Steering & controls 455 - aqua services

Steering & controls 455 - aqua services

Steering & controls 455 - aqua services

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

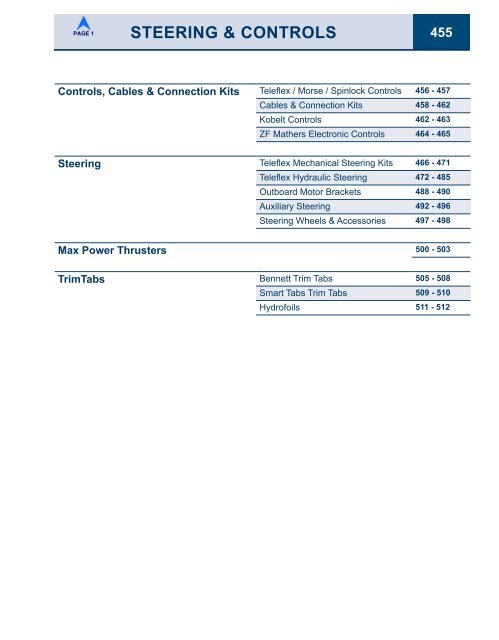

STEERING & CONTROLS <strong>455</strong><br />

Controls, Cables & Connection Kits 456 - 457<br />

458 - 462<br />

462 - 463<br />

Z 464 - 465<br />

<strong>Steering</strong> T 466 - 471<br />

T 472 - 485<br />

488 - 490<br />

492 - 496<br />

497 - 498<br />

Max Power Thrusters 500 - 503<br />

TrimTabs 505 - 508<br />

509 - 510<br />

511 - 512

456<br />

Controls<br />

STEERING & CONTROLS<br />

Morse S & Twin S Controls<br />

Model S and Twin S top mounted <strong>controls</strong> are the traditional<br />

control style for use on boats with gasoline or diesel engines and<br />

hydraulic transmissions, and are a popular choice for dual station<br />

rigs. Model S can be mounted to control<br />

clutch or throttle. The Twin S can be used to<br />

control clutch and throttle or, on twin engine<br />

applications, two clutches or two throttles.<br />

Features adjustable stops, adjustable brake<br />

for each lever and an optional detent kit.<br />

MOR 31002-001 <br />

MOR CH5200P <br />

Parts:<br />

MOR 22328 <br />

MOR 47307 <br />

MOR 42152 <br />

<br />

MOR 39489-002 <br />

Morse MT-3 Controls<br />

Top or binnacle mounted control provides onehanded<br />

positive engine control with excellent<br />

control feel characteristics. Recommended for<br />

single station applications only. Single and twin<br />

engine, inboard, outboard and I/O, diesel or gasoline<br />

react quickly and positively to MT-3 <strong>controls</strong>. Start<br />

and warm-up operations are carried out with hand<br />

lever pulled out at neutral detent position to give<br />

throttle action with clutch disengaged. Return to<br />

neutral re-engages clutch function. Forward, reverse<br />

and neutral detents on single and twin models. Builtin<br />

friction drag prevents slippage and throttle creep<br />

while under way. Die cast handle and housing are<br />

heavily chrome plated.<br />

MOR 308601 <br />

MOR 308602 <br />

Parts:<br />

MOR 308742 <br />

<br />

MOR 305499 <br />

<br />

MOR 32778-002 <br />

MOR 38853 <br />

MOR 35232-001 <br />

MOR 35232-004 <br />

Teleex Model SR Control<br />

Recommended for single and dual station<br />

applications and for single and twin engines with<br />

hydraulic transmissions. Easy to install, easy to<br />

maintain. All connections and adjustments are<br />

made by removing stainless steel cover.<br />

TFM CH5400P <br />

Parts:<br />

MOR 36774 <br />

MOR 41117 <br />

<br />

MOR 40090 <br />

<br />

MOR 39490-002 <br />

MOR 36326 <br />

Morse SL-3 Single Lever Controls<br />

Provides dual-function, single-lever control for<br />

virtually all stern drive, outboard and inboard<br />

engines. The design is based upon rotary motion,<br />

with the entire gear mechanism enclosed and<br />

permanently lubricated creating a rm yet<br />

effortless feel throughout the entire lever travel.<br />

A push button disengages the clutch for engine<br />

warm up. Positive detent lets you clearly feel each<br />

gear selection and an adjustable brake prevents<br />

throttle creep. The <strong>controls</strong> are adjustable<br />

in 15 o increments creating 24 possible cable<br />

entry positions for horizontal through vertical<br />

installation. Deluxe models feature trim and tilt<br />

switches in the handle.<br />

MOR 309473 <br />

MOR 309474 <br />

MOR 309475-002 <br />

<br />

MOR 309476 <br />

MOR 309478-002 <br />

<br />

MOR 309479 <br />

Teleex MV-3 Ski/Jet Boat Control<br />

Dual function, single lever control for jet and<br />

ski boats.<br />

• Emergency cut-off<br />

• Built-in friction drag reduces throttle creep<br />

• Neutral interlock prevents accidental<br />

shifting<br />

• Pull-out clutch disengagement feature<br />

for engine warm-up with automatic<br />

disengagement<br />

TFM CH2920P<br />

Teleex CH1725P Single Engine Control<br />

A balanced handle design provides an incredibly<br />

smooth yet positive feel. For starboard gunwale<br />

mounts. Suitable for both universal (3300 type) or<br />

OEM type control cables without adaptation.<br />

• Suitable for most single engine, single station<br />

boats<br />

• Dual action lever (throttle-shift control on one<br />

handle)<br />

• Trim & Tilt function<br />

• Drag adjustment on all models<br />

• Easy installation and set up<br />

• Neutral “warm up” button for throttle only operation<br />

TFM CH1752P

Controls<br />

457<br />

Morse MV-2 Single Lever Control<br />

The MV-2 is the choice of competition ski boat<br />

drivers. It provides single-lever control of both<br />

shift and throttle in a classic styling design. It has<br />

a pull-out clutch disengagement feature for engine<br />

warm-up and a neutral interlock to help prevent<br />

accidental shifting. Mounts port or starboard and<br />

can be congured for use with any engine.<br />

MOR 306950 <br />

Teleex ST Single Control<br />

• For panel or wheel box side mounting<br />

• Used with 3300/33C type cables<br />

• Made of durable die casting with chrome nish<br />

• Recommended for gasoline and diesel engines with<br />

light throttle loads<br />

• 3.20:1 mechanical advantage<br />

TFM CH2400P<br />

Sea-Dog Single Function Engine Control<br />

This economically priced engine control is made from sand cast<br />

brass and nished in chrome plating.<br />

• Uses #10 F.H. mounting screw<br />

SED 232300<br />

Teleex Sailboat Control<br />

For all sail engine applications in which a side<br />

mount control is desirable.<br />

• Single lever, dual action for throttle & shift<br />

• Neutral engine warm-up control<br />

• Surface mount design for quick, tidy<br />

installation<br />

• Includes hardware for two 3300/33C type<br />

cables<br />

• Positive shift detents and neutral lock-out<br />

• Weatherproof exterior, rugged die cast frame<br />

• Meets/exceeds all applicable industry standards<br />

TFM CH2100P<br />

Spinlock Throttle Control<br />

Designed to replace the Teleex model B700,<br />

CH2100P and CH2600P face plate.<br />

Using ATCU under power is exactly like using<br />

a normal throttle lever-except you can remove<br />

the handle at any time. Run the engine in<br />

neutral simply by pushing the handle inwards-which disengages the<br />

clutch. Return the handle to the minimum throttle position, and it<br />

smoothly re-engages.<br />

• Handle not included<br />

• Uses a universal winch handle as control<br />

• No risk of line snags when sailing or under power<br />

• Allows the engine control to be located anywhere on deck<br />

• Waterproof seal<br />

• Deters boat theft<br />

SPI ATCU/1<br />

STEERING & CONTROLS<br />

Notes

Proven solutions for performance yachts<br />

Composite Tunnel<br />

Thrusters<br />

• Custom designed motor<br />

• Maintenance free drive leg<br />

• Case-hardened spiro-conical gears<br />

• Low noise emission<br />

• Lightweight composite construction<br />

• No anode, no oil reservoir<br />

• Full range for all boat sizes<br />

Control Panels<br />

• Water resistant<br />

• Childproof activation<br />

• Auto shutdown<br />

• Motor overheat warning<br />

Compact Retractable<br />

VIP Retractable<br />

Accessories<br />

• Fuses<br />

• Tunnel adapters<br />

• Tunnels<br />

www.max- power.com

458<br />

Cables<br />

Teleex 3300 Heavy Duty Cables - 172 Series<br />

Teleex OMC 400 Replacement Cables - 170 Series<br />

Universal cables are drop-in replacements for many boats using<br />

aftermarket <strong>controls</strong> or the following engine makers’ <strong>controls</strong>:<br />

