Hose and Flexible Tubing (MS-01-180;rev_6;en-US) - Swagelok

Hose and Flexible Tubing (MS-01-180;rev_6;en-US) - Swagelok

Hose and Flexible Tubing (MS-01-180;rev_6;en-US) - Swagelok

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FL Series Metal <strong>Hose</strong><br />

Features<br />

■ Highly flexible all-metal hose.<br />

■ 316L stainless steel annular convoluted core.<br />

■ 1/4 <strong>and</strong> 1/2 in. sizes <strong>and</strong> working pressures from vacuum to<br />

1500 psig (103 bar).<br />

■ Single braid layer of 321 stainless steel <strong>en</strong>sures hose<br />

pressure containm<strong>en</strong>t (M).<br />

■ End connections welded in accordance with ASME Boiler<br />

<strong>and</strong> Pressure Vessel Code Section IX.<br />

<strong>Hose</strong> <strong>and</strong> <strong>Flexible</strong> <strong>Tubing</strong> 21<br />

■ Exhibits strong performance in dynamic cycling<br />

applications.<br />

■ Commonly used in high-temperature vacuum <strong>and</strong> g<strong>en</strong>eral<br />

purpose dynamic-cycling applications.<br />

■ St<strong>and</strong>ard <strong>and</strong> custom assemblies available.<br />

■ Options include hose covers, hose tags, <strong>and</strong> additional<br />

helium leak testing. See page 83 for details.<br />

METAL<br />

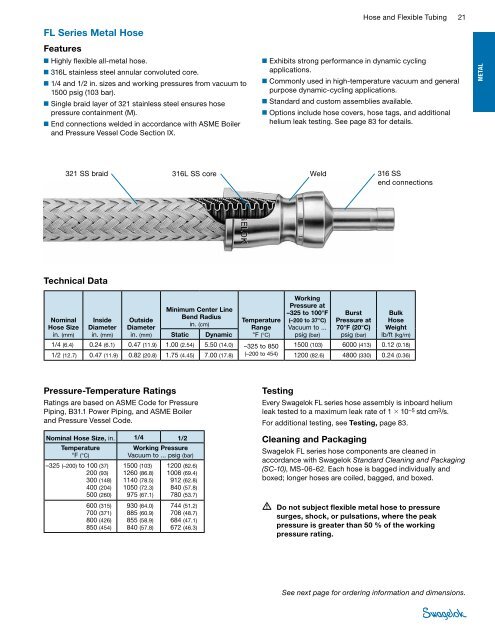

321 SS braid 316L SS core Weld<br />

316 SS<br />

<strong>en</strong>d connections<br />

Technical Data<br />

Nominal<br />

<strong>Hose</strong> Size<br />

in. (mm)<br />

Inside<br />

Diameter<br />

in. (mm)<br />

Outside<br />

Diameter<br />

in. (mm)<br />

Minimum C<strong>en</strong>ter Line<br />

B<strong>en</strong>d Radius<br />

in. (cm)<br />

Static<br />

Dynamic<br />

Temperature<br />

Range<br />

°F (°C)<br />

Working<br />

Pressure at<br />

–325 to 100°F<br />

(–200 to 37°C)<br />

Vacuum to ...<br />

psig (bar)<br />

Burst<br />

Pressure at<br />

70°F (20°C)<br />

psig (bar)<br />

Bulk<br />

<strong>Hose</strong><br />

Weight<br />

lb/ft (kg/m)<br />

1/4 (6.4) 0.24 (6.1) 0.47 (11.9) 1.00 (2.54) 5.50 (14.0) –325 to 850 1500 (103) 6000 (413) 0.12 (0.18)<br />

1/2 (12.7) 0.47 (11.9) 0.82 (20.8) 1.75 (4.45) 7.00 (17.8) (–200 to 454) 1200 (82.6) 4800 (330) 0.24 (0.36)<br />

Pressure-Temperature Ratings<br />

Ratings are based on ASME Code for Pressure<br />

Piping, B31.1 Power Piping, <strong>and</strong> ASME Boiler<br />

<strong>and</strong> Pressure Vessel Code.<br />

Nominal <strong>Hose</strong> Size, in. 1/4 1/2<br />

Temperature<br />

°F (°C)<br />

–325 (–200) to 100 (37)<br />

200 (93)<br />

300 (148)<br />

400 (204)<br />

500 (260)<br />

600 (315)<br />

700 (371)<br />

800 (426)<br />

850 (454)<br />

Working Pressure<br />

Vacuum to ... psig (bar)<br />

1500 (103)<br />

1260 (86.8)<br />

1140 (78.5)<br />

1050 (72.3)<br />

975 (67.1)<br />

930 (64.0)<br />

885 (60.9)<br />

855 (58.9)<br />

840 (57.8)<br />

1200 (82.6)<br />

1008 (69.4)<br />

912 (62.8)<br />

840 (57.8)<br />

780 (53.7)<br />

744 (51.2)<br />

708 (48.7)<br />

684 (47.1)<br />

672 (46.3)<br />

Testing<br />

Every <strong>Swagelok</strong> FL series hose assembly is inboard helium<br />

leak tested to a maximum leak rate of 1 3 10 –5 std cm 3 /s.<br />

For additional testing, see Testing, page 83.<br />

Cleaning <strong>and</strong> Packaging<br />

<strong>Swagelok</strong> FL series hose compon<strong>en</strong>ts are cleaned in<br />

accordance with <strong>Swagelok</strong> St<strong>and</strong>ard Cleaning <strong>and</strong> Packaging<br />

(SC‐10), <strong>MS</strong>‐06‐62. Each hose is bagged individually <strong>and</strong><br />

boxed; longer hoses are coiled, bagged, <strong>and</strong> boxed.<br />

Do not subject flexible metal hose to pressure<br />

surges, shock, or pulsations, where the peak<br />

pressure is greater than 50 % of the working<br />

pressure rating.<br />

See next page for ordering information <strong>and</strong> dim<strong>en</strong>sions.