Please note - Swinburne University of Technology

Please note - Swinburne University of Technology Please note - Swinburne University of Technology

Heat transfer. One dimensional steady state conduction in series. Thick wall cylinders. Convection. Radiation. Heat exchangers. Refrigeration. Vapour compressing cycle. Coefficient of performance. Machine dynamics. Cyclics speed and energy fluctuations in rotating machinery. Flywheels. Crank effort diagrams. Friction clutches. Single and multiplate types. Torque transmitted, Belt drives. Flat and vee sections. Centrifugal tension. Maximum power transmitted. lntroduction to mechanical engineering: design competition. References Hannah, J. and Stephens, R.C. Mechanics of Machines: Elementary Theory and Examples. 4th edn, London, Edward Arnold, 1984 Rayner, J. Basic Engineering Thermodynamics on 51 Units. 3rd edn, London, Longman, 1971 Rogers, G.F.C. and Mayhew, Y.R. Thermodynamic and Transport Properties of Fluids. 4th edn, Oxford, Blackwell, 1988 Recommended Kinsky, R. Heat Engineering: An Introduction to Thermodynamics. 3rd edn. Sydney, McGraw-Hill, 1989 MMI 22 Chemistry and Materials Subject aims To introduce all engineering students to the concepts in chemistry and materials technology and their application in the processing of engineering materials. Subject description This subject uses basic concepts in chemistry and materials technoloqv in order to understand the behaviour and properti&of materials. Students are introduced to a range of .manufacturing methods used in the processing of materials. In particular the chemistry topics relate to both energy systems and materials. Material presented in this subject has been chosen largely on the basis of maximising the educational benefit to all students regardless of the course pursued in later years. Syllabus Introduction: elements and compounds. Periodic table. Chemical bonding states of matter. Thermodynamics: first law. Forms of energy. Internal energy, enthalpy. Hess's law. Direction of chemical reactions. Chemical equilibria. Chemical kinetics. Stoichiometry. Electrochemistry: oxidation and reduction. Oxidation numbers. Redox reactions. Electrode potentials and galvanic cells. The Nernst equation. Equilibrium constants from cell potentials. Practical galvanic cells. Corrosion and protection methods. Organic chemistry: addition and condensation polymers. Fuels. Aliphatic and aromatic organic compounds. Structure of materials includinq atomic packing and density. Material deformation, strengt6ening mechanisms. Phase equilibria and phase diagrams. Engineering alloys. Materials processing in manufacturing: methods including casting, forming, cold working, hot working, recrystallisation: polymer processing including extrusion and injection, moulding of thermosets and thermoplastics. Finishing methods: machining, grinding and polishing. Specifications Measurement of hardness and strength of materials. Failure modes influence of environment. Textbooks Chemistry Towns, A.P. eta/. The Wheel Reinvented. 3rd edn, Hawthorn: S.I.T. Dept. of Applied Chemistry, 1989 Materials and Processes Callister, W. Materials Science and Engineering: an Introduction. 3rd edn, New York, Wiley, 1994 ~ ~ 1 2Engineering 3 Graphics and CAD No. of hours per week: two and a half hours for two semesters Instruction: lecutes and tutorials Assessment: examination (40%) and assessed work (30%) Subject aims The aim of the subject is to introduce students to the fundamentals of engineering drawing standards used for graphical communication, and to guide them in developing the required skills and abilities for presenting their design ideas either as sketches or finished drawings by using the drawing board or a CAD system. Furthermore, the subject aims at introducing the students to 3D spatial relationships and graphical methods for solving engineering problems. Subject description The topics covered during the year refer to orthographic projection, auxiliary projection, relationships of points and lines in three dimensional space, intersections of solid objects, development of surfaces, detail drawings, assembly drawings, civil engineering conventions, electrical and electronic engineering conventions, mechanical engineering conventions, graphical presentations and graphical solutions to engineering problems, and engineering drawing analysis. The subject is taught on both the drawing board and CAD system. Equal time is given to each method of drawing while an effort is made to coordinate the topic coverage in order to highlight their part~cular advantage. Each topic is covered by an introductory part followed by a hands-on exercise to reinforce the theory. Out of class assignments are also an integral part of this subject.

