Department of Electronics - IPN - IN2P3

Department of Electronics - IPN - IN2P3

Department of Electronics - IPN - IN2P3

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

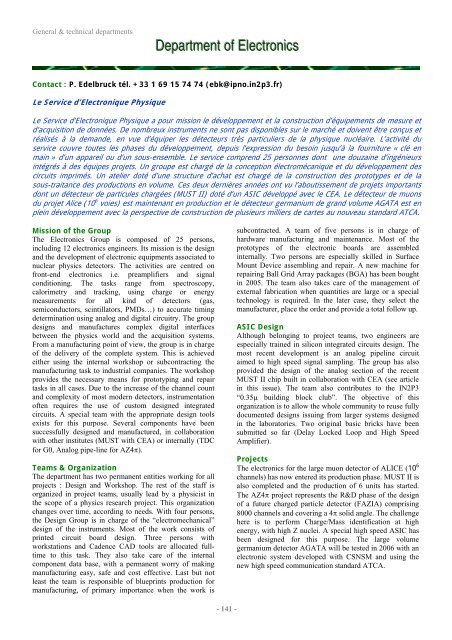

General & technical departments<br />

Deparrttmentt <strong>of</strong>f Electtrroni<br />

ics<br />

Contact : P. Edelbruck tél. +33 1 69 15 74 74 (ebk@ipno.in2p3.fr)<br />

Le Service d’Electronique Physique<br />

Le Service d’Electronique Physique a pour mission le développement et la construction d’équipements de mesure et<br />

d’acquisition de données. De nombreux instruments ne sont pas disponibles sur le marché et doivent être conçus et<br />

réalisés à la demande, en vue d’équiper les détecteurs très particuliers de la physique nucléaire. L’activité du<br />

service couvre toutes les phases du développement, depuis l’expression du besoin jusqu’à la fourniture « clé en<br />

main » d’un appareil ou d’un sous-ensemble. Le service comprend 25 personnes dont une douzaine d’ingénieurs<br />

intégrés à des équipes projets. Un groupe est chargé de la conception électromécanique et du développement des<br />

circuits imprimés. Un atelier doté d’une structure d’achat est chargé de la construction des prototypes et de la<br />

sous-traitance des productions en volume. Ces deux dernières années ont vu l’aboutissement de projets importants<br />

dont un détecteur de particules chargées (MUST II) doté d’un ASIC développé avec le CEA. Le détecteur de muons<br />

du projet Alice (10 6 voies) est maintenant en production et le détecteur germanium de grand volume AGATA est en<br />

plein développement avec la perspective de construction de plusieurs milliers de cartes au nouveau standard ATCA.<br />

Mission <strong>of</strong> the Group<br />

The <strong>Electronics</strong> Group is composed <strong>of</strong> 25 persons,<br />

including 12 electronics engineers. Its mission is the design<br />

and the development <strong>of</strong> electronic equipments associated to<br />

nuclear physics detectors. The activities are centred on<br />

front-end electronics i.e. preamplifiers and signal<br />

conditioning. The tasks range from spectroscopy,<br />

calorimetry and tracking, using charge or energy<br />

measurements for all kind <strong>of</strong> detectors (gas,<br />

semiconductors, scintillators, PMDs…) to accurate timing<br />

determination using analog and digital circuitry. The group<br />

designs and manufactures complex digital interfaces<br />

between the physics world and the acquisition systems.<br />

From a manufacturing point <strong>of</strong> view, the group is in charge<br />

<strong>of</strong> the delivery <strong>of</strong> the complete system. This is achieved<br />

either using the internal workshop or subcontracting the<br />

manufacturing task to industrial companies. The workshop<br />

provides the necessary means for prototyping and repair<br />

tasks in all cases. Due to the increase <strong>of</strong> the channel count<br />

and complexity <strong>of</strong> most modern detectors, instrumentation<br />

<strong>of</strong>ten requires the use <strong>of</strong> custom designed integrated<br />

circuits. A special team with the appropriate design tools<br />

exists for this purpose. Several components have been<br />

successfully designed and manufactured, in collaboration<br />

with other institutes (MUST with CEA) or internally (TDC<br />

for G0, Analog pipe-line for AZ4π).<br />

Teams & Organization<br />

The department has two permanent entities working for all<br />

projects : Design and Workshop. The rest <strong>of</strong> the staff is<br />

organized in project teams, usually lead by a physicist in<br />

the scope <strong>of</strong> a physics research project. This organization<br />

changes over time, according to needs. With four persons,<br />

the Design Group is in charge <strong>of</strong> the “electromechanical”<br />

design <strong>of</strong> the instruments. Most <strong>of</strong> the work consists <strong>of</strong><br />

printed circuit board design. Three persons with<br />

workstations and Cadence CAD tools are allocated fulltime<br />

to this task. They also take care <strong>of</strong> the internal<br />

component data base, with a permanent worry <strong>of</strong> making<br />

manufacturing easy, safe and cost effective. Last but not<br />

least the team is responsible <strong>of</strong> blueprints production for<br />

manufacturing, <strong>of</strong> primary importance when the work is<br />

subcontracted. A team <strong>of</strong> five persons is in charge <strong>of</strong><br />

hardware manufacturing and maintenance. Most <strong>of</strong> the<br />

prototypes <strong>of</strong> the electronic boards are assembled<br />

internally. Two persons are especially skilled in Surface<br />

Mount Device assembling and repair. A new machine for<br />

repairing Ball Grid Array packages (BGA) has been bought<br />

in 2005. The team also takes care <strong>of</strong> the management <strong>of</strong><br />

external fabrication when quantities are large or a special<br />

technology is required. In the later case, they select the<br />

manufacturer, place the order and provide a total follow up.<br />

ASIC Design<br />

Although belonging to project teams, two engineers are<br />

especially trained in silicon integrated circuits design. The<br />

most recent development is an analog pipeline circuit<br />

aimed to high speed signal sampling. The group has also<br />

provided the design <strong>of</strong> the analog section <strong>of</strong> the recent<br />

MUST II chip built in collaboration with CEA (see article<br />

in this issue). The team also contributes to the <strong>IN2P3</strong><br />

“0.35μ building block club”. The objective <strong>of</strong> this<br />

organization is to allow the whole community to reuse fully<br />

documented designs issuing from larger systems designed<br />

in the laboratories. Two original basic bricks have been<br />

submitted so far (Delay Locked Loop and High Speed<br />

Amplifier).<br />

Projects<br />

The electronics for the large muon detector <strong>of</strong> ALICE (10 6<br />

channels) has now entered its production phase. MUST II is<br />

also completed and the production <strong>of</strong> 6 units has started.<br />

The AZ4π project represents the R&D phase <strong>of</strong> the design<br />

<strong>of</strong> a future charged particle detector (FAZIA) comprising<br />

8000 channels and covering a 4π solid angle. The challenge<br />

here is to perform Charge/Mass identification at high<br />

energy, with high Z nuclei. A special high speed ASIC has<br />

been designed for this purpose. The large volume<br />

germanium detector AGATA will be tested in 2006 with an<br />

electronic system developed with CSNSM and using the<br />

new high speed communication standard ATCA.<br />

- 141 -

General & technical <strong>Department</strong>s<br />

The electtrroni<br />

ics <strong>of</strong>f ALIICE dimuon ttrracki ing chamberrs<br />

<strong>IPN</strong>O Participation : V. Chambert, P. Courtat, S. Drouet, B.-Y. Ky, J-M. Martin, C. Oziol<br />

