strong>of</strong>fice,<br />

Pius Baschera, became Chairman<br />

<strong>of</strong> the Board <strong>of</strong> Directors, effective<br />

on the same date.<br />

Bo R<strong>is</strong>berg trained as a mechanical<br />

engineer in Canada and earned<br />

a Master <strong>of</strong> Business Admin<strong>is</strong>tration<br />

in Switzerland. He came to<br />

<strong>Hilti</strong> in 1999 as Head <strong>of</strong> the Business<br />

Unit Drilling and Demolition.<br />

From 2001 to 2006, as a member<br />

<strong>of</strong> the Executive Board, he was responsible<br />

for the business areas,<br />

for the supply chain (compr<strong>is</strong>ing<br />

production, sourcing and log<strong>is</strong>tics)<br />

and for <strong>new</strong> business & technology.<br />

Since fall 2006 R<strong>is</strong>berg has<br />

served as President <strong>of</strong> the European<br />

Power Tool Association<br />

(EPTA).

Company<br />

Page 8<br />

An honor for<br />

three men<br />

They came from the four corners <strong>of</strong> the world.<br />

From every country where <strong>Hilti</strong> operates. Many <strong>of</strong><br />

them had never been to Europe before. Hundreds<br />

<strong>of</strong> them came to the Sw<strong>is</strong>s Alpine village <strong>of</strong> Davos<br />

to honor three men: Michael <strong>Hilti</strong>, Pius Baschera<br />

and Egbert Appel.<br />

None <strong>of</strong> the three men realized<br />

the log<strong>is</strong>tical and organizational<br />

levers they set in motion<br />

months before. The <strong>new</strong>ly constituted<br />

Executive Board, cons<strong>is</strong>ting<br />

<strong>of</strong> Bo R<strong>is</strong>berg, Marco Meyrat,<br />

Chr<strong>is</strong>toph Loos and Stefan Nöken,<br />

had initiated a huge surpr<strong>is</strong>e party<br />

for their departing colleagues. After<br />

13 years these men were leaving<br />

one position at the end <strong>of</strong> 2006<br />

to take up another one at the beginning<br />

<strong>of</strong> 2007 (read more in<br />

the article Goodbye and hello on<br />

page 7).<br />

More than 750 hands swung red<br />

light sticks in the dark <strong>of</strong> the Davos<br />

Convention Center’s main hall as<br />

the three men, amazed and speechless,<br />

were led onto the stage. The<br />

moment was inspiring and moving<br />

– for everyone. As Michael <strong>Hilti</strong>,<br />

Pius Baschera and Egbert Appel<br />

were honored with both humorous<br />

and poignant speeches, some participants<br />

were daubing at their<br />

eyes. Then Michael <strong>Hilti</strong>, speaking<br />

not only <strong>of</strong> those employees present<br />

in the hall, spoke one sentence<br />

that put everything into perspective.<br />

“You make my life worthwhile.”<br />

A moving scene.<br />

750 red sticks shine<br />

on the three men<br />

from the dark hall.<br />

The <strong>new</strong> Executive<br />

Board, dressed<br />

in dark clothes,<br />

arranged th<strong>is</strong> tribute.<br />

Strong emotions, friendly encounters.<br />

Pius Baschera, Michael <strong>Hilti</strong> and Egbert Appel<br />

clearly enjoyed the evening.

Magazine 1/2007<br />

Company<br />

Page 9<br />

Strategy: the<br />

three Cs continue<br />

Three Cs lead <strong>Hilti</strong> employees through their pr<strong>of</strong>essional<br />

life and to strategically-solid deeds. The<br />

<strong>Hilti</strong> Group has been oriented on the Champion<br />

3C corporate strategy since 1996 – and will continue<br />

to be in the future.<br />

The customer comes first –<br />

without exception. That <strong>is</strong><br />

what the first C stands for. <strong>Hilti</strong><br />

provides its customers with unique<br />

competency – the source <strong>of</strong> the<br />

second C. The products, systems<br />

and services <strong>of</strong>fered to the customers<br />

are d<strong>is</strong>tingu<strong>is</strong>hed by path<br />

breaking innovation and total quality.<br />

The third C stands for concentration<br />

on markets and products<br />

where <strong>Hilti</strong> can achieve and sustain<br />

leadership positions.<br />

While staff worked toward their immediate<br />

operational goals in 2006,<br />

the <strong>Hilti</strong> Group’s Executive Board<br />

and Executive Management Team<br />

were preparing for the next strategic<br />

period, to stretch into 2015.<br />

At the International Strategy Forum<br />

in Davos, which brought together<br />

some 150 members <strong>of</strong> upper management<br />

from around the world in<br />

November 2006 (and where the surpr<strong>is</strong>e<br />

party took place – see “An<br />

honor for three men”) the third<br />

phase <strong>of</strong> the corporate strategy was<br />

inaugurated: <strong>Hilti</strong> will continue on<br />

its growth path, pr<strong>of</strong>iling itself even<br />

more d<strong>is</strong>tinctly by means <strong>of</strong> its<br />

products and services, increasing<br />

productivity further in all areas<br />

while at the same time making its<br />

employees and their development<br />

its main priority. Bo R<strong>is</strong>berg, setting<br />

the tone for h<strong>is</strong> work as Chief<br />

Executive Officer, said: “Our core<br />

competency remains the same as<br />

ever: providing innovative solutions,<br />

developed with the help <strong>of</strong><br />

our practical expert<strong>is</strong>e and direct<br />

customer relations. Th<strong>is</strong> will continue<br />

to form the bas<strong>is</strong> <strong>of</strong> our business<br />

model.”<br />

Twelve design awards<br />

Design awards are raining down on <strong>Hilti</strong> products<br />

and the <strong>Hilti</strong> toolbox. Corporate Chief Designer<br />

Stephan Niehaus accepted 12 awards. More than<br />

any other company in the branch. Design gives<br />

<strong>Hilti</strong> products the added value <strong>of</strong> an unm<strong>is</strong>takable<br />

