- Page 1 and 2:

Part No. 08162SL (Rev. A) Service M

- Page 3 and 4:

Table Of Contents Chapter 1 - Safet

- Page 5 and 6:

Table of Contents GENERAL SAFETY IN

- Page 7 and 8:

Maintenance and Service 1. Before s

- Page 9 and 10:

Safety and Instruction Decals Numer

- Page 11 and 12:

Chapter 2 Table of Contents Product

- Page 13 and 14:

Torque Specifications Recommended f

- Page 15 and 16:

Standard Torque for Dry, Zinc Plate

- Page 17 and 18:

Chapter 3 Kubota Diesel Engine Tabl

- Page 19 and 20:

Specifications Item Make / Designat

- Page 21 and 22:

Removal (Fig. 1) 1. Park machine on

- Page 23 and 24:

Removal (Fig. 5) CAUTION B The muff

- Page 25 and 26:

DANGER Because diesel fuel is highl

- Page 27 and 28:

Removal (Fig. 8) 1. Park machine on

- Page 29 and 30:

Engine Removal (Fig. 9) 1. Park mac

- Page 31 and 32:

3. Slowly lower engine into the mac

- Page 33 and 34:

Coupler Removal (Fig. 16) NOTE: The

- Page 35 and 36:

Chapter 4 Hydraulic System Table of

- Page 37 and 38:

General Information Operator’s Ma

- Page 39 and 40:

Hydraulic Hose and Tube Installatio

- Page 41 and 42:

Adjustable Fitting (Fig. 8) 1. Make

- Page 43 and 44:

Hydraulic System This page is inten

- Page 45 and 46:

Traction Circuit: 4WD (Mow) The tra

- Page 47 and 48:

Traction Circuit: Transport (2WD) T

- Page 49 and 50:

Lower Cutting Deck A four section g

- Page 51 and 52:

Raise Cutting Deck A four section g

- Page 53 and 54:

Mow Circuit Hydraulic flow for the

- Page 55 and 56:

Hydraulic System This page is inten

- Page 57 and 58:

Steering Circuit A four section gea

- Page 59 and 60:

Engine Cooling Fan Circuit A four s

- Page 61 and 62:

Hydraulic Test Fitting Kit This kit

- Page 63 and 64:

Problem Traction power is lost or u

- Page 65 and 66:

Testing The most effective method f

- Page 67 and 68:

Procedure for Traction Circuit Char

- Page 69 and 70:

Procedure for Traction Circuit Reli

- Page 71 and 72:

Procedure for Counterbalance Pressu

- Page 73 and 74:

Procedure for Rear Traction Circuit

- Page 75 and 76:

Procedure for Traction Circuit Redu

- Page 77 and 78:

Procedure for Cutting Deck Circuit

- Page 79 and 80:

Procedure for Cutting Deck Manifold

- Page 81 and 82:

Procedure for Cutting Deck Gear Pum

- Page 83 and 84:

Procedure for Cutting Deck Motor Ca

- Page 85 and 86:

Procedure for Steering Circuit Reli

- Page 87 and 88:

Procedure for Lift/Lower Circuit Re

- Page 89 and 90:

Procedure for Steering and Lift/Low

- Page 91 and 92:

Procedure for Engine Cooling Fan Ci

- Page 93 and 94:

Procedure for Engine Cooling Fan Ci

- Page 95 and 96:

Service and Repairs General Precaut

- Page 97 and 98:

Charge Hydraulic System NOTE: When

- Page 99 and 100:

NOTE: The front frame needs to be l

- Page 101 and 102:

Removal (Fig. 48) CAUTION The radia

- Page 103 and 104:

Removal (Fig 49) 1. Park machine on

- Page 105 and 106:

IMPORTANT: Use caution when clampin

- Page 107 and 108:

Hydraulic System This page is inten

- Page 109 and 110:

Removal (Fig. 53) 1. Park machine o

- Page 111 and 112:

Hydraulic System This page is inten

- Page 113 and 114:

Removal (Fig. 56) 1. Park machine o

- Page 115 and 116:

Removal (Fig. 57) 1. Park machine o

- Page 117 and 118:

Hydraulic System This page is inten

- Page 119 and 120:

Removal (Fig. 59) NOTE: The ports o

- Page 121 and 122:

4WD Manifold Service (Fig. 60) 1. M

- Page 123 and 124:

Removal (Fig. 61) 1. Read the Gener

- Page 125 and 126:

Filter Manifold Service (Fig. 62) F

- Page 127 and 128:

Hydraulic System This page is inten

- Page 129 and 130:

Removal (Fig. 64) 1. Park machine o

- Page 131 and 132:

CAUTION The centering springs are u

- Page 133 and 134:

Removal (Fig. 67) 1. Park machine o

- Page 135 and 136:

Disassembly (Fig. 68) 1. Pump oil o

- Page 137 and 138:

Removal (Fig. 69) 1. Park machine o

- Page 139 and 140:

8. Remove and discard back--up gask

- Page 141 and 142:

Hydraulic System This page is inten

- Page 143 and 144:

Removal (Fig. 75) 1. Read the Gener

- Page 145 and 146:

Fan Drive Manifold Service (Fig. 76

- Page 147 and 148:

Cutting Deck Motor Removal 1. Park

- Page 149 and 150:

IMPORTANT: Mark the relative positi

- Page 151 and 152:

Hydraulic System This page is inten

- Page 153 and 154:

Removal (Fig. 85) NOTE: The ports o

- Page 155 and 156: PTO Manifold Service (Fig. 86) For

- Page 157 and 158: Hydraulic System This page is inten

- Page 159 and 160: Removal (Fig. 88) 1. Park machine o

- Page 161 and 162: Disassembly (Fig. 89) 1. Plug all p

- Page 163 and 164: Removal (Fig. 90) 1. Park machine o

- Page 165 and 166: Removal (Fig. 91) 1. Park machine o

- Page 167 and 168: Disassembly (Figs. 92 and 93) 1. Re

- Page 169 and 170: Removal (Fig. 94) 1. Read the Gener

- Page 171 and 172: Chapter 5 Electrical System Table o

- Page 173 and 174: Special Tools Order special tools f

- Page 175 and 176: Troubleshooting CAUTION Remove all

- Page 177 and 178: Cutting Deck Operating Problems The

- Page 179 and 180: Adjustments Wing Deck Position Swit

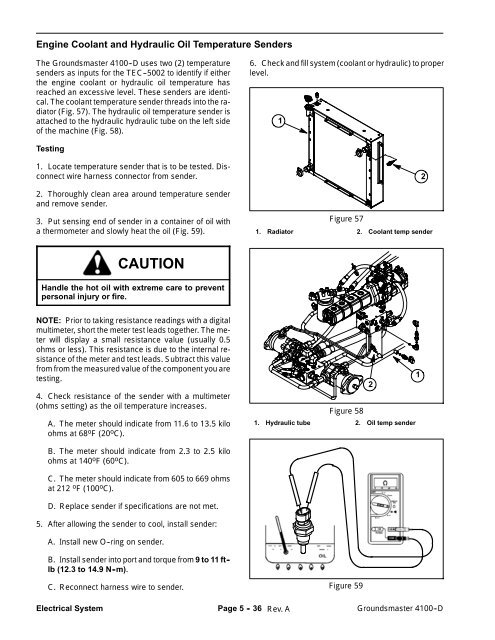

- Page 181 and 182: Component Testing For accurate resi

- Page 183 and 184: Warning Lights Engine Oil Pressure

- Page 185 and 186: Transport / 4WD Switch The transpor

- Page 187 and 188: Seat Switch The seat switch is norm

- Page 189 and 190: Hour Meter The hour meter is locate

- Page 191 and 192: Start, Engine Shutdown, Seat, Alarm

- Page 193 and 194: TEC -5002 Controller Groundsmaster

- Page 195 and 196: Fuel Gauge The fuel gauge can be te

- Page 197 and 198: Glow Controller The glow controller

- Page 199 and 200: Dual Temperature Switch The dual te

- Page 201 and 202: Traction Neutral Switch The tractio

- Page 203 and 204: Fusible Links The Groundsmaster 410

- Page 205: Cutting Deck Raise and Lower Switch

- Page 209 and 210: 2. Conduct a hydrometer test of the

- Page 211 and 212: Chapter 6 Axles, Planetaries and Br

- Page 213 and 214: General Information Operator’s Ma

- Page 215 and 216: 3. Chock rear wheels and jack up fr

- Page 217 and 218: This page is intentionally blank. A

- Page 219 and 220: Removal (Fig. 6) 1. Park machine on

- Page 221 and 222: NOTE: The planetary wheel drive ass

- Page 223 and 224: This page is intentionally blank. A

- Page 225 and 226: 8. Remove cap screw and flange nut

- Page 227 and 228: Bevel Gear Case and Axle Case The f

- Page 229 and 230: Bevel Gear Case and Axle Case Insta

- Page 231 and 232: 9. Remove the bevel gear case/axle

- Page 233 and 234: Axle Shafts The following procedure

- Page 235 and 236: 7. Secure the lock nut with the sta

- Page 237 and 238: Differential Gear Inspection 1. Mea

- Page 239 and 240: Pinion Gear to Ring Gear Engagement

- Page 241 and 242: Chapter 7 Chassis Table of Contents

- Page 243 and 244: Disassembly (Fig. 1) 1. Park machin

- Page 245 and 246: CAUTION When changing attachments,

- Page 247 and 248: Removal (Fig. 5) 1. Park machine on

- Page 249 and 250: Disassembly (Fig. 8) 1. Disassemble

- Page 251 and 252: NOTE: Most of the seat suspension c

- Page 253 and 254: Removal 1. Park machine on a level

- Page 255 and 256: Chapter 8 Cutting Deck Table of Con

- Page 257 and 258:

General Information CAUTION Never i

- Page 259 and 260:

This page is intentionally blank. C

- Page 261 and 262:

Removal (Fig. 1) 1. Position machin

- Page 263 and 264:

This page is intentionally blank. C

- Page 265 and 266:

Removal (Fig. 6) 1. Position machin

- Page 267 and 268:

Cutting Deck Link Service Disassemb

- Page 269 and 270:

This page is intentionally blank. C

- Page 271 and 272:

Installation (Fig. 13) 1. Position

- Page 273 and 274:

2. Install outer bearing spacer int

- Page 275 and 276:

Removal (Fig. 20) 1. Park machine o

- Page 277 and 278:

Disassembly (Fig. 22) 1. Park machi

- Page 279 and 280:

Chapter 9 Foldout Drawings Table of

- Page 281 and 282:

CENTER DECK MANIFOLD COUNTERBALANCE

- Page 283 and 284:

CONTINUES FROM SHEET 1 CONTINUES FR

- Page 285 and 286:

CONTINUES TO SHEET 2 CONTINUES TO S

- Page 287 and 288:

CONTINUES TO SHEET 2 WHEN THE PTO S

- Page 289 and 290:

CONTINUES TO SHEET 2 CONTINUES TO S

- Page 291 and 292:

YELLOW GRAY YELLOW/BLACK VIOLET WHI

- Page 293 and 294:

FLOW DIVIDER SOLENOID Groundsmaster

- Page 295 and 296:

(STARTER) (STARTER) (STARTER) Groun

- Page 297 and 298:

BLUE GRAY VIOLET BLACK YELLOW GRAY