Air hydrAulic pump - Harbor Freight Tools

Air hydrAulic pump - Harbor Freight Tools

Air hydrAulic pump - Harbor Freight Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

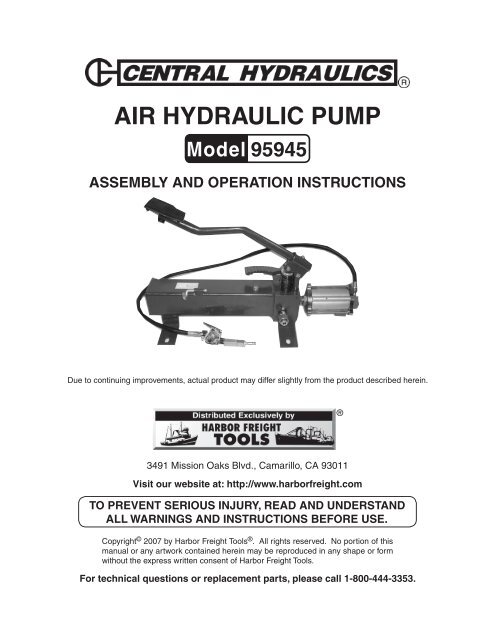

<strong>Air</strong> hydraulic <strong>pump</strong><br />

Model 95945<br />

Assembly And Operation Instructions<br />

Due to continuing improvements, actual product may differ slightly from the product described herein.<br />

®<br />

3491 Mission Oaks Blvd., Camarillo, CA 93011<br />

Visit our website at: http://www.harborfreight.com<br />

To prevent serious injury, read and understand<br />

all warnings and instructions before use.<br />

Copyright © 2007 by <strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong> ® . All rights reserved. No portion of this<br />

manual or any artwork contained herein may be reproduced in any shape or form<br />

without the express written consent of <strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong>.<br />

For technical questions or replacement parts, please call 1-800-444-3353.

Overall Pump Dimensions<br />

Hydraulic Fluid Capacity<br />

Oil Capacity<br />

<strong>Air</strong> Inlet Assembly<br />

Specifications<br />

16-3/4” L (23” L including <strong>Air</strong> Cylinder) X 9-1/4” W<br />

(Including mounting base), 15-1/4” L (base)<br />

1.4 Quarts<br />

44 Fluid oz.<br />

<strong>Air</strong> Hose 3/8” I.D. X 4’<br />

<strong>Air</strong> Pressure<br />

Maximum Hydraulic Pressure<br />

Operating Position<br />

Features<br />

Weight<br />

1/4” -18 NPT Female<br />

Die-cast <strong>Air</strong> Valve with Locking Lever<br />

110 to 120 PSI<br />

10,000 PSI<br />

Horizontal only<br />

Foot Pedal <strong>pump</strong> and release<br />

<strong>Air</strong> Bleeder Valve (Finger operated)<br />

Pedal Hold-Down Latch<br />

Bolt-Down Holes in feet of Bracket<br />

29 lb. (with Oil)<br />

Save This Manual<br />

You will need this manual for the safety warnings and precautions, assembly, operating,<br />

inspection, maintenance and cleaning procedures, parts list and assembly diagram.<br />

Keep your invoice with this manual. Write the invoice number on the inside of the front<br />

cover. Write the product’s serial number in the back of the manual near the assembly<br />

diagram, or write month and year of purchase if product has no serial number. Keep this<br />

manual and invoice in a safe and dry place for future reference.<br />

GENERAL SAFETY RULES<br />

WARNING!<br />

READ AND UNDERSTAND ALL INSTRUCTIONS<br />

Failure to follow all instructions listed below may result in<br />

serious injury.<br />

SAVE THESE INSTRUCTIONS<br />

Work Area<br />

1.<br />

2.<br />

Keep your work area clean and well lit. Cluttered benches and dark areas invite<br />

accidents.<br />

Keep bystanders, children, and visitors away while operating this <strong>Air</strong> Hydraulic<br />

Pump. Distractions can cause you to lose control.<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