face.<br />

Aperson needs no more than<br />

ten seconds to make a dec<strong>is</strong>ion.<br />

They make th<strong>is</strong> dec<strong>is</strong>ion with<br />

their senses. How does the grip feel<br />

on a particular tool? How does a<br />

switch sound when it’s thrown? It<br />

takes a matter <strong>of</strong> seconds to generate<br />

sustainable product enthusiasm<br />

in a customer. “Th<strong>is</strong> <strong>is</strong> why we do<br />

everything we can to ensure that<br />

the customer can actually see, feel<br />

and hear the quality and durability<br />

<strong>of</strong> our tools,” says Corporate Chief<br />

Designer Stephan Niehaus. Design<br />

<strong>is</strong> the means to express the added<br />

value <strong>of</strong> <strong>Hilti</strong> tools without using<br />

words.<br />

It’s about much more than mere superficial<br />

beauty. It must come from<br />

within, and externally express the<br />

advantages found inside a tool. The<br />

international jury <strong>of</strong> experts for<br />

the iF product design award in<br />

Hanover, Germany, therefore bestowed<br />

four awards on <strong>Hilti</strong> at<br />

the beginning <strong>of</strong> March: for the<br />

TE 106 breaker, TE 7-C rotary<br />

hammer, two polygon ch<strong>is</strong>els and<br />

for the <strong>new</strong> toolbox.<br />

The international expert jury for<br />

the red dot awards, given by the<br />

Design Zentrum Nordrhein Westfalen,<br />

gave <strong>Hilti</strong> eight awards. The<br />

jury gave the TE 7-C rotary hammer<br />

the red dot award: best <strong>of</strong> the<br />

best for the tool’s “outstanding design<br />

qualities.” The toolbox also<br />

scored points here as the three-dimensional<br />

symbol for the <strong>Hilti</strong><br />

brand. In addition to the twin<br />

award winning TE 106 and polygon<br />

ch<strong>is</strong>el, red dot awards were<br />

given to the SID/SIW 144-A tangential<br />

impact screwdriver, the<br />

WSC 70-A36 cordless hand-held<br />

circular saw, the TE 7-A cordless<br />

rotary hammer and the PX 10<br />

transpointer.<br />

The iF design award <strong>of</strong> the Inter -<br />

national Forum Design in Hanover<br />

and the Design Zentrum Nordrhein<br />

Westfalen’s red dot award are<br />

among the most coveted and<br />

renown design prizes in the world.<br />

Some 2000 products from roughly<br />

40 countries are submitted annually<br />

for the iF product design awards<br />

alone.

Construction<br />

Page 10<br />

Handling 12,<br />

ComEd, an electric transm<strong>is</strong>sion and d<strong>is</strong>tribution company in the United<br />

States, <strong>is</strong> currently engaged in a major substation fire protection program.<br />

An important piece <strong>of</strong> th<strong>is</strong> program <strong>is</strong> installing <strong>Hilti</strong> firestop products in cable<br />

penetrations at many <strong>of</strong> its larger substations. Seen as a proactive<br />

step, installing firestops will limit fire or smoke damage to a controlled<br />

area, which in turn improves reliability by minimizing potential outages times.<br />

by Manfred Schiefer (text) and Dan White (photos)<br />

Entering the substation, the<br />

lights are turned on and the<br />

neon tubes give <strong>of</strong>f a ghostly, pale<br />

light along the long row <strong>of</strong> dull,<br />

gray-colored switchgear cabinets.<br />

The first floor holds switching<br />

equipment and the basement, also<br />

called a cable space, contains power<br />

and control cables. At the desk station<br />

electrical maps, a phone, and<br />

various phone numbers are found.<br />

One <strong>of</strong> the numbers <strong>is</strong> for ComEd’s<br />

control center. Jim Ford, LTT General<br />

Manager Specialty Construction<br />

Div<strong>is</strong>ion, goes to the phone and

Magazine 1/2007<br />

Construction<br />

Page 11<br />

000 volts<br />

dials th<strong>is</strong> number to reports our v<strong>is</strong>it<br />

to the ComEd <strong>of</strong>fice because they<br />

must be notified who <strong>is</strong> entering, the<br />

purpose, and duration.<br />

Next, the team gathers for a job<br />

safety briefing. It <strong>is</strong> important that<br />

everyone knows who <strong>is</strong> doing what,<br />

what the critical steps are and what<br />

safety-relevant <strong>is</strong>sues they should<br />

be thinking about. Because we will<br />

be working in the cable space, we<br />

d<strong>is</strong>cuss confined space entry and<br />

emergency exit procedures. After<br />

the briefing, the hatches are opened,<br />

air quality <strong>is</strong> monitored, and the air<br />

and rescue equipment <strong>is</strong> put in<br />

place.<br />

“Down in the hole, Bill,“ says<br />

David, as he steps onto the rung <strong>of</strong><br />

a ladder and looks up once again.<br />

He wants to make certain that Bill<br />

knows he’s going down. “Going<br />

down, Bill,” follows Tom, who<br />

briefly looks up before descending<br />

into the hole. “Going down:” one<br />

after another, the workers descend<br />

Descending into a substation with special equipment.