Collaboration : Institut de Physique Nucléaire d’Orsay, Saha Institute <strong>of</strong> Nuclear Physics, Istituto<br />

Nazionale di Fisica Nucleare Sezione di Cagliari, Subatech Nantes<br />

L’électronique des chambres à fils du bras Dimuon d’Alice<br />

Le bras Dimuon de l’expérience Alice du Cern comprend entre autres un système de reconstruction de traces des<br />

particules composé de 10 chambres à fils reparties dans 5 stations. L’<strong>IPN</strong>O a en charge la coordination de<br />

l’électronique pour tout le bras Dimuon, ainsi que la construction de la station 1. Le système de lecture des<br />

chambres comprend des cartes frontales de lecture et de numérisation des données, des bus de transmission vers<br />

les châssis CROCUS de lecture et un châssis de transmission et de mise en forme du trigger. Après une brève<br />

présentation de ces systèmes nous décrirons de façon plus détaillée le système CROCUS.<br />

<strong>Electronics</strong> architecture<br />

The ALICE dimuon arm is, for the main parts, composed <strong>of</strong><br />

several absorbers, <strong>of</strong> a trigger system, <strong>of</strong> a dipole and <strong>of</strong> a<br />

tracking system. The tracking system is composed <strong>of</strong> five<br />

stations with two chambers for each <strong>of</strong> them.<br />

<strong>IPN</strong> Orsay is in charge <strong>of</strong> the electronics coordination for<br />

the tracking system (fig 1). It means that front-end<br />

electronics (≈20 000 Manu boards, more than 10 6 channels),<br />

CROCUS read out crates (≈ 22 crates), trigger dispatching<br />

crates (2 crates) and the related s<strong>of</strong>tware were designed at<br />

Orsay and we will produced for the whole Dimuon<br />

collaboration.<br />

Besides these elements, data bus transmission (bus patch)<br />

were designed at Orsay but each station adapted the system<br />

for its needs and produced them.<br />

Orsay is also responsible for the design and production <strong>of</strong><br />

transmission boards called translators and bridges both for<br />

station 1 and 2.<br />

CROCUS crate<br />

A rough estimation <strong>of</strong> the typical information<br />

number to read in the case <strong>of</strong> a “mean” collision gives<br />

about 150 kB distributed in the five stations. Using a safety<br />

factor <strong>of</strong> 2, the electronics will have to handle an<br />

acquisition rate <strong>of</strong> 1200 evts/s for the lead beams and <strong>of</strong><br />

DETECTOR<br />

FEE<br />

FEE<br />

2 x 32<br />

PADs<br />

PATCH BUS<br />

Up to 26 or 3 x 17<br />

MANU BOARD.<br />

Up to 100 PATCH BUS<br />

per detector.<br />

HIGH VOLTAGE<br />

MANU<br />

SLOW CONTROL<br />

DETECTOR: Chapter 1<br />

FEE: Chapter 2<br />

MANU: Chapter 2.1<br />

READ OUT: Chapter 3<br />

DISPATCHING: Chapter 3.2<br />

CROCUS: Chapter 3.3<br />

SOFTWARE: Chapter 3.4<br />

LOW VOLTAGE: Chapter 4<br />

HIGH VOLTAGE: Chapter 5<br />

SLOW CONTROL: Chapter 6<br />

EMC: Chapter 7<br />

ALICE TRACKING DIMUON SYSTEM:<br />

ELECTRONICS & SOFTWARE<br />

Translator<br />

Board.<br />

LOW VOLTAGE<br />

EMC<br />

10 Meter max<br />

Ribbon cable<br />

READ OUT.<br />

CROCUS Crate<br />

Up to 50 PATCH BUS connected.<br />

FRT<br />

DAQ<br />

Optical link:<br />

DDL<br />

100 meter.<br />

PC<br />

CRT<br />

SOFTWARE<br />

Ribbon cable<br />

40 meter<br />

TCI<br />

One crate for all<br />

CROCUS.<br />

FFT FTD<br />

Link to download:<br />

Pedestals.<br />

DSP code.<br />

From CTP<br />

Trigger information:<br />

L0, L1…..<br />

ETHERNET:<br />

- Monitoring.<br />

- Stand alone DAQ.<br />

- Test configuration.<br />

fig 1:<br />

2000 evts/s for the high intensity Ca beams.<br />

- 142 -<br />

The choice has been done to use DSP AD21160M (Digital<br />

Signal Processor) farms to achieve the data readout coming<br />

from the FEE. These DSPs are gathered in « clusters » in 20<br />

specific crates called CROCUS (Cluster Read Out<br />

Concentrator Unit System). Each crate is composed <strong>of</strong> 5<br />

cards called « frontal » directly connected to the Patch<br />

buses by ribbon cables and <strong>of</strong> a concentrator card which<br />

collects the data coming from all the frontal cards then,<br />

after, formatting, transmits them to the SIU (Source<br />

Interface Unit) which will achieve the transmission towards<br />

the DDL (Detector Data Link) (fig 1). This modularity<br />

provides a high readout speed and minimizes the

General & technical <strong>Department</strong>s<br />

consequences <strong>of</strong> a malfunctioning <strong>of</strong> an element. Moreover,<br />

the use <strong>of</strong> all these DSPs permits the buffering <strong>of</strong> events at<br />

