Disaster Management Plan - Barmer

Disaster Management Plan - Barmer

Disaster Management Plan - Barmer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Disaster</strong> <strong>Management</strong> <strong>Plan</strong><br />

OIL & GAS CAIRN’S RAJASTHAN UPSTREAM<br />

FACILITY<br />

9 th September 2010<br />

Prepared for<br />

Cairn India Limited<br />

Prepared by:<br />

Environmental and Geospatial Solutions<br />

3/14, 1st Cross Street, 1st Main Road, Kalaimagal Nagar, Ekkatuthangal, Chennai – 32<br />

044- 4271 9815, 6515 2789, mails@egssindia.com<br />

www.egssindia.com

CONTENTS<br />

Executive Summary 1<br />

Part 1: General 4<br />

1 Introduction 5<br />

1.1 <strong>Disaster</strong> <strong>Management</strong> 7<br />

1.2 Description of CIL Site 11<br />

1.3 District Profile – Social, Economic & Demographic 15<br />

1.3.1 General Profile 15<br />

1.3.2 Demography 17<br />

1.3.3 Socio- Economic Profile 17<br />

1.4 <strong>Disaster</strong> <strong>Management</strong> Philosophy 18<br />

1.5 Theme 19<br />

1.6 Objectives 19<br />

1.7 Scope of Work 20<br />

1.8 Methodology 20<br />

2 Vulnerability Assessment and Risk Analysis 23<br />

2.1 Man-Made Hazards Assessment 24<br />

2.1.1 Fires 24<br />

2.1.2 Accidents 25<br />

2.1.3 Other Hazards 25<br />

2.2 Vulnerability Analysis of Cairn Operations 25<br />

2.2.1 Fire and Explosion Risk Assessment at MPT 26<br />

2.2.2 Fire and Explosion Risk Assessment at RGT 41<br />

2.3 Hazard Mapping 47<br />

2.3.1 Mapping of hazard zones for MPT and RGT 48<br />

2.3.2 Mapping of Hazard Zones for well fields 49<br />

2.3.3 Mapping of Hazard Zones for Pipelines 50<br />

2.4 Natural Hazards Assessment 50<br />

2.4.1 Floods 51<br />

2.4.2 Earthquake 51<br />

2.4.3 Drought 52<br />

2.4.4 Sandstorm 52<br />

2.4.4 Epidemics 52<br />

3 Preventive Measures 54<br />

[i]

3.1 Overview of Recent <strong>Disaster</strong>s 54<br />

3.1.1 Jaipur Fire Incident 54<br />

3.1.2 Mexican Oil Spill 55<br />

3.2 Human/ Industry Induced <strong>Disaster</strong>s 56<br />

3.2.1 Potential causes of fire: 56<br />

3.2.2 Preventive Measures Adopted by Cairn 56<br />

3.2.3 Prevention of other Man-made Risks 58<br />

3.3 Natural <strong>Disaster</strong>s 60<br />

3.3.1 Preventive and Mitigation Measures for Floods 60<br />

3.3.2 Earthquake Preparedness and Mitigation 62<br />

3.3.3 Other Preparedness Measures 65<br />

3.4 Training Needs Analysis 66<br />

4 Mainstreaming DM Concerns into Developmental <strong>Plan</strong>s/Programmes 67<br />

4.1 <strong>Disaster</strong> Development Continuum 67<br />

4.1.1 <strong>Disaster</strong>s affect development 67<br />

4.1.2 Development affects disasters 68<br />

4.2 Negative Realm 69<br />

4.3 Positive Realm 70<br />

4.4 National Development Schemes Addressing DRR 70<br />

4.5 Role of CIL 71<br />

4.5.1 CIL Development Initiatives 71<br />

4.5.2 Civil Society Partnership 72<br />

5 Preparedness Measures 73<br />

5.1 Resources Availability 73<br />

5.2 Community Involvement in <strong>Disaster</strong> preparedness 73<br />

5.2.1 Need for Community Participation 74<br />

5.2.2 Salient Features of CBDM 74<br />

5.2.3 Components for CBDM 75<br />

5.2.4 Culture of Prevention 75<br />

5.3 Critical Elements of Community Based <strong>Disaster</strong> <strong>Management</strong> 76<br />

5.4 Conditions for CBDM 77<br />

5.5 Risk Knowledge 78<br />

5.6 <strong>Disaster</strong> Risk Reduction Strategies 79<br />

5.6.1 Financial and Livelihood Strategies 79<br />

5.6.2 Microfinance 79<br />

[ii]

5.6.3 Insurance 79<br />

5.6.4 Social Funds 80<br />

5.7 Support by External Actors 80<br />

5.7.1 Nehru Yuva Kendra: 81<br />

5.7.2 NSS, NCC, Rangers/Rovers and Scouts/ Guides: 81<br />

5.7.3 Civil Defence: 81<br />

5.7.4 Home Guards: 82<br />

5.7.5 <strong>Barmer</strong> Municipal Administration 82<br />

5.7.6 District Zilla Parishad 83<br />

5.7.7 Jesai Army Command, Rajasthan 83<br />

5.8 Operational Emergency Preparedness 83<br />

5.8.1 <strong>Management</strong> and Control of Emergencies 84<br />

5.8.2 Preparation and <strong>Plan</strong>ning 86<br />

5.8.3 Sufficient Competent Personnel 86<br />

5.8.4 Detection of Incidents 87<br />

5.8.5 Emergency Communications 87<br />

5.8.6 Medical Facilities and Support 88<br />

5.8.7 Security Incidents 88<br />

5.8.8 External Support 88<br />

6 Response 89<br />

6.1 Incident Classification 89<br />

6.2 Incident Response Structure 90<br />

6.2.1 Incident Response Teams (IRT) 91<br />

6.2.2 Emergency Response Team (ERT) 92<br />

6.2.3 Emergency <strong>Management</strong> Team (EMT) 92<br />

6.2.4 Crisis <strong>Management</strong> Team (CMT) – Strategic Response 93<br />

6.2.5 Oil Spill Support agencies 93<br />

6.2.6 Health, Safety and Security 94<br />

6.2.7 Oil Spill Response <strong>Management</strong> 95<br />

6.2.8 Logistics 99<br />

6.2.9 Communications 99<br />

6.2.10 Oil Spill Scenarios 100<br />

6.2.11 Causes and Sources of Spill 100<br />

6.3 Escape & Evacuation Assessment (EEA) 101<br />

6.3.1 Escape and Evacuation Procedures 102<br />

[iii]

6.3.2 Impairment of escape and evacuation means 102<br />

6.3.3 Safe Muster Areas 103<br />

6.3.4 Communication System 104<br />

6.3.5 Estimated Escape Time to Safe Area 105<br />

6.3.6 Mapping of Evacuation Routes for Settlements 108<br />

6.3.7 Early Warning and Evacuation (EWS) for Community 108<br />

6.3.8 Medical Evacuation 110<br />

6.4 Reporting and Notification Reporting 110<br />

6.4.1 Incident Reporting 110<br />

6.4.2 Notification 111<br />

6.5 Media Communication 111<br />

6.6 Emergency Response Procedures (ERP) 111<br />

6.7 Sphere Standards 111<br />

7 Partnership with Other Stakeholders 113<br />

7.1 Stake holder Analysis 113<br />

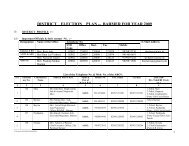

7.2 District Authorities in <strong>Barmer</strong> 114<br />

7.3 Community Based <strong>Disaster</strong> Organizations 114<br />

7.3.1 Select NGOS 114<br />

7.4 Role of Media 115<br />

7.4.1 Before a <strong>Disaster</strong> 115<br />

7.4.2 During a disaster 115<br />

7.4.3 After a disaster 116<br />

7.4.4 NGOs Role in Media 116<br />

8 Financial Arrangements 117<br />

8.1 Funds 117<br />

8.2 Annual Budgets 118<br />

8.3 Fund Allocation for Hazard Preparedness 118<br />

Part 2: <strong>Disaster</strong> Specific Action <strong>Plan</strong> 119<br />

9 Preface For SOPs 120<br />

A. On-Site Fire Related Emergencies 120<br />

B. Fire Scenarios & Emergency Response 120<br />

C. Oil Spill Related Emergencies 121<br />

9.1 SOP: Crude oil pipeline leak 122<br />

9.2 SOP: Oil Well blowout 127<br />

9.3 SOP: Gas Well Blowout 132<br />

[iv]