Construction<br />

Page 12<br />

John R. Bettler,<br />

head <strong>of</strong> the<br />

Fire Protection<br />

Engineering<br />

Group at ComEd:<br />

“Effective fire<br />

protection <strong>is</strong> like<br />

insurance for us.”<br />

into the lower regions <strong>of</strong> the electrical<br />

substation until all but one <strong>is</strong><br />

in the basement. Bill has to stay<br />

above ground to record who enters<br />

and exits, observe the air meters<br />

and, in case <strong>of</strong> an emergency, call<br />

for help.<br />

Safety first<br />

Once down in the cable space,<br />

you realize the difficulties in applying<br />

firestops in a substation and<br />

why ComEd demands the incredible<br />

attention to safety. The basement<br />

<strong>is</strong> filled with cables. From<br />

every wall <strong>of</strong> the station’s basement,<br />

power cables energized at<br />

12,000 volts enter the station and<br />

r<strong>is</strong>e up through core-drilled holes<br />

into the switchgear upstairs. Also,<br />

control cable pans hang from the<br />

ceiling, carrying hundred <strong>of</strong> cables<br />

used for metering, power and control<br />

<strong>of</strong> the electric equipment.<br />

In addition to the cables, the ceiling<br />

<strong>is</strong> low and the floor <strong>is</strong> constructed<br />

<strong>of</strong> tamped gravel. “A lot <strong>of</strong> times<br />

the basement <strong>is</strong> below the ground<br />

water level,” says Jim Ford, “The<br />

power lines enter the substation<br />

through the basement walls, so the<br />

buildings are never completely watertight.”<br />

Th<strong>is</strong> can make the work<br />

areas slippery.<br />

All <strong>of</strong> the penetrations from the<br />

basement to the first floor need to<br />

be sealed. The firestop material <strong>is</strong><br />

installed from the cablespace to<br />

Complacency<br />

<strong>is</strong> the greatest r<strong>is</strong>k.<br />

Andy Grein <strong>of</strong><br />

ComEd and Jim Ford<br />

<strong>of</strong> the installation<br />

special<strong>is</strong>ts LTT.<br />

maintain clearance from exposed<br />

electrical parts in the switchgear.<br />

In th<strong>is</strong> way, the penetrations can be<br />

sealed without having to take the<br />

equipment out <strong>of</strong> service. ComEd<br />

and Luse worked closely with <strong>Hilti</strong><br />

engineers to develop seals that<br />

would work for th<strong>is</strong> application.<br />

These <strong>new</strong> designs and work practices<br />

amounted to huge savings in<br />

time and expense.<br />

ComEd, based in Chicago, Illino<strong>is</strong>,<br />

<strong>is</strong> a subsidiary <strong>of</strong> Exelon,<br />

one <strong>of</strong> the largest energy producers<br />

in the USA. ComEd d<strong>is</strong>tributes<br />

electri<strong>city</strong> to 3.7 million endusers<br />

in Illino<strong>is</strong>. To do th<strong>is</strong>, they<br />

must maintain more than 78,000<br />

miles <strong>of</strong> power lines and operate<br />

hundreds <strong>of</strong> transformer substations.<br />

“Safety <strong>is</strong> paramount,” says ComEd<br />

Project Manager Andy Grein, “especially<br />

when we have installers<br />

working in an energized environment.”<br />

Before the special<strong>is</strong>ts from<br />

Luse are allowed to go into the<br />

substation they must first complete<br />

a five-day training program.<br />

In addition to the dangers posed<br />

by the electri<strong>city</strong> and working in a<br />

confined space, the workers are<br />

also trained in CPR and other first<br />

aid techniques so that they are<br />

prepared for any type <strong>of</strong> incident<br />

that might occur.<br />

Although the workers acclimatize<br />

quickly to the dangerous environment,<br />

they must be careful to never<br />

to become complacent. “Th<strong>is</strong> <strong>is</strong><br />

the greatest r<strong>is</strong>k,” says Jim Ford<br />

from LTT. “Having a feeling <strong>of</strong> familiarity<br />

with 12,000 volt cables<br />

can breed a relaxed attitude, which<br />

increases the dangers significantly.”<br />

To fight th<strong>is</strong>, the team has a<br />

safety meeting before work and<br />

also d<strong>is</strong>cusses safety procedures<br />

after lunch and again at the end <strong>of</strong><br />

the day. “In 30,000 working hours<br />

we have not had an accident or a<br />

breakdown,” says Ford in pointing<br />

out the success <strong>of</strong> the safety program<br />

he developed.<br />

A fire in a substation can greatly<br />

impact a utility’s financial situation,<br />

reliability and customer sat<strong>is</strong>faction.<br />

Steps taken to mitigate or<br />

reduce the damage can have a big<br />

impact. “Effective fire protection<br />

<strong>is</strong> like insurance for us,” says John<br />

R. Bettler, head <strong>of</strong> the Fire Protection<br />

Engineering Group at ComEd.<br />

“It helps us to attain our primary<br />

goal – to make sure that our customers’<br />

lights never go out.” These<br />

fire protection upgrades make<br />

sense, because they will limit<br />

losses and down time in the event<br />

<strong>of</strong> a fire.