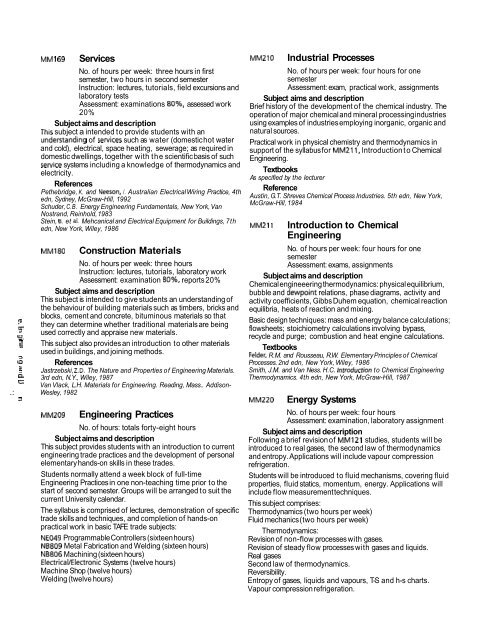

(0 MMI 69 Services ~M2lo Industrial Processes No. of hours per week: three hours in first semester, two hours in second semester Instruction: lectures, tutorials, field excursions and laboratory tests Assessment: examinations 80%, assessed work 20% Subject aims and description Thls subject a intended to provide students with an understanding of services such as water (domestic hot water and cold), electrical, space heating, sewerage; as required in domestic dwellings, together with the scientific basis of such service systems including a knowledge of thermodynamics and electricity. References Pethebridge, K. and Neeson, I. Australian Electrical Wiring Practice, 4th edn, Sydney, McGraw-Hill, 1992 Schuder, C.B. Energy Engineering Fundamentals, New York, Van Nostrand, Reinhold, 1983 Stein, 8, et ai. Mehcanical and Electrical Equipment for Buildings, 7th edn, New York, Wiley, 1986 ~ ~ 1 8Construction 0 Materials No. of hours per week: three hours Instruction: lectures, tutorials, laboratory work Assessment: examination 80%, reports 20% Subject aims and description This subject is intended to give students an understanding of the behaviour of building materials such as timbers, bricks and blocks, cement and concrete, bituminous materials so that they can determine whether traditional materials are being 2 used correctly and appraise new materials. L9. This subject also provides an introduction to other materials . - used in buildings, and joining methods. 2 10 w References Jastrzebski, Z.D. The Nature and Properties of Engineering Materials. 3rd edn, N.Y., Wiley, 1987 Van Vlack, L.H. Materials for Engineering. Reading, Mass.. Addison- :. Wesley, 1982 3 MMZO~ Engineering Practices No. of hours: totals forty-eight hours Subject aims and description This subject provides students with an introduction to current engineering trade practices and the development of personal elementary hands-on skills in these trades. Students normally attend a week block of full-time Engineering Practices in one non-teaching time prior to the start of second semester. Groups will be arranged to suit the current University calendar. The syllabus is comprised of lectures, demonstration of specific trade skills and techniques, and completion of hands-on practical work in basic TAFE trade subjects: NE049 Programmable Controllers (sixteen hours) NB809 Metal Fabrication and Welding (sixteen hours) NB806 Machining (sixteen hours) Electrical/Electronic Systems (twelve hours) Machine Shop (twelve hours) Welding (twelve hours) No. of hours per week: four hours for one semester Assessment: exam, practical work, assignments Subject aims and description Brief history of the development of the chemical industry. The operation of major chemical and mineral processing industries using examples of industries employing inorganic, organic and natural sources. Practical work in physical chemistry and thermodynamics in support of the syllabus for MM211, lntroduction to Chemical Engineering. Textbooks As specified by the lecturer Reference Austin, G.T. Shreves Chemical Process Industries. 5th edn, New York, McGraw-Hill, 1984 ~M21 I Introduction to Chemical Engineering No. of hours per week: four hours for one semester Assessment: exams, assignments Subject aims and description Chemical engineeering thermodynamics: physical equilibrium, bubble and dewpoint relations, phase diagrams, activity and activity coefficients, Gibbs Duhem equation, chemical reaction equilibria, heats of reaction and mixing. Basic design techniques: mass and energy balance calculations; flowsheets; stoichiometry calculations involving bypass, recycle and purge; combustion and heat engine calculations. Text books Felder, R.M. and Rousseau, R.W. Elementary Principles of Chemical Processes. 2nd edn, New York, Wiley, 1986 Smith, J.M. and Van Ness. H.C. lntroduction to Chemical Engineering Thermodynamics. 4th edn, New York, McGraw-Hill, 1987 ~ ~ 2 2Energy 0 Systems No. of hours per week: four hours Assessment: examination, laboratory assignment Subject aims and description Following a brief revision of MM121 studies, students will be introduced to real gases, the second law of thermodynamics and entropy. Applications will include vapour compression refrigeration. Students will be introduced to fluid mechanisms, covering fluid properties, fluid statics, momentum, energy. Applications will include flow measurement techniques. This subject comprises: Thermodynamics (two hours per week) Fluid mechanics (two hours per week) Thermodynamics: Revision of non-flow processes with gases. Revision of steady flow processes with gases and liquids. Real gases Second law of thermodynamics. Reversibility. Entropy of gases, liquids and vapours, T-S and h-s charts. Vapour compression refrigeration.