9.4 SOP: Earthquake 137<br />

9.5 SOP: Floods 142<br />

9.6 SOP: Biological Hazards 146<br />

Part 3: Cross-Cutting Issues 149<br />

10 Review and Updation of <strong>Plan</strong>s 150<br />

11 Coordination and Implementation 151<br />

11.1 Need for Mock Drill 151<br />

11.1.1 For Effective Mock Drill 151<br />

11.1.2 Types of Drills and Exercises 152<br />

11.1.3 Composition of Participants 153<br />

11.1.4 Observers/Evaluators 154<br />

11.1.5 Community Participation 154<br />

11.2 Preparatory Procedure 154<br />

11.2.1 Tips for Conducting Safe Mock Drill 155<br />

11.3 Guidelines for Mock Drill Design 155<br />

11.3.1 Scope 156<br />

11.3.2 Statement of Purpose 156<br />

11.3.3 Objectives 156<br />

11.3.4 Scenario narrative 157<br />

11.3.5 Drill Activity 157<br />

11.3.6 Expected actions/roles and responsibilities 157<br />

11.3.7 Expected response/evaluation criteria 157<br />

11.4 Guidelines for Conducting Mock Drill 158<br />

11.4.1 Pre-drill Briefing 158<br />

11.4.2 Drill Initiation 158<br />

11.4.3 Drill Activity 158<br />

11.5 Guidelines for Drill Evaluation 159<br />

11.5.1 Evaluation Team 159<br />

11.5.2 Elements for Evaluation 159<br />

11.6 Feedback & Improvements 160<br />

11.6.1 Mock Drill Evaluation Report 161<br />

12 recommendations 162<br />

Appendix A – Emergency Contact Numbers 164<br />

1 Hotline Numbers 164<br />

2 Wireless Call Signs 164<br />

[v]

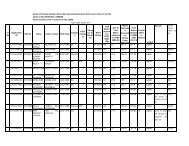

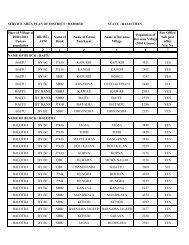

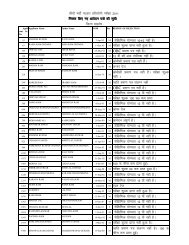

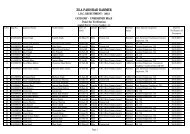

3 Contact numbers of District <strong>Disaster</strong> <strong>Management</strong> Cell 165<br />

4 Telephone numbers of the important officials in the district 166<br />

5 Police officials 168<br />

6 Municipality 169<br />

7 Health Department 170<br />

8 Healthcare centres in <strong>Barmer</strong> 171<br />

9 Hospitals 177<br />

10 Veterinary hospitals/pharmacies in the district 178<br />

11 Public Health Engineering Department 179<br />

12 Public Works Department 185<br />

13 Other officials 188<br />

14 Voluntary Organisations and NGOs in the Region 189<br />

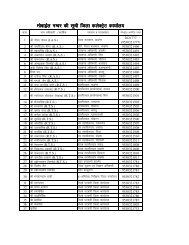

15 List of Divers/Swimmers in the district 192<br />

16 List of officials trained in fire Fighting and control 198<br />

Appendix B – Maps 200<br />

Appendix C – Incident Action <strong>Plan</strong>s (IAPS) 211<br />

IAPs for Fire Response On-Site 211<br />

Action In the Event of a Fire 211<br />

1. Propane Pool fire from Propane Storage, Refrigeration Package (RGT Facility) 212<br />

2 Fire in the well head in well pad 213<br />

3. Crude Oil fire at Production separator (MPT) 213<br />

4. Fire at the flare area & knock out drum 214<br />

5. Fire in the Diesel Storage, Export Oil, Condensate, Off spec and Settling tanks 215<br />

6. Electrical sub stations 216<br />

7. Buildings (Central Control Building & Fire Station) 217<br />

8. Fire in Chemical Laboratory Building 218<br />

9. Oil & Gas Leakage in Pig Launcher Area (at MPT/ RGT) followed by fire 218<br />

10. Fire/ Gas Leak in Cross country pipe line. 219<br />

11. Fire in Mangala Train 1 facilities 220<br />

12. Fire in Enhanced Oil Recovery (EOR) 221<br />

13. Fire situations in <strong>Barmer</strong> Hill Project (EWT) 222<br />

16. Fire situation “Major Construction Activities within MPT / RGT/ MT-1 / Well pads” 222<br />

17. Fire in “OB Camps & Office Building” 223<br />

Appendix D – Fire Protection Arrangements 225<br />

1 Mangala Processing Terminal 225<br />

[vi]

2 Mangala Train - 1 (Start up production package) 228<br />

Appendix E – Emergency Resources 231<br />

Cairn Resources 231<br />

District/Government Resources 233<br />

Other Corporate Resources 235<br />

Appendix F – <strong>Barmer</strong> District Profile 237<br />

Glossary of Terms 251<br />

[vii]

List of Figures<br />

Figure 1: <strong>Disaster</strong> <strong>Management</strong> Cycle .................................................................................................................................................... 10<br />

Figure 2: CIL's Rajasthan Field – Mangala ........................................................................................................................................... 12<br />

Figure 3: MPT Processing Systems Overview ...................................................................................................................................... 13<br />

Figure 4: CIL Facilities Diagram ............................................................................................................................................................... 15<br />

Figure 5: Risk contours from Process Events at MPT ....................................................................................................................... 29<br />

Figure 6: Risk Contours due to Incoming Raageshwari pipelines at MPT ............................................................................... 30<br />

Figure 7: Individual and Combined F-N curves for Crude and Gas Release Events .............................................................. 31<br />

Figure 8: Process Gas and Liquid Leak Frequencies per Hole-Size Category .......................................................................... 36<br />

Figure 9: Process Gas Leak Frequency per Event and per Hole-Size Category ...................................................................... 37<br />

Figure 10: Process Liquid Leak Frequency per Event and Hole-Size Category ...................................................................... 38<br />

Figure 11: Iso-Risk Contours ...................................................................................................................................................................... 44<br />

Figure 12: F-N Curve Day-Night ............................................................................................................................................................... 45<br />

Figure 13: Iso-Risk Contour of Typical Well Pad ............................................................................................................................... 45<br />

Figure 14: Group Risk F-N Curve, Typical Well Pad .......................................................................................................................... 46<br />

Figure 15: Worst Case Radii ....................................................................................................................................................................... 47<br />

Figure 16: Relationship between <strong>Disaster</strong>s and Development ..................................................................................................... 69<br />

Figure 17: Organisation Links for Emergency <strong>Management</strong> in CIL ........................................................................................... 85<br />

Figure 18: Tier Classification in CIL ........................................................................................................................................................ 90<br />

Figure 19: Tiers and Response Teams .................................................................................................................................................... 91<br />

Figure 20: Oil Spill Response Decision Tree ......................................................................................................................................... 96<br />

Figure 21: Risk Contours at MPT shown along with Muster points ........................................................................................ 103<br />

List of Tables<br />

Table 1: Largest Risk Contributors to the Societal Risk from Process Events in MPT ......................................................... 32<br />

Table 2: Individual Risks at Specific Buildings/Locations at MPT .............................................................................................. 33<br />

Table 3: Jet Fire Hazard Results IN MPT ............................................................................................................................................... 35<br />

Table 4: Failure Frequencies for Gas Events in MPT ........................................................................................................................ 37<br />

Table 5: Failure Frequency Applied for Liquid Events on MPT .................................................................................................... 38<br />

Table 6: Base Leak Frequency from EGIG ............................................................................................................................................. 40<br />

Table 7: Used Pipeline Failure Frequency for DN100 and DN300 .............................................................................................. 40<br />

Table 8: Location Specific Individual Risk (LSIR) at Different Reference Points in RGT .................................................... 44<br />

Table 9: Consequence Analysis Results for LFL and Jet Fire Heat Radiation at RGT ........................................................... 46<br />

Table 10: List of Villages within the Hazard Zones at MPT ........................................................................................................... 48<br />

Table 11: Villages within Maximum Hazard Zones for Well Fields ............................................................................................ 49<br />

Table 12: Risk Prone Villages along Pipelines ..................................................................................................................................... 50<br />

Table 13: Summary of Terrestrial Containment and Control Techniques ............................................................................... 97<br />

Table 14: Probabilities of Potential Sources of Oil Spills ............................................................................................................. 100<br />

Table 15: Total Time for Escape and Evacuation in MPT ........................................................................................................... 107<br />

List of Photographs<br />

Photograph 1: Mangala Processing Terminal .................................................................................................................................... 12<br />

Photograph 2: MPT Oil Storage Tanks ................................................................................................................................................... 12<br />

Photograph 3: Raageshwari Terminal .................................................................................................................................................. 14<br />

