Multi Pro 5700 - Toro

Multi Pro 5700 - Toro

Multi Pro 5700 - Toro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Spray Pump Drive Circuit Relief Pressure Test<br />

1. Make sure hydraulic oil is at normal operating temperature<br />

by operating the machine for approximately 10<br />

minutes. Make sure the hydraulic tank is full.<br />

2. Park machine on a level surface, stop engine, engage<br />

parking brake, and remove key from the ignition<br />

switch. After turning engine off, operate all hydraulic<br />

controls to relieve hydraulic system pressure.<br />

CAUTION<br />

8. Open control valve on tester, slow engine speed and<br />

shut off engine. Record test results.<br />

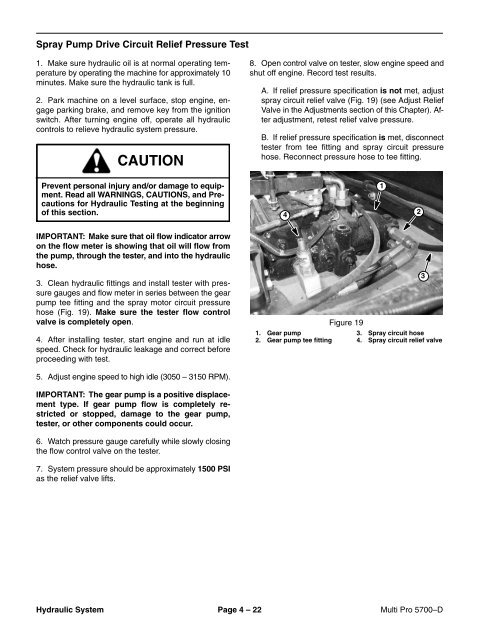

A. If relief pressure specification is not met, adjust<br />

spray circuit relief valve (Fig. 19) (see Adjust Relief<br />

Valve in the Adjustments section of this Chapter). After<br />

adjustment, retest relief valve pressure.<br />

B. If relief pressure specification is met, disconnect<br />

tester from tee fitting and spray circuit pressure<br />

hose. Reconnect pressure hose to tee fitting.<br />

Prevent personal injury and/or damage to equipment.<br />

Read all WARNINGS, CAUTIONS, and Precautions<br />

for Hydraulic Testing at the beginning<br />

of this section.<br />

4<br />

1<br />

2<br />

IMPORTANT: Make sure that oil flow indicator arrow<br />

on the flow meter is showing that oil will flow from<br />

the pump, through the tester, and into the hydraulic<br />

hose.<br />

3. Clean hydraulic fittings and install tester with pressure<br />

gauges and flow meter in series between the gear<br />

pump tee fitting and the spray motor circuit pressure<br />

hose (Fig. 19). Make sure the tester flow control<br />

valve is completely open.<br />

4. After installing tester, start engine and run at idle<br />

speed. Check for hydraulic leakage and correct before<br />

proceeding with test.<br />

Figure 19<br />

1. Gear pump 3. Spray circuit hose<br />

2. Gear pump tee fitting 4. Spray circuit relief valve<br />

3<br />

5. Adjust engine speed to high idle (3050 – 3150 RPM).<br />

IMPORTANT: The gear pump is a positive displacement<br />

type. If gear pump flow is completely restricted<br />

or stopped, damage to the gear pump,<br />

tester, or other components could occur.<br />

6. Watch pressure gauge carefully while slowly closing<br />

the flow control valve on the tester.<br />

7. System pressure should be approximately 1500 PSI<br />

as the relief valve lifts.<br />

Hydraulic System Page 4 – 22 <strong>Multi</strong> <strong>Pro</strong> <strong>5700</strong>–D