ICGSMA Bulletin - Indian Coast Guard

ICGSMA Bulletin - Indian Coast Guard

ICGSMA Bulletin - Indian Coast Guard

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

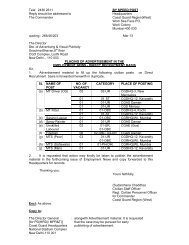

<strong>ICGSMA</strong> BULLETIN (JAN - MAR 13)<br />

likely cause of the low idle RPM.<br />

DEFECT IDENTIFICATION<br />

After a detailed discussion with Senior<br />

Engineer Officer and Engineer Officer, it was<br />

decided to remove and dismantle the governor for<br />

speculating the defect.<br />

A team comprising of the Senior Engineer<br />

Officer and two ERAs worked towards DR of the DG<br />

set. On dismantling the governor drive end parts, it<br />

was observed that a small metallic chip with thread<br />

strands had got stuck with the oil pump suction<br />

strainer.<br />

THE DEFECT On starting of DG set, the hydraulic<br />

oil is pumped through the oil pump suction strainer<br />

to the power piston of the governor. The power<br />

piston movement is transferred to the PTR Fuel<br />

pump via mechanical linkage for maximum fuel<br />

rack during starting and for further RPM<br />

adjustment. As the oil strainer was choked, the<br />

pump ceased to develop sufficient pressure to<br />

operate the power piston which resulted in<br />

sluggish mechanical lever movement to fuel pump.<br />

DEFECT RECTIFICATION<br />

The suction strainer and pipe were cleaned<br />

with air and re-fitted with governor. Subsequently,<br />

trials were undertaken and found satisfactory at<br />

1500 RPM on both idle and with load conditions.<br />

OBSERVATIONS<br />

The position of the governor strainer was<br />

intricate to locate visually from oil filling cap.<br />

Despite oil renewal the obstruction from oil<br />

strainer was not cleared. This was the main reason<br />

for the team in speculating the cause of defect.<br />

LESSON LEARNT<br />

The governor without oil filling strainer<br />

may cause ingress of foreign matter into the sump<br />

during routines. Care should be taken that the oil is<br />

added carefully using a clean container with<br />

portable cloth or commercial plastic strainer.<br />

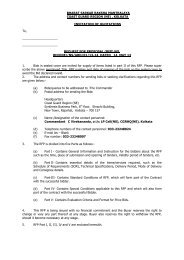

RECOMMENDATION<br />

This defect may minor in nature, but equally<br />

unique and rare. A lot of attention is needed to<br />

locate and avoid complexity of such defects. It is<br />

highly recommended that a renewable cup shaped<br />

plastic strainer be incorporated on the governor of<br />

the DG set to prevent any kind of blockage by<br />

impurities.<br />

A CASE STUDY - DEFECT ANALYSIS ON<br />

RO PLANT FOR LOW PERMEATE OUTPUT<br />

WITH HIGH SALINITY<br />

ICGS Meera Behn<br />

The ship is fitted with 05 TPD RO Plant,<br />

Make: Rochem Separation. The plant was<br />

overhauled and DT modules were service<br />

exchanged in Mar 12 during SR-11 at Mumbai by<br />

PAC firm M/s Rochem Separation, Mumbai. The<br />

plant is being utilized to meet fresh water<br />

requirement of the ship.<br />

In the month of Feb 13 almost 01 year after<br />

overhauling it was noticed that the permeate<br />

output of the plant has been decreased to 125 LPH,<br />

whereas designed output is 208 LPH. The plant DT<br />

modules were chemically cleaned by RO cleaner<br />

33, 22 and 11 but no improvement observed. The<br />

salinity of permeate also observed comparatively<br />

high as 1700 µ cm. The permeate output further<br />

decrease to 70 LPH and Plant start tripping view VS<br />

60 (servo control valve) closure indicated by<br />

permanent illumination of lamp no 4 and 5 on RO<br />

plant panel. Indication of this defect was<br />

understood as malfunction/failure of servo control<br />

valve.<br />

An insight to trouble shooters 11