REV 07f<br />

Page

Personal Safety<br />

1.<br />

2.<br />

3.<br />

4.<br />

Stay alert. Watch what you are doing, and use common sense when operating.<br />

Do not use this <strong>Air</strong> Hydraulic Pump while tired or under the influence<br />

of drugs, alcohol, or medication. A moment of inattention while operating may<br />

result in serious personal injury.<br />

Dress properly. Do not wear loose clothing or jewelry. Contain long hair.<br />

Keep your hair, clothing, and gloves away from moving parts.<br />

Do not overreach. Keep proper footing and balance at all times. Proper footing<br />

and balance enables better control of the tool in unexpected situations.<br />

Use safety equipment. Always wear eye protection. Always wear ANSI-approved<br />

safety goggles when using or performing maintenance on this tool. Dust<br />

mask, nonskid safety shoes, hard hat, or hearing protection must be used for appropriate<br />

conditions.<br />

Tool Use And Care<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

Do not force the tool. Use the correct tool for your application. The correct<br />

tool will do the job better and safer at the rate for which it is designed. Do not force<br />

the tool and do not use the tool for a purpose for which it is not intended.<br />

<strong>Tools</strong> are dangerous in the hands of untrained users. Keep children away from<br />

this <strong>Air</strong> Hydraulic Pump. Disconnect any air supply before leaving this Pump unattended.<br />

Maintain tools with care. Keep tools clean. Properly maintained tools are less<br />

likely to bind and are easier to control. Do not use a damaged tool. Tag damaged<br />

tools “Do not use” until repaired.<br />

Check for misalignment or binding of moving parts, breakage of parts, and any<br />

other condition that may affect the tool’s operation. If damaged, have the tool<br />

serviced before using. Many accidents are caused by poorly maintained tools.<br />

Use only accessories that are recommended by the manufacturer for your<br />

model. Accessories that may be suitable for one tool may become hazardous<br />

when used on another tool.<br />

Service<br />

1.<br />

2.<br />

Tool service must be performed only by qualified repair personnel. Service or<br />

maintenance performed by unqualified personnel could result in a risk of injury.<br />

When servicing a tool, use only identical replacement parts. Follow instructions<br />

in the “Inspection, Maintenance, And Cleaning” section of this manual.<br />

Use of unauthorized parts or failure to follow maintenance instructions may create<br />

a risk damage to the tool, and/or personal injury.<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

Page

SPECIFIC SAFETY RULES<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

Do not adjust the factory set Safety Valve. This valve should only be set, or reset<br />

by a qualified technician.<br />

This air hydraulic <strong>pump</strong> must be secured tightly to a secure and stable surface<br />

to prevent dynamic pressure from moving it around as you work. Make<br />

sure it is not a tripping hazard.<br />

Follow all manufacturer’s instructions for the air compressor and all attachments<br />

you are using.<br />

Maintain a safe working environment. Make sure there is adequate surrounding<br />

workspace. Do not use this product in a damp or wet location.<br />

The brass components of this product contain lead, a chemical known to the<br />

State of California to cause birth defects (or other reproductive harm). (California<br />

Health & Safety Code § 25249.5, et seq.)<br />

NEVER press the end of the hose against your skin or the skin of another<br />

person or animal. It is possible to inject fluids into your skin using this tool inappropriately.<br />

Hydraulic components must be opened and serviced only by a qualified<br />

technician.<br />

Use clean, dry, and regulated compressed air. Do not exceed the recommended<br />

110-120 PSI. Never use oxygen, carbon dioxide, combustible gases, or any other<br />

bottled gas as a power source for this tool.<br />

Maintain labels and nameplates on the tool. These carry important information.<br />

If unreadable or missing, contact <strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong> for a replacement.<br />

Unpacking<br />

When unpacking, check to make sure that the item is intact and undamaged. If any<br />

parts are missing or broken, please call <strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong> at the number shown on the<br />

cover of this manual as soon as possible.<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