different levels in the readout chain.<br />

Each CROCUS crate has many functions :<br />

- it picks up the detectors data, it concentrates them, it<br />

sends them to the DAQ<br />

- it generates the Front-end control signals and send<br />

them to the front-end through buses<br />

- it picks up trigger signals from dispatching crate and it<br />

broadcasts them to the Front-end electronics<br />

- It generates calibration signals, it sends them to the<br />

detectors, and it processes the calibration data and it<br />

sends them to the DAQ<br />

- It detects failures on the read out chain<br />

The production <strong>of</strong> the 22 crates is foreseen for 2006.<br />

The very complex s<strong>of</strong>tware design is in progress<br />

All the CROCUS crates are close to the detector (less than<br />

10 meters) to insure a good efficiency <strong>of</strong> the data<br />

acquisition through 8 bits/ 20Mo/s linkport. The crate itself<br />

is a specific one VME 6U 9T, amagnetic aluminum made,<br />

very compact to be easily integrated on the detector.<br />

The CROCUS architecture concentrates data with the<br />

following scheme :<br />

- each CROCUS frontal board (CROCUS_FRT) receives<br />

data from 10 buses and it concentrates them within 2<br />

front-end DSP.<br />

- All the front-end DSP (10 for a CROCUS crate) are<br />

connected through the back plane (CROCUS_back) to<br />

2 DSP called concentrators located. Each connection is<br />

done with a linkport.<br />

- The concentrator DSP are located on a concentrator<br />

board called CROCUS_CRT.<br />

- A master DSP located on CROCUS_CRT gathers all<br />

the data via a parallel bus 320MB/s and sends them<br />

through a Xilinx FPGA to the SIU unit<br />

- The SIU unit transmits data to ALICE DAQ with an<br />

optical fiber.<br />

References<br />

Fig 2 : CROCUS crate prototype<br />

CROCUS_FRT, CROCUS_CRT, CROCUS_Back boards<br />

are designed. Their integration in the specific crate is in<br />

progress.<br />

[1] The electronics <strong>of</strong> ALICE dimuon tracking chamber PRR<br />

(2003)<br />

- 143 -

General & technical departments<br />

The ASIIC developmentt actti ivitti<br />

ies <strong>of</strong>f tthe Electtrroni<br />

ics Grroup<br />

<strong>IPN</strong>O Participants : J.-C. Cuzon, S. Drouet, P. Edelbruck, E. Wanlin<br />

Les activités de développements d’ASICS du Service d’Electronique Physique<br />

Les détecteurs développés dans le domaine de la physique nucléaire embarquent aujourd’hui une instrumentation<br />

de plus en plus complexe qui peut parfois comporter plusieurs millions de voies de mesure. Les niveaux de<br />

précision requis, les volumes de données, la complexité des traitements effectués en ligne et les vitesses de<br />

transfert conduisent fréquemment à abandonner les technologies d’électronique traditionnelle (discrète) et à<br />

recourir aux techniques d’intégration sur silicium. Le Service d’Electronique Physique de l’Institut est engagé dans<br />

cette voie depuis de nombreuses années et possède à son actif des réalisations importantes. On peut citer un<br />

circuit de mesure de temps (TDC) destiné à la spectrométrie de masse, une chaîne de mesure pour les détecteurs<br />

au silicium développée en collaboration avec le CEA et dernièrement une mémoire analogique rapide destinée à la<br />

numérisation de signaux à très grandes vitesses. Le savoir-faire acquis par le groupe dans le domaine du<br />

développement d’ASIC est aujourd’hui significatif et les outils informatiques disponibles permettent d’aborder le<br />

développement de circuits analogiques-numériques complexes.<br />

The complexity <strong>of</strong> the electronic equipment embedded in<br />

nuclear physics detectors is becoming quite complex in<br />

terms <strong>of</strong> technical specifications but also in terms <strong>of</strong><br />

channel count. A detector may comprise several millions <strong>of</strong><br />

electronic channels. The required precision level, the<br />

volume <strong>of</strong> data and the complexity <strong>of</strong> the processing<br />

performed online <strong>of</strong>ten leads to move from traditional<br />

discrete technology to integrated solutions. The <strong>Electronics</strong><br />

Group <strong>of</strong> the Institute has started integrating designs many<br />

years ago and several components have been developed.<br />

CRT-C DST-9<br />

I) was instrumented in the early 90’s with discrete<br />

electronics. The second generation detector had several<br />

hundreds <strong>of</strong> channels and clearly required an integrated<br />

solution. A collaboration team was set up between <strong>IPN</strong> and<br />

CEA for the design <strong>of</strong> an ASIC. The aim was to come up<br />

with a chip performing timing and energy measurements<br />

for 16 channels in a single chip (preamplifier, trigger,<br />

shaper, time to analog converter and data read-out). The<br />

preamplifier, the energy section and the logic interfaces<br />

were designed at <strong>IPN</strong> and the timing and the multiplexing<br />

modules at CEA.<br />

The first achievement was a chipset aimed to mass<br />

spectroscopy. The issue at this time (mid 90’s) was more <strong>of</strong><br />

a technical nature. The requirement was to measure time<br />

intervals with a resolution better than 0.25 ns and a very<br />

high repetition rate (multi-hit). Less than 20 ns may have<br />

elapsed between two successive events. These features<br />

were absolutely not achievable with commercial<br />

components and have led to the design <strong>of</strong> two original<br />

ASICs. The development has been performed using a<br />

bipolar technology from the French silicon founder<br />

Thomson. It was a success and the chips have been used in<br />

a wide range <strong>of</strong> instrument during 10 years. They represent<br />

the heart <strong>of</strong> CTN, a module aimed to mass spectroscopy,<br />

now in use in many laboratories worldwide, as well as<br />

COMET, a general purpose acquisition board used at<br />

Tandem and CERN. They have also been implemented in<br />

TOHR, a high resolution instrument for nuclear biology<br />

research and recently in G0, an experiment in hadronic<br />

physics (TJNAF-USA).<br />

MUST<br />

Many experiments in nuclear physics use detectors<br />

sensitive to charged particles. Semi-conductor devices are<br />

very well suited for this purpose and allow for a precise<br />

measurement <strong>of</strong> energy, time and position. Position<br />

measurements are using matrix <strong>of</strong> silicon detectors with<br />

high channel counts. The first detector <strong>of</strong> this kind (MUST<br />

- 144 -<br />

MAR<br />

View <strong>of</strong> the ASIC MAR<br />

Another field rapidly developing in nuclear instrumentation<br />

is the digital pulse shape analysis <strong>of</strong> signals issued by

General & technical departments<br />

detectors <strong>of</strong> many kinds. These techniques can be used for<br />

the localization <strong>of</strong> an interaction within a crystal<br />

(Germanium) and for the mass over charge discrimination<br />

<strong>of</strong> the incoming particle (silicon or scintillators). Off the<br />

shelf fast flash ADCs can be used directly when the signals<br />

are reasonably slow. With faster signals, the analog to<br />

digital conversion cannot be performed directly. One way<br />

to overcome this difficulty is to sample and store the fast<br />

signal in a high speed analog memory (pipeline) and to<br />

“replay” the portion <strong>of</strong> interest at a lower rate, allowing for<br />

the use <strong>of</strong> a conventional flash ADC. The technique is<br />

called FISO (Fast In - Slow Out). Although such methods<br />

are now well known, no component is available on the<br />

market place. The technique is clearly relevant for the<br />

AZ4π R&D program and the design <strong>of</strong> such an analog<br />

pipeline was decided.<br />

The recording device is composed <strong>of</strong> a matrix <strong>of</strong> 1240<br />

analog storage cells. Each cell is written in turn, with a time<br />

interval <strong>of</strong> 0.5 ns. The matrix is handled as a ring buffer,<br />