Magazine 1/2007<br />

Construction<br />

Page 13<br />

Ceilings perforated like Sw<strong>is</strong>s<br />

cheese. The numerous control,<br />

measuring and live power cables<br />

lead through hundreds <strong>of</strong><br />

penetrations. <strong>Hilti</strong> engineers<br />

have developed tailor-made<br />

firestop designs for sealing<br />

the various field conditions<br />

encountered.<br />

The task, however, <strong>is</strong> anything but<br />

simple. “The ceilings <strong>of</strong> transformer<br />

substations look like Sw<strong>is</strong>s<br />

cheese,” says Luse Project Manager<br />

Lance Simms. “In addition to<br />

the live power cables there are control<br />

cables everywhere, leading up<br />

to the switchgear cabinets.” In<br />

order to seal the hundreds <strong>of</strong> penetrations<br />

found in one ComEd substation<br />

<strong>Hilti</strong> fire protection engineers<br />

developed many unique<br />

designs (engineering judgments)<br />

for sealing <strong>new</strong> field conditions as<br />

they were encountered. “The turn<br />

around time from <strong>Hilti</strong>, for producing<br />

these <strong>new</strong> firestop solutions <strong>is</strong><br />

quite impressive,” says Simms.<br />

The hatches that allow access to<br />

the substation basements pose a<br />

particular challenge. ComEd<br />

needs to be able to open them at<br />

any time, yet they must provide a<br />

barrier to heat and smoke from the<br />

basement in the event <strong>of</strong> a fire.<br />

<strong>Hilti</strong> products are also used for th<strong>is</strong><br />

solution. The hatch <strong>is</strong> covered on<br />

its underside with <strong>Hilti</strong> CP 675T<br />

firestop board, turning it into a heat<br />

shield. The board <strong>is</strong> surrounded by<br />

wrap strip that will expand and<br />

close <strong>of</strong>f gaps in the event <strong>of</strong><br />

a fire. With th<strong>is</strong> barrier in place,<br />

the hatch <strong>is</strong> still light enough that<br />

it can be opened by ComEd field<br />

crews. “Th<strong>is</strong> <strong>is</strong> a true innovation<br />

for us,” says Bettler.<br />

The majority <strong>of</strong> the firestops provide<br />

a 3-hour fire rating, but in<br />

some field conditions only a<br />

smoke seal can be installed. R<strong>is</strong>k<br />

assessments are performed when<br />

needed to evaluate the seal design.<br />

Pre-walk downs <strong>of</strong> the sites by<br />

ComEd and Luse establ<strong>is</strong>h the basic<br />

designs. Additionally, ComEd<br />

supplies a field engineer who<br />

spends 2-3 days a week with the<br />

crews who can evaluate the seal requirements<br />

and the installation<br />

hazards if something <strong>new</strong> emerges.<br />

The field engineer also provides a<br />

quality review <strong>of</strong> all the installed<br />

seals.<br />

ComEd has implemented an impressive<br />

firestop program. And as<br />

we leave the station after notifying<br />

the control center, it <strong>is</strong> easy to understand<br />

the rigor around safety.<br />

Driving away from the station, seeing<br />

all the well-lit homes, shopping<br />

centers, and commercial centers, it<br />

<strong>is</strong> easy to see the need.<br />

Installation and inspection<br />

The demands placed on the<br />

firestop designs used in ComEd facilities<br />

are much greater than those<br />

found in commercial construction.<br />

The considerable weight and mass<br />

<strong>of</strong> the bundled cables called for<br />

the development <strong>of</strong> unique firestop<br />

designs to meet the challenges<br />

<strong>of</strong> the large penetrants found in<br />

substations. Other <strong>is</strong>sues, like<br />

cable vibration produced by the<br />

flow <strong>of</strong> electri<strong>city</strong> in high voltage<br />

cables created a concern that vibration<br />

may loosen the firestop<br />

materials.<br />

Currently, ComEd plans on implementing<br />

an annual inspection program<br />

to review the conditions <strong>of</strong><br />

the sealed basement areas and inspect<br />

for any damage. Initially, engineering<br />

will perform th<strong>is</strong> review to<br />

make sure policies and procedures<br />

are being followed but over time<br />

th<strong>is</strong> will be moved over to the maintenance<br />

workforce. “We are working<br />

on a monitoring program that<br />

immediately identifies possible<br />

changes to installed systems and<br />

minimizes possible damage,” says<br />

Bettler.

Focus on Russia<br />

Page 14<br />

<strong>Moscow</strong> <strong>builds</strong><br />

a <strong>new</strong> <strong>city</strong>

Magazine 1/2007<br />

Focus on Russia<br />

Page 15<br />

The hectic pace <strong>of</strong> high-r<strong>is</strong>e construction has broken out along<br />

the bank <strong>of</strong> the slow-moving Moskva River in Russia’s capital<br />

<strong>city</strong>. Fifteen skyscrapers will soon form the <strong>new</strong> <strong>city</strong> center,<br />

known as <strong>Moscow</strong> City. New streets, tunnels and bridges must<br />

also be built. <strong>Moscow</strong> <strong>is</strong> a <strong>city</strong> in the midst <strong>of</strong> transformation.<br />

<strong>Moscow</strong> City: individual<br />

towers are already standing.<br />

The ones to follow will break<br />

height records.<br />

By Ursula Trunz (text) and Uli Reitz (photos)

Focus on Russia<br />

Page 16<br />

<strong>Moscow</strong>’s skyline <strong>is</strong> changing. The Federation Tower<br />

will sit in between the two ex<strong>is</strong>ting towers.<br />

The western part <strong>of</strong> the<br />

Federation Tower looks down<br />

on the first few stories <strong>of</strong> the<br />

what will be the triangular<br />

eastern part. Small photo: the<br />

north tower <strong>is</strong> almost fin<strong>is</strong>hed.<br />

The western part <strong>of</strong> the Federation Tower (middle <strong>of</strong> photo) <strong>is</strong> as high as it will get. The eastern part will one day<br />

look down at it, along with the Embankment Tower (at right). Photo at top: the <strong>Moscow</strong> skyline sees the r<strong>is</strong>e <strong>of</strong> the<br />

Federation and Embankment Towers.

Magazine 1/2007<br />

Focus on Russia<br />

Page 17<br />

It can’t bee seen from Red<br />

Square. Or from old Arbat<br />

Street or, initially, from the Cathedral<br />

<strong>of</strong> Chr<strong>is</strong>t the Savior. But<br />

Alexey Nebaev, a Muscovite to the<br />

depths <strong>of</strong> h<strong>is</strong> heart, wrings h<strong>is</strong><br />

hands with fascination and wonder.<br />

“<strong>Moscow</strong> <strong>is</strong> being transformed.”<br />

From the pedestrian<br />

bridge leading from the Cathedral<br />

<strong>of</strong> Chr<strong>is</strong>t the Savior over the dark,<br />

flowing Moskva one can detect the<br />

small tooth jutting up on the ho rizon.<br />

That must be <strong>Moscow</strong> City,<br />

the <strong>new</strong> <strong>city</strong> within the <strong>city</strong><br />

