Environmental & Social Report - Subaru

Environmental & Social Report - Subaru

Environmental & Social Report - Subaru

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

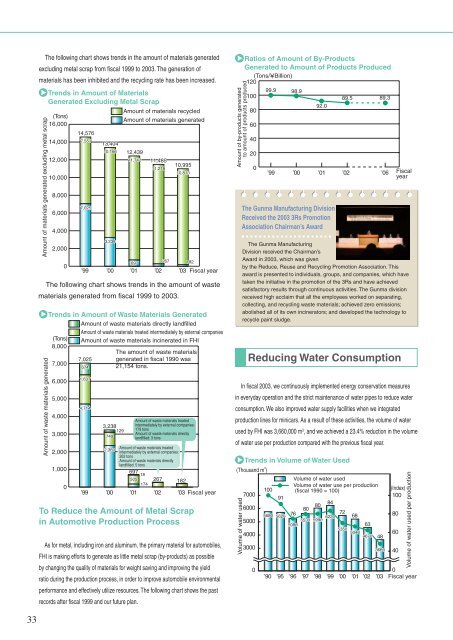

The following chart shows trends in the amount of materials generated<br />

excluding metal scrap from fi scal 1999 to 2003. The generation of<br />

materials has been inhibited and the recycling rate has been increased.<br />

Amount of materials generated excluding metal scrap<br />

Trends in Amount of Materials<br />

Generated Excluding Metal Scrap<br />

Amount of materials recycled<br />

(Tons)<br />

Amount of materials generated<br />

16,000<br />

14,000<br />

12,000<br />

10,000<br />

8,000<br />

6,000<br />

4,000<br />

2,000<br />

0<br />

14,576<br />

7,551<br />

7,025<br />

13,404<br />

10,166 12,439<br />

11,742<br />

3,238<br />

697<br />

11,485<br />

11,218<br />

10,995<br />

10,813<br />

267 182<br />

’99 ’00 ’01 ’02 ’03 Fiscal year<br />

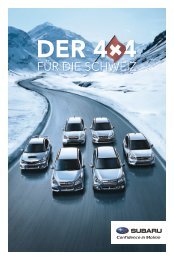

The following chart shows trends in the amount of waste<br />

materials generated from fi scal 1999 to 2003.<br />

Amount of waste materials generated<br />

Trends in Amount of Waste Materials Generated<br />

(Tons)<br />

8,000<br />

7,000<br />

6,000<br />

5,000<br />

4,000<br />

3,000<br />

2,000<br />

1,000<br />

0<br />

Amount of waste materials directly landfilled<br />

Amount of waste materials treated intermediately by external companies<br />

Amount of waste materials incinerated in FHI<br />

7,025<br />

674<br />

1,637<br />

4,714<br />

3,238<br />

129<br />

749<br />

The amount of waste materials<br />

generated in fiscal 1990 was<br />

21,154 tons.<br />

Amount of waste materials treated<br />

intermediately by external companies:<br />

179 tons<br />

Amount of waste materials directly<br />

landfilled: 3 tons<br />

2,360<br />

Amount of waste materials treated<br />

intermediately by external companies:<br />

262 tons<br />

Amount of waste materials directly<br />

landfilled: 5 tons<br />

697<br />

18<br />

505 267 182<br />

174<br />

’99 ’00 ’01 ’02 ’03 Fiscal year<br />

To Reduce the Amount of Metal Scrap<br />

in Automotive Production Process<br />

As for metal, including iron and aluminum, the primary material for automobiles,<br />

FHI is making efforts to generate as little metal scrap (by-products) as possible<br />

by changing the quality of materials for weight saving and improving the yield<br />

ratio during the production process, in order to improve automobile environmental<br />

performance and effectively utilize resources. The following chart shows the past<br />

records after fi scal 1999 and our future plan.<br />

Amount of by-products generated<br />

to amount of products produced<br />

Ratios of Amount of By-Products<br />

Generated to Amount of Products Produced<br />

(Tons/Billion)<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

99.9 98.9<br />

92.0<br />

The Gunma Manufacturing Division<br />

Received the 2003 3Rs Promotion<br />

Association Chairman’s Award<br />

89.5<br />

89.3<br />

’99 ’00 ’01 ’02 ’06<br />

The Gunma Manufacturing<br />

Division received the Chairman’s<br />

Award in 2003, which was given<br />

by the Reduce, Reuse and Recycling Promotion Association. This<br />

award is presented to individuals, groups, and companies, which have<br />

taken the initiative in the promotion of the 3Rs and have achieved<br />

satisfactory results through continuous activities. The Gunma division<br />

received high acclaim that all the employees worked on separating,<br />

collecting, and recycling waste materials; achieved zero emissions;<br />

abolished all of its own incinerators; and developed the technology to<br />

recycle paint sludge.<br />

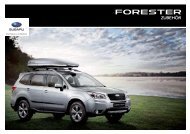

Reducing Water Consumption<br />

Fiscal<br />

year<br />

In fi scal 2003, we continuously implemented energy conservation measures<br />

in everyday operation and the strict maintenance of water pipes to reduce water<br />

consumption. We also improved water supply facilities when we integrated<br />

production lines for minicars. As a result of these activities, the volume of water<br />

used by FHI was 3,660,000 m 3 , and we achieved a 23.4% reduction in the volume<br />

of water use per production compared with the previous fi scal year.<br />

(Thousand m 3 )<br />

Volume of water used<br />

Trends in Volume of Water Used<br />

7000<br />

6000<br />

5000<br />

4000<br />

3000<br />

0<br />

Volume of water used<br />

Volume of water use per production<br />

100 (fiscal 1990 = 100)<br />

91<br />

84<br />

80<br />

80<br />

76<br />

72<br />

5680 5620<br />

68<br />

5530 5990 6220<br />

5080<br />

63<br />

5350 5040 4670 48<br />

3660<br />

’90 ’95 ’96 ’97 ’98 ’99 ’00 ’01 ’02 ’03<br />

(Index)<br />

100<br />

80<br />

60<br />

40<br />

Volume of water used per production<br />

0<br />

Fiscal year