MLS light shield - Fusion UV Systems Inc.

MLS light shield - Fusion UV Systems Inc.

MLS light shield - Fusion UV Systems Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECHNOTES<br />

Heraeus Noble<strong>light</strong> <strong>Fusion</strong> <strong>UV</strong> <strong>Inc</strong>.<br />

Modular Light Shield <strong>Systems</strong><br />

<strong>MLS</strong> <strong>Systems</strong><br />

Low Cost And Quick Delivery<br />

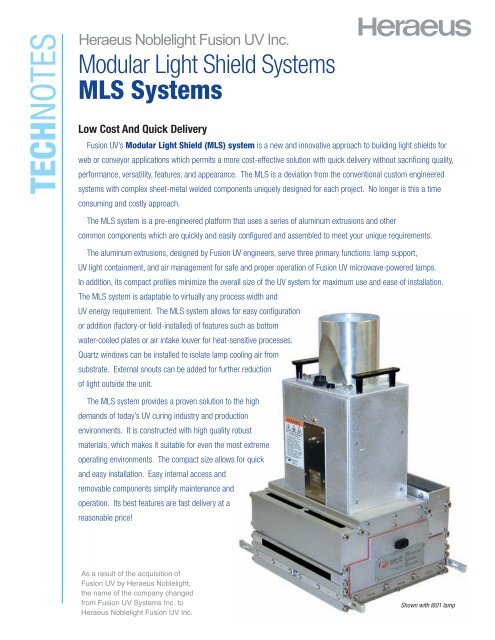

<strong>Fusion</strong> <strong>UV</strong>’s Modular Light Shield (<strong>MLS</strong>) system is a new and innovative approach to building <strong>light</strong> <strong>shield</strong>s for<br />

web or conveyor applications which permits a more cost-effective solution with quick delivery without sacrificing quality,<br />

performance, versatility, features, and appearance. The <strong>MLS</strong> is a deviation from the conventional custom engineered<br />

systems with complex sheet-metal welded components uniquely designed for each project. No longer is this a time<br />

consuming and costly approach.<br />

The <strong>MLS</strong> system is a pre-engineered platform that uses a series of aluminum extrusions and other<br />

common components which are quickly and easily configured and assembled to meet your unique requirements.<br />

The aluminum extrusions, designed by <strong>Fusion</strong> <strong>UV</strong> engineers, serve three primary functions: lamp support,<br />

<strong>UV</strong> <strong>light</strong> containment, and air management for safe and proper operation of <strong>Fusion</strong> <strong>UV</strong> microwave-powered lamps.<br />

In addition, its compact profiles minimize the overall size of the <strong>UV</strong> system for maximum use and ease of installation.<br />

The <strong>MLS</strong> system is adaptable to virtually any process width and<br />

<strong>UV</strong> energy requirement. The <strong>MLS</strong> system allows for easy configuration<br />

or addition (factory-or field-installed) of features such as bottom<br />

water-cooled plates or air intake louver for heat-sensitive processes.<br />

Quartz windows can be installed to isolate lamp cooling air from<br />

substrate. External snouts can be added for further reduction<br />

of <strong>light</strong> outside the unit.<br />

The <strong>MLS</strong> system provides a proven solution to the high<br />

demands of today’s <strong>UV</strong> curing industry and production<br />

environments. It is constructed with high quality robust<br />

materials, which makes it suitable for even the most extreme<br />

operating environments. The compact size allows for quick<br />

and easy installation. Easy internal access and<br />

removable components simplify maintenance and<br />

operation. Its best features are fast delivery at a<br />

reasonable price!<br />

As a result of the acquisition of<br />

<strong>Fusion</strong> <strong>UV</strong> by Heraeus Noble<strong>light</strong>,<br />

the name of the company changed<br />

from <strong>Fusion</strong> <strong>UV</strong> <strong>Systems</strong> <strong>Inc</strong>. to<br />

Heraeus Noble<strong>light</strong> <strong>Fusion</strong> <strong>UV</strong> <strong>Inc</strong>.<br />