Page

Assembly Instructions<br />

Note: For additional information regarding the parts listed in the following pages, refer to<br />

the Assembly Diagram near the end of this manual.<br />

WARNING! Make sure the <strong>Air</strong> Hydraulic Pump is unplugged from its air supply<br />

and all pressure is released before making any adjustments to the tool.<br />

Note: The Pump comes fully assembled, but you will need to attach a hydraulic hose (not<br />

included) to the <strong>Air</strong> Inlet (9) located on the Pump Body (43) before using this <strong>Air</strong><br />

Hydraulic Pump. This hydraulic hose (not included) is how you will attach all tools.<br />

SET UP DIAGRAM<br />

Hydraulic<br />

Pump<br />

<strong>Air</strong><br />

Compressor<br />

Recommended <strong>Air</strong> Line Components<br />

Note: For best service you should incorporate an oiler, regulator and in-line filter as shown<br />

in Figure 1. If you are not using an automatic oiler system, before operation add<br />

a few drops of Pneumatic Tool Oil (not included) to the airline connection. Add an<br />

additional few drops after each hour of continual use. Hoses, couplers, oilers, regulators<br />

and filters are all available at <strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong>.<br />

Operation Instructions<br />

Note: This <strong>Air</strong> Hydraulic Pump is designed to operate either pneumatically or manually. It<br />

is an ideal power source for various body, frame and alignment applications. It can<br />

be used with different ram kits, shop presses and hydraulic pullers (not included) that<br />

operate up to 10,000 PSI. It is equipped with a factory set Safety Valve to prevent<br />

sudden hydraulic failure. This Pump should be installed in a fixed location.<br />

Note: Check the oil level before using. The Pump Reservoir (46) should be full but after<br />

shipping it may need to be topped off. Check the oil in the <strong>pump</strong> reservoir prior to<br />

use. Remove the Filler Plug (36) and add the fluid being careful not to spill. Replace<br />

the Filler Plug (36) and wipe up any spilled hydraulic fluid. Periodically check the<br />

fluid level.<br />

For best operation: Before use, pull the Breather Valve (35) out. After use,<br />

replace the Breather Valve (35).<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

REV 07f<br />

Page

PNEUMATIC TOOL OPERATION<br />

1.<br />

2.<br />

3.<br />

4.<br />

Depress Foot Pedal Release (34) with one hand while you lower the Foot Pedal (31)<br />

with your foot, locking it in the down position using the Hold-down Clamp (42).<br />

With the <strong>Air</strong> Valve (47) in the released position, attach the air hose from your compressor<br />

to the <strong>Air</strong> Valve (47).<br />

As pressure may be present, verify that the system is not pressurized before hydraulic<br />

hoses are connected or disconnected. Verify this by pressing the Foot Pedal<br />

Release (34) to release any internal hydraulic pressure. Attach a hydraulic hose<br />

(not included) to the <strong>Air</strong> Inlet (9). You will attach all tools being used with your Pump<br />

to this hose.<br />

Hold the lever on the <strong>Air</strong> Valve to apply pressure. Use the Foot Pedal Release to<br />

release pressure. The lever on the <strong>Air</strong> Valve (50) may be held down by the attached<br />

Lock Lever (A33). Disconnect the air supply after use.<br />

MANUAL TOOL OPERATION<br />

1.<br />

2.<br />

3.<br />

4.<br />

If the Foot Pedal (31) is in the lowered position, take pressure off the Foot Pedal (31)<br />

using the Foot Pedal Release (34). Then using your hand, unhook the Hold-down<br />

Clamp (42) and let the Foot Pedal (31) raise to its full height.<br />

Attach a hydraulic hose (not included) to the <strong>Air</strong> Inlet (9). You will attach all tools<br />

being used with your <strong>pump</strong> to this hose.<br />

Pump the Foot Pedal (31) slowly but continually as you are using an attached tool.<br />

This will keep constant hydraulic pressure applied to the tool you are using.<br />

Depress the Foot Pedal Release (34) to release hydraulic pressure.<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