Photograph 4: MPT Cross-Country Pipeline Valve Pit ..................................................................................................................... 14<br />

Photograph 5: Sandstorm Near Cairn Facility during Daytime .................................................................................................. 52<br />

Photograph 7: Consultation with Village Head and Members ..................................................................................................... 74<br />

Photograph 6: Community Consultation at Jogasar Kuan ............................................................................................................. 74<br />

Photograph 8: During the DMP Presentation Meeting at <strong>Barmer</strong> Collectorate .................................................................... 82<br />

Photograph 9: DMP Presentation being made by EGSS at <strong>Barmer</strong> Collectorate .................................................................. 82<br />

[viii]

ABBREVIATIONS<br />

AGI Above Ground Installation<br />

BA Breathing Apparatus<br />

BLEVE Boiling Liquid Expanding Vapour<br />

Explosion<br />

BOPD Barrels of Oil Per Day<br />

BS&W Basic Sediment & Water<br />

CBDM Community Based <strong>Disaster</strong><br />

<strong>Management</strong><br />

CBEWS Community Based Early Warning<br />

Systems<br />

CBO Community Based Organisations<br />

CIL Cairn India Limited<br />

CMHO Chief Medical Health Officer<br />

CMP Crisis <strong>Management</strong> <strong>Plan</strong><br />

CMT Crisis <strong>Management</strong> Team<br />

CO 2 Carbon di-oxide<br />

CRA Commissioner for Revenue<br />

Administration<br />

CG Core Group<br />

CSO Civil Society Organisation<br />

CSR Corporate Social Responsibility<br />

CWC Central Water Commission<br />

DCP Dry Chemical Powder<br />

DM <strong>Disaster</strong> <strong>Management</strong><br />

DMC District <strong>Management</strong> Committee<br />

DMP <strong>Disaster</strong> <strong>Management</strong> <strong>Plan</strong><br />

DRM <strong>Disaster</strong> Risk <strong>Management</strong><br />

DRR <strong>Disaster</strong> Risk Reduction<br />

EEA Emergency Evacuation Assessment<br />

EGF Early Gas Facility<br />

EGIG European Gas pipeline Incident data<br />

Group<br />

EMP Emergency <strong>Management</strong> <strong>Plan</strong><br />

EMT Emergency <strong>Management</strong> Team<br />

EOR Enhanced Oil Recovery<br />

EPPR Emergency Prevention, Preparedness<br />

and Response<br />

ERC Emergency Response Centre<br />

ERP Emergency Response Procedures<br />

ERT Emergency Response Team<br />

ESD Emergency Shut Down<br />

EWS Early warning system<br />

FCP Forward Control Point<br />

FRT Forward Response Team<br />

FERA Fire and Explosion Risk Assessment<br />

GIS Geographical Information Systems<br />

GPS Global Positioning System<br />

HSE Health Safety and Environment<br />

IAP Incident Action <strong>Plan</strong><br />

IMT Incident <strong>Management</strong> Team<br />

ICG Intergovernmental Coordination Group<br />

ICC Incident Control Centre<br />

ICS Incident Command System<br />

IDRN India <strong>Disaster</strong> Resource Network<br />

IDSP Integrated Disease Surveillance Program<br />

[ix]

IM Installation Manager<br />

IMD Indian Meteorological Department<br />

IMG Incident <strong>Management</strong> Guide<br />

INGOs International Non-Governmental<br />

Organisations<br />

IOC Indian Oil Corporation<br />

IRP Incident Response <strong>Plan</strong><br />

IRT Incident Response Team<br />

LHV Lower heating value<br />

MSIHC Manufacture, Storage & Import of<br />

Hazardous Chemicals<br />

MMSCFD Million Standard Cubic Feet per<br />

Day<br />

NCC National Cadet Corps<br />

NDMA National <strong>Disaster</strong> <strong>Management</strong><br />

Authority<br />

NFPA National Fire Protection Association<br />

NGO Non-governmental organisations<br />

NIDM National Institute for <strong>Disaster</strong><br />

<strong>Management</strong><br />

NSS National Social Service<br />

NYK Nehru Yuva Kendra<br />

PLI Public Liability Insurance (1991)<br />

PPE Personal Protective Equipment<br />

PRA Participatory Rural Appraisal<br />

PRI Panchayat Raj Institutions<br />

QRA Qualitative Risk assessment<br />

RGT Raageshwari Gas Terminal<br />

RNAO Rajasthan Northern Area Operations<br />

RTA Road Traffic Accident<br />

SCBA Self Contained Breathing Apparatus<br />

SDMA State <strong>Disaster</strong> <strong>Management</strong> Authority<br />

SHG Self Help Groups<br />

SOP Standard Operating Procedure<br />

UNDP United Nations Development<br />

Programme<br />

UNISDR United Nations International Strategy<br />

for <strong>Disaster</strong> Reduction<br />

VHF Very High Frequency Wireless system<br />

VLMC Village Level Monitoring Committee<br />

VOC Volatile Organic Chemical<br />

WATSAN Water and sanitation<br />

OISD Oil Industry Safety Directorate<br />

OSCP Oil Spill Contingency <strong>Plan</strong><br />

PAGA Public Address and General Alarm<br />

[x]

ACKNOWLEDGEMENTS<br />

• Secretary, State <strong>Disaster</strong> <strong>Management</strong> and Relief, Government of Rajasthan<br />

• Deputy Secretary, State <strong>Disaster</strong> <strong>Management</strong> and Relief, Government of Rajasthan<br />

• Deputy Secretary, Department of Petroleum<br />

• District Collector, <strong>Barmer</strong> district<br />

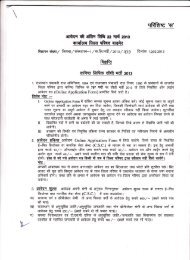

• Office of the District Collector, <strong>Disaster</strong> <strong>Management</strong> and Mitigation, Govt. of<br />

Rajasthan, <strong>Barmer</strong><br />

• Office of Superintendent of Police, <strong>Barmer</strong><br />

• Cairn Staff at Gurgaon and Jaipur<br />

• Cairn Staff at MPT, RGT and <strong>Barmer</strong><br />

• Nehru Yuva Kendra, <strong>Barmer</strong><br />

• Office of Home Guards, <strong>Barmer</strong><br />

• Office of Civil Defence, <strong>Barmer</strong><br />

• Office of District Medical and Health Department, <strong>Barmer</strong><br />

• Office of District Education Department, <strong>Barmer</strong><br />

• Help Age India, <strong>Barmer</strong> (NGO partners of Cairn)<br />

• SURE, <strong>Barmer</strong> (NGO partners of Cairn)<br />

• Dhara Sansthan, <strong>Barmer</strong> (NGO partners of Cairn)<br />

• Office of Army Unit, Jesai<br />

• NSS Unit of MBC Govt College, <strong>Barmer</strong><br />

• Office of SSA, Education Department, <strong>Barmer</strong><br />

• Community leaders/members of Jogasar Kuan Village<br />

<strong>Disaster</strong> <strong>Management</strong> <strong>Plan</strong> Preparation Team<br />

Ramasami Sundaresan FIFireE - Health & Safety, Emergency Preparedness, Incident<br />

Investigation specialist, 36 years oil & petrochemical industry experience<br />

Dr. K. M. Parivelan Ph.D – is DM Specialist who has worked with UN agencies like UNHCR,<br />

UNDP covering Humanitarian Affairs and <strong>Disaster</strong> <strong>Management</strong><br />

A. Sivakumar MSc - IIT Mumbai – Hydrogeology and Environmental Professional with 18<br />

years international experience in oil & gas industry<br />

Indira Reddy MSc - Environmental <strong>Management</strong> Australia – Project Coordination and GIS<br />

expert<br />

[xi]

EXECUTIVE SUMMARY<br />

Cairn India Limited is a BSE listed company with interests in oil and gas exploration,<br />

production and pipeline transportation. It has operating blocks in Andhra Pradesh, Gujarat<br />

and Rajasthan. Cairn India has just completed development of major oil and gas fields in<br />

the <strong>Barmer</strong> district of Rajasthan and commissioned world class processing facilities and a<br />

650 km crude oil pipeline to supply the oil to refineries in Gujarat. Keeping in view the<br />

vulnerability of the communities living surrounding Cairn India’s facilities and along the<br />

pipelines, the Government of Rajasthan directed Cairn India to submit a <strong>Disaster</strong><br />

<strong>Management</strong> <strong>Plan</strong> that would address all major hazards and the appropriate response.<br />

Cairn India Limited (CIL) commissioned Environmental and Geo Spatial Solutions (EGSS),<br />