On the following day, Alexey<br />

Nebaev drives with us to <strong>Moscow</strong><br />

Lomonosov University. The colossal<br />

construction, built in the 1950s,<br />

along with seven other buildings<br />

from the Stalin era, pitch and fall out<br />

<strong>of</strong> the otherw<strong>is</strong>e flat construction<br />

landscape. <strong>Moscow</strong> Lomonosov<br />

University stands atop one <strong>of</strong><br />

seven hills in the <strong>city</strong>. Viewed from<br />

th<strong>is</strong> vantage point, <strong>Moscow</strong> City<br />

r<strong>is</strong>es out <strong>of</strong> the southwest and fairly<br />

shoves itself into the <strong>city</strong>’s skyline.<br />

Th<strong>is</strong> <strong>is</strong> where we are headed.<br />

“<strong>Moscow</strong> will soon have two <strong>city</strong><br />

centers. The political center, based<br />

around the Kremlin, and the commercial<br />

center, based around<br />

<strong>Moscow</strong> City,” says Alexey Nebaev<br />

while we’re on the way to the<br />

Metro. Escalators, steep, long and<br />

moving twice as fast as anywhere<br />

else, take us deep below the <strong>city</strong><br />

surface. Trains then transport us<br />

past beautifully-decorated stops<br />

that are lighted in the manner <strong>of</strong><br />

theater halls <strong>of</strong> an earlier era. They<br />

will bring us to our futur<strong>is</strong>tic target.<br />

15 skyscrapers over a surface area<br />

<strong>of</strong> 60 hectares (148 ac), lying directly<br />

on the Moskva’s Krasnopresnenskaya<br />

embankment, represent<br />

<strong>Moscow</strong>’s answer to Manhattan.<br />

And it’s growing daily. The<br />

small tooth we observed turns<br />

out to be the western segment <strong>of</strong><br />

the Federation Tower. It has already<br />

reached its planned height<br />

<strong>of</strong> 235.4 meters (772 ft) while<br />

the eastern segment continues to<br />

grow upward, eventually reaching<br />

a height <strong>of</strong> 340 meters (1140 ft).<br />

A 435 meter-tall spire (1427 ft)<br />

will r<strong>is</strong>e between the two towers,<br />

statically uniting them while housing<br />

panoramic elevators. The Federation<br />

Tower will be Europe’s<br />

highest skyscraper.<br />

Russia lost its ability to build<br />

skyscrapers over the last 50 years,<br />

as local special<strong>is</strong>ts freely admit.<br />

The Turk<strong>is</strong>h construction company<br />

Ant Yapi <strong>is</strong> building the western<br />

tower while a Chinese company<br />

constructs the eastern tower. Both<br />

companies brought their workers<br />

with them to <strong>Moscow</strong>, so on the<br />

western tower Turk<strong>is</strong>h <strong>is</strong> the common<br />

language while on the eastern<br />

tower Chinese can be heard. Even<br />

the written instruction to the<br />

workers are in their local languages.<br />

As countries move closer<br />

together, it seems they remain at a<br />

d<strong>is</strong>tance.<br />

The construction elevator takes us<br />

to one <strong>of</strong> the lower, practically fin<strong>is</strong>hed<br />

floors <strong>of</strong> the west tower. The<br />

Russian Armo Group has establ<strong>is</strong>hed<br />

temporary <strong>of</strong>fices here to<br />

plan the water, heating, air conditioning<br />

and alarms and sprinkler installations.<br />

They will be installed<br />

together by a subcontractor. Project<br />

manager Alexander Mo<strong>is</strong>eev sees<br />

the height <strong>of</strong> the building as the<br />

biggest challenge, in addition to the<br />

question as to how efficiency, quality<br />

and price can best be combined.<br />

One hundred so-called communication<br />

centers are planned for the<br />

apartments on the upper ten stories<br />

<strong>of</strong> the 60-story building, that will<br />

primarily house commercial <strong>of</strong>fice<br />

space, where the pipes will all meet<br />

and consumption <strong>of</strong> water and energy<br />

will be monitored. In build -<br />

ing these communication centers<br />

Alexander Mo<strong>is</strong>eev <strong>is</strong> using the<br />

<strong>Hilti</strong> MN channel installation system<br />

exclusively. “According to my<br />

calculations we will have to drill<br />

ten-times fewer holes in the concrete,<br />

enhancing our efficiency. We<br />

also have greater flexibility with<br />

the <strong>Hilti</strong> system. On top <strong>of</strong> that,<br />

they are appealing to look at. The<br />

savings we will see in terms <strong>of</strong> fastening<br />

points and working time will<br />

more than make up for the higher<br />

price. We’re not rich enough to use<br />

cheap materials.”<br />

Our next station <strong>is</strong> the northern<br />

tower. The beefy round construction,<br />

with four squared supports, <strong>is</strong><br />

a “mere” 29 stories tall and <strong>is</strong> being<br />

built by the Austrian Strabag<br />

company. Water supply, as well<br />

as heating, air conditioning and<br />

ventilation has been farmed out to<br />

the Austrian VA Tech company.<br />

<strong>Hilti</strong> Russia has set up a container<br />

for these customers directly at<br />

the construction site where they<br />

have direct access to all the material<br />

required for the installation<br />

work. Having the available material<br />

in the immediate vicinity <strong>is</strong><br />

just as important as the material’s<br />

quality.<br />

From the ro<strong>of</strong> <strong>of</strong> the northern tower<br />

Alexey Nebaev scans the area as

Focus on Russia<br />

Page 18<br />

he had done previously on the hill<br />

at <strong>Moscow</strong> Lomonosov University.<br />

Although he coordinates all contacts<br />

to the customers at <strong>Moscow</strong><br />

City as <strong>Hilti</strong>’s Top Project Manager,<br />

he can hardly grasp the<br />

dimensions <strong>of</strong> the overall construction<br />

plan. “More than 70 compa -<br />

nies and subcontractors are participating<br />

in the project. When I arrive<br />

I sometimes don’t know where to<br />

start.” Dealing with the dozens <strong>of</strong><br />

contact partners and consulting<br />

<strong>Hilti</strong> engineers he needs a great<br />

deal <strong>of</strong> nerves and special<strong>is</strong>t knowledge.<br />

Additionally, the product<br />

range varies according to individual<br />

customer and project to project.<br />

There’s no product line that <strong>is</strong> not<br />

represented here. One year ago<br />

<strong>Hilti</strong> Russia invited representatives<br />

from the developers, insurance<br />

companies, <strong>of</strong>ficial authorities and<br />

the construction and engineer companies<br />

involved to a fire protection<br />

seminar. The topic <strong>is</strong> gaining significance<br />

for skyscrapers and requires<br />

the experience <strong>of</strong> experts.<br />

est segment r<strong>is</strong>e to the 59th <strong>of</strong> a<br />

planned 60 stories, jutting blackly<br />

into the blue <strong>Moscow</strong> sky. Up there<br />

the team <strong>of</strong> engineer Özgür Barlas<br />

– working for the Turk<strong>is</strong>h construction<br />

company Enka – are fastening<br />

trapezoidal steel sheeting to<br />

the steel beams with the <strong>Hilti</strong> DX<br />

76 powder-actuated fastener. He<br />

has no time to enjoy the view <strong>of</strong><br />

the <strong>city</strong> from th<strong>is</strong> l<strong>of</strong>ty height. Having<br />

completed h<strong>is</strong> studies two<br />

years ago he laughs when he says<br />

that th<strong>is</strong> <strong>is</strong> “my first skyscraper.”<br />

New height record<br />

Far below us <strong>is</strong> an as yet undeveloped<br />

spot <strong>of</strong> land, traversed by<br />

stray dogs. “That’s where the Russia<br />

Tower will be built. It was<br />

planned by the famous architect<br />

Sir Normal Foster,” says Alexey<br />

Nebaev. In <strong>Moscow</strong> one talks<br />

about the fact that th<strong>is</strong> <strong>is</strong> to be<br />

the highest skyscraper in the<br />

world. And that something even<br />

higher <strong>is</strong> to be built next to<br />

<strong>Moscow</strong> City.<br />

In <strong>Moscow</strong>, with its 15 million inhabitants,<br />

one also speaks <strong>of</strong> running<br />

out <strong>of</strong> room. On average, one<br />

person lives on approximately a<br />

bit more than 20 square meters<br />

(215 sq ft), as much as one-third<br />

less than in the rest <strong>of</strong> Europe.<br />

Each year about five million<br />

square meters (53,819,500 sq ft) <strong>of</strong><br />

residential space <strong>is</strong> constructed.<br />

Prices are r<strong>is</strong>ing inexorably. In<br />

2006 alone prices are said to have<br />

doubled to an average 4500 dollars<br />

per square meter. Traffic <strong>is</strong> also a<br />

hot topic <strong>of</strong> d<strong>is</strong>cussion. <strong>Moscow</strong>’s<br />