i.e. writing is performed continuously, overwriting the<br />

older cells, until the process is stopped by a trigger signal.<br />

The content is then frozen and the stored voltages can be<br />

read out through a read bus.<br />

successfully tested. 25 units have been packaged and will<br />

been used to build up a first set <strong>of</strong> prototype boards for the<br />

actual detector. However, a few flaws have been detected<br />

and corrections will be performed. A new prototype will be<br />

submitted to the founder at the beginning <strong>of</strong> 2006<br />

The fast amplifier<br />

Several building blocks had to be especially designed for<br />

this application:<br />

- The storage cell itself, composed <strong>of</strong> a capacitor<br />

associated to very accurate switching devices<br />

- The delay-locked-loop, an element delivering the 0.5<br />

ns time interval<br />

- The read and write amplifiers, with a bandwidth as<br />

large as 350 MHz and high slew rate<br />

- The logic <strong>of</strong> the whole system.<br />

The building blocks were designed in such a way that they<br />

can be reused later, even for a different application.<br />

Furthermore, two <strong>of</strong> them were made available to the entire<br />

<strong>IN2P3</strong> community through the special “club 035” structure<br />

started in 2004.<br />

The amplifier test chip<br />

Perspectives<br />

The delay-locked-loop<br />

The blocks were first manufactured as single elements in<br />

special test chips and tested. The entire design has then<br />

been assembled and the complete chip manufactured<br />

beginning <strong>of</strong> 2005. The circuit was functional and has been<br />

The <strong>Department</strong> <strong>of</strong> <strong>Electronics</strong> has now built up a valuable<br />

experience in ASIC design. Skilled engineers doted with<br />

powerful CAD tools are available within the Institute.<br />

Numerous physics project can and will use these techniques<br />

in the future. They will benefits in both the increase <strong>of</strong> the<br />

performance level (precision, energy and timing<br />

resolutions) and the complexity level : complex signal<br />

processing over millions <strong>of</strong> channels.<br />

- 145 -

General & technical departments<br />

MAR :: An asic fforr tthe ffastt digittal<br />

lizatti<br />

ion <strong>of</strong>f currrrentt signals<br />

<strong>IPN</strong>O Participation : J.-C. Cuzon, S. Drouet, P. Edelbrück, L. Leterrier, E. Wanlin<br />

MAR : un asic pour la numérisation rapide des signaux de courant<br />

Développé il a 4 ans, le préamplificateur à grande vitesse PACI <strong>of</strong>fre une image précise du processus de collection<br />

de charge d'un détecteur de silicium. Ce signal peut être employé pour la discrimination en Masse/Energie dans ce<br />

type détecteur, en utilisant des techniques de filtrages numériques. Comme aucun composant du commerce ne<br />

s’adapte à nos contraintes, nous avons décidé de concevoir un circuit intégré (asic) d’une mémoire analogique<br />

(MAR) qui échantillonne le signal à très grande vitesse (jusqu'à 2 GSPS) avec la possibilité d’être lue à une vitesse<br />

inférieure (50 MSPS) en employant un ADC du commerce. La pr<strong>of</strong>ondeur de stockage de cette mémoire est<br />

d’environ 1240 échantillons, avec une vitesse d'écriture réglable (de 100MSPS jusqu’à 2GSPS). Après l’étape de la<br />

conception et du dessin physique, le layout a été envoyé chez le fondeur (AMS) en décembre 2004 et nous avons<br />

reçu 25 puces encapsulées en mars 2005. Actuellement nous sommes en train de tester les performances et<br />

fonctionnalités de cet asic MAR dans le but de réaliser une carte d’acquisition rapide.<br />

Introduction<br />

Four years ago, the <strong>Electronics</strong> group developed a new<br />

version <strong>of</strong> charge preamplifier called PACI having an<br />

additional output <strong>of</strong> which the signal is a faithful<br />

representation <strong>of</strong> the current pulse. The knowledge <strong>of</strong> the<br />

shape <strong>of</strong> this pulse makes possible to obtain additional<br />

information (A, Z...) in order to improve discrimination.<br />

Accordingly, the electronics group is designing and<br />

realizing a fast acquisition system allowing to digitalize the<br />

output current signal <strong>of</strong> a preamplifier PACI. These current<br />

signals have the following time characteristics: minimum<br />

rise time <strong>of</strong> 2-3ns, duration <strong>of</strong> the impulse <strong>of</strong> few 10ns to<br />

100ns.<br />

Considering the minimum rise time, the digitalization<br />

system must be very fast, more than 1GSPS (giga samples<br />

per second). Knowing that the very fast converters (><br />

1GSPS) available in the market do not correspond to our<br />

application (too high dissipation, high price, 8 bits <strong>of</strong><br />

resolution), the SEP decided to develop a ASIC which<br />

memorize the current signal at 2GSPS in an analog way.<br />

on one <strong>of</strong> the DLL, this one is lower than 10ps rms. The<br />

average value <strong>of</strong> one delay is 502ps.<br />

When the analog levels <strong>of</strong> input current signal are<br />

memorized in the asic, all the samples are sent to an analogto-digital<br />

converter with a sampling frequency <strong>of</strong> 50MSPS<br />

and with 12bits resolution. The digitized samples are then<br />

processed by a FPGA realizing a digital processing <strong>of</strong> the<br />

data.<br />

The diagram below represents the test bench which permits<br />

to characterize the MAR asic.<br />

Presentation <strong>of</strong> the asic MAR<br />

This ASIC called MAR (Fast Analog Memory = Mémoire<br />

Analogique Rapide) is based on an analog pipeline structure<br />

storing the samples in an analog circular buffer. The aim <strong>of</strong><br />

this memory is to memorize in an analog way the current<br />

signal coming from the detector via the PACI preamplifier.<br />

This analog signal is sampled at 500ps (2GSPS) by the<br />

1239 memorizing cells made <strong>of</strong> capacitors and MOS<br />

switches. Thus, this memory can store a 619.5ns signal<br />

when the time base is 500ps.<br />

In the asic, the 1239 cells are placed in matrix form : 59<br />

lines by 21 columns. Thus, each line contains 21 memory<br />

cells. This dimension was not taken randomly : thanks to<br />

this one, the asic can sample the signal with various time<br />

Fig. 2 : Photo <strong>of</strong> the test bench with the asic MAR<br />

bases without having time distortion. The following time<br />

bases are available : 500ps, 1ns, 2ns, 5ns and 10ns.<br />

Features <strong>of</strong> the asic MAR<br />

It is important to note that each line is made up <strong>of</strong> 21 • Built in 0.35µm CMOS technology by AMS<br />

memory cells and a DLL (Delay Locked Loop). These 59 • Area : 23mm²<br />

DLLs give all the precision <strong>of</strong> the moment <strong>of</strong> sampling. On • Supply voltage : 3.3V ; Power : 800mW<br />

the first version <strong>of</strong> the asic, jitter measurements were made • Input span : 2Vpp<br />