BMW, Chrysler, Honda, Nissan, Suzuki, Tohatsu, Volvo, Yamaha<br />

and others. Our cables feature Lubri-Core, which makes them<br />

smooth operating and long-lasting. Stainless steel and brass ttings<br />

are used. Minimum bend radius is 6”. Nominal travel is 3”. 10-32"<br />

thread ends.<br />

TFM CC17210 TFM CC17216 <br />

TFM CC17211 TFM CC17217 <br />

TFM CC17212 TFM CC17218 <br />

TFM CC17213 TFM CC17219 <br />

TFM CC17214 TFM CC17220 <br />

TFM CC17215 <br />

Teleex TFXTREME 3300 Cables - 633 Series<br />

Direct replacement O.M.C., Johnson/Evinrude & Gale<br />

(Pre 1979) throttle/shift control cables. Teleex cables feature<br />

Lubri-Core, which makes them smooth operating and long-lasting.<br />

Stainless steel and brass ttings are used. Core wire is stainless<br />

steel for smooth operation and long life.<br />

TFM CC17009<br />

TFM CC17010<br />

TFM CC17011<br />

TFM CC17012<br />

TFM CC17013<br />

TFM CC17014<br />

TFM CC17015<br />

TFM CC17016<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Teleex TFXTreme 4300BC Cables - 430 Series<br />

STEERING & CONTROLS<br />

TfXtreme uses a unique splined core wire to achieve the<br />

“impossible”. Its ridges allow a close t with the cable’s inner<br />

liner, but with minimum contact, so the core glides back and<br />

forth like a skater on ice. If you’re a twin station user, you’ll<br />

be able to keep upper and lower station <strong>controls</strong> smooth and in<br />

sync without the annoying loss of RPM or gearshift movement<br />

at either station. Minimum bend radius is 4”. Nominal travel is<br />

3”. 10/32" thread ends.<br />

TFM CCX63306 TFM CCX63319 <br />

TFM CCX63307 TFM CCX63320 <br />

TFM CCX63308 TFM CCX63321 <br />

TFM CCX63309 TFM CCX63322 <br />

TFM CCX63310 TFM CCX63323 <br />

TFM CCX63311 TFM CCX63324 <br />

TFM CCX63312 TFM CCX63325 <br />

TFM CCX63313 TFM CCX63326 <br />

TFM CCX63314 TFM CCX63327 <br />

TFM CCX63315 TFM CCX63328 <br />

TFM CCX63316 TFM CCX63329 <br />

TFM CCX63317 TFM CCX63330 <br />

TFM CCX63318 TFM CCX63332 <br />

Teleex 33C Cables - 332 Series<br />

Universal cables are used for diesel engines, commercial craft and<br />

some jet boats. 4300BC cables have one bulkhead and one clamp<br />

end. Our cables feature Lubri-Core, which makes them smooth<br />

operating and long-lasting. Stainless steel and brass ttings are<br />

used. Minimum bend radius is 5”. Nominal travel is 3”. 1/4"-28<br />

UNF thread ends.<br />

TFM CCX43010 <br />

TFM CCX43011 <br />

TFM CCX43012 <br />

TFM CCX43013 <br />

TFM CCX43014 <br />

TFM CCX43015 <br />

TFM CCX43016 <br />

TFM CCX43017 <br />

TFM CCX43018 <br />

TFM CCX43019 <br />

TFM CCX43020 <br />

Teleex TFXTreme 4300CC Cables - 433 Series<br />

Type 33C Supreme is a highly efcient, super smooth operating<br />

cable, designed specically for use on multiple station applications<br />

and installations where complex cable routing makes control<br />

operation difcult with ordinary cables. It can be easily substituted<br />

for Morse 33C and most other competitive marine control cables<br />

to upgrade control operation. Max. travel is 3", rod end thread is<br />

10-32. Minimum 4" bend radius.<br />

TFM CC33210 TFM CC33218 <br />

TFM CC33211 TFM CC33219 <br />

TFM CC33212 TFM CC33220 <br />

TFM CC33213 TFM CC33221 <br />

TFM CC33214 TFM CC33222 <br />

TFM CC33215 TFM CC33223 <br />

TFM CC33216 TFM CC33224 <br />

TFM CC33217 <br />

4300CC cables have two clamp ends and feature Lubri-Core, which<br />

makes them smooth operating and long-lasting. Stainless steel and<br />

brass ttings are used. Minimum bend radius is 5”. Nominal travel<br />

is 3”. 1/4"-28 UNF thread ends.<br />

TFM CCX43306 TFM CCX43320 <br />

TFM CCX43307 TFM CCX43321 <br />

TFM CCX43308 TFM CCX43322 <br />

TFM CCX43309 TFM CCX43323 <br />

TFM CCX43310 TFM CCX43324 <br />

TFM CCX43311 TFM CCX43325 <br />

TFM CCX43312 TFM CCX43326 <br />

TFM CCX43313 TFM CCX43328 <br />

TFM CCX43314 TFM CCX43330 <br />

TFM CCX43315 TFM CCX43332 <br />

TFM CCX43316 TFM CCX43334 <br />

TFM CCX43317 TFM CCX43336 <br />

TFM CCX43318 TFM CCX43338 <br />

TFM CCX43319 TFM CCX43340

Cables / Connection Kits<br />

459<br />

Morse Dual Station Transfer Unit<br />

For use with S and SR two lever<br />

control systems when installed in<br />

a parallel dual station system. The<br />

Transfer Unit permits the two clutch<br />

and/or the two throttle cables from the <strong>controls</strong> to be connected<br />

to a single cable leading aft to the engine. These units are<br />

recommended where long or difcult cable paths make parallel<br />

installations costly and/or difcult to operate. One transfer unit is<br />

required for each function of each engine.<br />

MOR 61371<br />

Morse Mounting Bracket<br />

All stainless steel angle mounting<br />

bracket for use with the DC control.<br />

MOR 48210<br />

Teleex Universal Connection Kits<br />

TFM CA37701P<br />

Universal 3300 Ball Joint 1/4"-28 (1)<br />

TFM CA27328P<br />

Parallel Connection Kit<br />

TFM CA27024P<br />

Universal Inboard Connection Kit<br />

Morse DC Control<br />

Designed to mount ush on a dashboard or side of a wheel box.<br />

Mounting with an angle bracket is optional. Recommended for<br />

throttle, choke, air or fuel shutdown, governor or valve control.<br />

Use with 33C series cables.<br />

MOR 301916 <br />

MOR 301555 <br />

Teleex Engine Connection Kits<br />

These kits provide control cable connection hardware, either for<br />

cable to engine/transmission or for cable to control unit. Most are<br />

specic to engine or control type and for use with two 3300 type<br />

cables, except where otherwise noted.<br />

*1 kit required for each cable<br />

TFM CA28020P<br />

Clamp & Shim kit universal<br />

TFM CA27321P<br />

Evinrude/Johnson O/B Kit (Pre 1979)<br />

► NOTE:<br />

Morse Parts - Ball Joints<br />

30 Series<br />

Part # A B C D<br />

MOR 31126 <br />

MOR 31799-001 <br />

MOR 35242 <br />

All units come complete with nut and lock washer.<br />

40 Series<br />

Part # A B C D<br />

MOR 29104 <br />

MOR 32267 <br />

Both units come complete with nut and lock washer.<br />

60 Series<br />

30 Series.......................... 10-32 RH Thread<br />

40 Series.........................1/4"-28 RH Thread<br />

60 Series........................5/16"-24 RH Thread<br />

Part # A B C D Style<br />

MOR 29108 <br />

MOR 38491 <br />

Both units come complete with nut and lock washer.<br />

STEERING & CONTROLS<br />

Morse Parts - Cable Brake<br />

Part # A B C<br />

MOR 44386 <br />

Cable brake ts 30,40 & 60 series cables.

460<br />

Connection Kits<br />

Morse Parts - Cable Hook Clips<br />

Single<br />

Part # A B C D E F G<br />

MOR 31419 <br />

Single<br />

Part # A B C D E<br />

MOR 36174 <br />

Morse Parts - Clamps<br />

30 Series<br />

Part # A B C<br />

MOR 32010 <br />

30 Series<br />

Part # A B C D E<br />

MOR 31509 <br />

40 Series<br />

Part # A B C D E F<br />

MOR 31532 <br />

MOR 42756<br />

<br />

60 Series<br />

STEERING & CONTROLS<br />

Dual<br />

Part # A B C D E<br />

MOR 35531 <br />

Morse Parts - Clevis<br />

30 Series<br />

Part # A B C D<br />

MOR 31125 <br />

MOR 31800 <br />

MOR 33395 <br />

Part # A B C D E<br />

MOR 36733 <br />

30L Series (No Hub)<br />

Part # A B C D E F<br />

MOR 37664 <br />

MOR 43229 <br />

40 Series<br />

Part # A B C D<br />

MOR 29025 <br />

MOR 42212 <br />

MOR 45985 <br />

60 Series<br />

Part # A B C D<br />

MOR 29132-001 <br />

MOR 42034 <br />

40 Series<br />

Part # A B C D E F<br />

MOR 21227 <br />

Morse Parts - Shims<br />

Part # A B C D<br />

MOR 35777 <br />

MOR 37884 <br />

MOR 31538

Connection Kits<br />

461<br />

Morse Parts - Pivots<br />

Morse Parts - Terminal Eye Pins<br />

30 Series<br />

Part # A B C D E<br />

MOR 31029 <br />

MOR 31539 <br />

MOR 32392 <br />

MOR 37691 <br />

MOR 39890 <br />

MOR 43939 <br />

MOR <strong>455</strong>83 <br />

40 Series<br />

Part # A B C D E<br />

MOR 31537 <br />

MOR 36361 <br />

MOR 39110 <br />

MOR 45199 <br />

30 Series<br />

40 Series<br />

Part # A B C D<br />

MOR 300965 <br />

MOR 301456* <br />

*Note: 301456 Pin Kit Includes eye pin, retaining<br />

ring, nut & washer.<br />

Part # A B C D<br />

MOR 47383 <br />

Morse Parts - Accessories<br />

<br />

<br />

<br />

Morse Parts - Spring Link Terminals<br />

30L Series<br />

Part # A B C<br />

MOR 31545 <br />

Morse Parts - Terminal Eyes<br />

30 Series<br />

Part # A B C D E<br />

MOR 300646 <br />

MOR 41884-01A<br />

MOR 61342<br />

MOR 300673<br />

MOR 302485<br />

MOR 37693<br />

MOR 294200<br />

<br />

<br />

<br />

<br />

<br />

<br />

Morse Parts - Control Adapter Parts<br />

These kits adapt 3300/33C series cables<br />

for use with other <strong>controls</strong>.<br />

MOR 301074<br />

Adapts 3300/33C series cables for use with<br />

Mercury/Mariner <strong>controls</strong><br />

STEERING & CONTROLS<br />

40 Series<br />

Part # A B C D E<br />

MOR 37639 <br />

MOR 41134 <br />

MOR 304939<br />

Adapts 3300/33C series cables for use with<br />

1979 and later OMC Controls.

