DISPERBYK-2155 100% High Solids Wetting and Dispersing Additive

DISPERBYK-2155 100% High Solids Wetting and Dispersing Additive

DISPERBYK-2155 100% High Solids Wetting and Dispersing Additive

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fact Sheet L-XS 23<br />

<strong>DISPERBYK</strong>-<strong>2155</strong><br />

<strong>100%</strong> <strong>High</strong> <strong>Solids</strong> <strong>Wetting</strong> <strong>and</strong> <strong>Dispersing</strong> <strong>Additive</strong><br />

Environmental concerns lead to<br />

modified coating formulations,<br />

<strong>and</strong> in the recent past there is a<br />

growing dem<strong>and</strong> for high solids<br />

systems. This technology calls for<br />

additives with high solids content.<br />

Often, these additives suffer from<br />

poor flowability, in particular if they<br />

have a higher molecular weight.<br />

Bringing the opposites in line,<br />

BYK developed a high molecular,<br />

<strong>100%</strong> solids additive that provides<br />

outst<strong>and</strong>ing deflocculation <strong>and</strong><br />

stabilization but avoids the usual<br />

drawbacks. <strong>DISPERBYK</strong>-<strong>2155</strong> is<br />

entirely flowable, storage stable <strong>and</strong><br />

covers a wide compatibility range.<br />

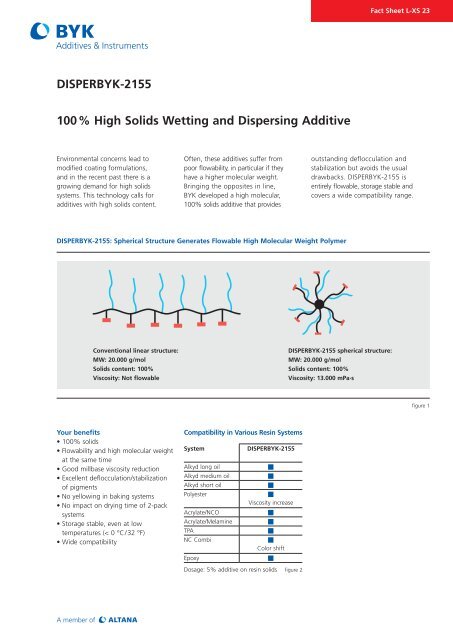

<strong>DISPERBYK</strong>-<strong>2155</strong>: Spherical Structure Generates Flowable <strong>High</strong> Molecular Weight Polymer<br />

Conventional linear structure:<br />

MW: 20.000 g/mol<br />

<strong>Solids</strong> content: <strong>100%</strong><br />

Viscosity: Not flowable<br />

<strong>DISPERBYK</strong>-<strong>2155</strong> spherical structure:<br />

MW: 20.000 g/mol<br />

<strong>Solids</strong> content: <strong>100%</strong><br />

Viscosity: 13.000 mPa·s<br />

figure 1<br />

Your benefits<br />

• <strong>100%</strong> solids<br />

• Flowability <strong>and</strong> high molecular weight<br />

at the same time<br />

• Good millbase viscosity reduction<br />

• Excellent deflocculation/stabilization<br />

of pigments<br />

• No yellowing in baking systems<br />

• No impact on drying time of 2-pack<br />

systems<br />

• Storage stable, even at low<br />

temperatures (< 0 °C/32 °F)<br />

• Wide compatibility<br />

Compatibility in Various Resin Systems<br />

System<br />

Alkyd long oil<br />

Alkyd medium oil<br />

Alkyd short oil<br />

Polyester<br />

Acrylate/NCO<br />

Acrylate/Melamine<br />

TPA<br />

NC Combi<br />

Epoxy<br />

<strong>DISPERBYK</strong>-<strong>2155</strong><br />

X<br />

X<br />

X<br />

X<br />

Viscosity increase<br />

X<br />

X<br />

X<br />

X<br />

Color shift<br />

Dosage: 5% additive on resin solids figure 2<br />

X

Fact Sheet L-XS 23<br />

<strong>High</strong> Transparency in Coatings<br />

Pigments: Heliogen Green* L 8730; Heliogen Blue* L 6975 figure 3<br />

<strong>Additive</strong> dosage: 25% on solid pigment<br />

Excellent Viscosity Reduction<br />

Viscosity [Pa·s]<br />

150<br />

100<br />

50<br />

0<br />

0.1 1<br />

10 100<br />

Pigment: Heliogen Green* L 9361 PG 36<br />

Shear rate [s -1 ]<br />

X St<strong>and</strong>ard <strong>Additive</strong> X <strong>DISPERBYK</strong>-<strong>2155</strong> figure 4<br />

*Heliogen is a registered trademark of BASF<br />

BYK-Chemie GmbH<br />

P.O. Box 10 02 45<br />

46462 Wesel<br />

Germany<br />

Tel +49 281 670-0<br />

Fax +49 281 65735<br />

info@byk.com<br />

www.byk.com/additives<br />

ANTI-TERRA ® , BYK ® , BYK ® -DYNWET ® , BYK ® -SILCLEAN ® , BYKANOL ® , BYKETOL ® , BYKOPLAST ® , BYKUMEN ® , <strong>DISPERBYK</strong> ® ,<br />

DISPERPLAST ® , LACTIMON ® , NANOBYK ® , SILBYK ® , <strong>and</strong> VISCOBYK ® are registered trademarks of BYK-Chemie.<br />

AQUACER ® , AQUAFLOUR ® , AQUAMAT ® , CERACOL ® , CERAFAK ® , CERAFLOUR ® , CERAMAT ® , CERATIX ® , <strong>and</strong> MINERPOL ®<br />

are registered trademarks of BYK-Cera.<br />

This information is given to the best of our knowledge. Because of the multitude of formulations, production, <strong>and</strong> application<br />

conditions, all the above-mentioned statements have to be adjusted to the circumstances of the processor. No liabilities,<br />

including those for patent rights, can be derived from this fact for individual cases.<br />

This brochure replaces all previous issues – printed in Germany.<br />

07/2008