Chennai to prepare a robust <strong>Disaster</strong> <strong>Management</strong> <strong>Plan</strong> document covering its upstream<br />

assets based in <strong>Barmer</strong> district i.e. Mangala Processing Terminal, Raageshwari Gas<br />

Processing Terminal, connected well pads and cross-country pipeline between MPT and<br />

RGT.<br />

<strong>Barmer</strong> district is one of the developing districts in Rajasthan. With harsh desert<br />

environment and erratic climatic conditions, coupled with poverty, illiteracy and lack of<br />

adequate infrastructure, it suffers very often from severe drought conditions and<br />

occasionally from devastating floods with a devastating impact on human life, economy and<br />

environment. Now with the rapid development of oil and gas fields by companies such as<br />

Cairn India and setting up of cement and power plants in the district, there is a significant<br />

socio-economic changes in the lives of the people of <strong>Barmer</strong> for good and at the same time<br />

introduced a new risk of potential major industrial accidents or disasters. It is possible to<br />

minimize the potential risks by:<br />

1. Identifying potential hazards and its impact in on-site and off-site areas<br />

2. Prepare and implement developmental plans to provide resilience to such disasters<br />

3. Developing early warning strategies<br />

4. Mobilize resources including communication and medicinal services, and<br />

5. To help in rehabilitation and post-disaster reconstruction.<br />

Thus the DMP document reviews all credible disaster scenarios and presents a systematic<br />

plan with suitable strategies for disaster preparedness and response. It also provides an<br />

operational framework and procedures for effective roll out and execution with effective<br />

engagement of the communities and the local district administration. Further the plan took<br />

into consideration the Jaipur Oil Depot fire (October 2009) incident, and related findings<br />

and recommendations of OISD. In addition the plan focuses on disaster prevention<br />

measures and proactive safety management. The DMP document is prepared in two<br />

separate formats:<br />

[1]

1. A full DMP Main report as per the suggested outline of the Government of Rajasthan<br />

which includes elaborate information on <strong>Barmer</strong> District Profile, Cairn Oil Field<br />

Facilities (Mangala Processing Terminal, Raageshwari Processing Terminal,<br />

Bhagyam and Aishwarya fields, Resources availability in the District to cope with<br />

disaster etc).<br />

2. A concise Manual with Standard Operating Procedures (SOPs) for credible disaster<br />

scenarios.<br />

The <strong>Disaster</strong> <strong>Management</strong> <strong>Plan</strong> (DMP) for Cairn's Rajasthan Upstream operations is<br />

developed with the objectives of protecting the communities in the region, their habitat<br />

and livelihood from calamities, both natural and human induced. The <strong>Plan</strong> is structured<br />

along the format recommended by the Government of Rajasthan and conforms to the<br />

relevant regulations such as the National <strong>Disaster</strong> <strong>Management</strong> Act, 2005.The DMP takes<br />

into cognizance the <strong>Disaster</strong> <strong>Management</strong> Authority structure at national, state, district,<br />

block and Panchayat levels.<br />

It is apt to mention here that the DMP is developed in line with national disaster<br />

management vision of "shifting the approach from reactive post-disaster response to one of<br />

proactive, pre-disaster preparedness and mitigation measures". The <strong>Plan</strong> spells out the roles<br />

and responsibilities applicable to all phases of the disaster management cycle:<br />

I. Pre-disaster-preparedness,<br />

II. Mitigation and prevention,<br />

III. <strong>Disaster</strong>-response action, and<br />

IV. Post-disaster- relief, rehabilitation and reconstruction.<br />

The DMP is structured as follows:<br />

Chapter I covers a brief introduction on <strong>Disaster</strong> <strong>Management</strong>, description of Cairn Project<br />

in Rajasthan Upstream facility, note on social, economic, demographic and geographical<br />

profiles of <strong>Barmer</strong> district;<br />

Chapter II addresses vulnerability assessment and risk analysis, covering human/ industry<br />

induced and natural hazards. It also includes detailed vulnerability analysis for operational<br />

areas in upstream facility with its off-site impact on nearby communities and environment;<br />

Chapter III deals with preventive and mitigation measures and strategies for various type<br />

of hazards covering; earthquake, floods, on-site operational hazards like crude oil/ gas<br />

pipeline leakage, oil well/ pad fire, tank fire, etc.;<br />

Chapter IV covers approaches to mainstream disaster management concerns into all facets<br />

of development;<br />

[2]

Chapter V deals with Preparedness measures involving various stakeholders including<br />

community participation. Here detailed community based disaster management approach<br />

is analysed for enhancement. It also includes an overview of the recent oil industry related<br />

disasters, the causes, consequences and lessons for prevention of such incidents;<br />

Chapter VI covers the Response strategies within CIL emergency management and its<br />

coordination with district administration. It includes emergency command structure, early<br />

warnings and evacuation mechanisms. It also considered the universally accepted ‘Sphere<br />

Standards’ for post disaster response context community needs;<br />

Chapter VII deals with scope for partnership with other stakeholders including academic<br />

institutions, and media.<br />

Chapter VIII deals with financial arrangements<br />

Chapters IX-XIV cover disaster specific action plan with Standard Operating Procedures for<br />

potential scenario, special hazards, precautions to be adhered.<br />

Chapter XV covers a brief note on the importance of reviews and updation of DMP on a<br />

regular basis.<br />

Chapter XVI deals with coordination and implementation aspects covering a detailed note<br />

on conducting mock drill and Business continuity plan.<br />

This DMP further takes into consideration aspects for community participation in all<br />

phases of disaster management. It includes disaster preparedness and mitigation vis-à-vis<br />

required improvements on ground with practical implementations like mock drills,<br />

operational procedures, preventive mechanisms, community awareness, early warning<br />

systems and coordination between private and governmental agencies in the event of a<br />

disaster. Thus the DMP document reviews and presents all credible disaster scenarios and<br />

has formulated a systematic plan in evolving a suitable strategy for disaster preparedness,<br />

mitigation and response.<br />

[3]

PART 1: GENERAL<br />

[4]

CHAPTER<br />

1<br />

1 INTRODUCTION<br />

This comprehensive disaster management plan for Rajasthan Upstream facility was drafted<br />

in accordance with the guidelines of the Government of Rajasthan. The disaster<br />

management plan covers natural and man-made disasters, emergency preparedness plans<br />

for on-site and off-site purposes and disaster relief and mitigation. Its prime objective is to<br />

mitigate the possible risks emanating from Cairn India Limited’s (CIL’s) oil field related<br />

operations onsite and offsite in <strong>Barmer</strong> District of Rajasthan.<br />

The Indian economy is rapidly industrialising and expanding. Energy is a major demand for<br />

an expanding economy and major oil explorations and oil production are happening now.<br />

Rajasthan is emerging as a key player in this sector and new oil fields are still being<br />

discovered. This rapid expansion has however increased the hazard, risk and vulnerability<br />

to the industry and the environment.<br />

The potential to have hydrocarbon related/ Industrial disasters are low in frequency but<br />

are very significant in terms of loss of lives, injuries, environmental impact and property<br />

damage. Frequency and severity of hydrocarbon related disasters has increased in last few<br />

years due to rapid increase in explorations, storage, processing, transportation of<br />

petrochemical products, specifically in densely populated areas. Hydrocarbon related<br />

accidents can occur due to lack of safety measure, technical breakdown, or due to a human<br />

error.<br />

A single incident can initiate a series of uncontrolled phenomenon such as large spills, fires<br />

and explosions. These eventually target humans, environment and infrastructure/property<br />

in the area and can be in the form of immediate and residual or long term consequences.<br />

Thus, it is imperative to develop preventive measures like adoption of safer engineering<br />

practices, improved performance of safety devices and reduction of human errors by<br />

regular checks.<br />

The government has also issued guidelines and laws for disaster management and<br />

mitigation. The Umbrella Act EPA, 1986 enacted after the incidence of Bhopal Gas Tragedy<br />

in 1984, and the rules MSIHC Rules 1989, EPPR Rules 1996, PLI Act 1991, besides Factories<br />

Act 1948 (amended thereafter) provided a systematic approach to disaster management<br />

[5]

framework at national, state, district and local levels, in the context of hydrocarbon related<br />

accident management and emergency response.<br />

DMPs thus become essential on two fronts: to have on-site and off-site preparedness; and<br />

secondly to comply with disaster management institutional mechanisms such as the<br />