- 146 -<br />

C DET<br />

C F<br />

PACI<br />

Sortie<br />

courant<br />

Sortie<br />

énergie<br />

Trig<br />

Mémoire<br />

Analogique<br />

Rapide<br />

ASIC "MAR"<br />

Convertisseur<br />

Analogique-Numérique<br />

50MHz / 12bits<br />

Contrôleur<br />

d'Acquisition<br />

Mémorisation<br />

Données<br />

Gestion USB<br />

Carte d'acquisition commandée par un module USB<br />

USB<br />

Traitement<br />

Données<br />

Visualisation<br />

Fig. 1 : Functional diagram <strong>of</strong> the test bench <strong>of</strong> the asic<br />

PC

General & technical departments<br />

• Input bandwidth : 350MHz<br />

• Expected S/N ratio: 72dB<br />

• Programmable time bases (in GSPS) : 2, 1, 0.5,<br />

0.2, 0.1<br />

• 1239 memory cells (matrix <strong>of</strong> 21x59 cells)<br />

• Memory depth : from 619.5ns to 12.39µs (in<br />

function <strong>of</strong> the selected time base)<br />

• Read time (Sending <strong>of</strong> all the analog samples to<br />

the ADC) : 25µs<br />

Asic status<br />

All the analog part <strong>of</strong> this ASIC was designed, simulated,<br />

optimized and drawing by the SEP.<br />

All the digital part allowing the control <strong>of</strong> the analog<br />

pipeline was designed by the SEP and the layout (drawing)<br />

was made at Strasbourg thanks to the help <strong>of</strong> A. Himmi<br />

(Laboratory IReS/<strong>IN2P3</strong>).<br />

The first version <strong>of</strong> the asic was sent to the AMS foundry at<br />

the beginning <strong>of</strong> December 2004, and we received 25 chips<br />

in the middle <strong>of</strong> march 2005.<br />

The design and the realization <strong>of</strong> the asic test bench was<br />

performed in parallel with the foundry <strong>of</strong> the asic.<br />

For few weeks, the SEP has tested the asic (cf. Fig.2), and<br />

for a first prototype, good results appeared. Below, we can<br />

see some sampling results (made by MAR):<br />

Fig. 3 : Sinusoidal signal with a 20MHz frequency and an<br />

amplitude 800mVpp<br />

Some mistakes appeared during the test. Thus, some<br />

correction <strong>of</strong> the layout will be done, and a new version <strong>of</strong><br />

the asic will be sent to the AMS foundry in the first quarter<br />

<strong>of</strong> 2006. So, the new version will be tested in mid-2006.<br />

It is important to note that the first version <strong>of</strong> the asic<br />

MAR works and thus, we will use it in a demonstration<br />

board for AZ4π experiment despite its imperfections.<br />

Future objective<br />

The final goal is to realize a fast acquisition board :<br />

C DET<br />

C F<br />

PACI<br />

Current<br />

Output<br />

Charge<br />

Output<br />

Analog-to-Digital<br />

Converter<br />

Fast Analog<br />

Memory<br />

MAR<br />

AD9235<br />

Sampling Board<br />

Acquisition controller<br />

+<br />

Data storage<br />

+<br />

Communication controller<br />

FPGA and DSP<br />

Analog-to-Digital<br />

Converter<br />

AD9235<br />

Fig. 5: Acquisition board for AZ4π<br />

GBit Link to<br />

DAQ<br />

Trigger<br />

&<br />

Timing<br />

This board will meet the following characteristics :<br />

‣ Compactness (a few cm²) for the integration close to<br />

the detectors (a few thousands channels must be<br />

equipped).<br />

‣ low thermal dissipation.<br />

‣ Modularity.<br />

‣ One energy channel.<br />

‣ One channel for the process <strong>of</strong> the current signal<br />

(shape analysis).<br />

So, the first objective is to correct the layout for the second<br />

version <strong>of</strong> MAR (mid-2006).<br />

The second objective is to realize a fast acquisition system<br />

for the AZ4π R&D program, with the collaboration <strong>of</strong> LPC<br />

Caen and INFN Florence. This system will integrate, <strong>of</strong><br />

course, the asic "MAR", and will be able to do recognitions<br />

<strong>of</strong> the current signals coming from the preamplifier PACI.<br />

For the first version <strong>of</strong> this system, we will use the first<br />

version <strong>of</strong> the asic MAR. The first version <strong>of</strong> this board will<br />

be available in the beginning <strong>of</strong> 2006.<br />

Fig. 4 : Sinusoidal signal with a 100MHz frequency and an<br />

amplitude 650mVpp<br />

- 147 -

General & technical department<br />

The Frrontt End Electtrroni<br />

ics <strong>of</strong>f tthe AGATA dettecttorr<br />

<strong>IPN</strong>O Participation : P. Edelbruck, X. Grave, C. Huss, C. Oziol, S. Royer.<br />

Collaboration : CCLRC, CSNSM, INFN, IReS.<br />

L’électronique de Front-End du détecteur AGATA<br />

AGATA est un spectromètre gamma destiné aux expériences de physique des noyaux exotiques. Il comprend 180<br />

cristaux de germanium de gros volume fonctionnant à basse température. Chaque cristal est segmenté en 36<br />

sections dont les électrodes sont lues par des préamplificateurs à faible bruit embarqués. Ce détecteur apportera,<br />

par rapport à ses prédécesseurs une grande amélioration en efficacité (zones mortes réduites) et en résolution. Il<br />

bénéficiera, au niveau de son électronique de deux innovations techniques majeures : un traitement entièrement<br />

numérique des signaux, associé à une méthode de localisation des interactions basée sur l’analyse des impulsions<br />

de collection de charge. Chacune des 7000 voies d’électronique sera munie d’un convertisseur Analogique-<br />

Numérique à grande vitesse et grande résolution (Flash ADC) associé à une électronique d’acquisition fortement<br />

intégrée. C’est cette électronique qui est en cours de développement à l’<strong>IPN</strong>, en collaboration étroite avec le<br />

CSNSM voisin. Ce dernier fournira les cartes de traitement de premier niveau (1250 unités) et l’<strong>IPN</strong> l’infrastructure<br />

bâtie sur le nouveau standard de télécommunication ATCA (360 cartes portées par 30 châssis).<br />

AGATA is a gamma ray detector aimed to high resolution γ<br />

-ray spectroscopy with exotic beams. Despite its large size,<br />

it is designed to be “portable” and will be used in several<br />

nuclear physics facilities in Europe. The detector is made <strong>of</strong><br />