Page

INSPECTION, MAINTENANCE, AND CLEANING<br />

WARNING! Make sure the <strong>Air</strong> Hydraulic Pump is disconnected from its air supply<br />

and all hydraulic pressure is released before performing any inspection, maintenance,<br />

or cleaning procedures.<br />

1.<br />

2.<br />

3.<br />

Before use, inspect the general condition of the air hydraulic <strong>pump</strong>. Check for<br />

loose screws, misalignment or binding of moving parts, cracked or broken parts,<br />

cracked welds, cracked or broken hoses, leaking oil, and any other condition that<br />

may affect its safe operation. If abnormal noise or vibration occurs, have the problem<br />

corrected before further use. Do not use damaged equipment.<br />

After use, wipe off with a clean moist cloth. Be sure to wipe away any spilled<br />

hydraulic fluid.<br />

Monthly, check and refill hydraulic fluid. (See note page 6.)<br />

Troubleshooting<br />

Problem Possible Causes Probable Solutions<br />

Foot Pedal (31) will<br />

not depress when<br />

trying to <strong>pump</strong>.<br />

Low hydraulic<br />

pressure<br />

Pump Body (43) is too full of hydraulic<br />

oil.<br />

1.<br />

2.<br />

Loose air fittings.<br />

Cracked hose.<br />

Make sure the Breather Valve (35) is<br />

open, letting the trapped oil escape if<br />

necessary.<br />

1.<br />

2.<br />

Tighten all fittings.<br />

Change any cracked or broken<br />

hoses. DO NOT FEEL FOR<br />

LEAKS WITH HANDS. HIGH<br />

PRESSURE CAN INJECT FLUID<br />

UNDER SKIN. DO NOT REPAIR<br />

WITH TAPE OR METAL CLAMPS.<br />

ALWAYS REPLACE THE HOSE.<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

Page

PLEASE READ THE FOLLOWING CAREFULLY<br />

The manufacturer and/or distributor has provided the parts list and assembly<br />

diagram in this manual as a reference tool only. Neither the manufacturer<br />

or distributor makes any representation or warranty of any kind to the buyer<br />

that he or she is qualified to make any repairs to the product, or that he or<br />

she is qualified to replace any parts of the product. In fact, the manufacturer<br />

and/or distributor expressly states that all repairs and parts replacements<br />

should be undertaken by certified and licensed technicians, and not by the<br />

buyer. The buyer assumes all risk and liability arising out of his or her repairs<br />

to the original product or replacement parts thereto, or arising out of his<br />

or her installation of replacement parts thereto.<br />

Record Product’s Serial Number Here:<br />

Note: If product has no serial number, record month and year of purchase instead.<br />

Note: Some parts are listed and shown for illustration purposes only, and are not available<br />

individually as replacement parts.<br />

Limited 1 Year warranty<br />

<strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong> Co. makes every effort to assure that its products meet high quality and durability<br />

standards, and warrants to the original purchaser that this product is free from defects in materials and<br />

workmanship for the period of one year from the date of purchase (90 days if used by a professional contractor<br />

or if used as rental equipment). This warranty does not apply to damage due directly or indirectly, to misuse,<br />

abuse, negligence or accidents, repairs or alterations outside our facilities, normal wear and tear, or to lack<br />

of maintenance. We shall in no event be liable for death, injuries to persons or property, or for incidental,<br />

contingent, special or consequential damages arising from the use of our product. Some states do not allow<br />

the exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion may<br />

not apply to you. This warranty is expressly in lieu of all other warranties, express<br />

or implied, including the warranties of merchantability and fitness.<br />

To take advantage of this warranty, the product or part must be returned to us with transportation<br />

charges prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise.<br />

If our inspection verifies the defect, we will either repair or replace the product at our election or we may<br />

elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. We will<br />

return repaired products at our expense, but if we determine there is no defect, or that the defect resulted<br />

from causes not within the scope of our warranty, then you must bear the cost of returning the product.<br />