four rings – the outermost <strong>of</strong> which<br />

circles the <strong>city</strong> with 108 kilometers<br />

(67 mi), are chronically jammed.<br />

Muscovites complain that they can<br />

no longer keep up contacts with<br />

friends and relatives as the drive<br />

through the <strong>city</strong> takes far too much<br />

time. Local psycholog<strong>is</strong>ts warn<br />

that sitting in traffic for hours can<br />

trigger aggression.<br />

The excavation work <strong>is</strong> the only<br />

thing completed on the Eurasia and<br />

Mercury Towers. There <strong>is</strong> also<br />

nothing to be seen <strong>of</strong> the two Capital<br />

City towers. But the three<br />

building components <strong>of</strong> the Embankment<br />

Tower are almost complete.<br />

The steel construction bears<br />

witness to the impressive size. The<br />

ends <strong>of</strong> the supports for the high-<br />

Alexander Mo<strong>is</strong>eev, Project Manager for the Russian<br />

Armo Group. Ten times fewer holes to drill ra<strong>is</strong>es efficiency<br />

in the western portion <strong>of</strong> the Federation Tower.<br />

<strong>Hilti</strong>’s Martin Tsaune provides<br />

the desired products directly on<br />

the construction site.

Magazine 1/2007<br />

Focus on Russia<br />

Page 19<br />

Differing methods <strong>of</strong> construction:<br />

the steel construction <strong>of</strong> the<br />

Embankment Tower (photo far left)<br />

and the concrete construction <strong>of</strong><br />

the Federation Towers (at left).<br />

Trapezoidal steel sheeting<br />

being fastened to the<br />

steel beams efficiently<br />

and reliably.<br />

Tunnel and bridge<br />

On the following day we travel to<br />

the north on Leningrad Street,<br />

known for traffic delays. To the<br />

right we see the prefabricated<br />

construction <strong>of</strong> Himke, a satellite<br />

<strong>of</strong> <strong>Moscow</strong>. “About 400,000 people<br />

live here,” estimates Igor<br />

Alexeev, our guide on th<strong>is</strong> day and<br />

a top project manager for <strong>Hilti</strong><br />

Russia for the civil engineering<br />

sector. And as we sit in traffic he<br />

tells us about Strogino, the first<br />

Metro station that <strong>is</strong> being establ<strong>is</strong>hed<br />

outside the outermost ring<br />

<strong>of</strong> <strong>Moscow</strong>. Strogino <strong>is</strong> the name<br />

<strong>of</strong> the suburb that the station will<br />

serve.<br />

Simultaneous with the extension<br />

<strong>of</strong> the Metro line, a <strong>new</strong> section towards<br />

the center <strong>of</strong> <strong>Moscow</strong> <strong>is</strong> being<br />

built on the Krasnopresnenskaya<br />

Highway, running from<br />

<strong>Moscow</strong> to Riga. The largest Russian<br />

construction companies are involved<br />

in th<strong>is</strong> rail and road project.<br />

Metrostroy serves as the general<br />

contractor while Mostotrest and<br />

Gordorstroy, to name just two, are<br />

also involved. The S<strong>is</strong>tema-Gals<br />

planning and construction company<br />

monitors and directs the construction<br />

<strong>of</strong> all participating companies.<br />

From an engineering point <strong>of</strong> view<br />

there are two unique sections <strong>of</strong><br />

the Krasnopresnenskaya Highway.<br />

Under the park-like forest<br />

<strong>of</strong> Zamoskvorechye a tunnel <strong>is</strong><br />

being constructed that <strong>is</strong> more than<br />

3 kilometers (1.9 mi) long. A cable-stayed<br />

bridge <strong>is</strong> also being<br />

built over the Moskva River. Near<br />

the <strong>city</strong>, yet still far enough away<br />

to have a rural feeling, th<strong>is</strong> area <strong>is</strong><br />

where well-to-do <strong>Moscow</strong> families<br />

have their dachas, or weekend cottages.<br />

Alexander Lushnikov and Bor<strong>is</strong><br />

Belov, the two directors <strong>of</strong> a div<strong>is</strong>ion<br />

<strong>of</strong> S<strong>is</strong>tema Gals, know the<br />

giant construction site as well as<br />

their own apartments. “The first<br />

section <strong>of</strong> the <strong>new</strong> road <strong>is</strong> above<br />

ground and leads away from<br />

<strong>Moscow</strong>’s outermost ring, d<strong>is</strong>appearing<br />

into the tunnel,” explains<br />

Alexander Lushnikov. It’s not<br />

merely one tunnel, but three, two<br />

<strong>of</strong> which have three lanes each,<br />

dedicated to one-way traffic.<br />

There <strong>is</strong> a smaller tunnel in the<br />

middle that has lateral connections<br />

to the other two for maintenance<br />

and an emergency exit. The<br />

Metro trains will travel on the<br />

lower level <strong>of</strong> one <strong>of</strong> the two larger<br />

tunnels.<br />

The conditions for building the<br />

tunnel were technically and eco-<br />

The Bolshoi’s <strong>new</strong> interior<br />

Özgür Barlas, from Turkey, <strong>is</strong> one <strong>of</strong><br />

the team working on the Embankment<br />

Tower: “My first skyscraper.”<br />

The world famous Bolshoi Theater<br />

in the center <strong>of</strong> <strong>Moscow</strong> will retain<br />

its classic features while being renovated.<br />

About half the 230 yearold<br />

theater, a UNESCO World Heritage<br />

Site, <strong>is</strong> being renovated. The<br />

remaining half was replaced by<br />

<strong>new</strong> construction. From outside<br />

the theater one cannot tell that the<br />

<strong>new</strong> construction actually extends<br />

underground. The <strong>new</strong> floors under<br />

the theater are for dressing<br />

rooms, restroom facilities and a<br />

bar. The theater itself will be scientifically<br />

restored and the 150 yearold<br />

pine beams, once restored,<br />

will be put back in place because<br />

<strong>of</strong> their contribution to the theater’s<br />

acoustics. The national cultural organization<br />

Roskultura, as the owner<br />

<strong>of</strong> the Bolshoi Theater, <strong>is</strong> investing<br />

some 15 billion rubles (450 million<br />

Inv<strong>is</strong>ible when<br />

viewed from<br />

the outside,<br />

the Bolshoi<br />

Theater <strong>is</strong><br />

getting more<br />

inside space.<br />

euro or 600 million dollars) until the<br />

theater reopens in 2008.

