ICGSMA Bulletin - Indian Coast Guard

ICGSMA Bulletin - Indian Coast Guard

ICGSMA Bulletin - Indian Coast Guard

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ICGSMA</strong> BULLETIN (JAN - MAR 13)<br />

down to idle RPM, de-clutched and subsequently<br />

both engines were shut down for defect<br />

investigation and rectification.<br />

DEFECT DIAGNOSIS<br />

An earth fault indication was observed on<br />

battery rectifier fitted in aft engine room. The<br />

following checks were undertaken by the ship staff.<br />

(a) Battery was removed from the system and<br />

checked for earthing.<br />

(b) Charger out put was disconnected from the<br />

system and checked for earthing.<br />

COMMON PAINT DEFECTS AND REMEDIES<br />

(DO YOU KNOW?)<br />

WRINKLING - Wrinkling happens when the paint<br />

forms film-like undulating waves. Applying too much<br />

paint or drying during high temperatures or painting on<br />

a topcoat before the undercoat is dry can cause this<br />

defect to happen.<br />

SOLUTION - Avoid applying too much paint. Make<br />

sure no paint accumulates around bolts, rivets, etc.<br />

Wait until each coat dries before you re-coat.<br />

from sensors on stbd Gear Box were disconnected,<br />

the earth fault indicator was disappeared on the<br />

panel. On investigation, the earth fault was<br />

detected on stbd Gear Box terminal box (X-20)<br />

ahead/astern solenoid plug card( CA3106), which<br />

is fitted on Gear Box. During checking, plug card<br />

was found defective and grounded with body.<br />

Finally defect was liquidated by ship’s staff on<br />

30 Jan 13 post replacement of new plug card from<br />

OBS . The cold checks were carried out and found<br />

satisfactory. Stbd Main Engine was started for trials<br />

and all parameters found to be working<br />

satisfactorily.<br />

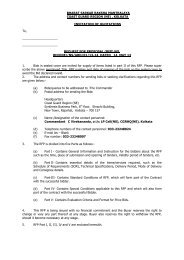

LESSON LEARNT:<br />

(a) Follow up the defined procedure for<br />

assessment / identification of defects.<br />

(b) Ensure sensors cables and plug cards are<br />

properly secured and protected from physical<br />

approach.<br />

A CASE STUDY- REPAIR OF MAIN<br />

ENGINE EXHAUST OVERBOARD PIPE<br />

(c) All terminal strips were checked for any<br />

grounding of cables in MCR and LOP.<br />

(d) All incoming and out going cable from sensors<br />

in main engine room LOP were disconnected one<br />

by one.<br />

(e) All control PCBs were removed and checked for<br />

earthing.<br />

(f) All power supply incoming breaker (24V DC)<br />

were switched off one by one.<br />

(g) Earthing in RCS terminal strips was checked.<br />

(h) Earthing in remote and local mode was<br />

checked.<br />

(j) All incoming and outgoing cables from sensors<br />

on Gear Box were disconnected.<br />

The moment incoming and outgoing cables<br />

ICGS Annie Besant<br />

1. Ship is fitted with two main engines Make:<br />

MTU Germany, Model: 12 V 538 TB 82.<br />

2. Ship’s both main engines exhaust over<br />

board pipes were corroded and holed at<br />

various places and sea water/exhaust smoke<br />

leakage was observed through both the<br />

exhaust pipes. Due to operational commitment<br />

the defect was taken care by affecting cold<br />

repair by the ship’s staff. Meanwhile joint<br />

inspection was carried out by local firms and<br />

the ship’s technical staff. The condition of the<br />

pipe was found to be alarming view excessive<br />

deterioration and position of the pipe, near the<br />

water line.<br />

An insight to trouble shooters 8