This warranty gives you specific legal rights and you may also have other rights which vary from<br />

state to state.<br />

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

Page

Hydraulic <strong>pump</strong> PARTS LIST<br />

Part Description Q’ty<br />

1 Ball 1<br />

2 Ball cap 2<br />

3 Spring 2<br />

4 Screw 1<br />

5 O-ring 1<br />

6 Safety Valve 1<br />

7 Plastic Cap 1<br />

8 Coupling Ring 1<br />

9 <strong>Air</strong> Inlet 1<br />

10 O-ring 1<br />

11 Dust Cap 1<br />

12 Ball 4<br />

13 Ball 1<br />

14 Screw 1<br />

15 Spring 3<br />

16 Screw 3<br />

17 Washer 2<br />

18 Screw 1<br />

19 Dust Ring 1<br />

20 Spring 1<br />

21 Spring Cap 1<br />

22 O-ring 1<br />

23 Nylon ring 1<br />

24 Piston 1<br />

Part Description Q’ty<br />

25 Pin 2<br />

26 R-pin 2<br />

27 Handle Socket 1<br />

28 Washer 1<br />

29 Bolt M8x25 1<br />

30 Pin 1<br />

31 Foot Pedal 1<br />

32 Rubber Pad 1<br />

33 Rubber 1<br />

34 Rubber Foot Pedal 1<br />

35 Breather Valve 1<br />

36 Filler Plug 1<br />

37 Oil Release piston 1<br />

38 O-ring 1<br />

39 Pin 1<br />

40 Screw 1<br />

41 Ball 1<br />

42 Hold-down clamp 1<br />

43 Pump Body 1<br />

44 Rubber 4<br />

45 <strong>Air</strong> Pump Assembly 1<br />

46 <strong>Air</strong> Hose 1<br />

47 Valve Body 1<br />

Note: In both the Hydraulic Pump Parts List on this page, and the <strong>Air</strong> Pump Parts List<br />

on page 11, numbers 46 and A32 are for the same <strong>Air</strong> Hose, and numbers 47 and<br />

A43 are both for the same Valve Body.<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

REV 07f<br />

Page

Hydraulic <strong>pump</strong> ASSEMBLY DIAGRAM<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

REV 07f<br />

Page 10

<strong>Air</strong> <strong>pump</strong> PARTS LIST<br />

Part Description Q’ty<br />

A01 <strong>Air</strong> Pump Cylinder 1<br />

A02 Nut 1<br />

A03 Sealing Ring 1<br />

A04 Nylon Ring 1<br />

A05 Copper Ring 1<br />

A06 <strong>Air</strong> Cylinder Seat 1<br />

A07 Nut 1<br />

A08 Spring 1<br />

A09 <strong>Air</strong> Pump Piston 1<br />

A10 O-ring 2<br />

A11 Big Piston 1<br />

A12 <strong>Air</strong> Cylinder 1<br />

A13 Screw 2<br />

A14 Lock Washer 2<br />

A15 Safety Cover 1<br />

A16 Filter 1<br />

A17 Silencing Pad 1<br />

A18 Small Piston 1<br />

A19 O-ring 1<br />

A20 O-ring 1<br />

A21 Sealing Ring 1<br />

A22 Bolt 3<br />

A23 Nylon Ring 1<br />

A24 O-ring 2<br />

Part Description Q’ty<br />

A25 O-ring 1<br />

A-26 <strong>Air</strong> Cylinder Cap 1<br />

A27 Bolt 4<br />

A28 Coupler Seat 1<br />

A29 Retaining Ring 1<br />

A30 O-ring 2<br />

A31 Coupler 1<br />

A32 <strong>Air</strong> Hose 1<br />

A33 Lock Lever 1<br />

A34 Release Lever 1<br />

A35 Nut 1<br />

A36 O-ring 1<br />

A37 O-ring 1<br />

A38 Packing 1<br />

A39 Throttle 1<br />

A40 Spring 1<br />

A41 Lock Nut 1<br />

A42 Bolt 1<br />

A43 Valve Body 1<br />

A44 Screw 1<br />

A45 Screen 1<br />

A46 O-ring 1<br />

A47 Quick Coupler-male 1<br />

A48 Coupler Seat 1<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

Page 11

<strong>Air</strong> <strong>pump</strong> ASSEMBLY DIAGRAM<br />

SKU 95945 For technical questions, please call 1-800-444-3353.<br />

Page 12