180 crystals <strong>of</strong> high purity germanium. Each crystal is<br />

segmented into 36 volumes, each <strong>of</strong> which bearing one<br />

electrode, also called segment, read by a high resolution<br />

preamplifier. The detector will provide significant<br />

improvements over its predecessors in terms <strong>of</strong> efficiency<br />

(reduced dead zones) and resolution. It will benefit from<br />

two major technical innovations: all signal processing will<br />

be entirely digital and new localisation algorithms will be<br />

performed on the charge signals, allowing for<br />

unprecedented spatial precision. To achieve these goals,<br />

each <strong>of</strong> the 7000 channels will be read out by a high speed<br />

analog to digital converter associated to a strongly<br />

integrated digital electronics. This electronics is currently<br />

being developed between <strong>IPN</strong> and the neighbour lab<br />

CSNSM. The later is providing the first level local level<br />

mezzanine boards (1250 units) while <strong>IPN</strong> is designing the<br />

infrastructure, based on the new ATCA telecom standard<br />

(360 boards located in 30 crates).<br />

Computing Architecture. This is a new hardware standard<br />

originally designed for telecommunication systems,<br />

featuring very high bandwidth (potentially hundreds <strong>of</strong><br />

Gbyte/s). One crate can accommodate up to 16 large<br />

boards, with a form factor well suited to carry the projected<br />

pre-processing modules. Communication between the<br />

chassis and the external world is performed by one or two<br />

switching boards locally connected to the carriers through<br />

high speed serial links located on the backplane. One single<br />

link <strong>of</strong>fers up to 10 Gbit/s <strong>of</strong> data rate. The actual<br />

communication protocol is not defined by the standard and<br />

remains open for a future choice. The first demonstrator<br />

will use the well known Gigabit Ethernet standard while the<br />

final version will use PCI-express or Infiniband <strong>of</strong>fering<br />

even more bandwidth.<br />

14U<br />

1,5U<br />

8U<br />

3 X 2 Carriers =<br />

1 cluster<br />

15<br />

13<br />

11 9 7 5 3<br />

1<br />

2<br />

3 X 2 Carriers =<br />

1 cluster<br />

4<br />

6 8 10 12 14 16<br />

SWITCH<br />

GbE<br />

ou<br />

PCIexpress<br />

CPU<br />

(option)<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16<br />

The 36 fold segmented germanium crystal<br />

The ATCA standard<br />

The AGATA throughput is currently estimated to 380<br />

Mbyte/s per crystal i.e. 2.2 Gbyte/s for the 6 crystal filling<br />

in one crate. A breakthrough was really required to cope<br />

with such a data rate. The solution was found with ATCA.<br />

The acronym stands for Advanced Telecommunications<br />

- 148 -<br />

4,5U<br />

23’’<br />

One chassis bearing the electronics <strong>of</strong> 6 crystals<br />

System architecture<br />

The signals issued by the crystals are first digitized in the<br />

vicinity <strong>of</strong> the detectors by an ensemble <strong>of</strong> ADC (14 bit -<br />

100 Msample/s) developed by IReS in Strasbourg. The high<br />

speed digital stream is transported to the local level

General & technical department<br />

processing electronics through optical fibres at the rate <strong>of</strong> 2<br />

Gbit/s. One set <strong>of</strong> fibres is handling 6 electrodes, 6 sets<br />

being required for one crystal, plus one for the central<br />

contact. Each fibre feeds one mezzanine card where the<br />

digital stream is rebuilt for processing using high speed<br />

deserializers (SERDES). Field Programmable Gate Arrays<br />

(FPGA) perform in real time the calculation <strong>of</strong> the energy<br />

<strong>of</strong> physical events (digital shaping) and the recording <strong>of</strong> the<br />

signal shape, just like a digital oscilloscope. Another type<br />

<strong>of</strong> mezzanine board (Global Trigger System) designed in<br />

Padova (INFN) provides an accurate clock to the whole<br />

system. It also delivers the “date” <strong>of</strong> all physical events<br />

with a resolution <strong>of</strong> 10 ns (Time Stamping).<br />

1 crystal<br />

6 Segments<br />

Digitiser<br />

6 Segments<br />

Digitiser<br />

Core<br />

Digitiser<br />

6 Segments<br />

Digitiser<br />

6 Segments<br />

Digitiser<br />

6 Segments<br />

Digitiser<br />

6 Segments<br />

Digitiser<br />

Central<br />

trigger<br />

GTS<br />

CORE<br />

SEG<br />

SEG<br />

SEG<br />

SEG<br />

SEG<br />

SEG<br />

ATCA<br />

DAC<br />

ATCA<br />

DAC<br />

Master<br />

Slave<br />

The electronics <strong>of</strong> one crystal<br />

Slow<br />

control<br />

PSA<br />

Or PrePSA<br />

Power<br />

management<br />

The pre-processing boards<br />

The pre-processing boards are built around state <strong>of</strong> the art<br />

FPGA <strong>of</strong> the Virtex-II pro family. Two chips are required<br />

for six channels. Each chip bears the deserialsers, one<br />

power-PC processor and several millions <strong>of</strong> programmable<br />

logic gates performing all the digital processing in real<br />

time. The boards communicate with the central control<br />

system through Ethernet links taken over from the carrier<br />

boards.<br />

Data acquisition<br />

Clock<br />

TCLK port<br />

Slow control<br />

OSC LOC<br />

CY<br />

2DP3120<br />

The carrier boards<br />

JTAG connect.<br />

JTAG<br />

JTAG<br />

SWITCH<br />

AS91L1006<br />

FPGA<br />

TCLK OSC LOC<br />

RevMII<br />

JTAG<br />

32 bits 100Mhz<br />

CPU TRACE<br />

LSA connect.<br />

JTAG<br />

FIFO<br />

CPU serial<br />

EEPROM<br />

Config CPU<br />

Switch<br />

10/100<br />

ZL50407<br />

DATA<br />

FIFO Acquisition<br />

FPGA<br />

FIFO Carrier<br />

XC2VP40/50<br />

FIFO<br />

JTAG<br />

CTRL<br />

AS91L1001<br />

The carrier board<br />

32 bits<br />

CPU<br />

SRAM<br />

256Ko<br />

OSC LOC<br />

RevMII<br />

32 bits<br />

100ME Base<br />

PHY Fabric<br />

MII<br />

C<br />

P<br />

U<br />

MOBILE<br />

SDRAM<br />

128Mo<br />

Micron<br />

selectMap<br />

EEPROM<br />

Config<br />

JTAG DAFC<br />

TCLK PORT<br />

HUB1<br />

HUB2<br />

PCI Express<br />

ou GbE<br />

I2C thermal<br />

And power<br />

control<br />

POWER<br />

3.3V 2.5V<br />

1,2V 1.5V 1.8V<br />

The role <strong>of</strong> the carrier boards is to provide an infrastructure<br />

to the processing mezzanine cards. Each detector will<br />

necessitate two carriers holding six segment mezzanines,<br />

one central contact mezzanine and one GTS card. The first<br />

facility <strong>of</strong>fered by the carrier is <strong>of</strong> a mechanical nature. One<br />