462<br />

Connection Kits / Controls<br />

STEERING & CONTROLS<br />

Morse Parts - Cable Adapter Kits<br />

These kits are used to adapt 3300/33C series cables to<br />

t directly into the existing engine connections.<br />

MOR 300557<br />

Adapts 3300/33C series cables for use with OMC<br />

sterndrives<br />

MOR 301729<br />

Adapts 3300/33C series cables for use with<br />

Evinrude/Johnson 55-235 h.p. 1978 to date, 20<br />

h.p. and up in 1986, 20-25-30 h.p. motors may<br />

need OMC Kit 397488, if motor does not have<br />

it installed already.<br />

MOR 302123<br />

Adapts 3300/33C series cables for use with Mercruiser.<br />

Kobelt 2090 Two Station Single Lever Controls<br />

Made from all die cast bronze<br />

and stainless steel hardware.<br />

A two station, single engine<br />

control system that requires only<br />

2 control heads and 4 cables and<br />

both handles will move together.<br />

Available in two systems - one<br />

for one engine applications and<br />

one for two engine applications.<br />

Each system consists of 1 master<br />

control head and one slave.<br />

Adapter kits are required, one<br />

for each cable, to connect cables<br />

to the master control. Order kit<br />

no. 2046-0901 for 33 cable and<br />

kit no. 2046-0902 for 43 cable.<br />

Two pull-pull cables per engine<br />

are required for interconnecting the master and slave stations.<br />

The control heads contain all the necessary parts to attach these<br />

interconnecting cables. All control heads are chrome plated and<br />

come equipped with neutral safety switch (es).<br />

• Maximum clutch stroke is 2-3/4" (70 mm)<br />

• Maximum throttle stroke is 2-5/8" (57 mm)<br />

KOB 2091-HKYZ <br />

KOB 2093-KYZ <br />

KOB 2092-JKYZ <br />

KOB 2094-KYZ <br />

Parts:<br />

KOB 2046-0901 <br />

KOB 2046-0902 <br />

Kobelt 2009 Twin Handle Control<br />

Made in all bronze and stainless steel with a chrome plated housing<br />

for medium duty applications. Provides 3" of stroke and can be used<br />

for one or two station installations with relatively short and straight<br />

throttle and shift runs. For use with 33C cables order the 2009-0901<br />

connection kit and for 43C order the 2009-0902 connection kit.<br />

One connection kit is required for each cable. These <strong>controls</strong> are<br />

available with either long or short handles or a combination and in<br />

right or left hand models. Frictions and detents are standard with<br />

neutral safety switches available as an option.<br />

• Short handle w/ friction, long handle with detent<br />

KOB 2009-AK<br />

• Two long handles with detent<br />

KOB 2009-BK<br />

• Two long chrome nished handles, one<br />

having detent the other friction<br />

• One neutral safety switch, one with<br />

interlock<br />

KOB 2009-DHKSU<br />

Parts:<br />

KOB 2009-0901 <br />

KOB 2009-0902 <br />

KOB 2009-0903 <br />

KOB 1201-0002 <br />

Kobelt 2015 Twin Lever Push-Pull Control<br />

All heavy duty bronze and stainless steel<br />

construction with chrome plated nish. The cable<br />

support bracket is shorter to allow for tight quarter<br />

installations. Other features include red and black<br />

coloured knobs and detent on clutch control.<br />

• For 33C cables order kit: 2015-0901<br />

• For 43C cables order kit: 2015-0902<br />

*One kit is required for each cable<br />

KOB 2015-DKU <br />

Parts:<br />

KOB 2015-0901 <br />

KOB 2015-0902 <br />

KOB 2015-0903 <br />

KOB 2030-0001 <br />

Kobelt 2044 Side Mount Heavy Duty<br />

Single Lever Control<br />

Side-mounted, heavy duty, single lever, throttle and<br />

shift control. All brass construction with chrome<br />

plated face plate and handle. The cable attaching<br />

bracket can be rotated at 90° increments. Neutral<br />

safety switch and neutral locking powerboat handle.<br />

• For 33C cables order kit: 2011-0901<br />

• For 43C cables order kit: 2011-0902<br />

*One connection kit is required for each cable.<br />

KOB 2044-HKX1<br />

Parts:<br />

KOB 2011-0901 <br />

KOB 2011-0902 <br />

KOB 1201-0002

Controls / Connection Kits<br />

463<br />

Kobelt 2046 Single Lever Control<br />

This medium duty single lever control is all bronze<br />

construction with chrome plated housing and handle.<br />

A pull-out handle provides an override for the throttle.<br />

The maximum clutch travel is 3" and throttle travel is<br />

1-5/8".<br />

• For 33C cables order kit: 2046-0901<br />

• For 43C cables order kit: 2046-0902<br />

The throttle travel may be increased to 2-5/8" by<br />

using the throttle stroke extension kit.<br />

• For 33C cables order kit: 2046-0905<br />

• For 43C cables order kit: 2046-0906<br />

*One connection kit required for each cable.<br />

KOB 2046 KU <br />

Parts:<br />

KOB 2046-0901 <br />

KOB 2046-0902 <br />

KOB 2046-0905 <br />

KOB 2046-0906 <br />

KOB 2046-0903 <br />

Kobelt Twin Handle Control<br />

A low prole control head manufactured entirely of<br />

bronze and stainless steel. It is intended for single<br />

function, single handle control (i.e. separate clutch<br />

and throttle handles).<br />

• Requires one connection kit per cable<br />

*Due to its design it can be used as a simple "dropin"<br />

replacement for a Morse SF unit.<br />

KOB 2022-K<br />

Parts:<br />

KOB 2011-0901 <br />

KOB 2011-0902 <br />

Kobelt 2047 Twin Engine<br />

Single Lever Control<br />

A medium duty control head constructed of bronze<br />

materials with chrome plated housing and handles.<br />

Incorporates a roller type detent as well as a<br />

independent throttle override. The maximum clutch<br />

travel is 3" and throttle travel is 2-3/8". (See below<br />

for cable kits)<br />

KOB 2047-KY<br />

Parts:<br />

KOB 2047-0901C <br />

KOB 2047-0901T <br />

Kobelt Ball Ends<br />

Rod ball ends are commonly used to connect a<br />

push-pull cable to the engine or clutch. The rod<br />

ball end is screwed onto the end of the cable, and<br />

the rod ball end uses a bolt through the ball end<br />

that attaches it to a lever.<br />

Part # Thread size Bolt hole Series<br />

KOB 2143 <br />

KOB 2144-3 <br />

Kobelt 2124 Compound Unit<br />

For two-station applications and for<br />

use on compound engine arrangements.<br />

On two-station applications, long<br />

cables sometimes require the use of 40<br />

series cables from the wheelhouse to<br />

the engine room. But many inboard/<br />

outboard engines are designed for<br />

connection of a 30 series cable. The Compound Unit can be<br />

installed just below the wheelhouse oor. Both stations are<br />

connected to it with 40 series cables, and a single 30 series cable<br />

runs to the clutch or throttle. On compound engine installations,<br />

the control cable unit runs into the Compound Unit and two cables<br />

lead away to the separate engine throttles.<br />

KOB 2124 <br />

Cable Connection Kits 30 Series 40 Series<br />

KOB 2124-0033 <br />

KOB 2124-0043 <br />

KOB 2124-0243 <br />

Kobelt 2128 Universal Adaptor Kit<br />

This universal adaptor kit was<br />

developed to avoid stocking hundreds<br />

of different adaptor kits. Virtually any<br />

bolt or preferably two bolts on the gear<br />

or engine, close to cable attaching point,<br />

can be used to install this universal<br />

adaptor kit. With its linkage and swivelling ends, cables can be run<br />

directly to the clamping bracket and allow easy cable installation;<br />

this avoids costly designing and fabrication. It can be used for<br />

parallel or series installations.<br />

KOB 2128 <br />

Cable clamp kits:<br />

KOB 2128-0031 <br />

KOB 2128-0032 <br />

KOB 2128-0041 <br />

KOB 2128-0042 <br />

STEERING & CONTROLS<br />

Kobelt Cable Clamp<br />

Single cable clamp for 30 series cables.<br />

KOB 2131-0030

464<br />

ZF Mathers Electronic Controls<br />

Synchronization is a standard feature on every processor increasing the operating<br />

efciency of any vessel by reducing fuel consumption. This also allows for single<br />

lever control of multiple engines. Other standard features include:<br />

• Plug-in installation<br />

• Neutral start interlock<br />

• High/Low idle<br />

• Warm-up mode<br />

• Audible and visual indicators<br />

• Reduction gear oil pressure interlock<br />

• External alarm interface<br />

All 9000 series components meet EMC, and CE standards as well as UL1500 with<br />

built in ignition protection.<br />

*Before ordering a ZF Mathers 9000 series electronic control system please call for<br />

a system conguration work sheet or allow our sales staff work out the details.*<br />