National <strong>Disaster</strong> <strong>Management</strong> Act of 2005, National <strong>Disaster</strong> <strong>Management</strong> Authority’s<br />

guidelines. Needless to add other sector specific safety norms and guidelines have to be<br />

taken into account such as OISD norms, environmental guidelines, etc.<br />

National <strong>Disaster</strong> <strong>Management</strong> Authority (NDMA) and OISD have also respectively issued<br />

some guidelines for petroleum related disasters. The Guidelines have laid emphasis on<br />

capacity building, risk assessment, information management and coordination of<br />

actions for enhancing the preparedness at various levels. Based on these Guidelines, this<br />

DMP was developed.<br />

With the renewed emphasis of the Government on disaster management and the paradigm<br />

shift in focus from rescue, relief & rehabilitation to prevention/mitigation and<br />

preparedness, a need to revisit the management of hydrocarbon related <strong>Disaster</strong>s has been<br />

felt to establish an institutionalized mechanism so that the hydrocarbon related disasters<br />

can be prevented and if they do occur, for their effective management.<br />

There has been a paradigm shift in the government’s focus from its rescue, relief, and<br />

restoration centric approach to a planning, prevention/mitigation and preparedness<br />

approach. The national vision on disaster management is ‘to build a safe and disasterresilient<br />

India by developing a holistic, proactive, multi-disaster and technology-driven<br />

strategy. This is to be achieved through a culture of prevention, mitigation and<br />

preparedness to generate a prompt and efficient response to tackle disasters. This Policy<br />

framework is also in conformity with the International Strategy for <strong>Disaster</strong> Reduction, the<br />

Rio Declaration, the Millennium Development Goals and the Hyogo Framework 2005-<br />

2015. 1<br />

It has been realised that effective Oil industry <strong>Disaster</strong> <strong>Management</strong> (CDM) is possible by<br />

the adoption of preventive and mitigation strategies as most petro-chemical disasters are<br />

preventable in comparison to natural disasters that are difficult to predict and prevent.<br />

The prime objective here is to ensure that the occurrence of hydrocarbon related accidents<br />

are minimised and the risks posed to life, environment and property are reduced. The DMP<br />

calls for a proactive, participatory, well-structured, fail-safe, multi-disciplinary and multisectoral<br />

approach involving all stakeholder groups and is aimed at refining and<br />

strengthening the various mechanisms from stages of planning to field operations.<br />

1 National <strong>Disaster</strong> <strong>Management</strong> Authority’s Policy outline, 2005<br />

[6]

1.1 DISASTER MANAGEMENT<br />

<strong>Disaster</strong> can be defined as “a serious disruption of the functioning of a community or a<br />

society causing widespread human, material, economic or environmental losses which exceed<br />

the ability of the affected community or society to cope using its own resources.” (Source:<br />

Reducing <strong>Disaster</strong> Risk, UNDP 2004). Some recent regional disasters include the Indian<br />

Ocean Tsunami in 2004 that affected parts of Asia and Africa and the South Asian<br />

Earthquake in 2005 which affected Pakistan and India. Some recent disasters in India were<br />

the flash floods in Rajasthan in 2006, Mumbai (Maharashtra) and Vadodara (Gujarat) in<br />

2005, the earthquake in Gujarat in 2001, the super cyclone in Orissa in 1999, the Uphaar<br />

Cinema Fire in Delhi in 1997, the recurrent droughts in parts of Rajasthan (1980s<br />

onwards), and the Bhopal Gas <strong>Disaster</strong> in 1984. <strong>Disaster</strong>s result from the combination of<br />

hazards, conditions of vulnerability and insufficient capacity or measures to reduce the<br />

potential negative consequences of risk. (Source: Living with Risk, UN ISDR 2002)<br />

Hazard is a potentially damaging physical event, phenomenon or human activity that may<br />

cause the loss of life or injury, property damage, social and economic disruption or<br />

environmental degradation. (Source: Living with Risk, UN ISDR 2002) For example:<br />

Earthquakes, flood and, industrial gas leakages are some examples of hazards. Hazards can<br />

be single, sequential or combined in their origin and effects. Hazardous events can vary in<br />

magnitude or intensity, frequency, duration, area of extent, speed of on set, spatial<br />

dispersion and temporal spacing. Based on their causes, hazards are categorized into two<br />

broad types – Natural hazards and Human/ industry – induced hazards.<br />

Vulnerability is the condition determined by physical, social, economic and environmental<br />

factors or processes, which increase the susceptibility of a community to the impact of<br />

hazards. (Source: Living with Risk, UN ISDR 2002) The scale of damage to a community from<br />

the impact of a given hazard does not only depend upon the community’s physical<br />

exposure to that hazard, but also on its vulnerability. Here, physical exposure refers to the<br />

elements at risk. These elements may include people, artefacts, infrastructure etc. (Source:<br />

Reducing <strong>Disaster</strong> Risk, UNDP 2004). Vulnerability, on the other hand, is determined by<br />

aspects in the physical environment, such as nature of housing, available open space etc, as<br />

well as aspects in the socio-economic domain such as level of income, nutritional status,<br />

marginalization, etc.<br />

Capacity is the combination of all the strengths and resources available within a<br />

community, society or organization that can reduce the level of risk, or the effects of a<br />

disaster. Capacity may include physical, institutional, social or economic means as well as<br />

skilled personal or collective attributes such as ‘leadership’ and ‘management.’ Capacity<br />

may also be described as capability. (Source: Living with Risk, UN ISDR 2002) Example: After<br />

the floods in Vadodara district (Gujarat) in 2005, it was seen that villages with existing<br />

[7]

<strong>Disaster</strong> <strong>Management</strong> Teams (DMTs) and <strong>Disaster</strong> <strong>Management</strong> Committees (DMCs)<br />

responded to the floods well in time, by rescuing people to pre-identified safe areas.<br />

Two concepts within the framework of ‘capacity’ that are often used in <strong>Disaster</strong><br />

<strong>Management</strong> are:<br />

Coping capacity: The manner in which people and organizations use existing resources to<br />

achieve various benefits during unusual, abnormal and adverse conditions of a disaster<br />

phenomenon or process. (Source: Reducing <strong>Disaster</strong> Risk, UNDP 2004).<br />

An example of coping capacity is the community kitchen set up by local village groups in<br />

community areas like temples and schools of Orissa after the 1999 cyclone.<br />

Resilience: The capacity of a system, community or society to resist or to change in order<br />

that it may obtain an acceptable level in functioning and structure. This is determined by<br />

the degree to which the social system is capable of organizing itself, and the ability to<br />

increase its capacity for learning and adaptation, including the capacity to recover from a<br />

disaster. (Source: Reducing <strong>Disaster</strong> Risk, UNDP 2004) For example; after the 2001 Gujarat<br />

earthquake, local communities began clearing the debris, retrieving materials and<br />

reconstructing their houses/work place, even before external help came from the government<br />

or other organizations. This was an example of resilience of the community.<br />

Risk is the probability of harmful consequences, or expected losses (deaths, injuries,<br />

property, livelihoods, economic activity disrupted or environment damaged) resulting from<br />

interactions between natural or human-induced hazards and vulnerable conditions.<br />

Risk is conventionally expressed by the equation: Risk = Hazard x Vulnerability<br />

Now we use the notation: Risk = Hazards x Vulnerability minus (-) Capacity. (Source:<br />

Reducing <strong>Disaster</strong> Risk, UNDP 2004)<br />

‘<strong>Disaster</strong> <strong>Management</strong>’ covers a broad range of interventions undertaken before, during<br />

and/or after a disaster to<br />

• prevent or minimize loss of life and property,<br />

• minimize human suffering and<br />

• Accelerate recovery.<br />

The management of a disaster can be viewed as a series of phases including Prevention,<br />

Mitigation, Preparedness, Response, Relief, and Recovery (Rehabilitation and<br />

Reconstruction).<br />

[8]

i) Prevention: Activities to provide outright avoidance of the adverse impact of hazards<br />

and means to minimize related environmental, technological and biological disasters.<br />

Depending on social and technical feasibility and cost/benefit considerations, investing in<br />

preventive measures is justified in areas frequently affected by disasters.<br />

For example, public awareness and education related to fire safety in public buildings could<br />

lead to prevention of fire-related disasters. <strong>Disaster</strong> risk reduction professionals express that<br />

changing attitudes and behaviour contribute to promoting a "culture of prevention".<br />

ii) Mitigation: Any action taken to minimize the extent of a disaster or potential disaster.<br />