carrier card will house four mezzanines built in the<br />

standard PMC form factor. The connexions to the detectors,<br />

to the ADC system and to the central trigger will be<br />

performed through the front panel with optic fibre<br />

connectors. The carrier board will also generate the<br />

voltages required by the various components. Up to 200 W<br />

<strong>of</strong> power will be converted into 6 different low voltages<br />

from the unique 48 V source provided by the ATCA<br />

backplane.<br />

Two large FPGA will handle the data acquisition process<br />

itself. Synchronisation signals will be received from the<br />

GTS board and distributed to all mezzanines. Trigger<br />

requests will be gathered from the central contact and sent<br />

to GTS. Trigger commands will then be dispatched to all<br />

cards. When the reading process is completed on each<br />

mezzanine (energy calculation, signal storage etc.) the<br />

carrier board will collect the data from all modules, build<br />

the event package and send it to the central DAQ through<br />

the backplane and the switch boards.<br />

Last but not least, the carrier will handle all the “slow<br />

control” issues, ranging from basic house keeping like<br />

power and temperature management, s<strong>of</strong>tware download, to<br />

physics parameter handling and online calibration<br />

procedures. As the total number <strong>of</strong> FPGA in the system<br />

will be very high (several thousands), all possible<br />

maintenance operation like updating the hardware codes<br />

(VHDL) will be feasible from the remote central control<br />

system without any manual intervention on the boards. All<br />

slow control communication will be performed through<br />

standard Ethernet links using the TCP/IP protocol, making<br />

remote control versatile and portable.<br />

Pulse shape analysis<br />

The 30 ATCA chassis will communicate with a large<br />

processor farm which will perform the in-line analysis <strong>of</strong><br />

all the channels in order to extract two important data :<br />

- The geometrical location <strong>of</strong> the interaction within the<br />

crystal. This information will permit a precise<br />

correction <strong>of</strong> the Doppler Effect affecting the energy<br />

measurement, leading to a resolution improvement <strong>of</strong><br />

an order <strong>of</strong> magnitude over existing detectors.<br />

- In the case <strong>of</strong> a Compton cascade, determine the<br />

position <strong>of</strong> each photon belonging to the event and<br />

calculate the total energy as well as the angle <strong>of</strong> the<br />

original photon.<br />

The next future<br />

Building and testing the electronics will take three steps :<br />

one single detector will be equipped and tested mid 2006 in<br />

Orsay. A demonstrator made <strong>of</strong> a large set <strong>of</strong> 15 detectors<br />

will then be constructed and used for real physics<br />

experiments in 2007. The complete detector with 180<br />

crystals will be ready by 2010.<br />

- 149 -

General & technical departments<br />

Electtrroni<br />

ics fforr MUST2 ((MUrr à Sttrri ip))<br />

<strong>IPN</strong>O Participation : J.-P. Baronick, D. Beaumel, P. Edelbruck, G. Guerin, P. Guilland, D. Lalande, L.<br />

Lavergne, L. Leterrier, V. Le Ven, A. Mongaillard, D. Rougier, S. Royer, S. Tanguy, M. Vilmay, E. Wanlin<br />

Collaboration : GANIL, CEA/DAPNIA.<br />

MUST2 est un télescope ∆E-E de seconde génération constitué d’un détecteur Si à 256 pistes double face suivi de<br />

deux détecteurs Si(Li) segmentés en 8 secteurs et de seize cristaux de CsI. Les détecteurs, l’électronique front end<br />

et la mécanique ont été pris en charge par le service détecteurs de la DR, le SEP et le SRM. L’électronique front<br />

end est réalisée autour d’un composant intégré full custom (MATE3), conçu en collaboration avec le CEA/DAPNIA.<br />

Pour l’électronique d’acquisition, elle a été conçue par le GANIL en standard VXI taille C. Actuellement, la<br />

production d’un ensemble de quatre télescopes est lancée et sera achevée en janvier 2006. Le reste de la<br />

production sera réalisé courant 2006. Les premières résolutions en énergies obtenues avec le détecteur Si à strips<br />

sont de l’ordre de 40keV avec une source alpha 3 pics et de 30keV au générateur d’impulsion.<br />

MUST II is a charged particle detector <strong>of</strong> second generation<br />

developed in collaboration with GANIL, CEA/DAPNIA<br />

and <strong>IPN</strong>. Each telescope (Fig 1) consists <strong>of</strong> a double-sided<br />

Silicon strips (Si strips) detector, followed by two Silicon<br />

Lithium (Si(Li)) detectors and sixteen Caesium Iodide (CsI)<br />

scintillators with photodiode read-out. The Si strips detector<br />

has128 strips on each side and the expected energy and time<br />

resolution are 50keV and 250ps for 5.48MeV alpha. Each<br />

Si(Li) detector is divided into 8 segments with the 120keV<br />

desired energy resolution. For the CsI, the requested energy<br />

resolution is 5% for 5.48MeV alpha.<br />

All mechanics has been designed by SRM. In particular,<br />

this mechanics is composed <strong>of</strong> the cooling system allowing<br />

to drain the heat <strong>of</strong> electronic devices <strong>of</strong> outside the vacuum<br />

chamber in order to hold a constant low temperature.<br />

Si (Li)<br />

Si (Strips)<br />

CsI<br />

Kapton<br />

Front end electronics<br />

The front end electronics, realized by SEP, is located close<br />

to the rear <strong>of</strong> each telescope and consists <strong>of</strong> two electronic<br />

boards called MUFEEX3 (MUst Front End <strong>Electronics</strong>) and<br />

MUFEEY3. The links between Si strips detectors and<br />

electronic boards are made via Kapton flexible circuits.<br />

Above, the top and bottom views <strong>of</strong> the MUFEEX3 board<br />

processing 128 signals from the junction side <strong>of</strong> Si strips<br />

detector, as well as the 16 channels <strong>of</strong> the Si(Li) detectors.<br />