The ZF Mathers 9000 series control system is a single lever electronic control system<br />

designed for precise, instant control of mechanical engines and gears or a mechanical<br />

and electronic throttle/shift combination. The system is easy to install with optional plug<br />

connectors and easy to route wires for control of up to 9 stations. The 9000 series system<br />

is compatible with gas or diesel, inboard, I/O’s or outboard engines.<br />

STEERING & CONTROLS<br />

Actuators<br />

Actuator mechanical throttle/mechanical shift w/ hard wired connections<br />

MMC 91100 <br />

Actuator electronic throttle/mechanical shift w/ plug connection<br />

MMC 92100* <br />

Control Heads<br />

All ZF control heads incorporate single-lever control of direction and speed, built in station transfer button,<br />

station in-command /synchronization indicator lights and audible warning indicator. Control heads are<br />

available with port or starboard levers (on single engine <strong>controls</strong>) and with or without plug-in connectors.<br />

All standard control heads are salt, spray and corrosion resistant.<br />

400 Series Controls:<br />

400 series <strong>controls</strong> come standard with black plastic T-levers but are available<br />

with a selection of optional handle styles.<br />

MMC 450-3L <br />

MMC 450-3R <br />

MMC 460-4 <br />

400 Series Optional Handles:<br />

MMC 473<br />

<br />

MMC 475<br />

<br />

MMC 476<br />

<br />

<br />

MC2000 Series Controls<br />

Stylish and functional these <strong>controls</strong> incorporate all<br />

the standard control features with a beautiful design<br />

and solid feel. MC2000 series <strong>controls</strong> are available<br />

on request with a variety of casing and lever nishes.<br />

MMC MC2000-2* <br />

*Request Item

ZF Mathers Electronic Controls<br />

465<br />

ZF Mathers Sample System Installations:<br />

Single engine (mechanical throttle and shift) two stations<br />

1 x MMC 91100 Actuator mechanical throttle/mechanical shift<br />

w/ hard wired connections<br />

2 x MMC 450-3L Single lever control (left)<br />

75’ MMC 350 8 Conductor shielded cable<br />

10’ MMC 349 2 Conductor shielded power cable<br />

10’ MMC 355 2 Conductor shielded starter interlock cable<br />

Twin engine (electronic throttle and mechanical shift) single station<br />

2x MMC 92100* Actuator electronic throttle/mechanical shift<br />

w/ plug connection<br />

1 x MMC 460-4 Twin lever control w/ plug connection<br />

1 x MMC 13316-10 Serial communication cable 10’<br />

2 x MMC 13239-15 Tach sensor harness 15’<br />

40’ MMC 350 8 Conductor shielded cable<br />

10’ MMC 349 2 Conductor shielded power cable<br />

10’ MMC 355 2 Conductor shielded starter interlock cable<br />

*Request Item<br />

ZF Mathers Trolling Valve Control Actuator<br />

For vessels equipped with mechanical trolling valves the ZF troll<br />

actuator incorporates precise, safe, and adjustable operation of the<br />

valves into a ZF 9000 series control system. By merely turning<br />

the trolling actuator on via your existing control transfer button<br />

the trolling valve is put into maximum slip mode. By advancing<br />

the control lever, propeller speed increases until full lock-up is<br />

achieved. The percentage and range of clutch slip as well as the<br />

throttle range are adjustable.<br />

MMC 90010*<br />

*Request Item<br />

ZF Mathers Automatic Power Selector<br />

Automatic power selector, which works with every electronic<br />

control system, automatically switches from one DC power<br />

source to another, giving a secondary power supply when needed.<br />

Operational with 12 or 24 volt batteries.<br />

MMC 13505<br />

ZF Mathers Emergency Backup Control<br />

Designed to provide a mechanical override to control the engines<br />

throttle and shift, should there be a system failure. May be mounted<br />

horizontally or vertically. Tension lock feature allows the control<br />

cable to be set and locked in one position.<br />

MMC 900* *Request Item<br />

ZF Mathers Remote Engine Control<br />

This portable lightweight and fully<br />

waterproof unit offers walkabout<br />

convenience along with the<br />

same standard features as a<br />

xed control head. Built<br />

in safety features include an<br />

emergency engine stop button,<br />

in-command indicator light,<br />

and a wrist strap kill switch safety lanyard. If the lanyard becomes<br />

detached, the remote immediately puts the engine in idle and shifts<br />

the transmission to neutral. Others features include, 25’ of exible<br />

cable, plug-in connection, and optional control for up to two bow<br />

thrusters.<br />

MMC 1213-1* <br />

MMC 1214-1* <br />

*Request Item<br />

ZF Mathers Weather-Tight Enclosure<br />

Ideal for control head mounting in exposed<br />

outside areas.<br />

MMC 12110<br />

STEERING & CONTROLS<br />

ZF Mathers Miscellaneous Items<br />

MMC 340 <br />

MMC 516 <br />

MMC 821 <br />

MMC 1114H <br />

MMC 350 <br />

MMC 355 <br />

MMC 349

466<br />

Mechanical <strong>Steering</strong><br />

selecting replacement mechanical steering<br />

How to Measure <strong>Steering</strong> Cables<br />

“Measure Twice. Order Once.”<br />

New Installation:<br />

Measure cable routing path from wheel<br />

center line to engine connection, as follows:<br />

A = Center line of wheel to gunwale (or<br />

deck, if routed downward),<br />

B = Dash to transom,<br />

C = Gunwale to centerline of cable<br />

connection at centered tiller.<br />

TYPICAL SINGLE STATION ROUTING<br />

C<br />

B<br />

A<br />

mechanicalsteering<br />

STEERING & CONTROLS<br />

For Cable Installations through the Engine<br />

Tilt Tube:<br />

Add A, B & C + 6”, then round up to the next<br />

foot. Order that length cable.<br />

For Cables Mounted to Transom, Splashwell<br />

or Stringer:<br />

Add A, B & C, then subtract 6” and round up to<br />

the next foot. Order that length cable.<br />

A single-cable, starboard drive push-pull mechanical cable<br />

system is shown in this diagram. If your mechanical system is<br />

different than the one depicted and/or you have any questions<br />

about mechanical steering after reviewing this guide, please<br />

contact Teleflex (Mechanical) Technical Service at (610)-495-<br />

7011 or www.tfxmarine.com.<br />

Cable routings (such as those found on pontoon boats) may<br />

vary from this drawing. Confirm length by laying a garden hose<br />

along cable path and measure run from wheel to engine<br />

connection point.<br />

CABLE THROUGH<br />

ENGINE TILT TUBE<br />

SPLASHWELL<br />

CABLE MOUNT<br />

TRANSOM CABLE MOUNT<br />

(similar to stringer type)<br />

Replacement of Existing Cable:<br />

If possible, find the part number stamped on the<br />

plastic jacket of the old cable. If you removed<br />

the old cable, measure for the replacement<br />

cable as follows:<br />

"Y" IN INCHES<br />

For Rotary <strong>Steering</strong> Cable Replacement,<br />

Measure Existing Cable as follows: Measure<br />

plastic cable jacket (“Y” dimension, shown in<br />

above drawing) in inches, add 18”, and round<br />

up to next foot. Order that length cable.<br />

For Rack <strong>Steering</strong> Cable Replacement,<br />

Measure Existing Cable as follows: Measure<br />

plastic cable jacket (“Y” dimension shown in<br />

above drawing) in inches, add 30”, and round<br />

up to next foot. Order that length cable.<br />

For JBS Jet Boat Cable Replacement,<br />

Measure Existing Cable as follows: Measure<br />

cable from tip to tip. (Round up to next foot if<br />

needed for even footage.) Order that length cable.<br />

If your engine does not have a tilt tube cable connection as<br />

shown at above, see “Connection Kits” pages in the back of<br />

this catalog to get the information or visit us on-line at<br />

www.teleflexmorse.com.