Mitigation can take place before, during or after a disaster, but the term is most often used<br />

to refer to actions against potential disasters. Mitigation measures are both physical and<br />

structural, such as flood defences or strengthening buildings as well as non-structural, such<br />

as training in disaster management, regulating land-use and public education, among<br />

others.<br />

iii) Preparedness: Activities and measures taken before a hazard event to ensure effective<br />

response to the impact of hazards. It involves measures that enable governments,<br />

community and individuals to respond rapidly to disaster situations and cope with them<br />

effectively.<br />

Preparedness includes<br />

• making of viable emergency plans<br />

• development of warning systems<br />

• maintenance of inventories<br />

• training of personnel<br />

• search and rescue measures<br />

• Evacuation plans for areas that may be ‘at risk’ for a recurring disaster.<br />

iv) Response/ Relief: The provision of assistance or intervention during or immediately<br />

after a disaster to meet the basic subsistence needs of the people affected. It can be of an<br />

immediate, short-term, or protracted duration. For example, search and rescue of affected<br />

people and provision of food, temporary shelter and medical care to the persons affected by<br />

the disaster are some common areas of intervention after a disaster.<br />

v) Rehabilitation: The operations and decisions taken after a disaster with a view to<br />

restore an affected community to its former living conditions, while encouraging and<br />

facilitating the necessary adjustments to the changes caused by the disaster.<br />

An example is counselling by professionals or community leaders to help reduce the<br />

psychological trauma of affected groups of children, women and others after a disaster.<br />

[9]

vi) Reconstruction: The action taken to re-establish a community following rehabilitation<br />

after a disaster. These actions would include construction of permanent housing, complete<br />

restoration of all services and physical infrastructure to the pre-disaster state etc.<br />

vii) Recovery: The term refers to decisions and actions related to rehabilitation and<br />

reconstruction taken after a disaster with a view to restoring or improving the pre-disaster<br />

living conditions of the affected community, while encouraging and facilitating necessary<br />

adjustments to reduce disaster risk. It is important to note that recovery (includes both<br />

rehabilitation and reconstruction) affords an opportunity to develop and apply<br />

disaster risk reduction measures.<br />

1.<br />

FIGURE 1: DISASTER MANAGEMENT CYCLE<br />

Generally India has been traditionally vulnerable to natural disasters on account of its<br />

unique geo-climatic conditions. Floods, droughts, cyclones, earthquakes and landslides<br />

have been recurrent phenomena. About 60% of the landmass is prone to earthquakes of<br />

various intensities; over 40 million hectares is prone to floods; about 8% of the total area is<br />

prone to cyclones and 68% of the area is susceptible to drought. In the decade 1990-2000,<br />

an average of about 4344 people lost their lives and about 30 million people were affected<br />

by disasters every year. The loss in terms of private, community and public assets has been<br />

astronomical.<br />

At the global level, there has been considerable concern over natural disasters. Even as<br />

substantial scientific and material progress is made, the loss of lives and property due to<br />

disasters has not decreased. In fact, the human toll and economic losses have mounted. It<br />

was in this background that the United Nations General Assembly, in 1989, declared the<br />

decade 1990-2000 as the International Decade for Natural <strong>Disaster</strong> Reduction with the<br />

[10]

objective to reduce loss of lives and property and restrict socio-economic damage through<br />

concerted international action, especially in developing countries.<br />

The super cyclone in Orissa in October, 1999 and the Bhuj earthquake in Gujarat in January,<br />

2001 underscored the need to adopt a multi dimensional endeavour involving diverse<br />

scientific, engineering, financial and social processes; the need to adopt multi disciplinary<br />

and multi sectoral approach and incorporation of risk reduction in the developmental plans<br />

and strategies.<br />

Over the past the past few years, the Government of India have brought about a paradigm<br />

shift in the approach to disaster management. The new approach proceeds from the<br />

conviction that development cannot be sustainable unless disaster mitigation is built into<br />

the development process. Another corner stone of the approach is that mitigation has to be<br />

multi-disciplinary spanning across all sectors of development. The new policy also<br />

emanates from the belief that investments in mitigation are much more cost effective than<br />

expenditure on relief and rehabilitation. <strong>Disaster</strong> management occupies an important place<br />

in this country’s policy framework as it is the poor and the under-privileged who are worst<br />

affected on account of calamities/disasters.<br />

The steps being taken by the Government emanate from the approach outlined above. The<br />

approach has been translated into a National <strong>Disaster</strong> Framework [a roadmap] covering<br />

institutional mechanisms, disaster prevention strategy, early warning system, disaster<br />

mitigation, preparedness and response and human resource development. The expected<br />

inputs, areas of intervention and agencies to be involved at the National, State and district<br />

levels have been identified and listed in the roadmap. This roadmap has been shared with<br />

all the State Governments and Union Territory Administrations. Ministries and<br />

Departments of Government of India, and the State Governments/UT Administrations have<br />

been advised to develop their respective roadmaps taking the national roadmap as a broad<br />

guideline. There is, therefore, now a common strategy underpinning the action being taken<br />

by all the participating organisations/stakeholders.<br />

1.2 DESCRIPTION OF CIL SITE<br />

Cairn India Ltd. (CIL) is developing the Rajasthan Block RJ-ON-90/1 in the state of<br />

Rajasthan, India. The RJ-ON-90/1 retained block area spreads over an area of about 3200-<br />

km2 and lies between 24°47'08'' to 26°26'01'' N latitude and 71°15'41'' to 72°04'3'' E<br />

longitudes. The RJ-ON-90/1 block is situated in <strong>Barmer</strong> and Jalore districts of southwestern<br />

Rajasthan i.e. within the Indian Thar desert area. It covers parts of <strong>Barmer</strong>, Shiv,<br />

Baytu and Gudamalani tehsils in <strong>Barmer</strong> district and Sanchore and Bagoda tehsils in Jalore<br />

district of Rajasthan.<br />

[11]

FIGURE 2: CIL'S RAJASTHAN FIELD – MANGALA<br />

Oil is mined from the well pads in the Mangala oil field. Bhagyam and Aishwariya oil fields<br />

are under development in the Northern Zone of the block and Saraswati and Raageshwari<br />

oil fields in the southern zone. All the above fields are located in <strong>Barmer</strong> district, Rajasthan.<br />

The northern fields in the block are envisaged to produce more than 160,000 barrels of oil<br />

per day (25, 437 tons of crude oil). The project comprises of the following key facilities:<br />

Mangala Process Terminal<br />

The production fluids from Mangala field is being processed at Mangala Process Terminal.<br />

The system also includes the 8 pig receivers at the MPT.<br />

Future production from up to 15 well pads at the Bhagyam field and up to 9 well pads at<br />

the Aishwariya fields will also be tied into the MPT via 3 dedicated pipelines.<br />

PHOTOGRAPH 2: MANGALA PROCESSING TERMINAL<br />

PHOTOGRAPH 1: MPT OIL STORAGE TANKS<br />

[12]

The production fluids are received in the inlet manifold and routed to the Inlet Slug<br />

Catchers. Design is premised on allowing dedicated well pad “clusters” and “tiebacks” to be<br />

routed to each train. The function of the slug catcher is to separate out any solids (e.g. sand,<br />

wax) from the production fluid and protect the downstream equipment from fouling, as<br />

well as dampening any slugging that will occur from the pipelines. The vessel will also act<br />

as the primary degasser. As a secondary purpose it is also designed to separate gas and free<br />

water (bulk water separation).<br />

The separated gas passes to the Associated Gas Compressors and the separated water is<br />

routed to the Produced Water Treatment System. The oil /water and emulsion stream is<br />

routed to the Production Heaters, where the temperature is increased to above the<br />

emulsion “break point”. The heater operating temperature is expected to be up to 90 deg C.<br />

The production stream then passes to the Production Separator, where further oil and<br />

water separation occurs and free gas, formed due to pressure let down and generation by<br />

heat addition is also separated. The gas is routed to the suction of the 3rd stage of the<br />

Vapour Recovery Unit. Separated water is routed to the Produced Water Treatment<br />

System. The oil and water stream passes to the Settling Tanks.<br />

The settling tanks provide the primary oil dehydration step; water from the tanks is<br />

removed in under level control and transferred to the Produced Water Treatment System.<br />

Oil from the Settling Tank is pumped to the Dehydrator for final dehydration to BS&W<br />

specification and onward transfer to oil storage. The degassed oil flows through<br />

electrostatic grid(s) for water droplet coalescence and separation.<br />

FIGURE 3: MPT PROCESSING SYSTEMS OVERVIEW<br />

[13]

From the export oil storange tanks, the crude oil is pumped in 24” export pipeline to Gujrat<br />

for sales to Govt. nominated customer.<br />

Raageshwari Field<br />

The Raageshwari Deep Gas field, situated within the RJ-ON-90/1 Contract Area, was<br />

discovered in 2003 by well RJ-E-1 (later renamed Raageshwari-1). Raageshwari Deep Gas<br />

is a tight, lean gas condensate reservoir, with excellent gas quality of approximately 80%<br />

methane, low CO2 and no H2S.<br />

There are 4 well pads located in the gas field. Wells have tested at gas production rates in<br />

the range 2-4mmscfd and producing condensate gas ratios in 40-50 bbl/mmscf range<br />