MUFEEX3 and MUFEEY3 boards are nearly the same.<br />

Apart from MUFEEY3 which processes 128 signals from<br />

the ohmic side <strong>of</strong> Si strips detector and 16 channels from<br />

photodiodes.<br />

Each MUFEE bears 9 MATE3 ASICs (Application Specific<br />

Integrated Circuits), each processing 16 channels in energy<br />

and time. These energy and time information are carried on<br />

2 analogue lines per board, read in current differential mode<br />

through twisted pair to the external VXI crate. The MATE3<br />

are connected in daisy chain and read one after the other.<br />

The readout time for 544 information is 80µs.<br />

In order to have a good immunity against the<br />

electromagnetic perturbations, all readout signals are<br />

transmitted in LVDS (Low Voltage Differential Signal).<br />

The slow control, assured via the I²C industrial protocol,<br />

allows in particular the configuration <strong>of</strong> the ASICs, the<br />

temperature monitoring, the test signal injection, the<br />

multiplexing <strong>of</strong> inspection channels, the board<br />

identification and the memorization <strong>of</strong> experiment<br />

parameters.<br />

On each MUFEE, one pulse generator drive each analogue<br />

test input <strong>of</strong> each MATE3, which allows to check the good<br />

functionality <strong>of</strong> all ASICs and to calibrate electronics<br />

channel.<br />

MATE3 (Must Asic for Time and Energy)<br />

It has been realized in collaboration with the CEA/DAPNIA<br />

from Saclay : SEP has developed the charge sensitive<br />

preamplifier, the energy channel and the logic I2C<br />

interface; CEA has taken responsibility for the timing<br />

energy and other blocks explained later and for the final<br />

assembly. The ASIC technology is the 0.8μm BICMOS<br />

from AMS. MATE3 has 16 channels and delivers three<br />

types <strong>of</strong> analogue information for each channel: time <strong>of</strong><br />

flight and energy loss <strong>of</strong> the detected particle and value <strong>of</strong><br />

DC leakage current. MATE3 also gives a trigger logic<br />

signal corresponding to the cross over <strong>of</strong> an adjustable<br />

threshold. The slow control <strong>of</strong> the ASIC is assured via the<br />

I2C industrial protocol.<br />

- 150 -

General & technical departments<br />

Architecture<br />

The block diagram <strong>of</strong> one MATE channel is shown<br />

hereafter:<br />

ini<br />

idf<br />

idf<br />

ininj<br />

cf1<br />

Idf<br />

CSA<br />

cf0<br />

¼Cf<br />

Rf<br />

selFiltre<br />

1us/3us<br />

Filtre & Ampli<br />

Filtre &<br />

Ampli<br />

hold<br />

Track&Hold<br />

TEMPS<br />

+ discri - TAC<br />

resetCSA seuils<br />

requêtei stop<br />

DAC 8 bits<br />

Requete j<br />

Canali<br />

REQUÊTE<br />

VIC<br />

DATA<br />

One channel consists in three main blocks : A charge<br />

sensitive preamplifier, the energy block, and the time and<br />

decision block.<br />

MATE3 must be able to accept current signals coming not<br />

only from both sides <strong>of</strong> the Si strip detector, but also from<br />

SiLi and CsI detectors. This means that each channel can<br />

process both signal polarities, from the charge sensitive<br />

preamplifier to the energy and time blocks. Furthermore,<br />

the charge sensitive preamplifier gain and the filter peaking<br />

time are programmable to suit various kind <strong>of</strong> detectors and<br />

particles.<br />

Charge sensitive preamplifier<br />

The architecture is a single ended folded cascade amplifier,<br />

bipolar, using MOS and bipolar transistors. The input<br />

transistor is a wide PMOS <strong>of</strong> 8500μm/1.2μm<br />

(gm=28.4mS). The rise time <strong>of</strong> the preamplifier is 10ns.<br />

A set <strong>of</strong> four integration capacitors programmable via two<br />

slow control bits is used to match the desired gain<br />

according to the selected detector.<br />

The maximum energies to be accepted by the charge<br />

sensitive preamplifier and energy block are +/-45MeV,<br />

225MeV and 200MeV for the Si strips, SiLi and CsI<br />

detectors respectively.<br />

Energy channel<br />

This block is composed <strong>of</strong> a shaper and a track and hold.<br />

The shaper consists <strong>of</strong> a CR-RC filter, with respectively 1<br />

and 3μs <strong>of</strong> peaking time, selectable by slow control, for the<br />

Si strips and SiLi/CsI detectors.<br />

Then, the amplitude <strong>of</strong> the signal is memorized via a track<br />

and hold stage on the rise time <strong>of</strong> the HOLD signal coming<br />

from MUVI. In read out mode, this memorized signal is<br />

sent to a Voltage to Current Converter (VIC) whose transfer<br />

gain is +/-2mA/V.<br />

Timing and decision channel<br />

This channel has two main objectives : determine quickly<br />

whether the channel has triggered or not and measure the<br />

time <strong>of</strong> flight <strong>of</strong> the particle.<br />

The first section is a fast CR 2 -RC filter with a peaking time<br />

<strong>of</strong> 22ns; it has a differential structure, thus providing<br />

immunity against parasitic coupling and reducing jitter to<br />

achieve a good time resolution. The differential outputs <strong>of</strong><br />

this shaper, then, pass through a leading edge discriminator,<br />

OU<br />

x16<br />

ENERGIE<br />

COURANT<br />

in which the threshold voltage is set by an internal 8 bits<br />

programmable DAC.<br />

The discriminator output gives the start signal to the time to<br />

amplitude converter (TAC) as well as the « REQUETE »<br />

signal which is ‘or wired’ with the other fifteen channels <strong>of</strong><br />

MATE3. The intrinsic time resolution <strong>of</strong> the TAC is 18ps<br />

FWHM. The TAC is stopped by an external signal “STOP”<br />

coming from MUVI.<br />

In read out mode, the time information is sent to a Voltage<br />

to Current Converter.<br />

The TAC has two programmable time ranges: 0ns/300ns<br />

and 0ns/600ns.<br />

Power consumption, layout and package<br />

The power consumption <strong>of</strong> the chip is 447mW. The layout<br />

is shown hereafter; the area is 41mm2<br />

(6.438*6mm.368mm). MATE is packaged in a ceramic 64<br />

pins TQFP64L.<br />

Inpac1<br />

Inpac16<br />

Complete telescope system<br />

The GANIL developed a VXI-C standard board, called<br />

MUVI (MUst in VXI), assuring the slow control, data<br />

coding, digital processing and data memorization for four<br />

telescopes. The management <strong>of</strong> trigger signals is performed<br />

by the GMT module.<br />

The communication between MUFEE and MUVI boards is<br />

carried in the eight meters transmission line.<br />

The ensemble <strong>of</strong> front end electronics is supplied by several<br />

CAEN power supply modules located in SY1527 system.<br />

Châssis VXI<br />

MUVI (VXI taille C)<br />

Mémorisation<br />

&<br />

Traitement<br />

&<br />

contrôle<br />

host<br />

Interface VXI<br />

Mise en forme<br />

4 bus analog<br />

& codage<br />

Signaux cont<br />

Slow control<br />

Bus I2C<br />

Trigger local<br />

Trigger externe<br />

GMT<br />

1 bus analog<br />

bus I2C 1 bus analog<br />

signaux cont.<br />

1 MATE2<br />

8 MATE2<br />

MUFEE Y<br />

INTERCSI<br />

128 strips en Y<br />

16 pads<br />

128 strips en X<br />

8 MATE2 1 MATE2<br />

1 bus analog<br />

signaux cont. bus I2C 1 bus analog<br />

Détecteur Si strips<br />

Détecteur Si(Li)<br />

16 pads<br />

Détecteur CsI<br />

MUFEE X<br />

- 151 -