Mechanical <strong>Steering</strong> Kits<br />

467<br />

Teleex Rotary Safe-T-QC <strong>Steering</strong> Kits<br />

• Ideal for power steered boats<br />

• Quick response of 3-turn steering<br />

• No-tools cable connection at the helm<br />

• Accepts wheels up to 16" dia<br />

• Replaces all Teleex Safe-T helms made since 1968<br />

• For single station use only<br />

• Single cable conguration<br />

Teleex Complete Kits:<br />

TFM SS13708 <br />

TFM SS13709 <br />

TFM SS13710 <br />

TFM SS13711 <br />

TFM SS13712 <br />

TFM SS13713 <br />

TFM SS13714 <br />

TFM SS13715<br />

TFM SS13716<br />

TFM SS13717<br />

TFM SS13718<br />

TFM SS13719<br />

TFM SS13720<br />

<br />

<br />

<br />

<br />

<br />

<br />

Teleex System Components:<br />

Cables<br />

TFM SSC6204 TFM SSC6217 <br />

TFM SSC6205 TFM SSC6218 <br />

TFM SSC6206 TFM SSC6219 <br />

TFM SSC6207 TFM SSC6220 <br />

TFM SSC6208 TFM SSC6222 <br />

TFM SSC6209 TFM SSC6224 <br />

TFM SSC6210 TFM SSC6226 <br />

TFM SSC6211 TFM SSC6228 <br />

TFM SSC6212 TFM SSC6230 <br />

TFM SSC6213 TFM SSC6232 <br />

TFM SSC6214 TFM SSC6234 <br />

TFM SSC6215 TFM SSC6236 <br />

TFM SSC6216 TFM SSC6238 <br />

TFM SSC6240 <br />

Helm<br />

TFM SH5094 <br />

Bezels<br />

TFM SB27484P <br />

TFM SB27483P <br />

Parts<br />

TFM SA35680P <br />

TFM SH5023 <br />

TFM SA27620P <br />

TFM SA39329P <br />

TFM 2724514P <br />

SH91523<br />

STEERING & CONTROLS

468<br />

Mechanical <strong>Steering</strong><br />

Teleex NFB "No Feed Back" Rotary Kits<br />

• 4.2 Turns lock-to-lock<br />

• Single cable conguration for most boats<br />

• Drop-in replacement for Safe-T steering<br />

• For non-power-steered single engines<br />

• V-6 or smaller: 50 MPH or less<br />

• Wheels to 16" dia<br />

Teleex Complete Kits:<br />

TFM SS14710<br />

TFM SS14711<br />

TFM SS14712<br />

TFM SS14713<br />

TFM SS14714<br />

TFM SS14715<br />

TFM SS14716<br />

TFM SS14717<br />

TFM SS14718<br />

TFM SS14719<br />

TFM SS14720<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

STEERING & CONTROLS<br />

Teleex System Components:<br />

Cables<br />

TFM SSC6204 TFM SSC6217<br />

TFM SSC6205 TFM SSC6218<br />

TFM SSC6206 TFM SSC6219<br />

TFM SSC6207 TFM SSC6220<br />

TFM SSC6208 TFM SSC6222<br />

TFM SSC6209 TFM SSC6224<br />

TFM SSC6210 TFM SSC6226<br />

TFM SSC6211 TFM SSC6228<br />

TFM SSC6212 TFM SSC6230<br />

TFM SSC6213 TFM SSC6232<br />

TFM SSC6214 TFM SSC6234<br />

TFM SSC6215 TFM SSC6236<br />

TFM SSC6216 TFM SSC6238<br />

TFM SSC6240<br />

Bezel<br />

TFM SB27150P <br />

Helm<br />

TFM SH4910 <br />

Parts:<br />

TFM SB27483P <br />

TFM SA38603P <br />

TFM SA39329P <br />

TFM SH91526P* <br />

*Request Item

Mechanical <strong>Steering</strong><br />

469<br />

Teleex "BM" Rack & Pinion <strong>Steering</strong> Kits<br />

• 4 turns lock-to-lock for power steered boats in which No<br />

FeedBack systems are not required<br />

• Accepts wheels up to 16" dia<br />

• BM Rack replaces 1984-date Teleex “The Rack” steering<br />

without dash modication<br />

• For single station use only<br />

• Single-cable conguration<br />

Teleex Complete Kits:<br />

TFM SS14110 <br />

TFM SS14111 <br />

TFM SS14112 <br />

TFM SS14113 <br />

TFM SS14114 <br />

TFM SS14115 <br />

TFM SS14116<br />

TFM SS14117<br />

TFM SS14118<br />

TFM SS14119<br />

TFM SS14120<br />

<br />

<br />

<br />

<br />

<br />

Teleex System Components:<br />

Cables<br />

TFM SSC13412<br />

TFM SSC13413<br />

TFM SSC13414<br />

TFM SSC13415<br />

TFM SSC13416<br />

TFM SSC13417<br />

TFM SSC13418<br />

TFM SSC13419<br />

TFM SSC13420<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Cables - Old Style "The Rack" Cable (1984-96)*<br />

TFM SSC12412 <br />

TFM SSC12413 <br />

TFM SSC12414 <br />

TFM SSC12415 <br />

TFM SSC12416<br />

TFM SSC12417<br />

<br />

<br />

*Does Not t "New Style"<br />

rack systems and is not<br />

TFM SSC12418 interchangeable with<br />

TFM SSC12419 SSC134 cables<br />

TFM SSC12420 <br />

STEERING & CONTROLS<br />

Helm<br />

TFM SH5210<br />

Bezel<br />

TFM SB39526P<br />

Parts:<br />

TFM SB27448P<br />

TFM SB27449P<br />

TFM SH91610P<br />

TFM SA39329P

470<br />

Mechanical <strong>Steering</strong><br />

Teleex <strong>Steering</strong> Connection Kits<br />

TFM SA27253P<br />

TFM SA27254P<br />

TFM SA27149P<br />

TFM SA27055P<br />

TFM SA27274P<br />

TFM SA27275P<br />

TFM SA27314P<br />

TFM SA27329P<br />

TFM SA27361P<br />

TFM SA39329P<br />

TFM SA27620P<br />

TFM SA37868P<br />

TFM 3924516P<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

STEERING & CONTROLS

Mechanical <strong>Steering</strong><br />

471<br />

Morse 290 <strong>Steering</strong> Components<br />

Available components and service items<br />

for Morse mechanical steering systems are<br />

listed below.<br />

MOR 308559 <br />

MOR 308561 <br />

MOR 309305 <br />

Davis Cable Buddy<br />

<strong>Steering</strong> cable lubrication system<br />

Includes:<br />

7/8" x 14 thread S/S nut<br />

Max-Lube, 90ml (3 oz)<br />

Filler tube<br />

• Fits most motors<br />

• Virtually eliminates cable wear<br />

o<br />

• Will prevent freezing to -40<br />

DIN 420<br />

Morse <strong>Steering</strong> Connection Kits<br />

Most boats and engines are supplied complete with steering cable<br />

connection kits. Listed below are speciality kits which are available<br />

for Morse <strong>controls</strong>.<br />

MOR 64480 <br />

MOR 300614 <br />

MOR 300617 <br />

Teleex Morse Command 290<br />

Replacement Cables<br />

Command 290 Rotary <strong>Steering</strong> Cable replaces<br />

304411-000-XXX.<br />

TFM SSC5210 <br />

TFM SSC5211 <br />

TFM SSC5212 <br />

TFM SSC5213 <br />

TFM SSC5214 <br />

TFM SSC5215 <br />

TFM SSC5216 <br />

TFM SSC5217 <br />

TFM SSC5218 <br />

Davis Lube II<br />

Allows sticky, hard to move steering rods to be<br />

properly and easily lubricated for smooth, easy<br />

steering action. The system includes a stainless<br />

steel lubricating nut with an oil seal and a grease<br />

(zerk) tting. This lubricator’s unique design keeps moisture and<br />

contaminants out while enabling you to pour or pump several<br />

types of lubricant in. Works for both mechanical and hydraulic<br />

systems. Fits all major US and foreign motors (7/8" x 14 pitch<br />

threads).<br />

• Salt and fresh water use<br />

DIN 425<br />

OMC <strong>Steering</strong> Cable Kit<br />

To ret “external steer” systems.<br />

Replaces obsolete steering cable with<br />

standard cable. Simply install a new<br />

standard helm kit in the boat and attach the ball and tube assembly<br />

at the transom.<br />

WES OMC-KIT<br />

Teleex Big-T Helm<br />

Inboards to 34 feet with one engine. Also<br />

suitable for stern drive boats with powerassisted<br />

steering. Big-T systems accept<br />

steering wheels up to 20" diameter.<br />

• Heavy duty helm<br />

• 3 turns lock-to-lock<br />

• Standard 3/4" tapered shaft<br />

• S/S cable outlet ends<br />

• Uses SSC72 series cables<br />

TFM SH5000<br />

STEERING & CONTROLS

472<br />

Hydraulic <strong>Steering</strong><br />

BayStar brings the same safety and comfort now common on larger outboard powered<br />

boats to outboard powered boats with a maximum 150 HP* (total) or less. BayStar<br />

kits come complete with everything needed for an install. The cylinder utilizes the factory outboard<br />

engine supplied drag link for simplied installation. For your convenience two lengths of 20’ cut to<br />

t tubing are supplied (2 x 20’ length). *Note* The ttings on the BayStar cylinder and the hose end<br />

of the tubing (the swaged on tting) are different from SeaStar and are not interchangeable.<br />