(based on flashing from well stream conditions to standard conditions). Condensate<br />

density on test has varied but approaches 60 API.<br />

Raageshwari Gas Terminal:<br />

The gas from well pads is feed into the finger type slug catcher to remove all the solids to<br />

prevent fouling of downstream equipments. The gas is then fed into 1st Stage Gas<br />

Separator to separate gas from water. Water produced is transferred to produce-water<br />

flash drums. Condensate from 1 st Stage Separator is feed into Feed/Bottom Exchanger<br />

resulting in a vapour free condensate stream which is routed to condensate storage tank<br />

and a vapour stream which is fed into Stripper Reboiler to eliminate the remaining liquid.<br />

PHOTOGRAPH 3: RAAGESHWARI TERMINAL<br />

PHOTOGRAPH 4: MPT CROSS-COUNTRY<br />

PIPELINE VALVE PIT<br />

The resultant gas is then fed into Gas-Gas Heat exchanger; the cooled gas is then fed to<br />

refrigeration package to separate out the propane. The production gas is then fed into the<br />

2 nd Stage Gas Separator. The separated water is routed to produce water flash drum. The<br />

resulting gas is fed to fuel gas header. Condensate from Stage Separators is fed to produced<br />

water flash drum to further separate water and gas, the resulting gas being routed to gas<br />

flare header.<br />

[14]

Thumbli Water Field:<br />

The crude oil from reservoirs at Mangala and other associated fields would be drilled using<br />

well pads concept. The reservoir will be water flooded in order to maintain reservoir<br />

pressure, provide voidage replacement and to maximize oil recovery. This water will be<br />

sourced from the “Thumbli aquifer” some 20km to the south-east of Mangala. There will be<br />

up to 5 well pads located in Thumbli Water Field. The formation volume factor of the<br />

Mangala crude is approximately 1.1. Therefore approximately 1.1 barrels of make-up water<br />

must be produced and injected for every barrel of oil that is extracted. The overall facilities<br />

diagram for Rajasthan Assets is provided in figure below.<br />

FIGURE 4: CIL FACILITIES DIAGRAM<br />

Since the CIL facilities are situated predominantly in the <strong>Barmer</strong> District, it is imperative to<br />

have a clear understanding of the geographical profile, natural hazards, risks and<br />

vulnerabilities in the region. In view of this, a short profile of the district has been collated<br />

and is given in the next section.<br />

1.3 DISTRICT PROFILE – SOCIAL, ECONOMIC & DEMOGRAPHIC<br />

1.3.1 GENERAL PROFILE<br />

<strong>Barmer</strong> district lies between 24°58′ - 26°32′ N and 70°5′ – 72°52′. On its north is<br />

Jaisalmer, to the south is Jalore, and Pali and Jodhpur are to the east. The total area of<br />

<strong>Barmer</strong> district is 28,114 km². <strong>Barmer</strong> district is 3,727 ft (1,136 m) above sea level and 22<br />

km in length. The longest river in the district is the Luni. It is 480 km in length and drains<br />

[15]

into the Gulf of Kutch passing through Jalore. <strong>Barmer</strong> district consists of <strong>Barmer</strong>, Baytu,<br />

Shiv, Chauhatan, Gudamalani and Balotra Tehsils.<br />

The district has a geographical area of 2.82 million hectares. In 2004-05, about 1.12<br />

percent of the area had forest cover, 7.2 percent constituted pasture land, 25.13 percent<br />

was fallow land and 51.63 percent was cultivated crop land. The remainder was either not<br />

available for cultivation or cultivable wasteland. Gross cropped area in 2004-05 was 1.55<br />

million hectares (1.79 million hectares in 2006-07) and area sown more than once stood at<br />

90,762 hectares. In 2006-07, some changes took place with net sown area being 60 percent<br />

of total area. It is the condition of the district that allows it to have only 6.24 percent area<br />

under double cropping. The forest cover marginally increased to 1.13 percent and<br />

permanent pastures and other grazing lands constituting 15.38 percent and barren and<br />

cultivable land another 18 percent.<br />

The characteristic features of the climate of the district are its dryness, extremes of<br />

temperature and the fitful and erratic nature of rainfall. The year may be divided into four<br />

seasons, winter from November to March, summer season from April to June, monsoon<br />

from July to mid-September and post-monsoon season up to the end of October.<br />

In summers the temperature soars to 48°C and in winters, it drops to 5°C. Primarily<br />

<strong>Barmer</strong> district is a desert where average rainfall in a year is 277 mm. However, extreme<br />

rainfall of 549 mm rain between August 16 and August 25, 2006 left many dead and caused<br />

huge losses. As many as 20 new lakes were formed and 6 of which covered an area of over<br />

10 km².<br />

Throughout summer, the heat is intense and scorching winds prevail. Even during<br />

monsoon, the air is dry in between the fitful spells of rain. The district is prone to droughts.<br />

The rainfall pattern among the regions is very much uncertain. Therefore, kharif cropping<br />

is too much uncertain in all the regions.<br />

The soils of the district are broadly desertic type. Qualitatively the soils are very poor and<br />

devoid of humus content. These soils are very deep and sandy, associated with dunes; inter<br />

dunes and sandy plain covering about 31 percent of the area. Dunes are the spectacular<br />

feature of the district and these occur scattered all over the area.<br />

Potable water in the district comes mainly from rain water harvested in large tanks. Wells,<br />

tube wells and hand pumps are also in use. The seasonal rivers, Luni and Jojree and the<br />

Narmada canal also flow through this district. However the water from the rivers is not<br />

potable.<br />

[16]

1.3.2 DEMOGRAPHY<br />

<strong>Barmer</strong> had population of 19,64,835 in 2001 of which males were 10,38,247 (52.84%) and<br />

females were 9,26,588 (47.16%). The district has 3.48 percent of state’s population and<br />

8.29 percent area. The population growth during 1991-2001 was 36.83 percent compared<br />

to 28.27 percent during 1981-1991. The rural population stood at 18,19,431 (92.6%),<br />

while the urban population was 1,45,404 (7.4%). The 5-14 years population was 5,45,120,<br />

15-59 years old were 9,78,039 and 60 plus population was 1,39,461. 15 percent of the<br />

population is under 6 years of age. The district has a population density of 69 per sq km in<br />

2001.<br />

The district has 3,09,739 households of which 91.95 percent are rural areas and only 8.1<br />

percent in urban areas. Of the rural population, 52.78 percent are males while this<br />

proportion is 53.92 percent in urban areas. Given the number of households in the district<br />

at 3,09,739, the average household size comes to 6.34. The average household size in rural<br />

areas is 6.39 compared to urban household size of 5.83. The family size in urban <strong>Barmer</strong> is<br />

thus lower than the rural family size. 28.3 percent houses are permanent type followed by<br />

14 percent that are semi-permanent and 57.8 percent are temporary type. The total<br />

literacy rate in the district is 59.00 with male literacy at 72.80 and female literacy at 43.04.<br />

1.3.3 SOCIO- ECONOMIC PROFILE<br />

Development is reflected in structure of the economy. Normally in the development<br />

process, it is said that, the contribution of agriculture would decline and the contribution of<br />

manufacturing would increase in the first stage. In the latter stage, the service sector would<br />

become important. In the recent times, <strong>Barmer</strong> has observed a structural change as<br />

depicted by district income estimates at current prices. According to Human Development<br />

Report, <strong>Barmer</strong> District, the total income generated in 1999-2000 was Rs.165071 lakh<br />

which increased to Rs. 259338 in 2004-05; a 1.57 time increase or 9.52 percent increase. In<br />

the recent times, the contribution of agriculture and allied sectors declined from 38.4<br />

percent to 32.3 percent from 1999-00 to 2004-05. There is an increase in contribution of<br />

mining and manufacturing sector from 20.5 percent to 24.0 percent during this period. The<br />

contribution of service sector/ tertiary sector improved from 41.2 percent to 43.8 percent.<br />

Despite this structural transformation, one finds that contribution of agriculture sector has<br />

declined by 7.7 percentage points, while contribution of livestock sector has increased by<br />

1.47 percentage points. Within mining and manufacturing sector, mining and registered<br />

manufacturing have gained in contribution while unregistered manufacturing has declined<br />

though still remaining an important contributor (6.53% share). Construction sector has<br />

improved contribution and in 2004-05 contributed 10.1 percent district’s income. The<br />

major activity in service sector is trade, hotel and restaurants (14.4%) and is followed by<br />