- Page 278 and 279: Bridge construction: steel, reinfor

- Page 280 and 281: Legal system in Australia, sources

- Page 282 and 283: ~ ~ 4 9 1 Biochemical Engineering N

- Page 284 and 285: ~~282 Communication Principles No.

- Page 286 and 287: ~~383 Electromagnetic Fields No. of

- Page 288 and 289: ~~403 Engineering Project Managemen

- Page 290 and 291: ~~475 Electrical Power and Machines

- Page 292 and 293: ~~502 Management Practice No. of ho

- Page 294 and 295: ~~563 Advanced Computer Techniques

- Page 296 and 297: ~~744 Design and Project No. of hou

- Page 298 and 299: EFI~O Engineering Physics No. of ho

- Page 300 and 301: GD220 Theory of Representation No.

- Page 302 and 303: IDIO~B Workshop Techniques 1A No. o

- Page 304 and 305: lo205 Design History 1B Prerequisit

- Page 306 and 307: support chosen solutions. This seme

- Page 308 and 309: 1~607 Design Research Skills No. of

- Page 310 and 311: ITIOS Behaviour and Communications

- Page 312 and 313: 1~401 Industry Based Learning 50 cr

- Page 314 and 315: Industry Based Learning 2 50 credit

- Page 316 and 317: 1~916 Programming the User Interfac

- Page 318 and 319: Resources for lnformation Systems D

- Page 320 and 321: Food processing. Freezing, storage

- Page 322 and 323: MFI~I Aircraft General Knowledge 1

- Page 324 and 325: ~ ~ 2 3 1 Aircraft General Knowledg

- Page 326 and 327: ~ ~ 3 4 0 Advanced Aerodynamics No.

- Page 330 and 331: Fluid Mechanics: Fundamental concep

- Page 332 and 333: Semester two aims to extend earlier

- Page 334 and 335: ~ ~ 3 2 Energy 0 Systems No, of hou

- Page 336 and 337: MM~~IC Control Engineering No. of h

- Page 338 and 339: ~ ~ 3 8 Managerial 1 Economics No,

- Page 340 and 341: M M ~ I Control Systems No. of hour

- Page 342 and 343: ~ ~ 4 8 Facilities 0 Planning and D

- Page 344 and 345: ~ ~ 5 Thermo/Fluid 2 0 ~ Mechanics

- Page 346 and 347: MM~~IA Engineering Ergonomics No. o

- Page 348 and 349: References Aris, R. Mathematical Mo

- Page 350 and 351: ~ ~ 6 0 Design 5 for Manufacture No

- Page 352 and 353: ~ ~ 6 1 Automation 4 and Machining

- Page 354 and 355: Structured programming in Turbo PAS

- Page 356 and 357: ~ ~ 6 3Machine 1 Systems No. of hou

- Page 358 and 359: R~sk control: concepts and definiti

- Page 360 and 361: MM~IO Risk Engineering Science No.

- Page 362 and 363: References Lane, N. Techniques for

- Page 364 and 365: ~ ~ 8 2Risk 6 Technology (Maintenan

- Page 366 and 367: ~ ~ 2 8 6 Building Materials 2 No.

- Page 368 and 369: ~ ~ 5 0 8 Industry Based Learning 5

- Page 370 and 371: Sterilisation methods: a wide range

- Page 372 and 373: Written assignments will form a maj

- Page 374 and 375: distillation, physical measurements

- Page 376 and 377: ~ ~ 7 1 6 Basic Colloid Science 7.5

(0<br />

MMI 69 Services ~M2lo Industrial Processes<br />

No. <strong>of</strong> hours per week: three hours in first<br />

semester, two hours in second semester<br />

Instruction: lectures, tutorials, field excursions and<br />

laboratory tests<br />

Assessment: examinations 80%, assessed work<br />

20%<br />

Subject aims and description<br />

Thls subject a intended to provide students with an<br />

understanding <strong>of</strong> services such as water (domestic hot water<br />

and cold), electrical, space heating, sewerage; as required in<br />

domestic dwellings, together with the scientific basis <strong>of</strong> such<br />

service systems including a knowledge <strong>of</strong> thermodynamics and<br />

electricity.<br />

References<br />

Pethebridge, K. and Neeson, I. Australian Electrical Wiring Practice, 4th<br />

edn, Sydney, McGraw-Hill, 1992<br />

Schuder, C.B. Energy Engineering Fundamentals, New York, Van<br />

Nostrand, Reinhold, 1983<br />

Stein, 8, et ai. Mehcanical and Electrical Equipment for Buildings, 7th<br />

edn, New York, Wiley, 1986<br />

~ ~ 1 8Construction 0<br />

Materials<br />

No. <strong>of</strong> hours per week: three hours<br />

Instruction: lectures, tutorials, laboratory work<br />

Assessment: examination 80%, reports 20%<br />

Subject aims and description<br />

This subject is intended to give students an understanding <strong>of</strong><br />

the behaviour <strong>of</strong> building materials such as timbers, bricks and<br />

blocks, cement and concrete, bituminous materials so that<br />

they can determine whether traditional materials are being<br />

2 used correctly and appraise new materials.<br />

L9.<br />

This subject also provides an introduction to other materials<br />

. - used in buildings, and joining methods.<br />

2<br />

10<br />

w<br />

References<br />

Jastrzebski, Z.D. The Nature and Properties <strong>of</strong> Engineering Materials.<br />