TEL HK-4200A <br />

Kit includes:<br />

• BayStar Helm Pump (HH4016)<br />

• BayStar Cylinder (HC4645)<br />

• BayStar Tubing Kit (HT4425)<br />

• 2 Bottles of hydraulic steering uid (HA5430)<br />

• Filler Kit (HA5438)<br />

STEERING & CONTROLS

Hydraulic <strong>Steering</strong><br />

473<br />

Teleex SeaStar <strong>Steering</strong><br />

The SeaStar Hydraulic <strong>Steering</strong> System is designed to handle Outboard , Stern drive and Inboard engines in boats up to 50<br />

feet. System selection, installation and service are substantially simplied with just three major components – helm, cylinder<br />

and tube or hose. These basic components are necessary in all applications. However as the system variables increase (e.g.:<br />

multiple engines, rudders, steering stations and autopilots), additional components may be required.<br />

• Suitable for both pleasure and commercial applications<br />

• Extra steering stations and/or auto-pilot are easily added<br />

SELECTING A SYSTEM<br />

1. Locate the type of boat you have in column A of the chart below. From the chart, select the steering system<br />

best suited to your boat. You may want to review the specic features for each system.<br />

2. Proceed to the appropriate section of the catalogue for a detailed component selection, ie. front or side mount<br />

system. If your specic engine is not listed in the application charts, select the next alternative from the chart.<br />

STEERING & CONTROLS<br />

RUNABOUT Intended for day boating. Typically a single engine<br />

but can be a dual engine boat. Includes tournament ski boats and<br />

performance outboards.<br />

BASS BOAT Single engine outboard powered boat designed<br />

specically for shing in protected waters. Typically performance<br />

oriented.<br />

INFLATABLES Boats manufactured of waterproofed fabric<br />

which are inated with air in order to achieve their shape. The<br />

bottom of the hull may be made of fabric or breglass. They<br />

typically have narrow transoms. Boats may be single or dual<br />

engine.<br />

WORK / COMMERCIAL / RESCUE Any of the previously<br />

listed applications involved in revenue producing or rescue<br />

activities. Typically a very severe service environment<br />

CENTRE CONSOLE Boat with control station located on a<br />

centerline mounted console. Generally designed specically for<br />

shing. Boats may be single or dual engine.<br />

CRUISER Cuddy/express/bridge cruiser primarily designed for<br />

cruising. It has overnight accommodations. Typically rigged with<br />

two steering stations. Boats may be single or dual engine.<br />

FISH ‘N’ SKI Single engine outboard powered boat designed for<br />

day shing or skiing in protected waters.<br />

OTHER FISH BOAT Boat primarily designed and equipped<br />

for offshore shing. May be rigged with a second steering station.<br />

Boats may be single or dual engine.

474<br />

Hydraulic <strong>Steering</strong><br />

Teleex SeaStar <strong>Steering</strong> Kits<br />

Includes helm, mounting hardware, oil, instructions & cylinder to t most out-boards made since 1984. For hose<br />

length, measure intended hose routing or existing cable path and add 2 feet to allow for engine tilt and steering cylinder<br />

movement. (steering wheel sold separately) optional tilt steering helms and helm mounting kits are available for repairs<br />

and service of existing SeaStar systems.<br />

STEERING & CONTROLS<br />

Teleex SeaStar <strong>Steering</strong> Kits<br />

• Include's HH5271 helm, HC5345 cylinder, HA5430 (2)<br />

oil, mounting hardware & hoses<br />

• 5 turns lock to lock<br />

• Single or dual up to 300 hp<br />

• 60 mph or less<br />

Kits, no hose (select hose kit from list)<br />

TEL HK-6400A <br />

TEL HK-6500Y <br />

Kits, complete w/ hose<br />

TEL HK-6316A <br />

TEL HK-6318A <br />

TEL HK-6320A <br />

Teleex SeaStar PRO Premium <strong>Steering</strong> Kit<br />

• Include's HH5770 helm, HC5345 cylinder, HA5430 (2)<br />

oil and mounting hardware<br />

• 4.25 turns lock to lock<br />

• Single outboards to 300 hp<br />

• For boats capable of 60 MPH or more<br />

TEL HK-7400A <br />

SeaStar Hose Kits<br />

TEL HO-5102 <br />

TEL HO-5104 <br />

TEL HO-5106 <br />

TEL HO-5108 <br />

TEL HO-5110 <br />

TEL HO-5112 <br />

TEL HO-5114 <br />

TEL HO-5116 <br />

TEL HO-5118 <br />

TEL HO-5120 <br />

TEL HO-5122 <br />

TEL HO-5124 <br />

TEL HO-5126 <br />

TEL HO-5140 <br />

The Basic System Consists Of Three Main Components:<br />

1/ The Helm Unit - The SeaStar helm pump is an axial piston pump specically designed for manual steering. It has a<br />

built-in lock valve to prevent the steering load from feeding back to the driver. The lock valve will not allow the rudder<br />

or drive unit to move until you move it with the steering wheel. The lock valve section of the helm also includes a relief<br />

valve. This relief valve provides over-pressure protection for mechanical components and hydraulic hoses and ttings.<br />

2/ The Cylinder - The most important differences between the variety of SeaStar steering systems available is the<br />

cylinder selection. The SeaStar system has a cylinder for most steering applications.<br />

3/ Hoses and Tubes - Required for the uid to ow under pressure from the helm pump to the cylinder.<br />

The objective is to match the steering system to the requirements of the vessel. This depends on:<br />

1) Type of vessel (i.e.: planing or displacement)<br />

2) Type of propulsion system in the vessel (i.e.: Outboard, Sterndrive, Inboard, etc.)<br />

3) The number of engines or rudders<br />

4) The total power of the engines (i.e.: Horsepower)<br />

Next choose a cylinder that best meets these requirements. Once the cylinder has been selected, the size of the helm<br />

pump is predetermined.

Hydraulic <strong>Steering</strong><br />

475<br />

Teleex SeaStar Hydraulic <strong>Steering</strong><br />

System selection, installation and service are substantially simplied with just two components - helm and cylinder. Three types<br />

of cylinders are available to handle the variables in OB, I/O and inboard power suitable for pleasure and commercial boats. Extra<br />

steering stations and/or an auto-pilot are easily added. SeaStar I and II helms differ in displacement to accommodate various<br />

cylinder volumes. Either of the new SeaStar helms along with an HA-5418 backmount kit will retrot an equivalent old style<br />

SeaStar helm into an existing dash cut-out. The new and old helms will work perfectly together in a twin station system.<br />

TEL HH-5770 <br />

TEL HH-5271 <br />

TEL HH-6541 <br />

TEL HH-5272 <br />

TEL HH-5273 <br />

TEL HH-5217 <br />

Teleex Hydraulic Cylinders<br />

Front Mount Cylinder Features<br />

• Balanced, even number of steering wheel turns from midships to hard over<br />

• Fits most big new outboard engines (except power assist models)<br />

• Suitable for autopilot interface<br />

• Subject to splashwell/bracket depth clearance<br />

Side Mount Cylinder Features<br />

• Alternative to front mount type if motor well space too restrictive<br />

• Unbalanced, uneven number of wheel turns from amidships to hard over left and right<br />

• Suitable for outboard engines with power steering<br />

• Not suitable for autopilot interface (Single Cylinder Only)<br />

• Subject to adequate splashwell with clearance<br />

Stern Mount Cylinder Features<br />

• These cylinders attach directly to the stern drive units.<br />

Four models are available to handle most applications<br />

STEERING & CONTROLS<br />

Inboard Mount Cylinder Features<br />

• These cylinders feature stainless steel ball joints and two axis<br />

articulation, simplifying installation<br />

Teleex Parts and Accessories: SeaStar Tie Bars<br />

TEL HO-5001A<br />

TEL HO-5004<br />

TEL HO-5006A<br />

TEL HO-5007<br />

TEL HO-5008A<br />

TEL HO-5072A<br />

TEL HO-6001<br />

TEL HO-6010

476<br />

Hydraulic <strong>Steering</strong><br />

STEERING & CONTROLS<br />

Teleex SeaStar Service Components<br />

TEL HA-5430<br />

TEL HA-5440<br />

TEL HS-5151<br />

TEL HS-5152<br />

TEL HS-5153<br />

TEL HS-5154<br />

TEL HS-5155<br />

TEL HS-5156<br />

TEL HS-5157<br />

TEL HS-5161<br />

TEL HS-5176<br />

TEL HS-5182<br />

TEL HS-5183<br />

TEL HS-5184<br />

TEL HT-5092<br />

TEL HT-5095<br />

TEL HT-5097<br />

TEL HT-5100<br />

TEL HB-0573<br />

Teleex SeaStar Accessories<br />

TEL HA-5417<br />

TEL HA-5418<br />

TEL HA-5419<br />

TEL HA-5424<br />

TEL HA-5450<br />

TEL HA-5431<br />

TEL HA-5432<br />

TEL HA-5438<br />

TEL HA-5820<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Teleex SeaStar Cylinder Adapter Plates<br />

TEL HO-5035<br />

TEL HO-5038A<br />

TEL HO-5043<br />

TEL HO-5367<br />

TEL HO-5028<br />

TEL HO-5039<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Teleex Outboard Add-A-Station/Auto Pilot Kit<br />