Focus on Russia<br />

Page 20<br />

Alexander Lushnikov:<br />

demanding tunnel construction.<br />

Sergey Kam<strong>is</strong>hov:<br />

“There’s never enough time!”<br />

Bor<strong>is</strong> Belov: “Corrosion res<strong>is</strong>tance<br />

<strong>is</strong> the most important thing.”<br />

Andrey Klibik: “I can share my<br />

ideas with <strong>Hilti</strong> as a customer.”<br />

logically difficult, says Alexander<br />

Lushnikov. “We used a tunneling<br />

machine <strong>of</strong> the Herrenknecht<br />

company <strong>of</strong> Germany. The drilling<br />

head had a diameter <strong>of</strong> 14.2 meters<br />

(46.5 ft). We were able to proceed<br />

with work on the tunnel while d<strong>is</strong>turbing<br />

the land above as little as<br />

possible.<br />

The inside <strong>of</strong> the tunnels are now<br />

being fin<strong>is</strong>hed and machines are<br />

working underground day and<br />

night. “Vremya,” says Sergey<br />

Kam<strong>is</strong>hov, the Deputy General<br />

Manager <strong>of</strong> Metrostroy. “We simply<br />

don’t have enough time!” It’s<br />

a good thing that everything <strong>is</strong> going<br />

according to plan. Alexander<br />

Lushnikov and Bor<strong>is</strong> Belov have<br />

been relying on <strong>Hilti</strong> anchor technology<br />

for about ten years. In the<br />

tunnel they are using it to install<br />

the ventilation equipment and the<br />

tunnel cladding. They are also using<br />

the <strong>Hilti</strong> MQ channel installation<br />

system for the cables and<br />

pipes. Bor<strong>is</strong> Belov likes the cor -<br />

rosion-res<strong>is</strong>tant properties <strong>of</strong> the<br />

material. “The longevity <strong>is</strong> worth<br />

more than what the material costs.<br />

And <strong>Hilti</strong> can’t be beaten when<br />

talking about the anchor’s approval.”<br />

He mentions the training<br />

<strong>of</strong>fered by <strong>Hilti</strong> as another im -<br />

portant point. “The anchors are<br />

only reliable if they’re correctly<br />

installed.”<br />

Bor<strong>is</strong> Belov was significantly involved<br />

in the technical design <strong>of</strong><br />

the tunnel and <strong>is</strong> now monitoring<br />

the realization <strong>of</strong> the plans. The<br />

tunnel may be impressive, but<br />

when speaking <strong>of</strong> outward beauty,<br />

the cable-stayed bridge, that connects<br />

to the tunnel section via<br />

a small above-ground section, <strong>is</strong><br />

in another category. The cables<br />

emerge from an almost horseshoeshaped<br />

arch <strong>of</strong> steel at the bridge’s<br />

midpoint in various angles and<br />

directions. At its highest point,<br />

the arch <strong>of</strong> steel <strong>is</strong> 106 meters<br />

(347.7 ft) above the surface <strong>of</strong> the<br />

Moskva. A restaurant in the form<br />

<strong>of</strong> an ostrich egg <strong>is</strong> to be “hung” on<br />

the arch at a height <strong>of</strong> 70 meters<br />

(229.6 ft). But for now, there are<br />

two workers at the edge <strong>of</strong> the<br />

Sausages and know-how<br />

Sergey Bor<strong>is</strong>ovich Tkachenko<br />

doesn’t waste words. “If a <strong>city</strong><br />

doesn’t evolve it dies.” The architect<br />

<strong>is</strong> the Director <strong>of</strong> the Scientific<br />

and Research Institute for General<br />

Plan <strong>of</strong> <strong>Moscow</strong>.<br />

Looking back some 20 years in time,<br />

Sergey Bor<strong>is</strong>ovich Tkachenko, or<br />

Sergey Bor<strong>is</strong>ovich, recalls that it was<br />

very quiet in terms <strong>of</strong> <strong>city</strong> planning in<br />

<strong>Moscow</strong>. Prefabricated buildings<br />

were thrown up at the edges <strong>of</strong> town<br />

and next to nothing was happening<br />

in the <strong>city</strong> center. “But ten years<br />

ago,” h<strong>is</strong> voice r<strong>is</strong>es, “<strong>Moscow</strong> began<br />

a phase <strong>of</strong> uncontrolled growth.<br />

Th<strong>is</strong> was the time <strong>of</strong> wild capital<strong>is</strong>m<br />

where people who had suddenly<br />

come into a great deal <strong>of</strong> money,<br />

wanted to set a personal architectural<br />

monument.” Sergey Bor<strong>is</strong>ovich<br />

speaks <strong>of</strong> “useless buildings without<br />

any architectural value.” While<br />

there was an overall plan, it only<br />

ex<strong>is</strong>ted on paper. “Since 1999 the<br />

legal prerequ<strong>is</strong>ites are in place for<br />

<strong>city</strong> planning and they are based<br />

on structure and order in the urban<br />

development <strong>of</strong> <strong>Moscow</strong>.”<br />

But th<strong>is</strong> doesn’t help limit the problems<br />

<strong>of</strong> Sergey Bor<strong>is</strong>ovich and h<strong>is</strong><br />

team. “We have to move industrial<br />

operations out <strong>of</strong> the <strong>city</strong> center<br />

and create <strong>new</strong> living space. We<br />

should also be creating green<br />

space.” There are 60 zones throughout<br />

the <strong>city</strong>, all within the outermost<br />

highway ring, that are zoned for<br />

high-r<strong>is</strong>es. Currently the construction<br />

<strong>of</strong> hundreds <strong>of</strong> hectares <strong>is</strong> being<br />

planned.<br />

“20 years ago we hardly had<br />

sausage and now we can chose<br />

from among many different kinds,”<br />

says Sergey Bor<strong>is</strong>ovich. “The situation<br />

<strong>is</strong> similar regarding know-how.<br />

We have various methods for dealing<br />

with problems. It’s just difficult<br />

deciding on which one.” He therefore<br />

finds d<strong>is</strong>cussions with special<strong>is</strong>ts<br />

from other big cities that much<br />

more important. In spite <strong>of</strong> h<strong>is</strong> v<strong>is</strong>ions<br />

<strong>of</strong> putting more public and<br />

private transportation underground,<br />

he remains real<strong>is</strong>tic. “The<br />

transportation problem will never<br />

be solved. Development <strong>is</strong> far outpacing<br />

planning.” In closing Sergey<br />

Bor<strong>is</strong>ovich Tkachenko says that<br />

every <strong>city</strong> has the same destiny.<br />

“Some people regret losing the old<br />

and the rest welcome change.”