3rd edn, N.Y., Wiley, 1987<br />

Van Vlack, L.H. Materials for Engineering. Reading, Mass.. Addison-<br />

:. Wesley, 1982<br />

3<br />

MMZO~ Engineering Practices<br />

No. <strong>of</strong> hours: totals forty-eight hours<br />

Subject aims and description<br />

This subject provides students with an introduction to current<br />

engineering trade practices and the development <strong>of</strong> personal<br />

elementary hands-on skills in these trades.<br />

Students normally attend a week block <strong>of</strong> full-time<br />

Engineering Practices in one non-teaching time prior to the<br />

start <strong>of</strong> second semester. Groups will be arranged to suit the<br />

current <strong>University</strong> calendar.<br />

The syllabus is comprised <strong>of</strong> lectures, demonstration <strong>of</strong> specific<br />

trade skills and techniques, and completion <strong>of</strong> hands-on<br />

practical work in basic TAFE trade subjects:<br />

NE049 Programmable Controllers (sixteen hours)<br />

NB809 Metal Fabrication and Welding (sixteen hours)<br />

NB806 Machining (sixteen hours)<br />

Electrical/Electronic Systems (twelve hours)<br />

Machine Shop (twelve hours)<br />

Welding (twelve hours)<br />

No. <strong>of</strong> hours per week: four hours for one<br />

semester<br />

Assessment: exam, practical work, assignments<br />

Subject aims and description<br />

Brief history <strong>of</strong> the development <strong>of</strong> the chemical industry. The<br />

operation <strong>of</strong> major chemical and mineral processing industries<br />

using examples <strong>of</strong> industries employing inorganic, organic and<br />

natural sources.<br />

Practical work in physical chemistry and thermodynamics in<br />

support <strong>of</strong> the syllabus for MM211, lntroduction to Chemical<br />

Engineering.<br />

Textbooks<br />

As specified by the lecturer<br />

Reference<br />

Austin, G.T. Shreves Chemical Process Industries. 5th edn, New York,<br />

McGraw-Hill, 1984<br />

~M21 I<br />

Introduction to Chemical<br />

Engineering<br />

No. <strong>of</strong> hours per week: four hours for one<br />

semester<br />

Assessment: exams, assignments<br />

Subject aims and description<br />

Chemical engineeering thermodynamics: physical equilibrium,<br />

bubble and dewpoint relations, phase diagrams, activity and<br />

activity coefficients, Gibbs Duhem equation, chemical reaction<br />

equilibria, heats <strong>of</strong> reaction and mixing.<br />

Basic design techniques: mass and energy balance calculations;<br />

flowsheets; stoichiometry calculations involving bypass,<br />

recycle and purge; combustion and heat engine calculations.<br />

Text books<br />

Felder, R.M. and Rousseau, R.W. Elementary Principles <strong>of</strong> Chemical<br />

Processes. 2nd edn, New York, Wiley, 1986<br />

Smith, J.M. and Van Ness. H.C. lntroduction to Chemical Engineering<br />

Thermodynamics. 4th edn, New York, McGraw-Hill, 1987<br />

~ ~ 2 2Energy 0 Systems<br />

No. <strong>of</strong> hours per week: four hours<br />

Assessment: examination, laboratory assignment<br />

Subject aims and description<br />

Following a brief revision <strong>of</strong> MM121 studies, students will be<br />

introduced to real gases, the second law <strong>of</strong> thermodynamics<br />

and entropy. Applications will include vapour compression<br />

refrigeration.<br />

Students will be introduced to fluid mechanisms, covering fluid<br />

properties, fluid statics, momentum, energy. Applications will<br />

include flow measurement techniques.<br />

This subject comprises:<br />

Thermodynamics (two hours per week)<br />

Fluid mechanics (two hours per week)<br />

Thermodynamics:<br />

Revision <strong>of</strong> non-flow processes with gases.<br />

Revision <strong>of</strong> steady flow processes with gases and liquids.<br />

Real gases<br />

Second law <strong>of</strong> thermodynamics.<br />

Reversibility.<br />

Entropy <strong>of</strong> gases, liquids and vapours, T-S and h-s charts.<br />

Vapour compression refrigeration.