Contains ttings for adding either a steering station or an auto pilot<br />

to an existing SeaStar outboard steering system. Includes 25' of<br />

3/8" nylon tubing and non-vented ll plug for helm at upper most<br />

station<br />

TEL HF 5501 <br />

Stern Drive Add-A-Station/Auto Pilot Kit<br />

Contains ttings for adding either a steering station or an auto pilot<br />

to an existing SeaStar stern drive steering system.<br />

TEL HF 5502 <br />

Teleex SeaStar Fittings Kits<br />

TEL HF-5512<br />

TEL HF-5513<br />

TEL HF-5507<br />

TEL HF-5508<br />

Teleex SeaStar Fittings<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

The ttings below are 3/8" compression ttings which utilize a<br />

9/16"-24 extra ne thread.<br />

TEL HF-5524 <br />

TEL HF-5526 <br />

TEL HF-5527 <br />

TEL HF-5528 <br />

TEL HF-5529 <br />

TEL HF-5534 <br />

TEL HF-5538 <br />

TEL HF-5518 <br />

TEL HF-5519 <br />

TEL HF-5520 <br />

Teleex Bulkhead Hose Kits<br />

For abusive environments, SeaStar outboard<br />

hose kits are equipped with protective<br />

coverings on both ends. One end includes a<br />

pigtail cover with connecting nut and bulkhead<br />

mounting plate, while the second has a bend protector.<br />

TEL HO-8108 <br />

TEL HO-8122 <br />

TEL HO-8122 <br />

TEL HO-8124

Hydraulic <strong>Steering</strong><br />

477<br />

Teleex SeaStar 1250V-1275V Variable Turns Hydraulic <strong>Steering</strong><br />

Capilano Helms and Cylinders are engineered and manufactured for heavy duty marine usage, and are suitable for commercial, work<br />

boat and pleasure boat applications. Capilano Hydraulic <strong>Steering</strong> has been designed to meet ABS, Lloyds and DNV specications.<br />

For all Pleasure and Work Boat applications 38ft. (11.5m) and smaller with some exceptions.<br />

Known world-wide for their ruggedness and reliability, the Capilano 1250V and 1275V steering systems are designed to meet ABS,<br />

Lloyds, and Det Norsk Veritas specications. The cast helm housing contains its own reservoir and cylinders are tted with bleeder<br />

valves to facilitate automatic purging. The variable displacement feature enables the user to adjust the steering wheel turns to suit<br />

various manoeuvre and weather conditions.<br />

Helm Pumps Displacement Relief Valve Ports<br />

TEL HH-5250 1.7 cu.in. - 3.4 cu.in. 1000 PSl 3/8" NPT<br />

TEL HH-5275 2.7 cu.in. - 5.4 cu.in. 1000 PSl 3/8" NPT<br />

Helm pump shaft: 3/4" standard taper with 5/8" NF threads<br />

N.B. Fitting kits ordered separately<br />

Teleex 1250V-1275V Cylinder Hoses<br />

<strong>Steering</strong> systems installed with copper tubing require short pieces of<br />

exible hose to accommodate slight cylinder movement. Hoses are supplied<br />

with 1/2" swivel are nuts on each end.<br />

Single cylinder hose kit<br />

TEL HA-5731 <br />

Twin cylinder installations (Four hoses required)<br />

TEL HA-5732 <br />

TEL HA-5733 <br />

Teleex 1250V-1275V Fitting Kits<br />

Single steering station and additional steering station S.A.E. are tube<br />

tting kits are available for use with 1/2" O.D. and 5/8" O.D. copper tubing.<br />

TEL HF-5590 <br />

TEL HF-5591 <br />

Teleex 1250V-1275V Tubing/Hoses Recommendations<br />

The use of soft refrigeration type copper tubing is recommended for<br />

optimum performance. If hydraulic hose must be used, select a hydraulic<br />

hose that is rated for 1000 PSl - 70 bar working pressure, and has a very low<br />

volumetric expansion rating. Recommended tubing - hose diameter.<br />

• For systems using model 1250V<br />

• 1/2" O.D. copper tubing, 1/2" I.D. hydraulic hose<br />

• If longest cylinder to helm run is over 40' use 5/8" tubing/hose<br />

• For systems using model 1275V<br />

• 5/8" O.D. copper tubing<br />

• 5/8" I.D. hydraulic hose<br />

STEERING & CONTROLS

478<br />

<strong>Steering</strong> / Glendenning<br />

STEERING & CONTROLS<br />

Teleex SeaStar<br />

Power Assist <strong>Steering</strong><br />

Systems<br />

Offers boat owners a new level of<br />

steering comfort and control by<br />

reducing wheel effort. Upgrade<br />

for your outboard, stern drive<br />

or inboard powered boat that is already equipped with hydraulic<br />

steering. SeaStar P/A easily ties into the existing SeaStar hydraulic<br />

steering system.<br />

TEL PA-1200-2 <br />

TEL PA-1315* <br />

* Request Item<br />

Features:<br />

• Easy as the power steering in your car<br />

• Dramatically increases steering comfort by reducing effort at<br />

the steering wheel<br />

• Easily-installed upgrade to existing SeaStar or SeaStar PRO<br />

manual system<br />

• Pro version available for SeaStar PRO type applications<br />

• Number of turns lock to lock remains the same as existing<br />

manual hydraulic system<br />

• Compatible with SeaStar Power Purge systems<br />

• Compatible with autopilots<br />

• Rugged, reliable and compact<br />

• Wiring harness included<br />

• Ignition protected (SAE J-1171)<br />

• 12V and 24V operation available<br />

• ABYC, CE, NMMA, ISO 10592 Approved<br />

Glendinning Smart Actuator II<br />

Teleex Power Purge Jr<br />

The average service on a SeaStar or<br />

BayStar system is about 30 minutes. With<br />

the power purge system this time can be<br />

reduced to about 10 minutes.<br />

Convenient, portable, quick connect<br />

ttings, clip on 12 volt hook-up,<br />

contaminant screen and a solid steering<br />

feel all add up to a valuable tool.<br />

TEL HA-5445-2<br />

No matter what type of engine or transmission your boat is equipped with, Glendinning’s Smart Actuator II<br />

is easy to install, more reliable in performance. The Smart Actuator II can handle one, two, or three engines<br />

(inboard, outboard, stern drive, or water jet) PLUS trim and tilt control of your engine with the Integrated<br />

Trim Control (optional) built into the control head handle for convenient on the y adjustments.<br />

• Single Lever Control - gear and throttle control are combined in a single handle, providing<br />

complete control over the speed and direction position of one engine and transmission<br />

• “Posi-lock” Gear Lockout Capability - for maximum safety around the dock, the transmission<br />

can be locked in neutral, allowing engine throttle operation only<br />

• Selectable Station Transfer Methods - transfer control from one station to another while<br />

maintaining engine speed or only when control handles are in neutral gear<br />

• Station Lockout Capability - prevents transfer of control from one station to another. The active<br />

station in control of the boat can lockout all other helm stations from taking control<br />

• Adjustable High Idle Settings - choose between 7 different high idle speed settings<br />

• Control Head Keypad Lights Dimmer - Dim or increase brightness of the control head keypad<br />

lights for daylight or nighttime operation<br />

• Dual Battery Inputs - addresses one of the most critical needs for any electronic engine control - battery power.<br />

Complete Controls includes the capability to receive power from 2 independent battery sources, ensuring that<br />

control system operation is never interrupted<br />

• Various Station Options - choice of control head station colours (chrome, gold, or black) and types (2-button,<br />

4-button, single engine, handheld remote, or sidemount <strong>controls</strong>)<br />

• “Optional” Mechanical Gear / Throttle Backup - in the event the system should ever experience an<br />

unrecoverable failure, this option allows you to bypass the normal system processor and continue control of<br />