Shown with I601 lamp

TECHNOTES<br />

Shown with bottom heat<br />

<strong>shield</strong> and bottom plate<br />

Modular Design<br />

The patented <strong>MLS</strong> system allows a <strong>light</strong> <strong>shield</strong> to be<br />

assembled in a fast and efficient manner. Extrusions are<br />

cut to the length that is required for the process and<br />

then bolted to endplates to form the primary <strong>light</strong><strong>shield</strong><br />

structure. It is completed by the addition of other<br />

standard components that include interior heat <strong>shield</strong>s,<br />

access doors, bottom <strong>shield</strong>ing, and mounting brackets for<br />

the RF detector(s).<br />

Multi-row <strong>MLS</strong> systems are assembled by joining<br />

individual single row units. A single exhaust duct<br />

connection is required for each single-row or two-row<br />

system.<br />

Shown with quartz window<br />

and bottom double air-intake louver<br />

Standard <strong>MLS</strong> systems are available for web widths<br />

of 6" - 60", and custom systems can be built for web<br />

widths up to 100". The modular concept is a costefficient<br />

platform for planning future<br />

capacity requirements. It is<br />

necessary to install only the number<br />

of <strong>MLS</strong> units that will be occupied<br />

with lamp systems. Additional <strong>MLS</strong><br />

units may be installed at a time<br />

when production requirements<br />

dictate expansion. The<br />

modular platform offers<br />

a solution that fulfills the<br />

current and future needs<br />

of the end-users in a<br />

timely and affordable<br />

manner.<br />

Lamp Orientation<br />

Shown with quartz window<br />

and bottom water-cooled plate<br />

<strong>MLS</strong> systems are available to support lamps in any<br />

orientation for processing webs traveling horizontally,<br />

vertically, or at any angle. Bottom-curing configurations<br />

are also available, where the lamps are hung to direct the<br />

<strong>light</strong> upward to expose the bottom of a horizontal web.<br />

Multi-row systems that require curing top and bottom of<br />

the web are easily configurable.<br />

Bottom Cooling Options<br />

Three bottom <strong>shield</strong>/cooling configurations are<br />

available for web systems. A bottom heat <strong>shield</strong><br />

combined with a bottom plate is recommended for<br />

processing opaque materials or less heat-sensitive<br />

substrates such as paper. For heat-sensitive films, bottom<br />

air cooling is recommended. This is accomplished by<br />

installing a double layer of air-intake (<strong>light</strong>-tight) louver in<br />

place of the bottom heat <strong>shield</strong> and bottom plate. If a<br />

heat-sensitive web is being run under low tension and<br />

cannot tolerate air movement, a stainless steel watercooled<br />

plate can be easily installed in place of the double<br />

layer of louver. The design of the bottom extrusions allows<br />

the bottom cooling hardware to be easily assembled in our<br />

factory or changed in the field for process modifications.<br />

One-row bottom cure,<br />

two-row top cure<br />

system<br />

Bottom cure<br />

configuration<br />

provides for<br />

lamp to slide<br />

into position

3-row system with<br />

7 lamps per row<br />

(70" wide)<br />

7-lamp wide<br />

<strong>MLS</strong> system with<br />

supply air plenum for<br />

a single duct connection<br />

(flex hose to each lamp not shown)<br />

Quartz Window<br />

Some applications may require<br />

a quartz window to be installed between the<br />

lamps and the substrate to isolate the<br />

lamp cooling air from the substrate.<br />

Quartz plates are mechanically held in<br />

an aluminum tray which simply slides<br />

into grooves on the extrusions. The<br />

quartz window is positioned about 1<br />

inch below the lamp. It can easily slide<br />

in and out of the system for ease<br />

of maintenance. A hinged<br />

access door with a tooloperated<br />

latch is provided on<br />

the front and/or rear side<br />

of the <strong>light</strong> <strong>shield</strong> for<br />

quartz window removal.<br />

Compact Size<br />

Another significant benefit of<br />

the <strong>MLS</strong> design is that the entire <strong>light</strong><br />

<strong>shield</strong> assembly is very compact without<br />

adversely affecting safety, operation, and<br />

performance.<br />

By minimizing the overall size of the system, this<br />

makes it easy for the end-user to install the unit<br />

into tight spaces. The overall length of a singlerow<br />

system (without external snouts) in the<br />

web direction is 14.25 inches (or 362 mm).<br />

A two-row system will simply be double<br />

that of the single-row system. The height<br />

of the <strong>light</strong> <strong>shield</strong> (not including the lamp<br />

and ducting) is 9.50 inches (or 241 mm).<br />

The width will vary depending on number<br />

of lamps per row.<br />

Shown with quartz &<br />

exterior snouts<br />

9.50"<br />

(241 mm)<br />

Compact size<br />

14.25"<br />

(362 mm)<br />

Close-up view of<br />

mounting bar with “T”<br />

shaped mounting foot

Other Features<br />

• <strong>MLS</strong> <strong>light</strong> <strong>shield</strong> supports all <strong>Fusion</strong> <strong>UV</strong> microwave-powered lamps.<br />

