HVAC - Resource Guide For Green Building Design - Trane

HVAC - Resource Guide For Green Building Design - Trane HVAC - Resource Guide For Green Building Design - Trane

EARTHWISE SYSTEMS CHILLED-WATER SYSTEMS (CWS) green options green criteria reference 1 2 Reduce waterflow rate in chilled-water loop (12-20˚F, or 6.7-11.1˚CΔT) condenser water loop (12-18˚F or 6.7- 10˚CΔT) Variable flow chilled-water systems Vary the water flow rate through the chiller evaporators during system operation • Increase efficiency of chilled-water plant so that pumps and cooling towers consume less energy • Reduce building materials (smaller pump, cooling tower, fan) • Reduce water pipe sizes, save cost and material Reduce system materials required, using fewer pumps than the common primarysecondary system; for example, reduced • piping connections • strainers • electrical connections • valves and specialties • pump starters • space required Improve system efficiency modestly by reducing pumping energy. (1) (2) (3) (4) (5) (6) (7) 3 System optimization controls Condenser water temperature reset and optimization • Improve system efficiency • Optimize the condenser water system by balancing the chiller and tower power • Iterate for the best condenser water temperature to minimize the combined chiller-tower energy use at all time (8) (9) 4 Pumping pressure-speed reset • Reset the pump operating pressure to ensure that the control valve needing the highest pressure is about 90% open • Save pump energy (10) 5 Refrigerant charge per ton Select systems that require less refrigerant charge to operate • Less refrigerant means less impact on the environment in case refrigerant leaks from the system • Use ASHRAE Standard 147 to further minimize leakage or overall refrigerant emissions (11) 2

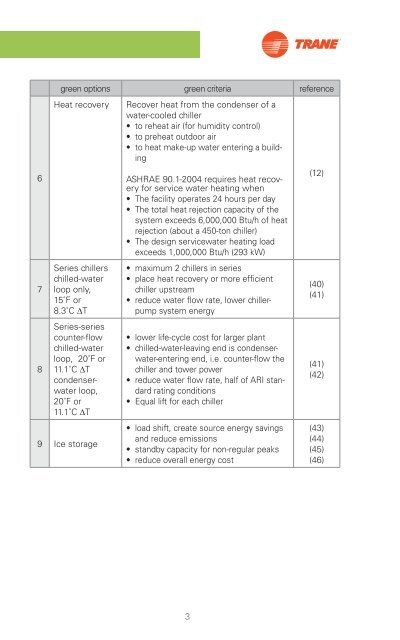

6 7 8 green options green criteria reference Heat recovery Series chillers chilled-water loop only, 15˚F or 8.3˚C ΔT Series-series counter-flow chilled-water loop, 20˚F or 11.1˚C ΔT condenserwater loop, 20˚F or 11.1˚C ΔT 9 Ice storage Recover heat from the condenser of a water-cooled chiller • to reheat air (for humidity control) • to preheat outdoor air • to heat make-up water entering a building ASHRAE 90.1-2004 requires heat recovery for service water heating when • The facility operates 24 hours per day • The total heat rejection capacity of the system exceeds 6,000,000 Btu/h of heat rejection (about a 450-ton chiller) • The design servicewater heating load exceeds 1,000,000 Btu/h (293 kW) • maximum 2 chillers in series • place heat recovery or more efficient chiller upstream • reduce water flow rate, lower chillerpump system energy • lower life-cycle cost for larger plant • chilled-water-leaving end is condenserwater-entering end, i.e. counter-flow the chiller and tower power • reduce water flow rate, half of ARI standard rating conditions • Equal lift for each chiller • load shift, create source energy savings and reduce emissions • standby capacity for non-regular peaks • reduce overall energy cost (12) (40) (41) (41) (42) (43) (44) (45) (46) 3

- Page 1 and 2: GREEN BUILDING HVAC Resource Guide

- Page 3: PREFACE Trane values guide us in ou

- Page 8 and 9: EARTHWISE SYSTEMS AIR-HANDLING SYST

- Page 10 and 11: EARTHWISE SYSTEMS DX UNITARY SYSTEM

- Page 12 and 13: CONTROL STRATEGIES ENERGY MANAGEMEN

- Page 14 and 15: EQUIPMENT UNITARY HEAT PUMP EFFICIE

- Page 16 and 17: EQUIPMENT ELECTRIC CHILLER EFFICIEN

- Page 18 and 19: REFRIGERANTS refrigerant theoretica

- Page 20 and 21: HVAC IMPACT on LEED ® LEED FOR NEW

- Page 22 and 23: HVAC IMPACT on LEED ® LEED FOR EXI

- Page 24 and 25: HVAC IMPACT on LEED ® LEED FOR COR

- Page 26 and 27: ENERGY MODELING FEATURES OF TRACE

- Page 28 and 29: ASHRAE 90.1-2004 APPENDIX G TABLE G

- Page 30 and 31: REFERENCE REFERENCE 1. CoolToolsTM

- Page 32 and 33: REFERENCE 43. MacCracken, M. M. 200

- Page 34 and 35: NOTES: 30

- Page 36: Literature Order Number............

6<br />

7<br />

8<br />

green options green criteria reference<br />

Heat recovery<br />

Series chillers<br />

chilled-water<br />

loop only,<br />

15˚F or<br />

8.3˚C ΔT<br />

Series-series<br />

counter-flow<br />

chilled-water<br />

loop, 20˚F or<br />

11.1˚C ΔT<br />

condenserwater<br />

loop,<br />

20˚F or<br />

11.1˚C ΔT<br />

9 Ice storage<br />

Recover heat from the condenser of a<br />

water-cooled chiller<br />

• to reheat air (for humidity control)<br />

• to preheat outdoor air<br />

• to heat make-up water entering a building<br />

ASHRAE 90.1-2004 requires heat recovery<br />

for service water heating when<br />

• The facility operates 24 hours per day<br />

• The total heat rejection capacity of the<br />

system exceeds 6,000,000 Btu/h of heat<br />

rejection (about a 450-ton chiller)<br />

• The design servicewater heating load<br />

exceeds 1,000,000 Btu/h (293 kW)<br />

• maximum 2 chillers in series<br />

• place heat recovery or more efficient<br />

chiller upstream<br />

• reduce water flow rate, lower chillerpump<br />

system energy<br />

• lower life-cycle cost for larger plant<br />

• chilled-water-leaving end is condenserwater-entering<br />

end, i.e. counter-flow the<br />

chiller and tower power<br />

• reduce water flow rate, half of ARI standard<br />

rating conditions<br />

• Equal lift for each chiller<br />

• load shift, create source energy savings<br />

and reduce emissions<br />

• standby capacity for non-regular peaks<br />

• reduce overall energy cost<br />

(12)<br />

(40)<br />

(41)<br />

(41)<br />

(42)<br />

(43)<br />

(44)<br />

(45)<br />

(46)<br />

3