Magazine 1/2007<br />

Focus on Russia<br />

Page 21<br />

Three tunnels for road, rail and maintenance/safety.<br />

Durable fastening solutions for the tunnel cladding.<br />

The ventilation<br />

system <strong>is</strong> also<br />

being fastened<br />

with <strong>Hilti</strong><br />

products.<br />

The drill bit head <strong>of</strong> the tunnel’s drilling machine has a<br />

diameter <strong>of</strong> 14.2 meters.<br />

A 1000 meter-long cable-stayed bridge connects to the tunnel. A restaurant<br />

<strong>is</strong> to be “hung” onto the steel arch.<br />

bridge. They are using <strong>Hilti</strong> diamond<br />

coring tools in preparing<br />

the guardrail for anchoring. At<br />

the head <strong>of</strong> the bridge we are met<br />

by Andrey Klibik, a worker for<br />

Mostootryad-99, a subcontractor<br />

responsible for installing the utility<br />

lines on the bridge. He simply has<br />

to talk about h<strong>is</strong> enthusiasm for<br />

<strong>Hilti</strong> technology and <strong>is</strong> convinced<br />

<strong>of</strong> the idea <strong>of</strong> mutual benefit. “We<br />

can both pr<strong>of</strong>it because, as a customer,<br />

we can share our ideas with<br />

<strong>Hilti</strong>.”<br />

The small settlement next to the<br />

bridge, cons<strong>is</strong>ting <strong>of</strong> wooden<br />

houses, <strong>is</strong> about to lose its le<strong>is</strong>urely<br />

pace and peace and quiet. Even<br />

Aleksandr Solzhenitsyn, who purportedly<br />

lives there, will have to<br />

get used to the no<strong>is</strong>e <strong>of</strong> cars rushing<br />

by. At the end, Alexander Lushnikov<br />

laughs and says in a philosophical<br />

manner: “It’s strange how<br />

<strong>new</strong> roads seem to create <strong>new</strong> and<br />

added traffic.” <strong>Moscow</strong>’s growth<br />

can’t be stopped.

Innovation<br />

Page 22<br />

Like drilling th<br />

1967 1979 1980<br />

The legendary <strong>Hilti</strong> TE 17 rotary hammer<br />

revolutionized concrete drilling. The secret<br />

<strong>is</strong> the tool’s electropneumatic hammering<br />

mechan<strong>is</strong>m.<br />

By Manfred Schiefer<br />

Before <strong>Hilti</strong> introduced the<br />

TE 17 rotary hammer to the<br />

market in 1967, drilling in concrete,<br />

masonry and other hard materials<br />

was very difficult. The only way the<br />

hammer drills prevalent at that time<br />

could work their way through the<br />

extremely res<strong>is</strong>tant materials was<br />

through the power <strong>of</strong> the operator.<br />

Th<strong>is</strong> was tiring and time-consuming.<br />

The development <strong>of</strong> the electropneumatic<br />

hammering mechan<strong>is</strong>m<br />

was to change all th<strong>is</strong>. But the<br />

first rotary hammers, put on the<br />

market in the 1960s in the USA,<br />

were too delicate to withstand the<br />

harsh construction site environment.<br />

“The first tools were largely<br />

taken out <strong>of</strong> action by dust,” says<br />

Philipp von Heimendahl, a product<br />

manager specializing in rotary hammer<br />

and breakers in the Drilling &<br />

Demolition Business Unit. “It was<br />

Martin <strong>Hilti</strong> who first looked not<br />

only at the hammering mechan<strong>is</strong>m,<br />

but considered the rotary hammer<br />

as a single system, where all components<br />

had to be optimally coordinated<br />

with one another.”<br />

<strong>Hilti</strong> engineers not only improved<br />

the electropneumatic hammering<br />

mechan<strong>is</strong>m, they developed an<br />

entire range <strong>of</strong> innovations: the robust<br />

connection end with a rollerlocking<br />

system ensured better<br />

power transfer to the drill bit<br />

even with the first <strong>Hilti</strong> TE 17. The<br />

sealed assembly helped keep dust<br />

out <strong>of</strong> the hammering mechan<strong>is</strong>m<br />

and allowed for permanent lubrication.<br />

The safety <strong>of</strong> the operator<br />

has also been important to<br />

<strong>Hilti</strong> from the start. The first <strong>Hilti</strong><br />

rotary hammer incorporated a<br />

mechanical slip clutch that pre-<br />

vents the sudden rotation <strong>of</strong> the<br />

tool on its own ax<strong>is</strong> when rebar<br />

are hit.<br />

Over the years, every part in<br />

the tool has been upgraded. From<br />

the first usage worldwide <strong>of</strong> an<br />

electronic motor control, to battery<br />

technology in rotary hammers,<br />

to welded drill-bit heads<br />

and the Polygon ch<strong>is</strong>el, to the<br />

Active Torque Control security<br />

system up through to <strong>new</strong> services<br />

such as <strong>Hilti</strong> Fleet Management<br />

and <strong>Hilti</strong> Lifetime Service.<br />

Th<strong>is</strong> year <strong>Hilti</strong> continues to bring<br />

further developments to the market.<br />

The product range will be<br />

expanded by several higher-performing,<br />

more robust rotary hammers,<br />

combihammers and breakers.<br />

Electropneumatic hammering principle<br />

The hammering action in a conventional hammer drill <strong>is</strong> generated by a cam<br />

mechan<strong>is</strong>m. The impact achieved <strong>is</strong> dependent on the pressure applied by<br />

the operator. In contrast, a tool employing the electropneumatic principle <strong>is</strong><br />

much more efficient, more comfortable and thus less tiring to work with: The<br />