ICGSMA Bulletin - Indian Coast Guard

ICGSMA Bulletin - Indian Coast Guard

ICGSMA Bulletin - Indian Coast Guard

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ICGSMA</strong> BULLETIN (JAN - MAR 13)<br />

from the pipe line and visually inspected the<br />

defective pipe along with ship’s staff. Further the<br />

pipe lines were cleaned with wire brush and<br />

chipped with chipping hammer. Excessive corrosion<br />

was observed on both the pipes with hole up to 4<br />

to 6 inches dimension.<br />

5. The firm has rectified the defect by using<br />

doublers at affected areas with 6 mm steel plate.<br />

6. On analyzing, the extent of corrosion is<br />

attributable to the following reason:<br />

(a) Direct contact with sea water and air<br />

simultaneously due to its design<br />

(Overboard opening is just above the<br />

water line).<br />

(b) Overboard pipes are subject to high<br />

temperature and seawater cooling while<br />

the engine is running.<br />

(c) Ageing of the pipes (ship has<br />

completed 22 years).<br />

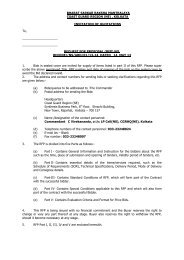

RECOMMENDATION<br />

Survey of the pipe to be undertaken in<br />

every ERDD/refit and complete renewal of the<br />

pipes may be undertaken in necessary under<br />

supervision of a class surveyor.<br />

A CASE STUDY-DEFECT RECTIFICATION<br />

OF IDLE RPM ON DIESEL GENERATOR<br />

INTRODUCTION<br />

A Sathish Kumar, USE(ER)<br />

C-133<br />

As part of its power generation and<br />

distribution (PGD) system, AOPV class of ships<br />

which are fitted with four Diesel Generators of<br />

make Cummins and model VTA-1710; each with an<br />

output of 400 KW and max. RPM of 1500.<br />

DEFECT DESCRIPTION.<br />

The defect pertains to one of the diesel<br />

generators onboard one of the AOPV. It was<br />

observed that the idling RPM of DG set No. 2 was<br />

not increasing beyond 700 from MSB remote<br />

adjusting knob.<br />

PRINCIPLE OF OPERATION.<br />

Each DG is fitted with an electro servo<br />

motor on top of the Governor’s RPM adjusting<br />

shaft. As the DG is started, the servo motor is<br />

controlled from MSB remote adjusting knob which<br />

rotates the governor RPM adjusting shaft and thus,<br />

engine RPM is stabilized.<br />

URGENCY OF DR.<br />

The ship was at sea on a long deployment<br />

(OSD). One out of the four DGs was already non<br />

operational due to defective alternator. Owing to<br />

defect of idling RPM on DG set No. 2, the power<br />

requirement of the ship was being fulfilled by the<br />

remaining two DG sets. There was no standby DG<br />

set. Consequently, DR of DG set No. 2 was critical.<br />

ANALYSIS AND INVESTIGATION.<br />

As preliminary checks, all fuel lines and<br />

filters were checked for leakage. Governor’s<br />

manual RPM adjusting knob operated from local<br />

and checked for rotation of RPM adjusting shaft.<br />

Governor oil drained and renewed. These<br />

measures undertaken did not yield any positive<br />

results towards rectification of the defect and the<br />

defect persisted.<br />

Further investigation revealed that the<br />

governor’s mechanical lever movement from<br />

hydraulic power piston for high throttle was<br />

sluggish during starting of the DG set. This was the<br />

An insight to trouble shooters 10