• External tunnel <strong>shield</strong>s (snouts) can easily bolt on for additional <strong>light</strong> containment.<br />

• Idler roll (3.5 inch dia.) assemblies, which are dynamically balanced to 1500 fpm web speed,<br />

can bolt onto the substrate entry and exit end for additional web support.<br />

• Mounting feet can be provided for installation on a horizontal<br />

mounting surface.<br />

• Supply and exhaust air plenums can be provided for<br />

air handling.<br />

• Focus adjustment bars fit into lamp boot, which allow the<br />

user to easily vary the distance from lamp to substrate<br />

for process variations.<br />

• Focus adjustment bars for bottom cure system are<br />

“sandwiched” between lamp and lamp<br />

hanger rails.<br />

• Outer finish is clear anodized. External tunnel<br />

<strong>shield</strong>s (snouts) are painted black.<br />

• Construction uses all metric hardware.<br />

Custom <strong>Systems</strong><br />

<strong>Fusion</strong> <strong>UV</strong> engineers can adapt the <strong>MLS</strong> platform beyond its standard capacity, and thus<br />

design custom configurations and features to meet unique requirements.<br />

3-row system shown with I601 M<br />

lamps and external tunnel <strong>shield</strong>s<br />

Heraeus Noble<strong>light</strong> <strong>Fusion</strong> <strong>UV</strong> <strong>Inc</strong>.<br />

Heraeus Noble<strong>light</strong><br />

<strong>Fusion</strong> <strong>UV</strong> <strong>Inc</strong>.<br />

Corporate Headquarters<br />

910 Clopper Road<br />

Gaithersburg, Maryland<br />

20878-1357 USA<br />

TEL: +1 301-527-2660<br />

FAX: +1 301-527-2661<br />

TEL: +1 888-276-8600<br />

(North American Toll Free)<br />

www.fusionuv.com<br />

e-mail: info.hnfn@heraeus.com<br />

Heraeus Noble<strong>light</strong><br />

<strong>Fusion</strong> <strong>UV</strong> <strong>Inc</strong>. West<br />

Torrance, California<br />

TEL: +1 310-370-9920<br />

FAX: +1 310-370-9152<br />

Heraeus Noble<strong>light</strong> GmbH<br />

Ismaning, Germany<br />

TEL: +49 89 899631-0<br />

FAX: +49 89 899631-10<br />

www.fusionuv.de<br />

e-mail: hng-uv@heraeus.com<br />

Heraeus Noble<strong>light</strong> (Shenyang)<br />

Ltd Shanghai Branch<br />

Shanghai, China<br />

TEL: +86 (21) 5445 2255<br />

FAX: +86 (21) 5445 2410<br />

Heraeus Noble<strong>light</strong> GmbH<br />

Beijing Office<br />

Beijing, P.R. China<br />

TEL: +86 (0) 10 64379182<br />

FAX: +86 (0) 10 64379283<br />

Heraeus Noble<strong>light</strong> GmbH<br />

Shenzhen Office<br />

Shenzhen, P.R. China<br />

TEL: +86 (0) 755 82839125<br />

FAX: +86 (0) 755 82839195<br />

www.fusionuv.com.cn<br />

e-mail: info.hns@heraeus.com<br />

Heraeus Noble<strong>light</strong><br />

<strong>Fusion</strong> <strong>UV</strong> K.K.<br />

Tokyo, Japan<br />

TEL: +81 3 5542 3980<br />

FAX: +81 3 5542 3992<br />

www.fusionuv.co.jp<br />

e-mail: info.hnfk@heraeus.com<br />

ISO 9001 Certified QMS<br />

• U.S. Patent No. 5471109; 5726815; 5838114; 6223453; 6509656; 6646384B2; 6690112B2; 6740892B2; 6908586B2; 7037460B2; 7055990B2<br />

Other U.S. and Foreign Patents Pending. We reserve the right to incorporate changes and improvements without notice.<br />

04/13 Printed in USA SB 642 ©2013 <strong>Fusion</strong> <strong>UV</strong>.