N2O production in a single stage nitritation/anammox MBBR process

N2O production in a single stage nitritation/anammox MBBR process

N2O production in a single stage nitritation/anammox MBBR process

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The bacteria perform<strong>in</strong>g the microbial conversion of nitrite <strong>in</strong>to d<strong>in</strong>itrogen gas are strict<br />

anaerobe autotrophs and the <strong>process</strong> has the potential to replace conventional<br />

nitrification/denitrification of recirculated high strength ammonium streams with<strong>in</strong> the<br />

wastewater treatment plant (Strous et al., 1997). No additional carbon source is needed,<br />

the oxygen demand is reduced by 50-60% <strong>in</strong> the nitrify<strong>in</strong>g step and the aeration can<br />

thereby be strongly reduced (Jetten et al., 2001, Fux et al., 2002). This means that the<br />

<strong>process</strong> offers an opportunity to decrease the carbon footpr<strong>in</strong>t of the wastewater<br />

treatment plant <strong>in</strong> terms of sav<strong>in</strong>g possibilities of both additional carbon source and<br />

power consumption (Jetten et al., 2004). Further advantages with the <strong>anammox</strong> <strong>process</strong><br />

is that the <strong>production</strong> of surplus sludge is m<strong>in</strong>imized and that high volumetric load<strong>in</strong>g<br />

rates can be obta<strong>in</strong>ed result<strong>in</strong>g <strong>in</strong> reduced operational and <strong>in</strong>vestment costs (Abma et<br />

al., 2007). Indications that the <strong>process</strong> may produce significant amounts of <strong>N2O</strong> gas with<br />

negative environmental impacts detract<strong>in</strong>g the <strong>process</strong> advantages. The aim of this<br />

study was to determ<strong>in</strong>e the amount of <strong>N2O</strong> produced <strong>in</strong> a <strong>nitritation</strong>/ <strong>anammox</strong> <strong>MBBR</strong><br />

<strong>process</strong> dur<strong>in</strong>g different operation modes.<br />

Materials and methods<br />

<strong>MBBR</strong> system<br />

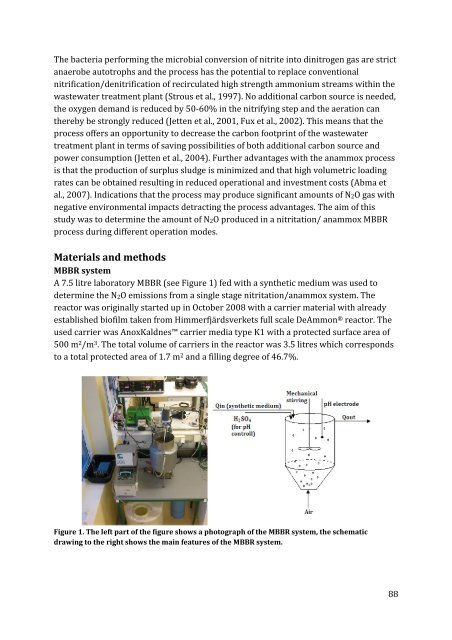

A 7.5 litre laboratory <strong>MBBR</strong> (see Figure 1) fed with a synthetic medium was used to<br />

determ<strong>in</strong>e the <strong>N2O</strong> emissions from a s<strong>in</strong>gle <strong>stage</strong> <strong>nitritation</strong>/<strong>anammox</strong> system. The<br />

reactor was orig<strong>in</strong>ally started up <strong>in</strong> October 2008 with a carrier material with already<br />

established biofilm taken from Himmerfjärdsverkets full scale DeAmmon ® reactor. The<br />

used carrier was AnoxKaldnes carrier media type K1 with a protected surface area of<br />

500 m 2 /m 3 . The total volume of carriers <strong>in</strong> the reactor was 3.5 litres which corresponds<br />

to a total protected area of 1.7 m 2 and a fill<strong>in</strong>g degree of 46.7%.<br />

Figure 1. The left part of the figure shows a photograph of the <strong>MBBR</strong> system, the schematic<br />

draw<strong>in</strong>g to the right shows the ma<strong>in</strong> features of the <strong>MBBR</strong> system.<br />

88