[17]

other services (7.175) and real estate activities (7.92%). However, the latter two activities<br />

have lost ground during this period. Transport, banking, railways, other transport,<br />

communication and public administration have gained in their shares in district income.<br />

Employment structure of the district economy is defined in terms of sectoral distribution of<br />

worker and work participation rates. There were 919729 workers in 2001, of which<br />

680208 were main workers and 239521 were marginal workers and 1045106 were nonworkers<br />

which mean the dependency ratio of 53.19 percent. In <strong>Barmer</strong> main workers<br />

constituted around 74 percent of all workers, while 26 percent were marginal workers.<br />

Among the main workers, 72.4 percent were cultivators and 2.8 percent agricultural<br />

workers, thereby implying that work force dependent on agriculture stood at 75.2 percent.<br />

Household industry just had 2.7 percent main workers. The other workers, those in service<br />

sectors and construction etc. constituted 22.2 percent of all workers.<br />

<strong>Barmer</strong> district in 2003 had 27048 holdings of which majority were 4 hectares and above<br />

(70.24%). Across tehsils, such holdings were 72.75 percent in <strong>Barmer</strong>, 73.48 percent in<br />

Baytu, 57.61 percent in Gudamalani, 59.51 percent in Pachpatra, 80.90 percent in Shiv as<br />

against the district average of 70.24 percent. Large holding does not mean much in rain fed<br />

areas. However, this pattern of holdings would reflect on agricultural practices. Large land<br />

holdings are a reflection of the harsh environmental conditions, and hence low population<br />

density (69 people per sq km).<br />

1.4 DISASTER MANAGEMENT PHILOSOPHY<br />

Cairn India’s <strong>Disaster</strong> management philosophy is to provide "reasonable assurance that<br />

adequate protective measures can and will be taken in the event of an emergency or<br />

disaster." This document sets forth emergency planning standards and defines the<br />

responsibilities of the organisations involved in emergency response. In addition, it is<br />

suggested that Cairn could also include the pro-active preparedness and mitigation centric<br />

strategies during implementation of this DM plan.<br />

Effective Multi Response Strategy and synergy of efforts is essential both at State and<br />

district level with institutional arrangements, inter-department linkages, role of NGOs,<br />

voluntary agencies and local communities in disaster management.<br />

Briefly stated, the disaster management philosophy is as under:-<br />

• Requires high quality in the design, construction and operation of the facilities to<br />

reduce the likelihood of malfunctions;<br />

• Recognises that equipment can fail and operators can make errors, therefore<br />

requires adequate layers of safety systems to reduce the chances of such<br />

malfunctions which could lead to accidents;<br />

[18]

• Recognises that, in spite of these precautions, accidents may happen, therefore<br />

requiring containment structures and other safety features to prevent escalation<br />

• Has in place organisations capable of responding to incident’s and emergency<br />

situations that may occur involving any of the Cairn India facilities or supporting<br />

operations, to preserve life, prevent injuries and damage to the environment and or<br />

assets.<br />

• Meets all statutory requirements for emergency response and disaster management.<br />

Cairn India Limited’s (CIL) responsibility is to properly manage any emergency or crisis<br />

situation so as to minimise the impact it may have on all personnel associated with its<br />

activities, the environment, the community, the Company’s financial position and<br />

reputation. To respond effectively to emergencies and incidents an agreed and approved<br />

<strong>Disaster</strong> <strong>Management</strong> <strong>Plan</strong> (DMP) is in place supported by a pre-established organisation,<br />

on-call and capable of mobilising and responding effectively to different levels of incidents<br />

that may occur. This organisation is staffed with competent individuals, organised into<br />

teams, with allocated and clearly defined roles and responsibilities and practised in their<br />

roles.<br />

This is in line with NDMA’s objective and vision which is ‘to build a safe and disasterresilient<br />

India by developing a holistic, proactive, multi-disaster and technology-driven<br />

strategy for disaster management. This will be achieved through a culture of prevention,<br />

mitigation and preparedness to generate a prompt and efficient response at the time of<br />

disaster’.<br />

1.5 THEME<br />

The DMP will focus on the following theme:<br />

In line with the National <strong>Disaster</strong> <strong>Management</strong> Authority’s vision, this DMP will focus on<br />

the paradigm shift from reactive post-disaster response to proactive pre-disaster<br />

prevention, mitigation and preparedness measures.<br />

1.6 OBJECTIVES<br />

The DMP has the following objectives:<br />

• To contextualise the learning from the IOC Jaipur oil depot fire<br />

• To synergise with the national stipulations on disaster management<br />

• To comprehensively address onsite and offsite emergency preparedness<br />

[19]

• To develop the DMP with community participatory approach<br />

• To have holistic and integrated approach to address all phases of disaster<br />

management; pre-disaster, during disaster and post-disaster<br />

• To improve the incident management system with clear missions and lines of<br />

authority<br />

• Develop a state of readiness for a prompt and orderly response to an emergency and<br />

to establish a high order of preparedness (equipment, personnel) commensurate<br />

with the risk<br />

• To ensure an orderly and timely decision-making and response process<br />

(notification, standard operating procedures)<br />

• Ensure effective coordination between Cairn India, local government, community<br />

and other agencies working to prevent and mitigate disasters.<br />

1.7 SCOPE OF WORK<br />

The DMP scope is to cover the following<br />

• Meeting requirements of Department of Petroleum, Government of Rajasthan<br />

• Guidelines of NDMA and SDMA Rajasthan<br />

• Incident Command System (ICS) based<br />

• Community & stakeholder participation<br />

• Pipeline vulnerability & risk assessment with District Administration<br />

• OISD recommendations vis-a-vis IOC Jaipur Terminal fire incident<br />

• GIS based Hazard Mapping<br />

1.8 METHODOLOGY<br />

EGSS has adopted a multi-disciplinary approach consisting of fire safety, incident<br />

management, risk and vulnerability analysis, disaster management policy review, GIS<br />

mapping and environmental impacts. The DMP is developed on the basis of collation of<br />

secondary data of CIL’s previous studies.<br />

EGSS has fielded a multi-disciplinary team consisting of:<br />

Ramasami Sundaresan FIFireE - Health & Safety, Emergency Preparedness, Incident<br />

Investigation specialist, 36 years oil & petrochemical industry experience<br />

[20]

Dr. K. M. Parivelan Ph.D – is DM Specialist who has worked with UN agencies like UNHCR,<br />

UNDP covering Humanitarian Affairs and <strong>Disaster</strong> <strong>Management</strong><br />

A. Sivakumar MSc - IIT Mumbai – Hydrogeology and Environmental Professional with 18<br />

years international experience in oil & gas industry<br />

Indira Reddy MSc - Environmental <strong>Management</strong> Australia – Project Coordination and GIS<br />

expert<br />

The project commenced formally on 14 th April 2010 with a kick-off meeting between CIL<br />

officials and EGSS team. The following secondary and tertiary data /information are<br />

collected from CIL:<br />

• QRA_FERA_EEA Report R1 Chapters – 3,6,13 & 18 (MPT)<br />

• EIA report – complete<br />

• QRA of Early Gas Supply System-Report Rev 1 August 09<br />

• QRA of Raageshwari Gas Terminal - Post Slug Catcher Rev 0 May 09<br />

• QRA of Raageshwari Well Pads-Final<br />

• RGT Bow-Tie Report Rev-2-14Jan2010<br />

• FERA-Early Gas Supply System Report Rev 1 Aug 09<br />

• FERA post Slug Catcher of RGT-Final-DECO-RX-R-REP-0018<br />

• QRA, FERA (RGT)<br />

• MPT process Rev 0 – SOPs<br />

o MPT28 HP-LP Flare Rev A2<br />

o MPT 18 - Sand Wash – Final<br />

o MPT 26 - Fuel Gas System rev<br />

o MPT 50-51-52 - ESD-PCS<br />

o MPT 57 Closed Drains rev<br />

o MPT 58 Hazardous Open Drains<br />

o MPT System 21 - Vapour Recovery Unit rev<br />

• RJON-MPT-OP-PRO-010 - Prod Headers & Pig Rx rev A1<br />

• RJON-MPT-OP-PRO-063 - Hazardous Waste Rev A1<br />

• SOP - Train-2 & 3 start up<br />

• 16 .DECO-MPT-FG-DWG-4601-01-B1 (Fire and safety Emergency lay out)-black –<br />

drawing<br />

• 16 .DECO-MPT-L-DWG-2400-01-B9-ColourPlot plan – drawing<br />

• MPT development overview<br />