your boat’s propulsion system<br />

Please Inquire For a Quote on a System

SeaStar Volumes & Capacity Charts<br />

479<br />

VOLUMES & CAPACITIES<br />

STEERING & CONTROLS

480<br />

SeaStar Outboard - Front Mount Guide<br />

STEERING & CONTROLS

SeaStar Outboard - Front Mount Guide<br />

481<br />

STEERING & CONTROLS

482<br />

SeaStar Outboard - Side Mount Guide<br />

STEERING & CONTROLS<br />

-2

SeaStar Inboard Guide<br />

483<br />

STEERING & CONTROLS

484<br />

SeaStar Sterndrive Guide<br />

STEERING & CONTROLS

SeaStar Sterndrive Guide<br />

485<br />

STEERING & CONTROLS

MODELS FOR<br />

FOUR STROKE MOTORS<br />

Advanced engineering, these models best handle the<br />

torque, weight and heft of 4 strokes.<br />

71090<br />

71091<br />

5 Position<br />

Manual<br />

5 Position<br />

Manual<br />

71092<br />

71095<br />

71096<br />

Hydraulic<br />

Electric<br />

MODELS FOR<br />

TWO STROKE MOTORS<br />

Designed for lighter weight, lower horse power “kicker”<br />

motors, these versatile and compact brackets have set<br />

the standard for over three decades.<br />

71033<br />

71039<br />

71056<br />

Welded<br />

Stainless Steel<br />

Stainless Steel<br />

71040<br />

71042<br />

71057<br />

71074<br />

71075<br />

71078<br />

Aluminum<br />

Fixed<br />

The most complete line of Auxiliary Outboard Motor<br />

Brackets available. Choose from 14 models, 2 or 4 stroke<br />

motors for runabouts, powerboats and sailboat transoms.<br />

Product<br />

Number<br />

Product<br />

Name<br />

Capacity<br />

(HP)<br />

Capacity<br />

(lbs)<br />

4-Stroke<br />

Motors<br />

2-Stroke<br />

Motors<br />

Vertical<br />

Travel<br />

71040 Aluminum Aux.<br />

to 8 59 8.5”<br />

Motor Bracket<br />

71042 Aluminum Aux.<br />

7.5 to 12 82 14.25”<br />

Motor Bracket<br />

71039 Stainless Steel<br />

7.5 to 12 82 14.25”<br />

Aux. Motor Bracket<br />

71074 Stationary Outboard<br />

to 15 75<br />

Fixed<br />

Motor Bracket<br />

71075<br />

Stationary Outboard<br />

to 15 75<br />

Fixed<br />

Motor Bracket<br />

71078<br />

Stationary Outboard<br />

to 15 75<br />

Fixed<br />

Motor Bracket<br />

71056<br />

Stainless Steel<br />

7.5 to 20 115 11.25”<br />

Aux. Motor Bracket<br />

Aluminum Aux.<br />

71057 7.5 to 20 115 11.25”<br />

Motor Bracket<br />

Stainless Steel Aux.<br />

71033 7.5 to 25 118 11.25”<br />

Motor Bracket<br />

Hydra Powered<br />

71095 to 25 148 13.25”<br />

Outboard Motor Bkt.<br />

Motor Bracket for<br />

71091 7.5 to 25 175 15.5”<br />

4-Stroke Motors<br />

Manual “Easy Pump”<br />

71092 7.5 to 25 175 14”<br />

Hyd. Lift Motor Bkt.<br />

Motor Bracket for<br />

71090 7.5 to 30 169<br />

4-Stroke Motors<br />

9.5”<br />

Hydra Powered<br />

71096 25 to 40 248<br />

13.25”<br />

Outboard Motor Bkt.<br />

MADE IN THE U.S.A.<br />

TO EXACTING STANDARDS<br />

For over 35 years, Garelick/EEz ® -In has led the field in<br />

Auxiliary Outboard Motor Brackets! As outboard motors<br />

have changed, so has our selection of brackets. We now<br />

offer five distinct styles ranging from manual lift/lower<br />

models to hydraulic powered systems designed for heavier,<br />

high torque, 4 stroke motors.<br />

GARELICK Mfg Co<br />

644 2nd Street, P.O. Box 8, St. Paul Park, MN 55071<br />

Voice 651.459.9795 • Fax 651.459.8269<br />

Form #962<br />

TIPS FOR SELLING<br />

AUXILIARY<br />

OUTBOARD<br />

MOTOR<br />

BRACKETS<br />

WWW.GARELICK.COM<br />

R<br />

R

SUPERIOR<br />

IN SEVERAL WAYS<br />

Discuss the quality of the components. We select durable raw<br />

materials. They contribute to a product that brings ease of<br />

operation to the user by helping to assist with the lift as it<br />

counterbalances and offsets the weight of the motor. Every model<br />

comes with the correct number of husky stainless steel springs,<br />

bushings and poly washers for easier lifting and lowering. High<br />

tensile alloy aluminum flexes for the torque of a motor, similar to an<br />

aircraft wing. All aluminum models are clear or black anodized for<br />

added corrosion resistance. Our hefty 304 stainless steel models,<br />

some even with reinforced welds, provide greater strength. All<br />

models come with a thick 2” poly mounting board uniquely<br />

designed and maintenance free, shaped to accommodate the width<br />

dimensions of wider locking clamps. Stainless models are<br />

equipped with a unique “built-in” transom angle adjustment to<br />

compensate for positive or negative trim so often needed on<br />

sailboats with reverse angle transoms. Comfortable 4-position<br />

height locking handles are spring loaded and snap locked in either<br />

up or down positions to help adjust for a boat’s weight distribution or<br />

sea conditions. Positive Safety Locks and twist knobs provide<br />

added security, locks the bracket in its up, stored position. With so<br />

many moving parts, all working in harmony, we can’t skimp on<br />

anything; and we don’t!<br />

MADE IN THE U.S.A.<br />

2” POLY<br />

MOUNTING<br />

BOARD<br />

S.S. TORSION<br />

SPRINGS<br />

POSITIVE SAFETY<br />

LOCKS<br />

AUXILIARY OUTBOARD<br />

MOTOR BRACKETS<br />

1<br />

PURPOSE OF<br />

A BRACKET<br />

"The handiest way to equip a small sailboat with auxiliary power - or a fishing<br />

craft with a low powered trolling engine - is to mount an outboard motor on the<br />

transom by means of a retractable bracket. This kind of bracket allows the<br />

boatman to lift the motor out of the water when not in use without removing it<br />

from the bracket." - Time/Life Library of Boating<br />

2<br />

NO<br />

APOLOGIES!<br />

Never apologize for price. Top quality and selection cost money; explain the<br />

quality and show the dealer or boat owner our built-in features. Durable<br />

components afford added safety and longer product life. Let them choose<br />

from the most comprehensive offering available for 2 and 4 stroke motors.<br />

3<br />

MAKING THE<br />

RIGHT SELECTION<br />

Depending on the length of the shaft, horsepower and weight of the outboard<br />

motor, combined with hull design and the proper Garelick/EEz®-In motor<br />

bracket selected, optimum motor performance, durability and safety can be<br />

achieved. The geographic (i.e., fresh or saltwater) location, that the bracket is<br />

sold or intended to be used in, will help determine whether an Anodized<br />

aluminum or stainless steel model should be selected. A properly matched<br />

motor, hull and bracket will contribute to safer operation and convenient<br />

auxiliary power. Refer to our Outboard Motor Bracket Selection Chart (also in<br />

our catalog) as a helpful guide.<br />

SATISFIED CUSTOMERS<br />

YEAR AFTER YEAR<br />

“I thought I’d let you all know how very satisfied I am with<br />

the motor lift system. It is working wonderfully. The location<br />

and height we installed it, worked out perfectly! This past<br />

weekend we trolled with it both days in 4’ to 5’ seas. The<br />

motor never got washed over and the prop never came out<br />

of the water either. Everyone at Knife River Marina is very<br />

impressed and a bit jealous. I hear lots of (oo-ahhas) and<br />

have had several inquiries about your product. I think I’ll be<br />

seeing more of your motor lifts in our marina soon.”<br />

- Joe Perrault Lakeland, MN - Regarding Model 71095<br />

4<br />

INSTALL, CARE,<br />

MAINTENANCE<br />

Every bracket comes complete with easy, step-by-step installation<br />

instructions and recommendations. Our important safety guidelines for<br />

installation and operating instructions should become very familiar to the<br />

boatman. * Always recommend the use of a heavy-duty Motor Safety<br />

Cable. (71030 included with all 4 stroke models)<br />

Be candid about maintenance. Although we provide for many<br />

maintenance free parts, owners should be told that just like other parts of<br />

their boats, moving components and hardware do sometimes loosen from<br />

vibration and should be checked often for retightening. Many factors,<br />

depending on local conditions, may contribute to minor corrosion.<br />

Aluminum and stainless, like other metals are not completely free from<br />

corrosion attack. To assure a continued bright finish, proper care such as<br />

regular fresh water rinsing and periodic cleaning with a mild abrasive<br />

cleaner should be done. A refurbish program is available by writing to our<br />

company at the address on the back of this brochure.<br />

5<br />

PROMOTE!<br />

Don't leave outboard motor bracket promotion to others. Promote,<br />

promote, promote! All models come in self-selling display boxes. Display<br />

your inventory of brackets, either on display stands with motors attached<br />

or mount a bracket and motor on boats in your showroom. For relatively<br />

few dollars, a properly fitted and installed motor bracket offers a degree<br />

of safety, convenience and piece of mind that auxiliary power can<br />

provide in an emergency. Tout that fact!<br />

IMPORTANT GUIDELINES<br />

Failure to observe these points could result in personal injury<br />

or damage to bracket, motor and boat!<br />

· Install bracket only in the "up" position.<br />

· Do not exceed the stated H.P. rating or weight.<br />

· Make sure the motor clamps are tight before use.<br />

· Use a safety cable when operating your motor.*<br />

· Remove your motor from the bracket when trailering.<br />

· Operate motor in lowest possible position, at low speeds<br />

and refrain from sharp turns.<br />

· Do not raise or lower bracket when motor is running.<br />

· Raise and tilt motor when not in use.<br />

· Avoid contact with moving parts.<br />

· Keep pivot bolts lubricated to ensure smooth operation.<br />

R

488<br />

Motor Brackets<br />

STEERING & CONTROLS<br />

Garelick Stainless Steel<br />

Outboard Motor Brackets<br />

• For use with motors equipped with long<br />

shafts and/or electric start<br />

• Made of 304 reinforced stainless steel with a<br />

2" poly mounting board<br />

• Stainless torsion springs<br />

• Adjustable transom angle<br />

• Stainless steel guide pins<br />

• Vertical travel: 11-1/4"<br />

• Mounting board: 9-1/2"W x 10-1/4"H x 2"T<br />

• Mounting bracket: 7-5/8"W x 7-1/8"H<br />

Motor Weight Not<br />

Part #<br />

H.P. Rating<br />

to Exceed<br />

GAR 71033* <br />

GAR 71056 <br />